Array type pressure measuring device based on packaging substrate

A technology of measuring device and packaging substrate, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, etc., can solve the temperature state of piezoresistive sensitive strip - difficult to test characterization, difficult to predict, complex integration and assembly of multi-channel pressure test circuit system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

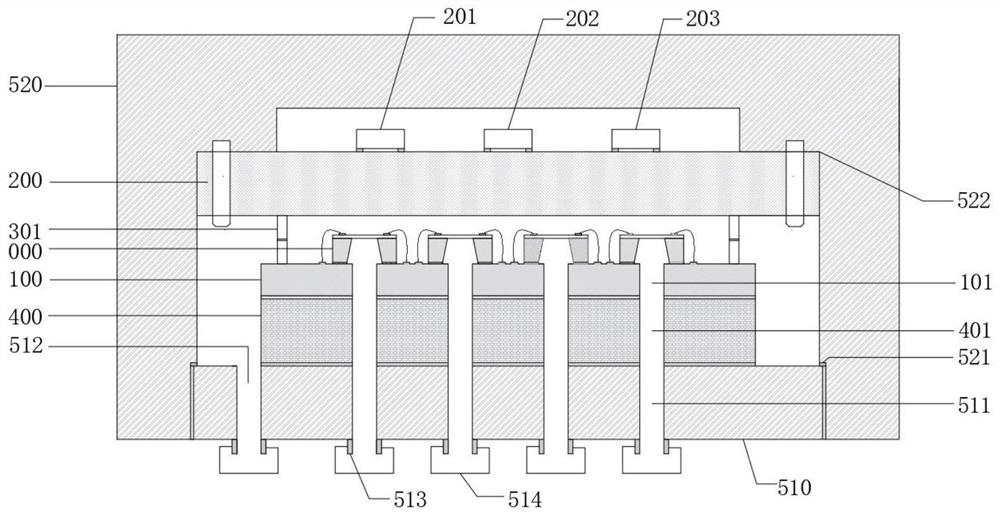

[0030] Design and integrated assembly method of array pressure measurement device based on packaging substrate such as figure 1 As shown, the pressure measurement device mainly includes a piezoresistive sensitive chip 000 , a packaging substrate 100 , a circuit board 200 , an electrical interconnection and fixing structure 300 , a gasket 400 and an alloy shell 500 .

[0031] In one embodiment of the present invention, the packaging substrate 100 is a silicon substrate or a glass substrate, further a TSV / TGV substrate.

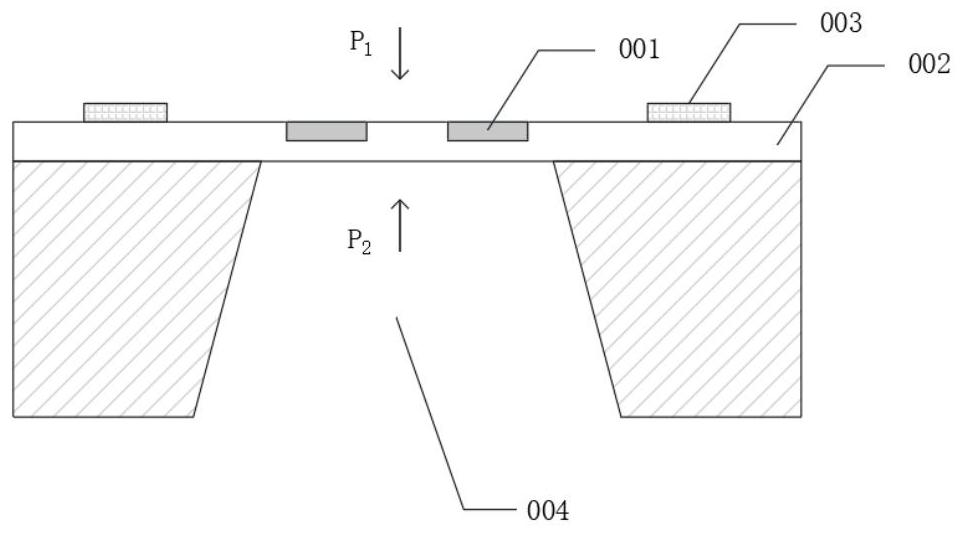

[0032] refer to figure 2 and image 3 , the piezoresistive sensitive chip 000 can be divided into a differential pressure piezoresistive sensitive chip 000a and an absolute pressure piezoresistive sensitive chip 000b. The piezoresistive sensitive chip 000 is a silicon substrate, and the piezoresistive strip 001, passivation layer 002 and Pad 003 are formed on the front of the piezoresistive sensitive chip 000 through epitaxy, oxidation, diffusion, sputtering...

Embodiment 2

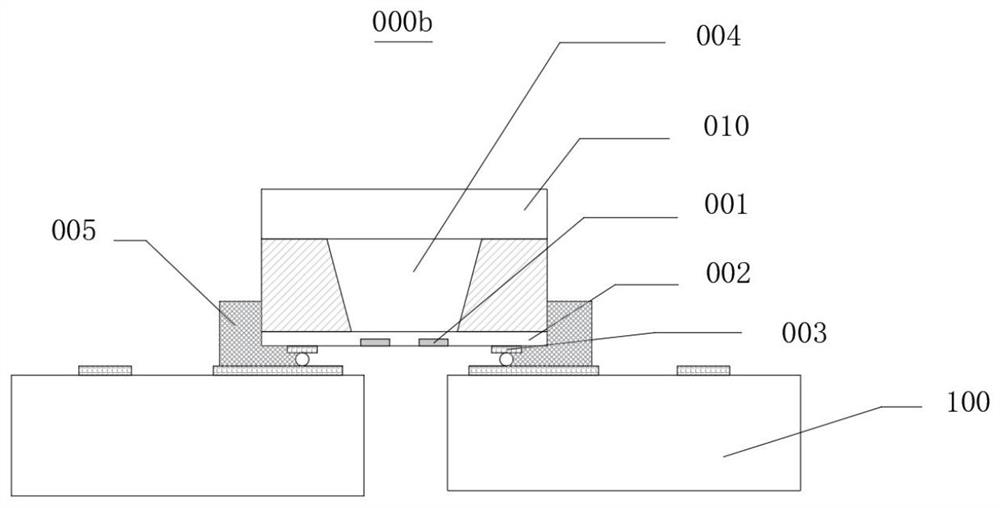

[0041] refer to Figure 5 and Figure 6 The difference between this embodiment and Embodiment 1 is that the piezoresistive sensitive chip 000 is flip-chip soldered on the packaging substrate 100, and the gap between the piezoresistive sensitive chip 000 and the packaging substrate 100 is sealed with a sealing ring 005, and the sealing ring 005 can be Silicone rubber or silicone sealant is used; the packaging substrate 100 and the circuit board 200 are stacked and placed in parallel, and the two are stacked through the electrical interconnection and the fixed structure 302 to realize electrical and fixed. The height is the height of the piezoresistive sensitive chip and flip-chip welding, The electrical interconnection and fixing structure 302 can be a combination of the Pad 303 and the TSV 304 ; for the rest, refer to Embodiment 1.

Embodiment 3

[0043] refer to Figure 7 , the pressure measuring device mainly includes a piezoresistive sensitive chip 000 , a package substrate 100 , a circuit board 200 , an electrical and fixed structure 300 , a gasket 400 , an alloy shell 500 and an interconnection substrate 600 .

[0044] The difference between this embodiment and Embodiment 1 is that the front side of the piezoresistive sensitive chip 000 is welded on the interconnect substrate 600 with at least one wiring layer on the surface; integrated on the interconnect substrate 600 in the form of wire bonding or mounting; optionally, the packaged instrument amplifier circuit 601, ADC 602, MCU 603, etc. are integrated on the circuit board 200 in the form of wire bonding or mounting; The substrate 600 and the circuit board 200 are stacked and placed in parallel, and the two are stacked with the fixed structure 301 through electrical interconnection to realize electrical and fixed. The height is the height of the instrument ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com