High-precision fiber-optic gyro system based on optical fiber temperature measurement and optical fiber loop structure

A fiber optic ring and fiber optic gyroscope technology, applied in thermometers, Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, etc., can solve the problem of affecting the accuracy and full temperature performance of high-precision fiber optic gyroscopes Problems such as real-time performance and accuracy of temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

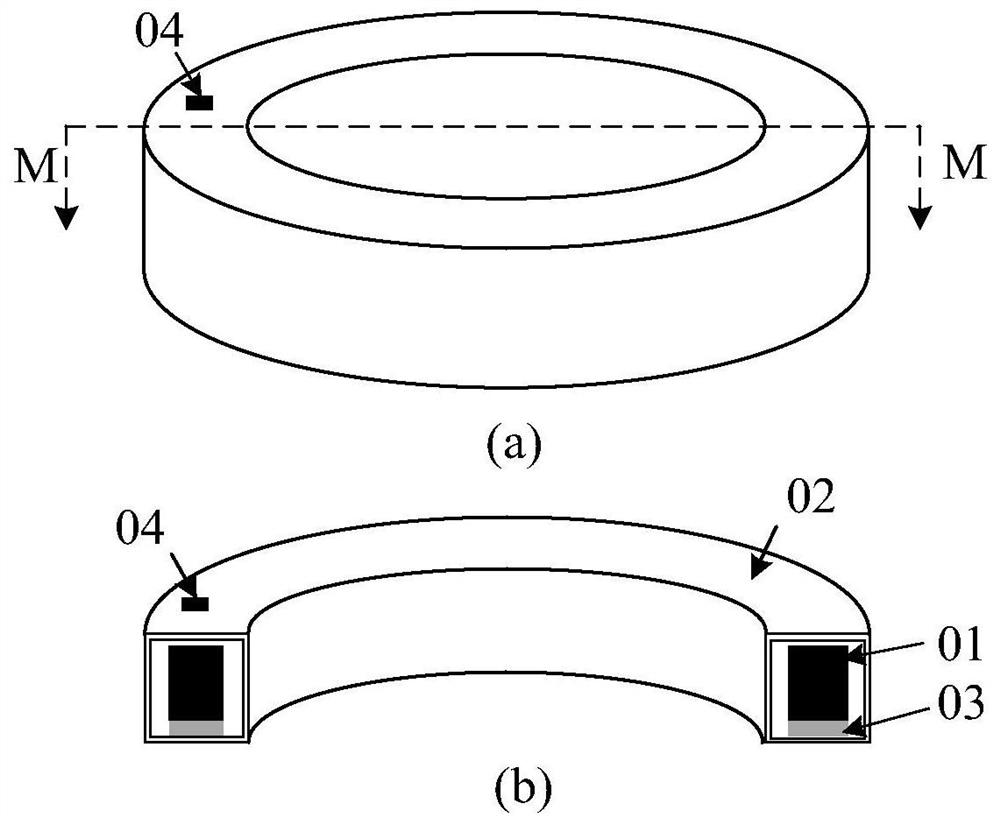

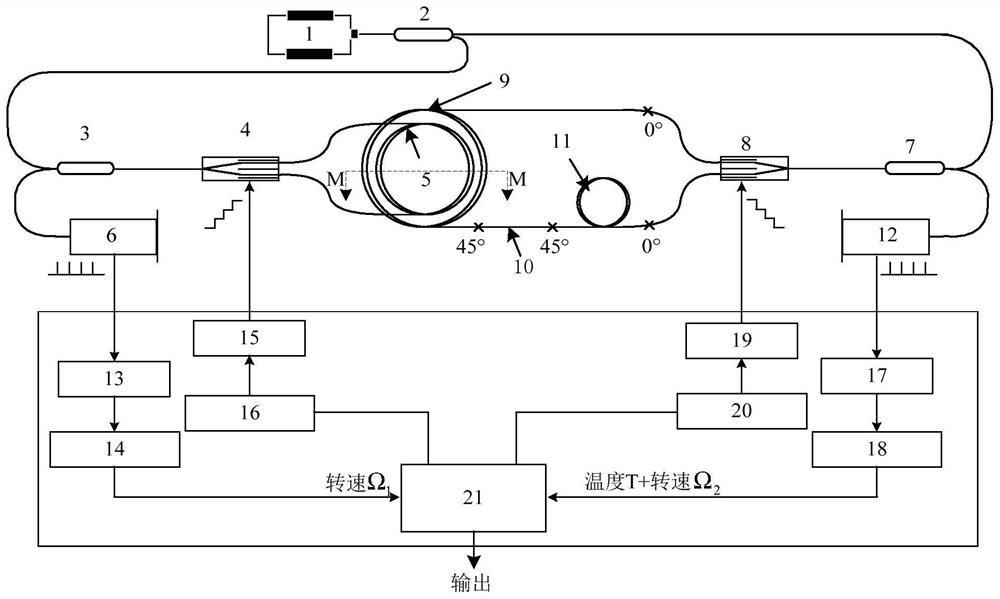

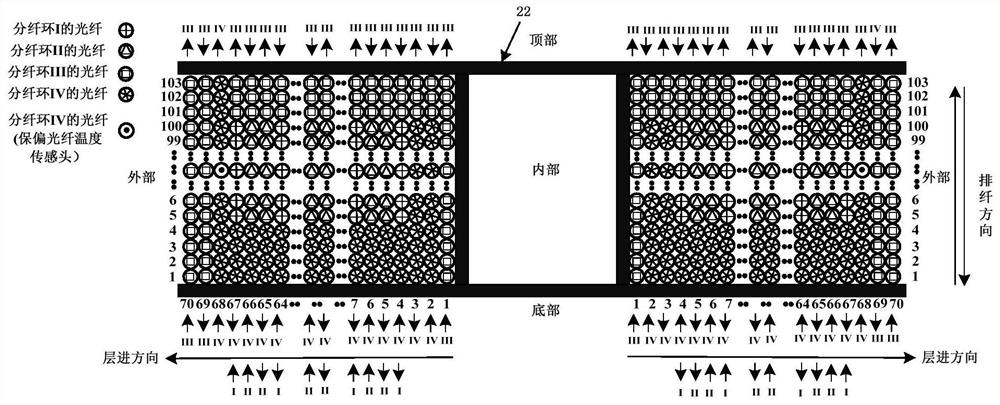

[0066] like figure 2 As shown, the high-precision fiber optic gyro system based on fiber optic temperature measurement provided in this embodiment includes a light source 1, a first coupler 2, a fiber optic gyro, a fiber optic temperature sensor, and a signal processor. The fiber optic gyroscope includes a second coupler 3 , a first Y waveguide 4 , a first fiber optic loop 5 and a first detector 6 , wherein both ends of the first fiber optic loop 5 are welded to the pigtails of the first Y waveguide 4 respectively. The fiber optic temperature sensor includes a third coupler 7, a second Y waveguide 8, a first polarization-maintaining fiber delay loop 9, a polarization-maintaining fiber temperature sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com