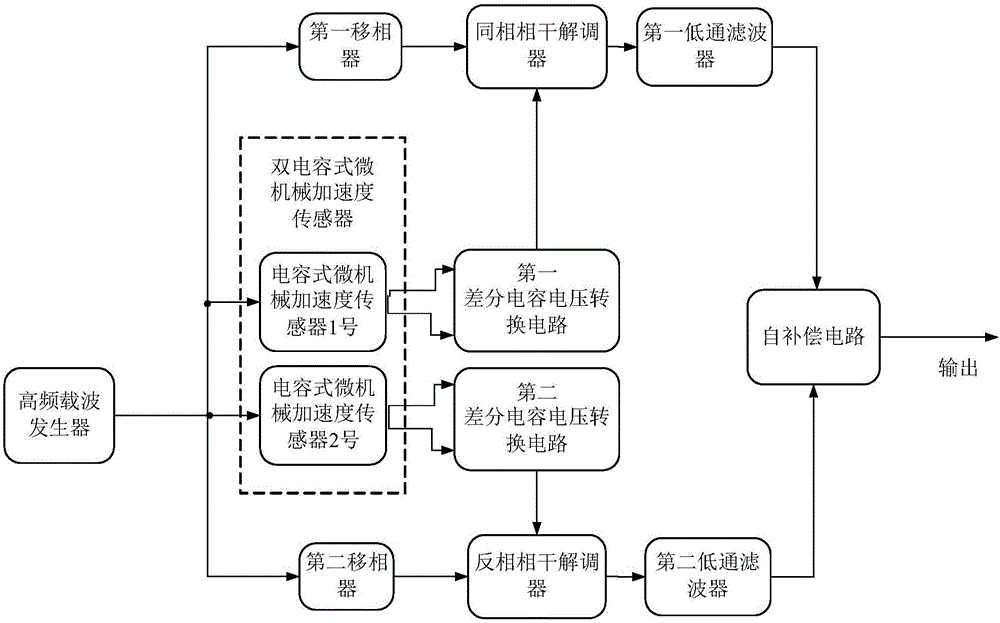

Dual-capacitance type micro-machine accelerator sensor and temperature self-compensating system based on it

An acceleration sensor and dual-capacitor technology, applied in the direction of measuring acceleration, speed/acceleration/shock measurement, instruments, etc., can solve problems affecting acceleration signal detection, avoid temperature measurement errors, improve temperature compensation accuracy, and eliminate nonlinear effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

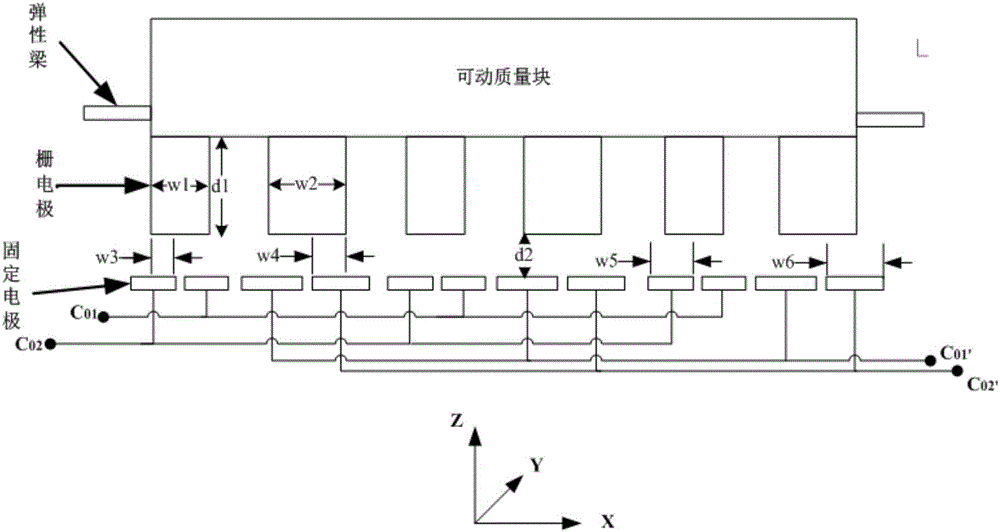

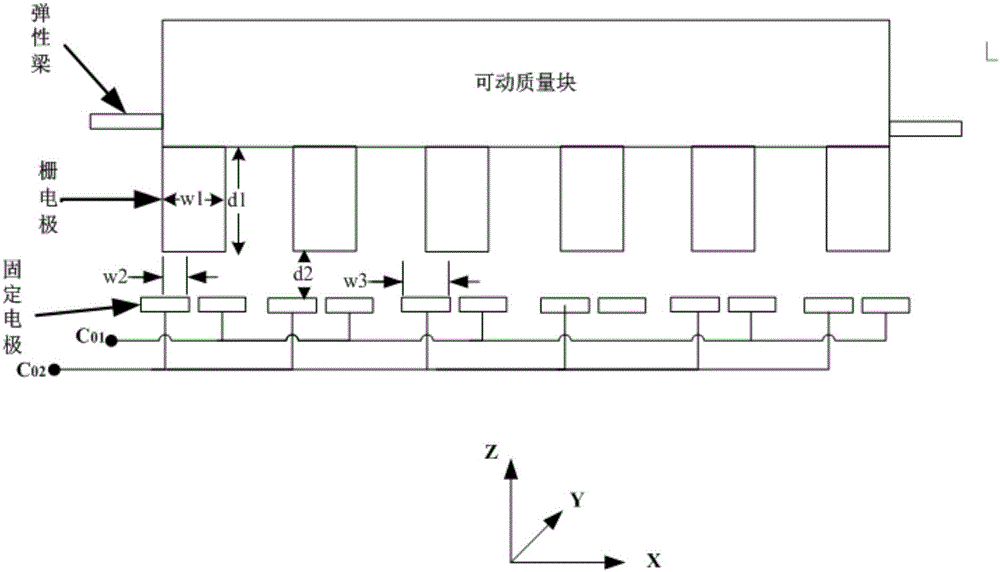

[0029] The existing variable-area gate structure capacitive detection micro-machine acceleration sensor such as image 3 As shown, the improved variable-area gate structure dual-capacitance micromachined acceleration sensor is as follows: figure 2 shown. The improvement method is as follows:

[0030] (1) Design the width of the gate electrode in the X direction as two different size parameters, such as figure 2 W1 and W2 are shown, where W1<W2.

[0031] (2) Design the width of the fixed aluminum electrode in the X direction as two different size parameters, such as figure 2 W5 and W6 shown, where W5<W6.

[0032] (3) Design the overlapping width between the gate electrode and the fixed aluminum electrode in the X direction as two different size parameters, such as figure 2 W3 and W4 shown, where W3<W4.

[0033] (4) The lengths of the gate electrode and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com