A temperature compensation method for a dual induction eight lateral logging tool and a coil system of a dual induction eight lateral logging tool

A technology of lateral logging and logging tools, which is applied in construction and other directions, can solve problems such as low measurement accuracy, distortion of logging curves, and excessive experience components, and achieve the effects of convenient operation and high temperature compensation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

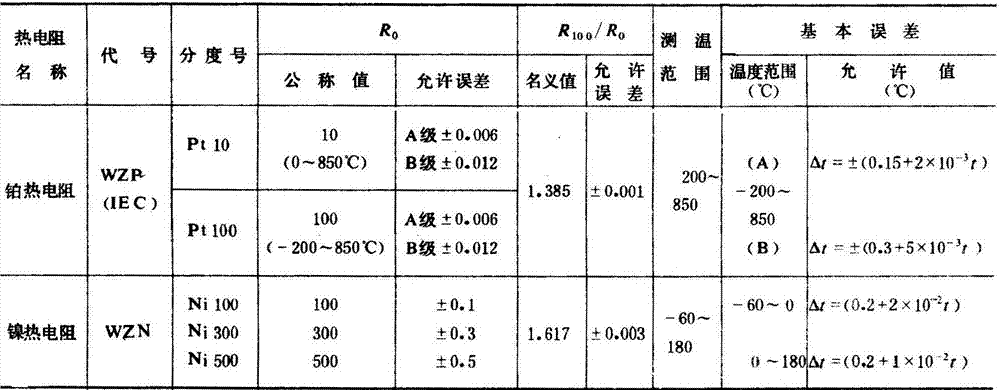

[0018] The object of the present invention is to provide a new probe temperature compensation method that can accurately respond to the temperature change of the probe and is easy to operate, aiming at the defects existing in the existing dual-induction eight-lateral instrument. And the method does not need to change the original instrument structure.

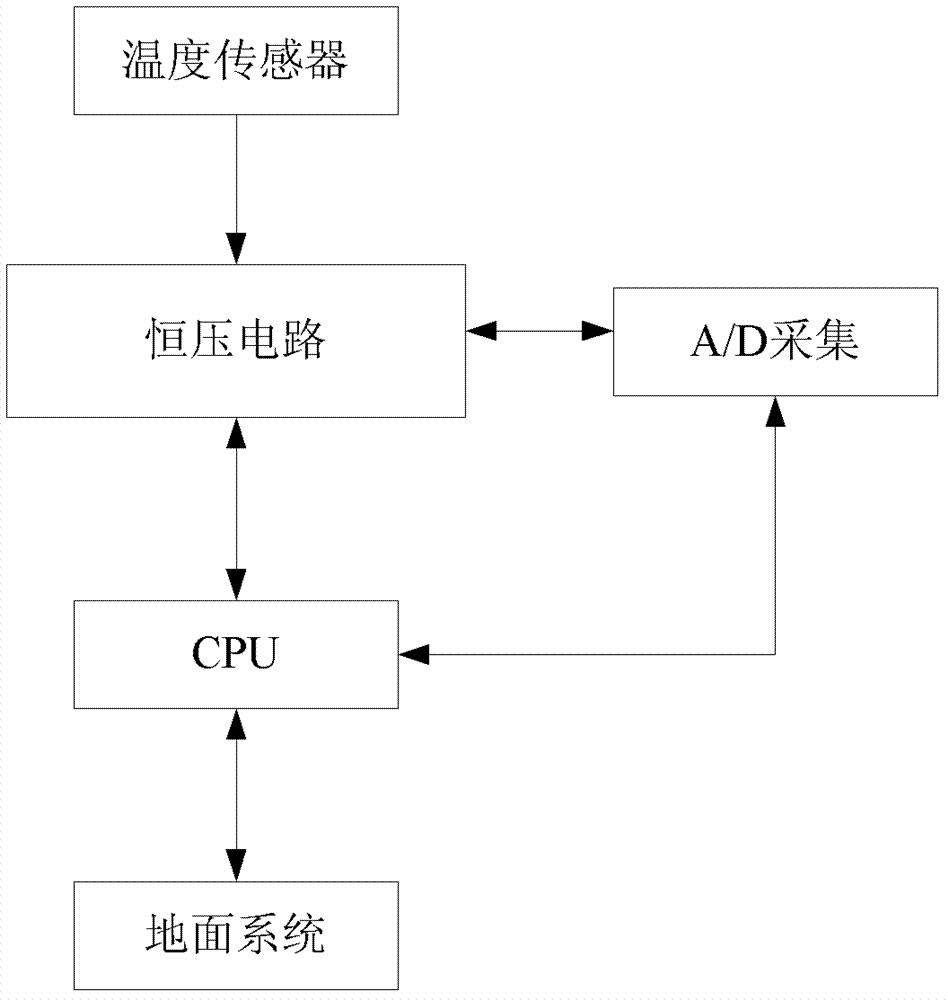

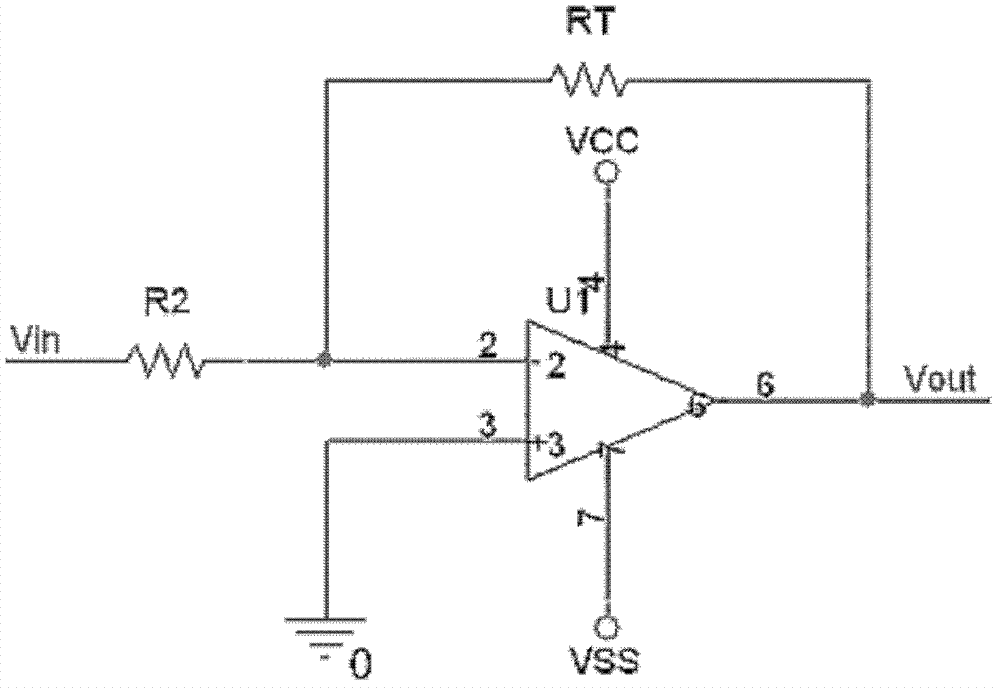

[0019] The solution is to place a high-precision temperature sensor in the middle of the sensing probe, connect the sensor to the feedback terminal of the constant voltage circuit in the launching sub, perform A / D sampling on the output of the constant voltage circuit, and transmit the sampled value to the CPU . The CPU calculates the sampling signal to obtain the real-time temperature of the sensing probe. Finally, the collected real-time logging data and the data variation caused by temperature at the same time are added together and transmitted to the ground system to obtain the final logging data.

[0020] Fix a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com