Simplified calibration method of pressure sensor

A pressure sensor and pressure technology, applied in the field of sensor measurement, can solve problems affecting calibration efficiency, energy consumption, and complicated settings, and achieve the effects of improving temperature compensation accuracy, expanding scale, and reducing temperature and pressure points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make those skilled in the art better understand the technical solutions of the present invention, the technical solutions of the present invention are further described in detail below with reference to the accompanying drawings and examples.

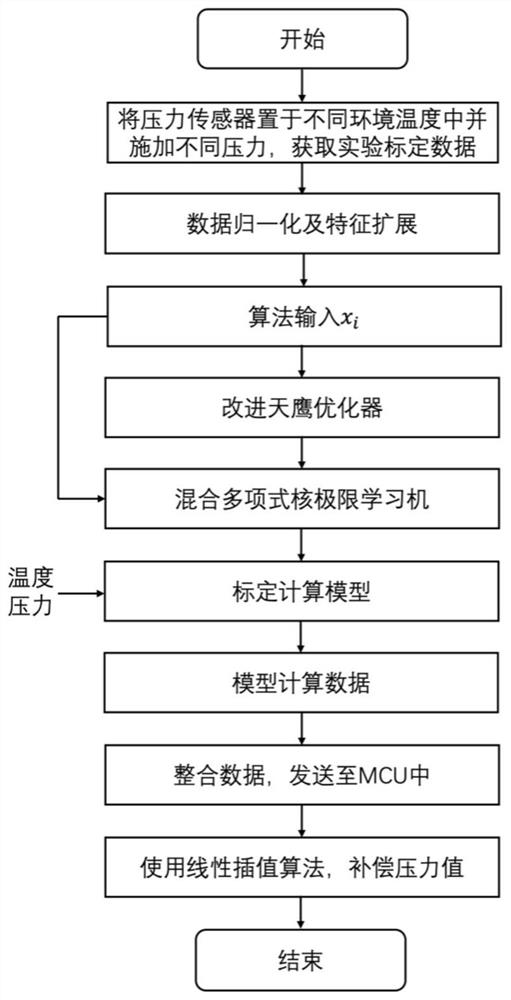

[0022] see attached Figure 1 , the present invention provides a simplified method for calibration of a pressure sensor, comprising the following steps:

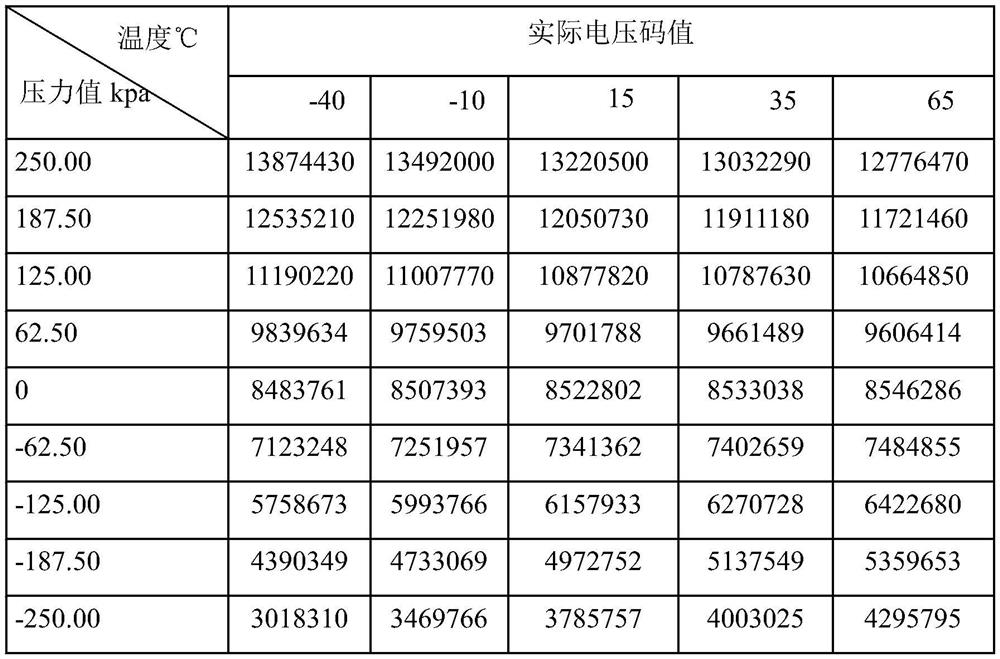

[0023] Step 1: Put the pressure sensor into the corresponding temperature environment, apply different pressures, obtain the output voltage code value of the AD chip, obtain a small amount of experimental calibration data, and form an experimental calibration data table, in which the voltage code value is expressed in decimal. After the calibration data collection is completed , and send it to the host computer. Table 1 is the experimental calibration data table of the 250kpa range pressure sensor selected for this example.

[0024] Table 1 is the experimental cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com