Wide-temperature-range high-precision sputtering film pressure sensor and manufacturing method thereof

A technology of pressure sensor and sputtering thin film, which is applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of narrow temperature range and inaccurate pressure measurement, and achieve the effect of wide temperature adaptation range, improved measurement accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

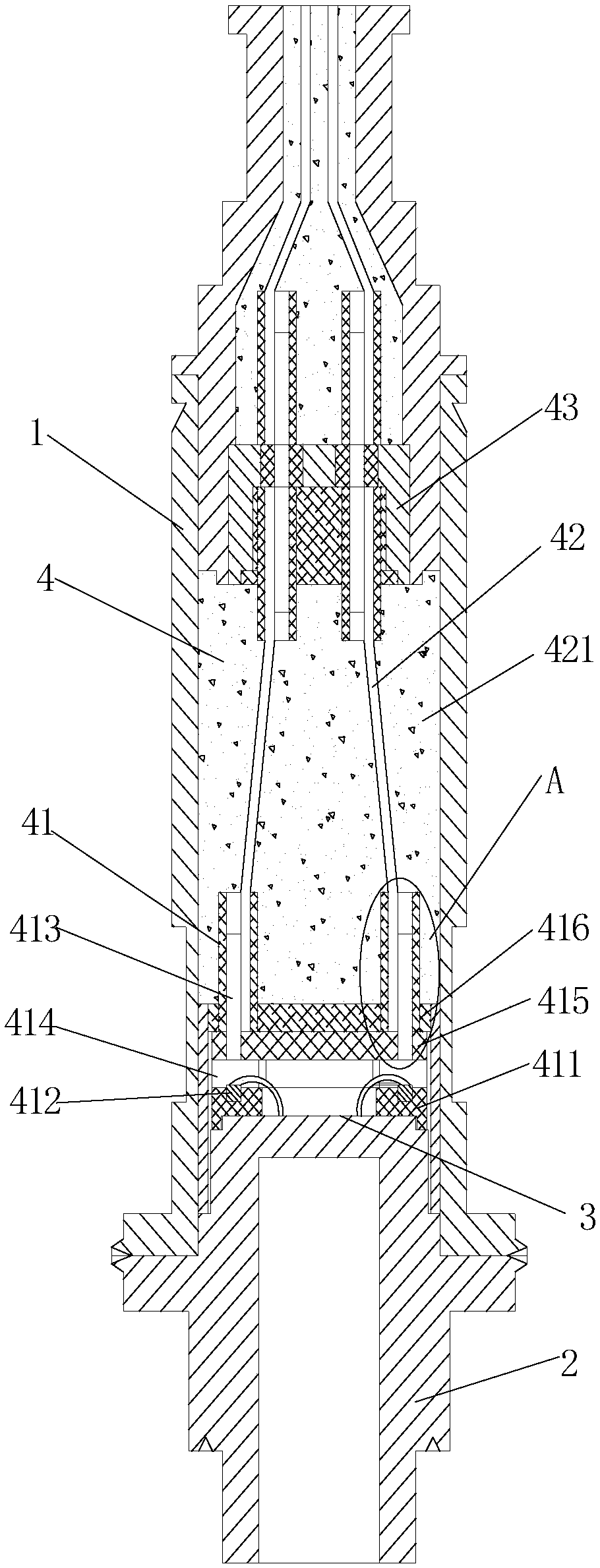

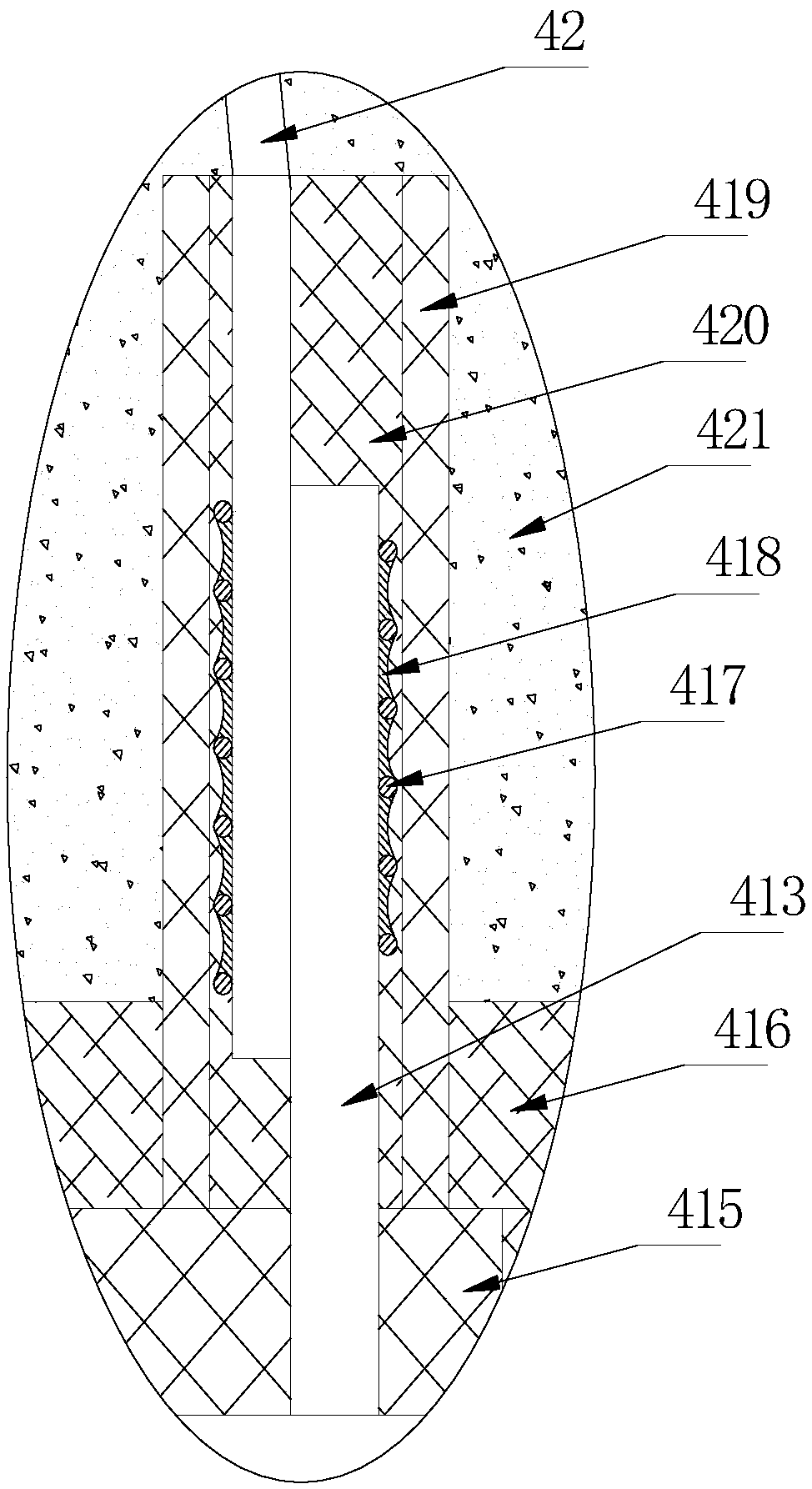

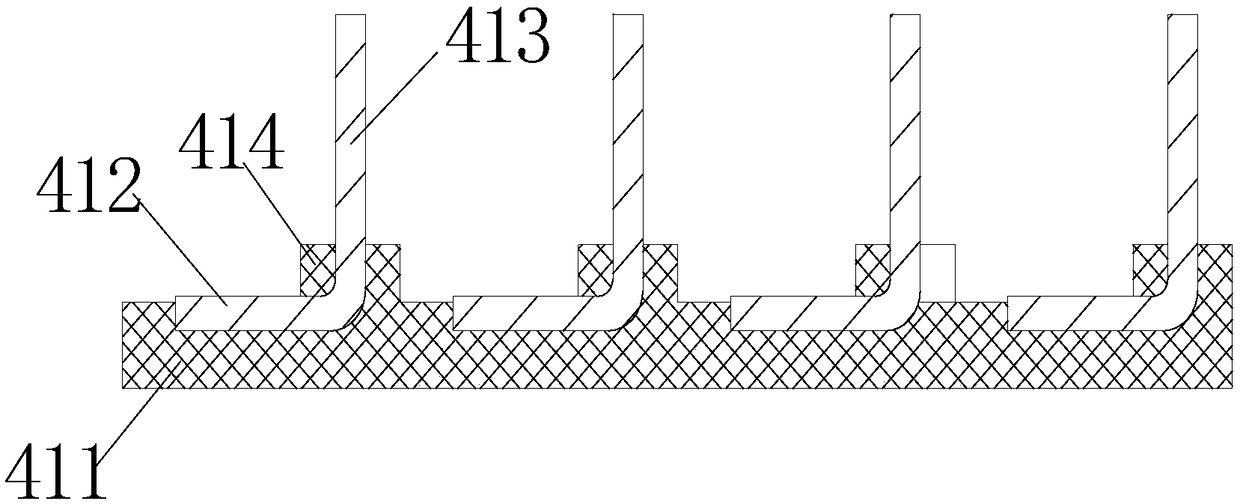

[0050] Such as Figure 1-5As shown, the high-precision sputtering film pressure sensor with wide temperature range of the present invention includes a housing 1, a pressure port 2, a sensitive element 3 and an adapter assembly 4, and the pressure interface 2, the sensitive element 3, and the adapter assembly 4 are connected in sequence, The sensitive element 3 and the adapter assembly 4 are arranged in the casing 1; the adapter assembly and the pressure interface are fixedly arranged at both ends of the casing, and the adapter assembly 4 includes a signal input terminal adapter assembly 41 and a signal output terminal connected by a wire 42 End transfer assembly 43, the sensitive element 3 includes a transition layer 31, an insulating layer 32 and a circuit layer arranged at the end of the pressure interface 2; the circuit layer is provided with a pressure measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com