Active silicon substrate manufacturing method

A manufacturing method and technology of silicon substrates, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as adhesion problems, processing, and difficult problems, and achieve high moisture absorption rate, good heat dissipation, and excellent CTE matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

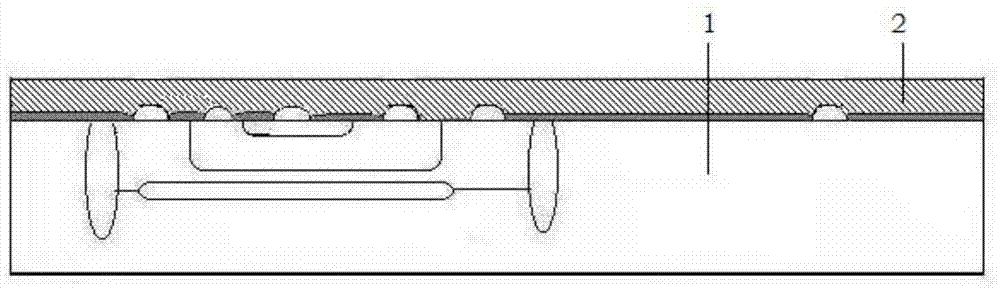

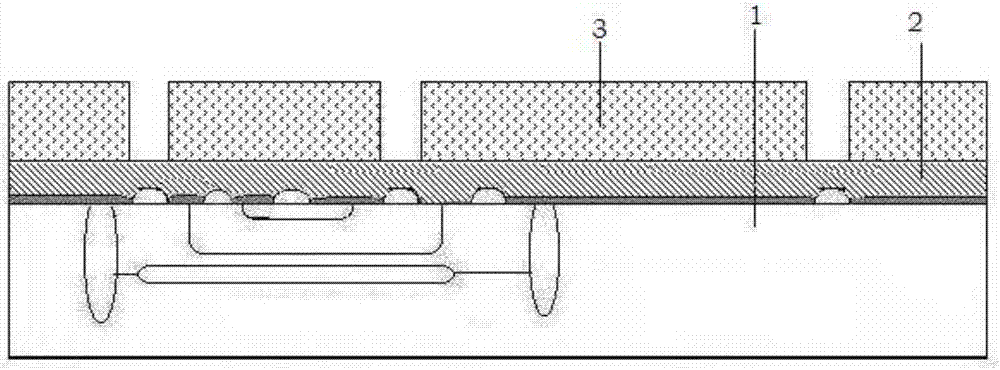

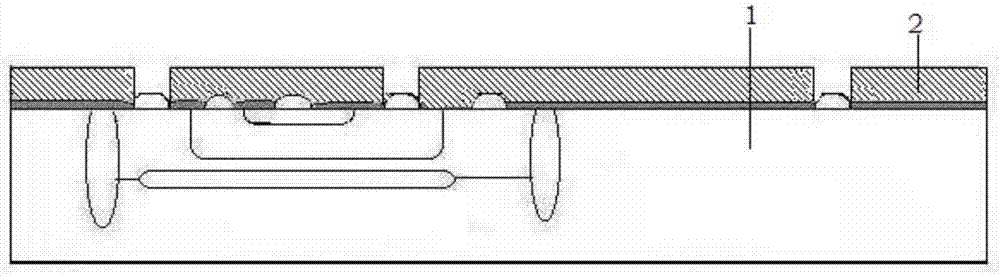

[0050] The manufacturing method of the active silicon substrate of this embodiment includes the following steps:

[0051] 1. Select Active silicon wafer 1 with a thickness of 500 microns;

[0052] 2. Fabricate the first layer of non-photosensitive BCB dielectric layer 2 on the active silicon wafer 1, specifically including:

[0053] 1) Ultrasonic cleaning of the active silicon wafer in step 1 with acetone and ethanol for 5 minutes (organic ultrasonic cleaning in this cleaning process), and then cleaning with argon plasma for 5 minutes with a cleaning power of 150W;

[0054] 2) Apply AP3000BCB tackifier, rotate at 2000 rpm for 20 minutes to dry, and then bake on a 100°C hot plate for 60 seconds;

[0055] 3) Coat the BCB solution at a coating speed of 800 rpm for 20 seconds (BCB thickness is about 5um), and bake on a 90°C hot plate for 120 seconds;

[0056] 4) Under a vacuum environment below 0.8mbar, perform soft curing on the BCB film layer. The soft curing conditions are sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com