Roller washing equipment with horizontal detection function and horizontal detection method thereof

A technology of level detection and drum washing, used in washing devices, other washing machines, parts of instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

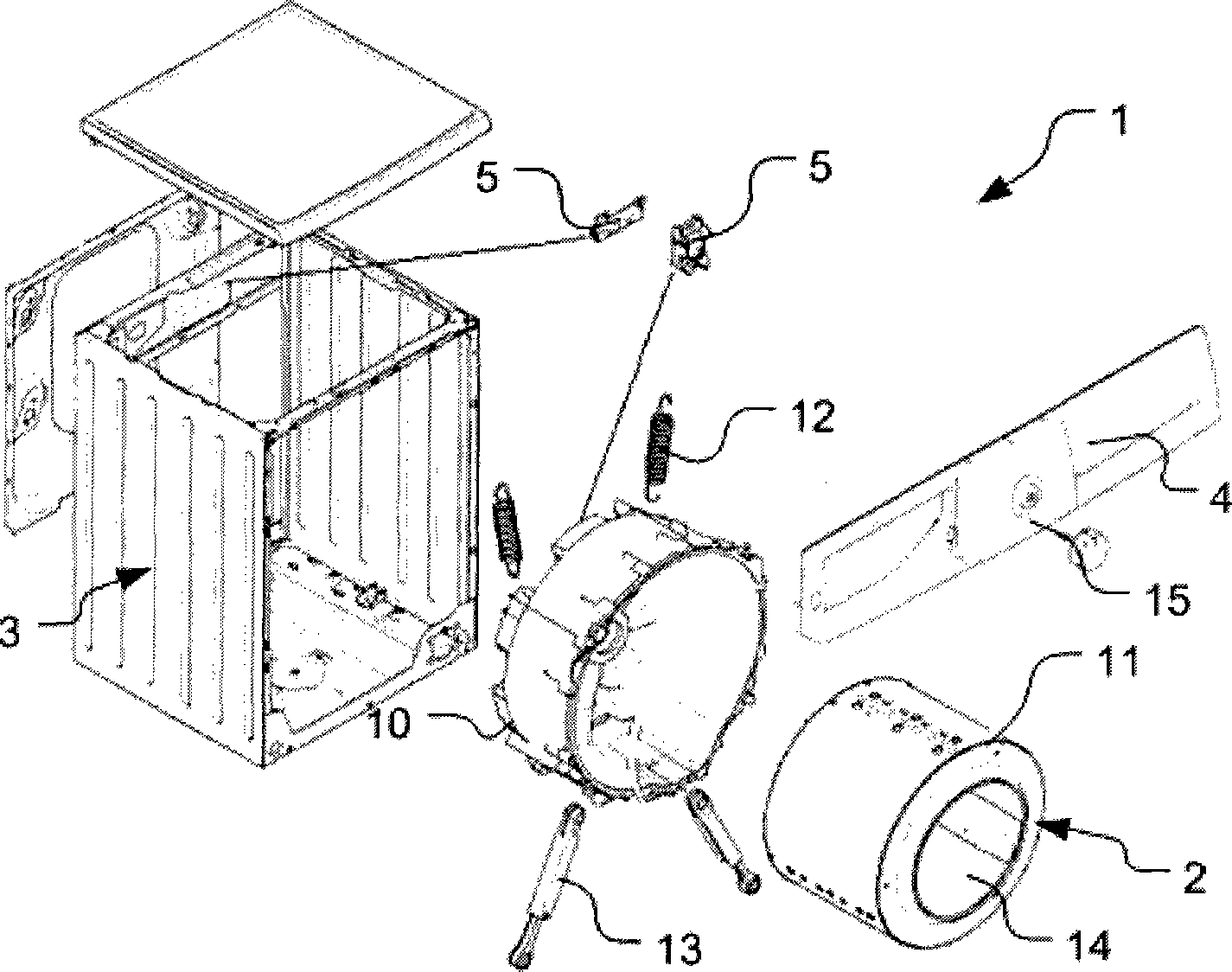

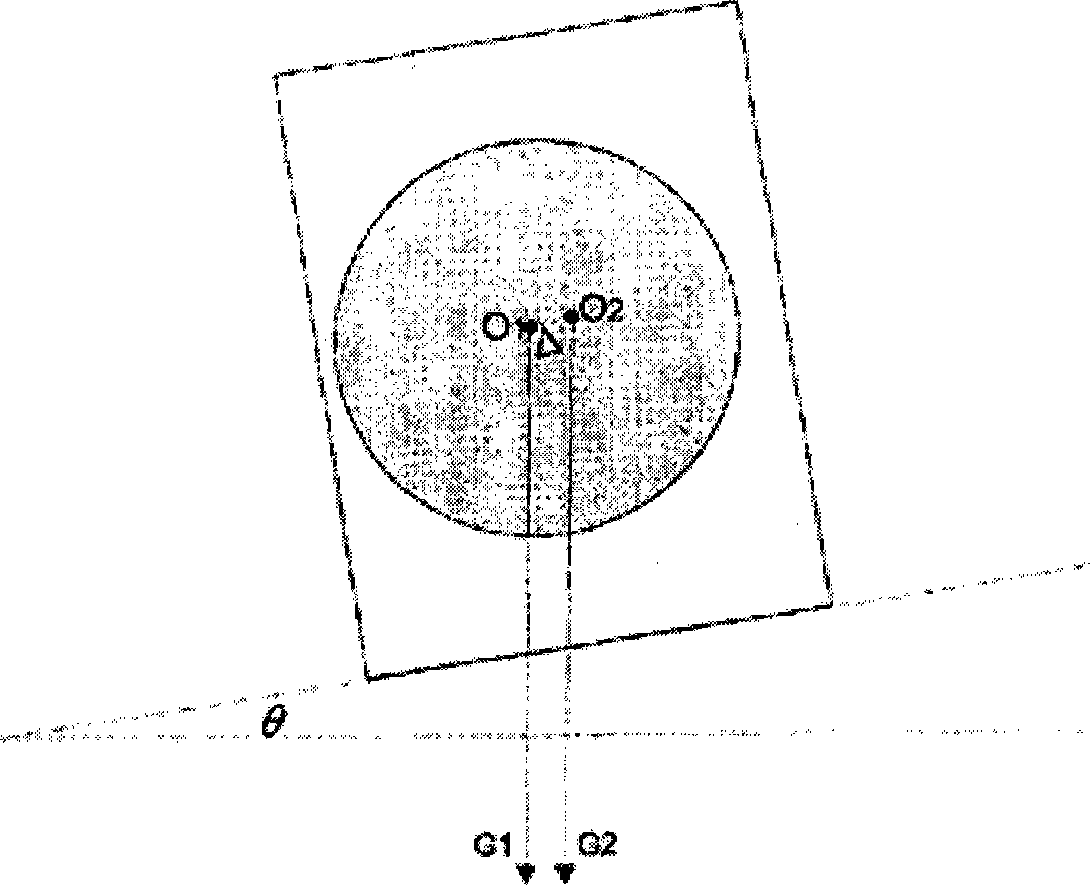

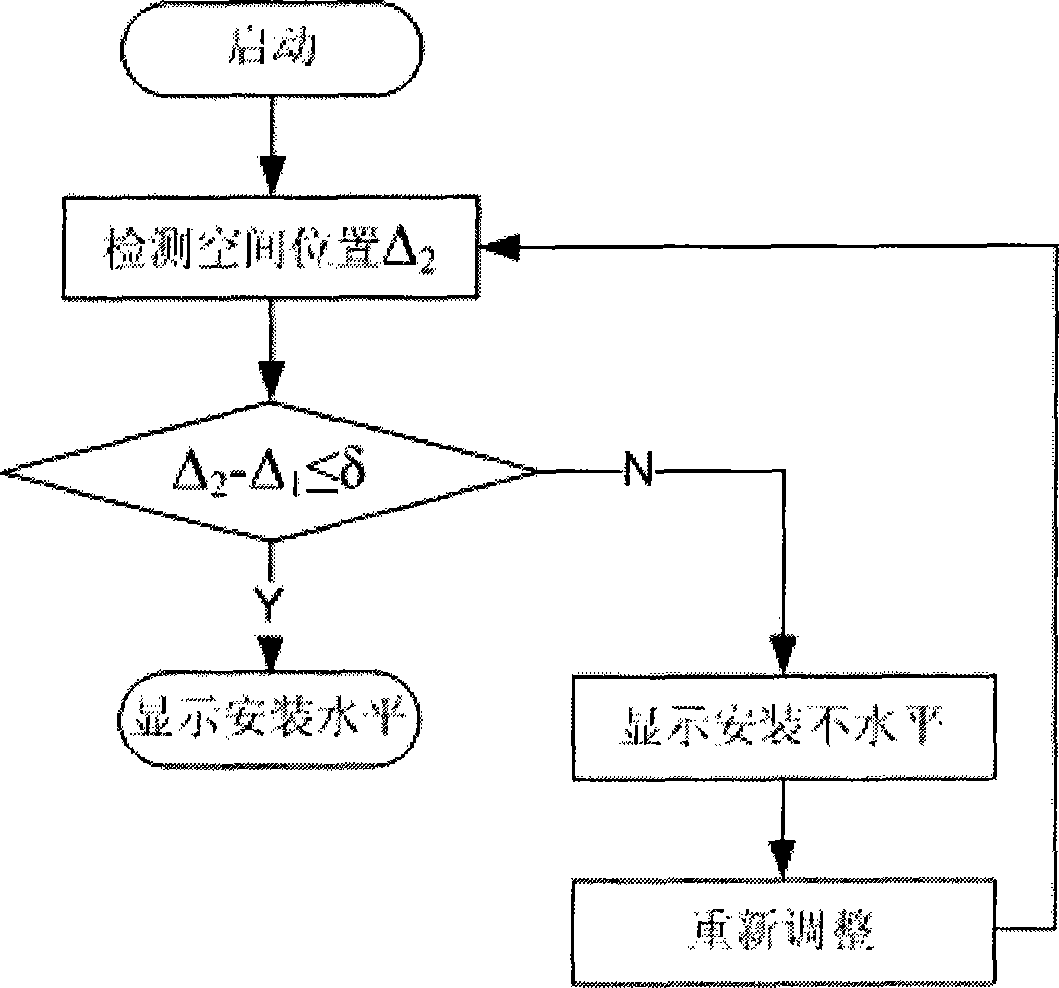

[0018] Please refer to as figure 1 As shown, it is a schematic diagram of a drum washing device equipped with a level detection function according to an embodiment of the present invention. Taking a drum washing machine as an example, the drum washing device 1 according to a specific embodiment of the present invention includes an outer tub 10 and a The drum 11 inside and driven by a motor (not shown in the figure) can rotate at a high speed. In order to balance the huge centrifugal force generated by the drum 11 under high-speed rotation, a balance module (Fig. not shown). The tub 10 , the drum 11 , the motor driving the drum 11 to rotate at a high speed, and the balance module to balance the centrifugal force together constitute a drum system 2 . The drum system 2 is built into the box body 3 of the drum washing device through the suspension springs 12 respectively arranged above the outer tub 10 and the support structure 13 arranged below the outer tub 10. The drum system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com