Patents

Literature

510 results about "Copper nickel alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

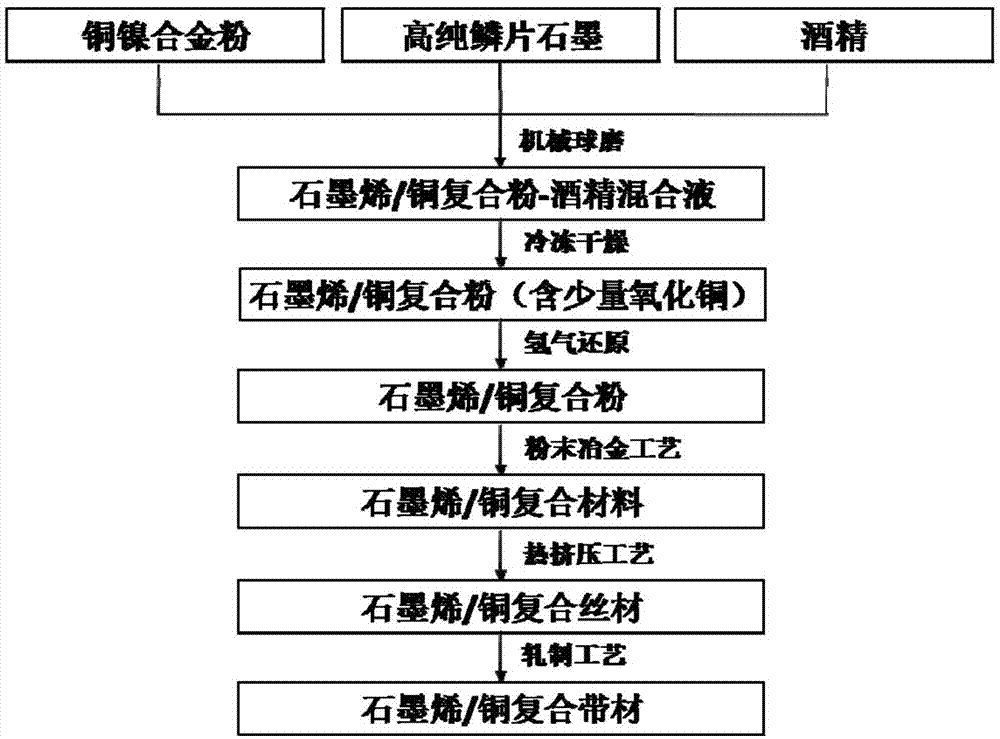

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

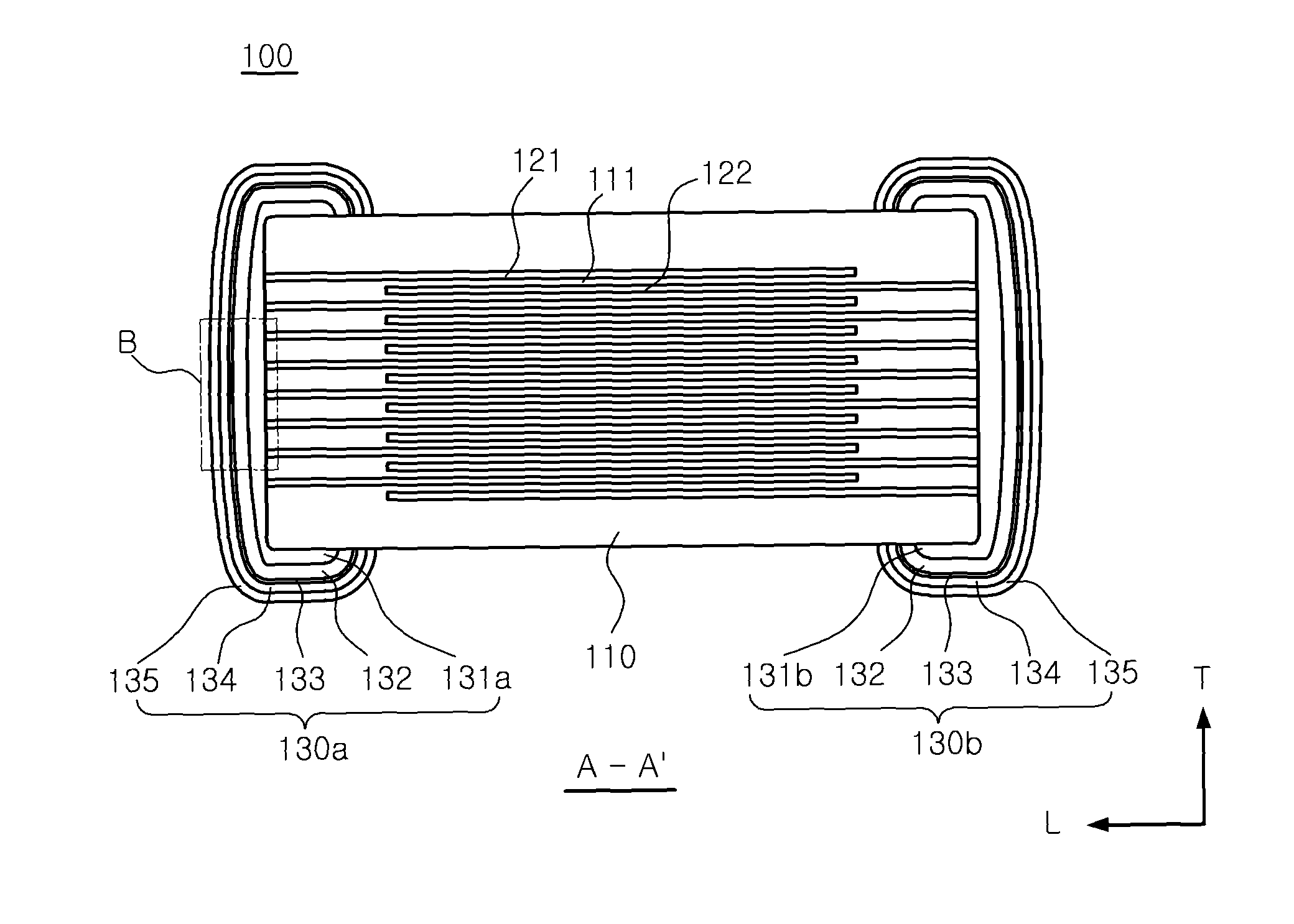

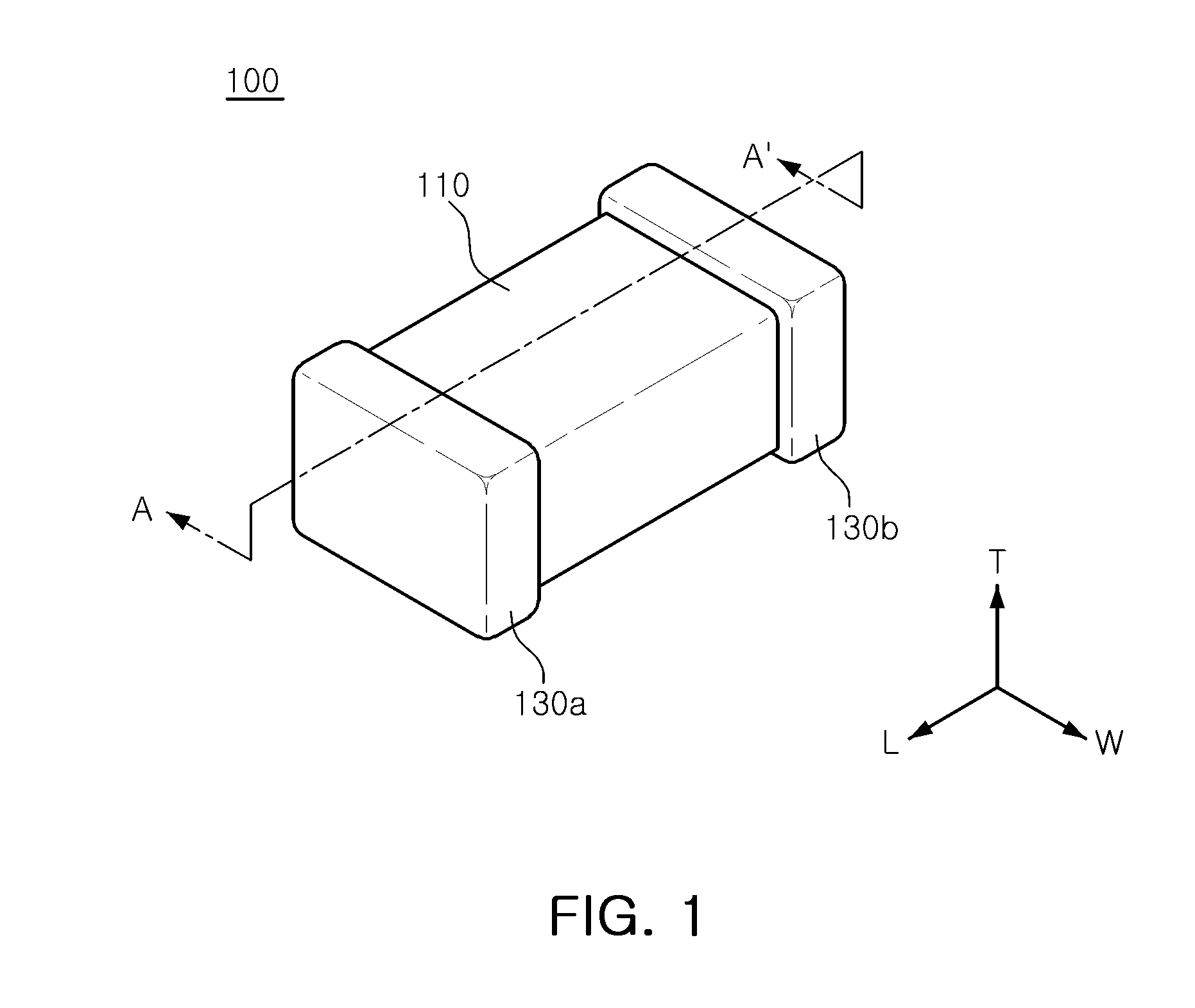

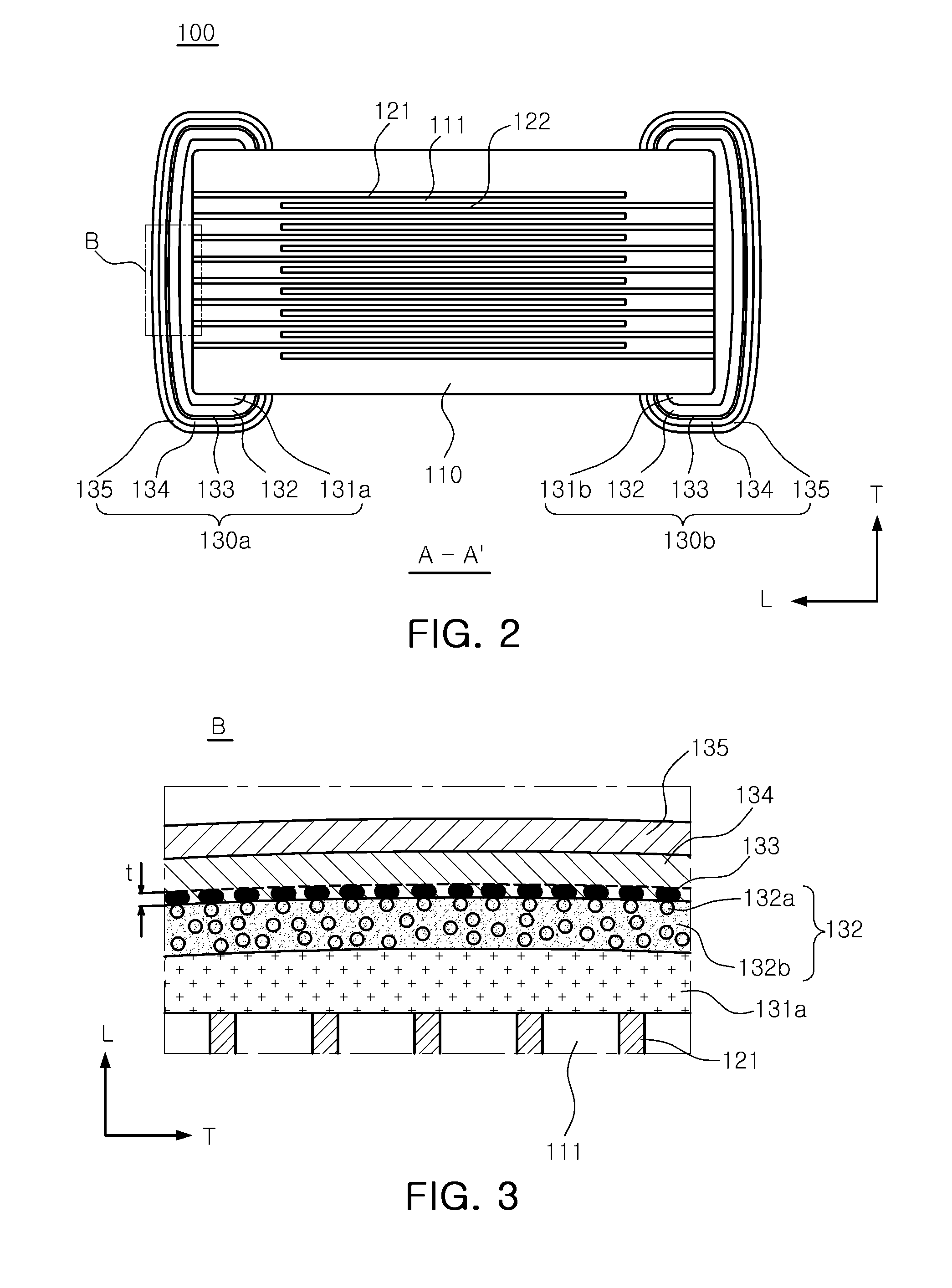

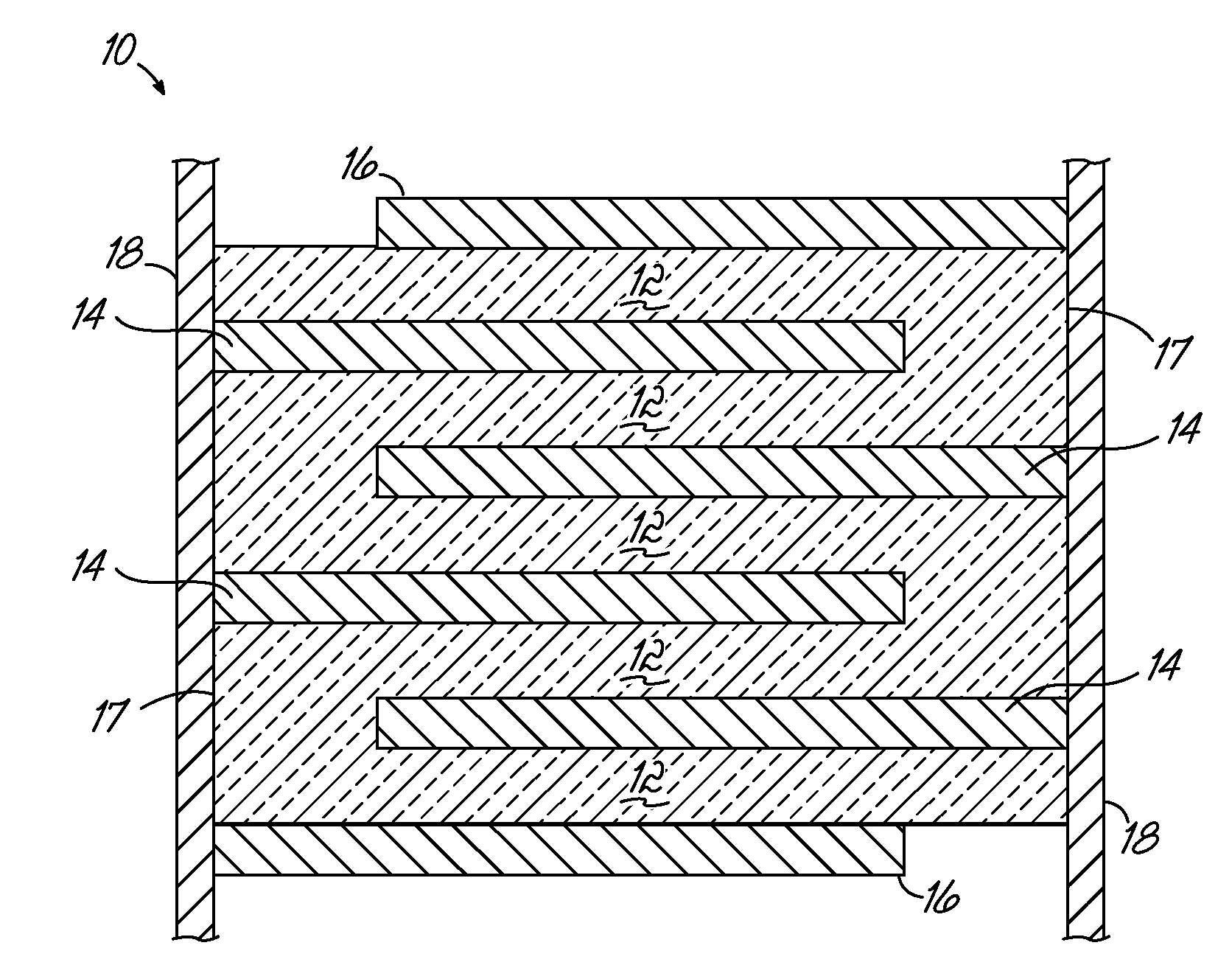

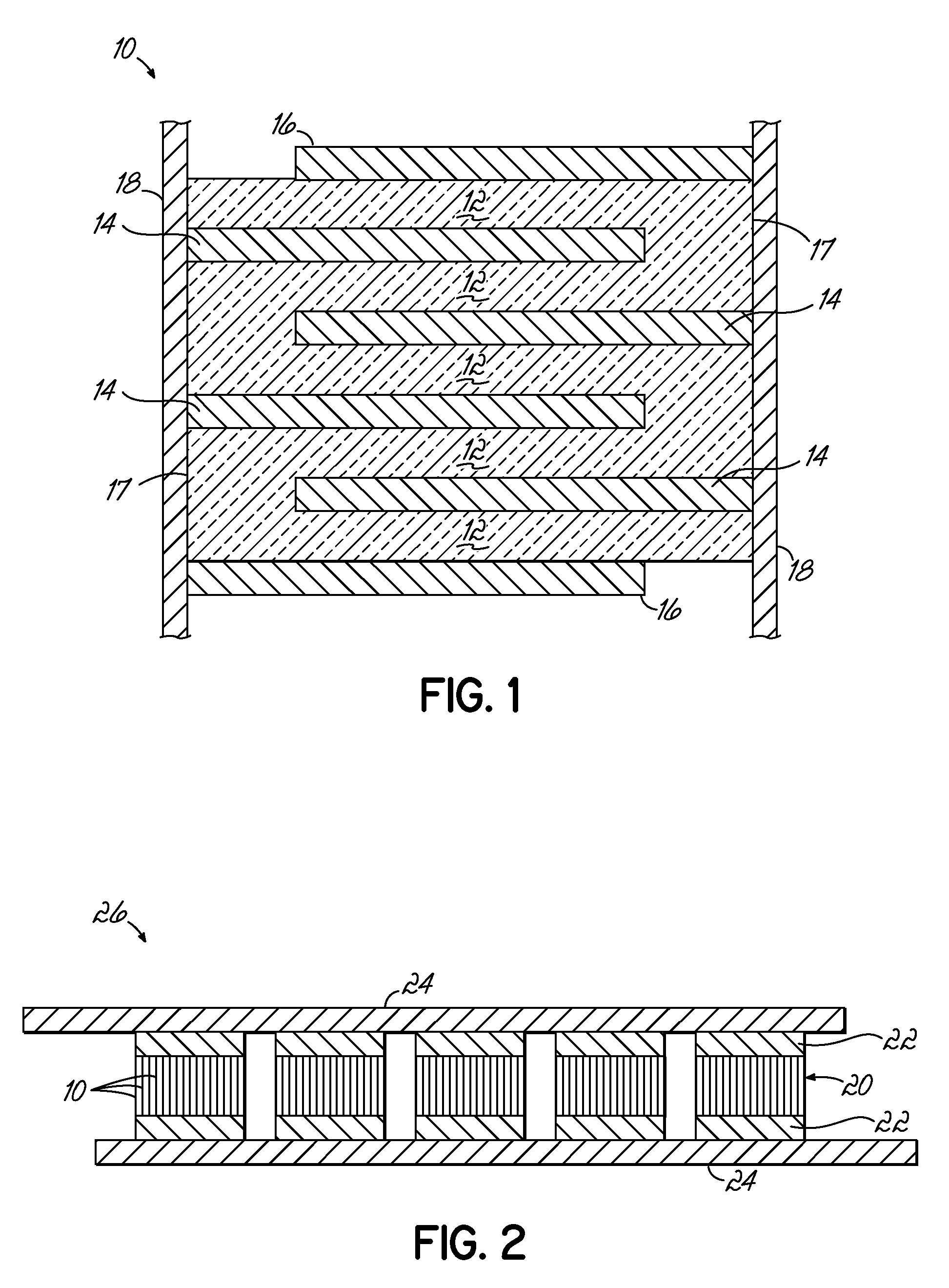

Multilayer ceramic capacitor and method of manufacturing the same

ActiveUS20140204502A1Fixed capacitor electrodesFixed capacitor dielectricCeramic capacitorDielectric layer

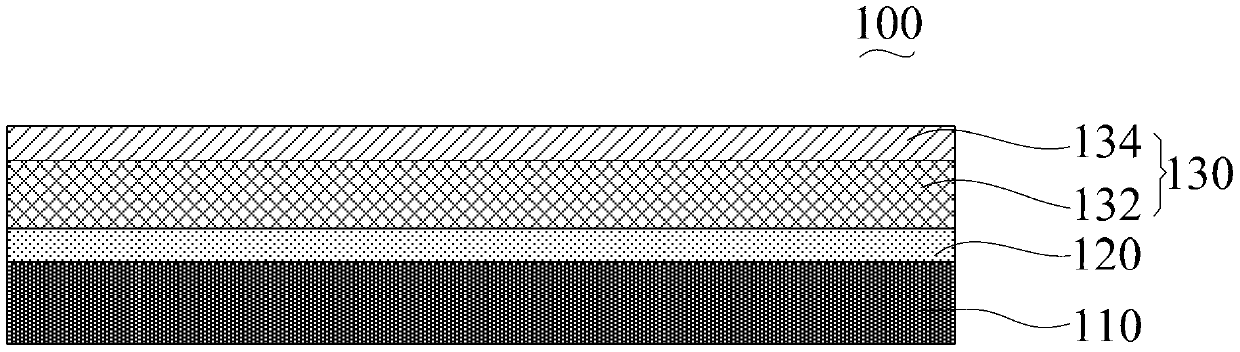

There is provided a multilayer ceramic capacitor including a ceramic body including dielectric layers, first and second internal electrodes formed within the ceramic body and disposed to face each other, having the dielectric layer interposed therebetween, first and second electrode layers disposed on outer surfaces of the ceramic body and electrically connected to the first and second internal electrodes, respectively, a conductive resin layer disposed on the first and second electrode layers and containing copper powder, a nickel plating layer disposed on an outer portion of the conductive resin layer, and a copper-nickel alloy layer disposed between the conductive resin layer and the nickel plating layer and having a thickness of 1 to 10 nm.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

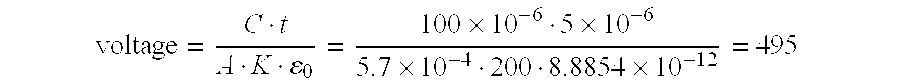

Sintered Dielectric Ceramic, Composition for Making, and Use Thereof In Multilayer Capacitor And Energy Storage Device

ActiveUS20100008019A1Reduce oxygen mobilitySuppressing grain growth during sinteringFixed capacitor dielectricStacked capacitorsDielectricElectrical connection

A batch powder composition for preparing a non-ferroelectric, sintered dielectric ceramic; a multilayer ceramic capacitor thereof; and an energy storage device. The batch powder contains a titanate powder of at least one of CaTiO3, SrTiO3, or CaxSr1-xTiO3 where x=0 to 1, and an acceptor additive. A sintering aid and a donor additive also may be present in the batch powder. The batch powder may be sintered at temperatures of about 1050° C. or less. The ceramic contains a titanate from the titanate powder, the acceptor additive, and the optional sintering aids and donor additive. The multilayer ceramic capacitor is made of the sintered dielectric ceramic and may have electrodes of copper or a copper-nickel alloy. An energy storage device has electrical connections connected to the electrodes of the multilayer ceramic capacitor. The electrical connections may be in electrical communication with additional multilayer ceramic capacitors.

Owner:IAN BURN CONSULTING

Non-magnetic cube texture Cu-based alloy composite base band and preparation method thereof

InactiveCN101786352AHigh mechanical strengthNo Magnetic GuaranteeMetal rolling arrangementsMetal layered productsSurface layerMold filling

The invention discloses a non-magnetic cube texture Cu-based alloy composite base band. The non-magnetic cube texture Cu-based alloy composite base band is prepared by compositing surface layers and a core layer and has the structure of surface layer, core layer and surface layer, wherein each surface layer is copper-nickel alloy in which the weight percentage of nickel is less than 50 percent; and the core layer is nickel-tungsten alloy in which the atomic percentage of tungsten is between 9 and 12 percent. A preparation method by using powder metallurgy comprises the following steps: (1) initial powder mixing and mold filling; (2) compressing and sintering of a composite green compact; (3) deforming and rolling of the sintered composite bullet; and (4) recrystallizing heat treatment for a cold rolling base band. The preparation method improves the mechanical strength of the whole base band and simultaneously ensures the non-magnetic performance of the whole base band; and the composite base band has high yield strength.

Owner:BEIJING UNIV OF TECH

Chip resistor

InactiveUS7782174B2Lower resistanceReduce failure rateResistor detailsThick film resistorsCeramic substrateResistive element

Owner:KOA CORP

Method of manufacturing a 2-layered flexible substrate

InactiveUS6045713AImprove adhesionDecorative surface effectsVacuum evaporation coatingCopper conductorCopper plating

A method of manufacturing a 2-layered flexible substrate includes forming an underlying metal layer on an insulation film with a deposition layer formed by a dry plating method using at least one of nickel, copper-nickel alloy, chromium and chromium oxide and a copper deposition layer formed by a dry plating method on the noted deposition layer, then forming a primary electric copper plated deposition layer on the underlying metal layer, then applying a treatment using at least one alkaline solution selected from inorganic alkaline solutions and organic alkaline solutions, then forming an electroless copper plated deposition layer as an intermediate metal layer on the primary electric copper plated deposition layer and, finally, forming a secondary electric copper plated deposition layer on the intermediate metal layer, thereby finally forming a copper conductor layer of 1 to 35 mu m thickness on the insulation film.

Owner:SUMITOMO METAL MINING CO LTD

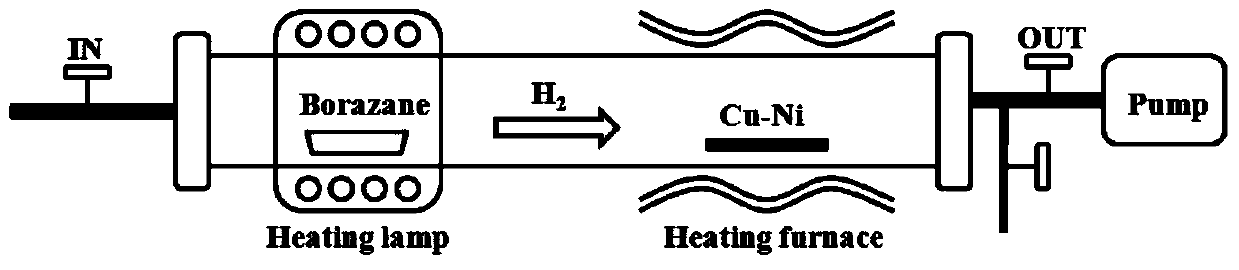

Method for preparing hexagonal boron nitride film

ActiveCN103774113AHigh crystallinityGood repeatabilityChemical vapor deposition coatingHexagonal boron nitrideMicrometer

The invention provides a method for preparing a hexagonal boron nitride film. The method comprises the following steps of firstly preparing a copper-nickel alloy foil as a substrate; placing the substrate into a chemical vapor deposition cavity with the pressure intensity of 20-5000 Pa to preserve the temperature of the substrate between 950 DEG C and 1090 DEG C; introducing a source substance with the temperature of 50-100 DEG C, and introducing a protective gas to grow for 10 minutes-3 hours so as to prepare the hexagonal boron nitride film on the surface of the copper-nickel alloy foil substrate. The method provided by the invention can be used for preparing hexagonal boron nitride crystal domains with different sizes and continuous films with different thicknesses on the copper-nickel alloy foil substrate by controlling growth parameters. The prepared hexagonal boron nitride crystal domains can achieve the maximal side length of hundreds of micrometers, have the advantages of good crystallinity, simple preparation condition, low cost, wide window of a condition parameter required by growth and good repeatability and lays the foundation for the wide application of the hexagonal boron nitride film in the fields of a graphene device and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

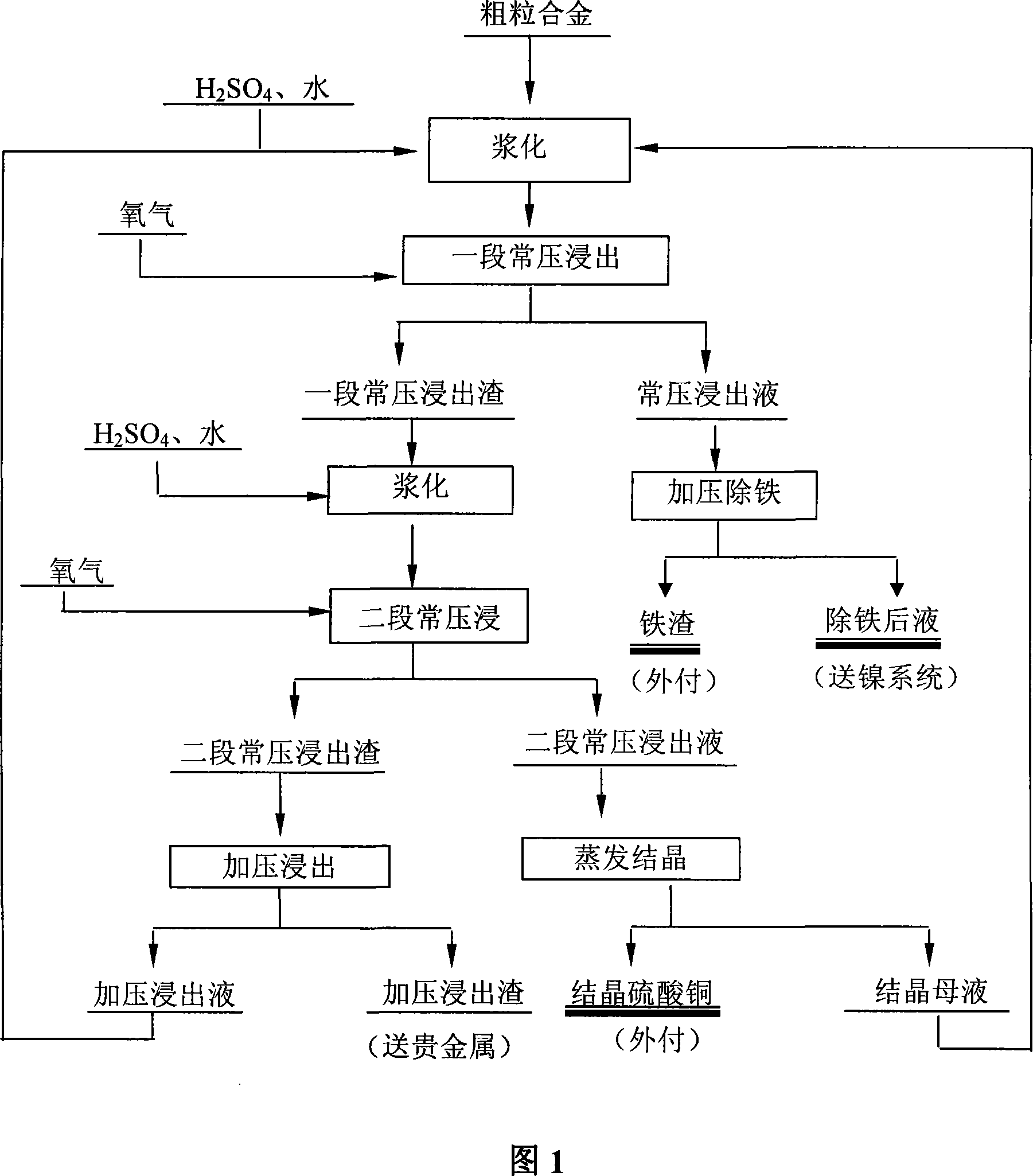

Solvent extraction method for acquiring alloy with magnetic separation copper bessemer matte

The invention relates to a leaching method for alloy obtained by magnetic separation nickel-copper bessemer matte. The invention is characterized in that two-stage atmospheric pressure leaching, pressurized leaching, pressurized deferrization and bluestone evaporation and crystal processes are adopted to obtain pressurized slag with higher noble metal concentration ratio, and the pressurized slag is delivered in the noble metal system directly. The method of the invention belongs to the metallurgical technology for treating the alloy (coarse grain alloy) material obtained by magnetic separation nickel-copper bessemer matte. Nickel, iron, and copper are leached out stage by stage, and the leached slag concentrated with noble metal can be sent for the noble metal processing. Leached lixivium solution including iron is pressurized for deferrization, and after the deferrization, the solution is nickel solution with less foreign impurities, which can be delivered in the nickel system. The lixivium solution including copper is evaporated and crystallized, to obtain bluestone to form the open circuit of copper, and crystallized mother solution is circularly used in the leaching system. The process has the advantages that the process is simple, highly efficient and environment friendly. The invention is suitable for the treatment of copper nickel alloy, and through adjusting the relative technical parameter, the invention is suitable for selectively leaching and segregating nickel, copper and noble metal from alloy mineral with various grades.

Owner:JINCHUAN GROUP LIMITED

Foundry practice method of heavy-duty car forward shaft

InactiveCN101480695AQuality improvementImprove hardenabilityMelt-holding vesselsFoundry mouldsShielding gasHeavy duty

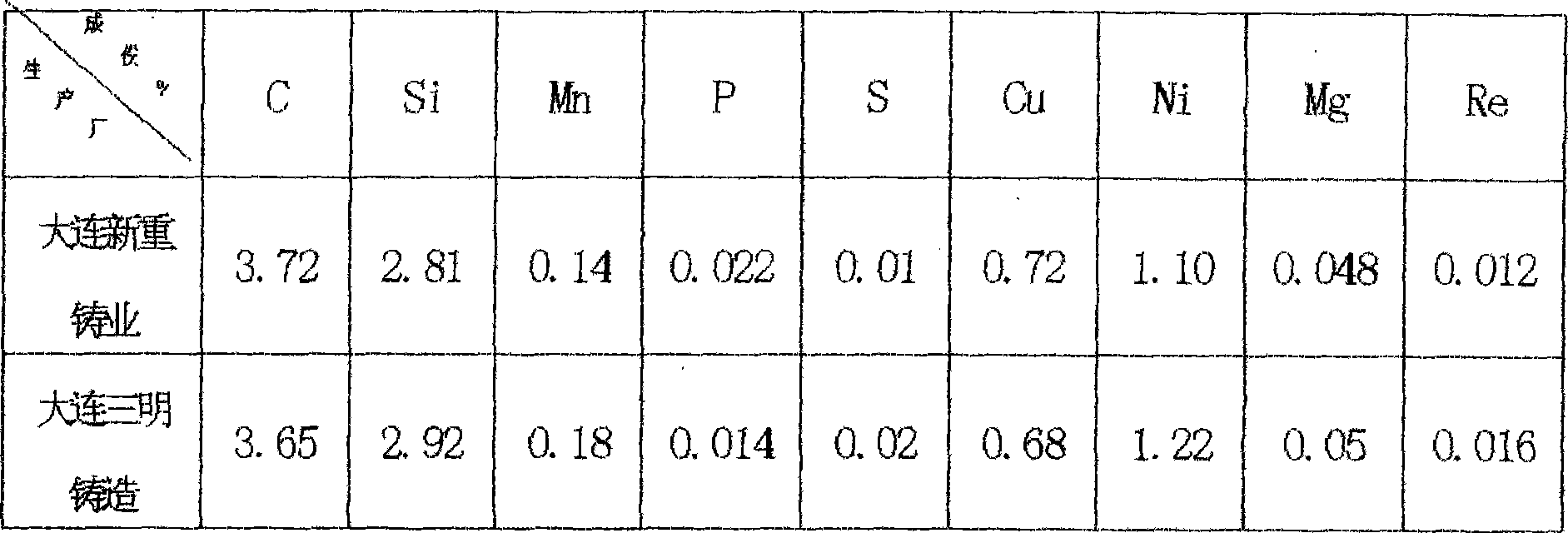

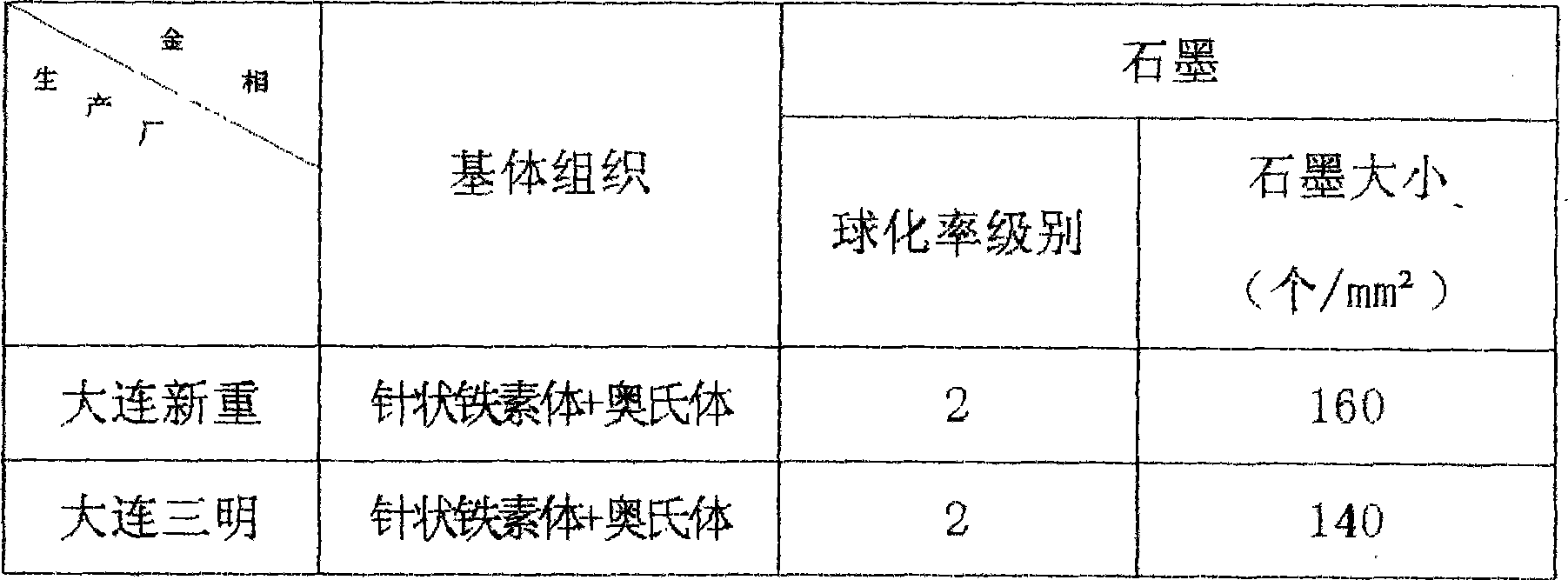

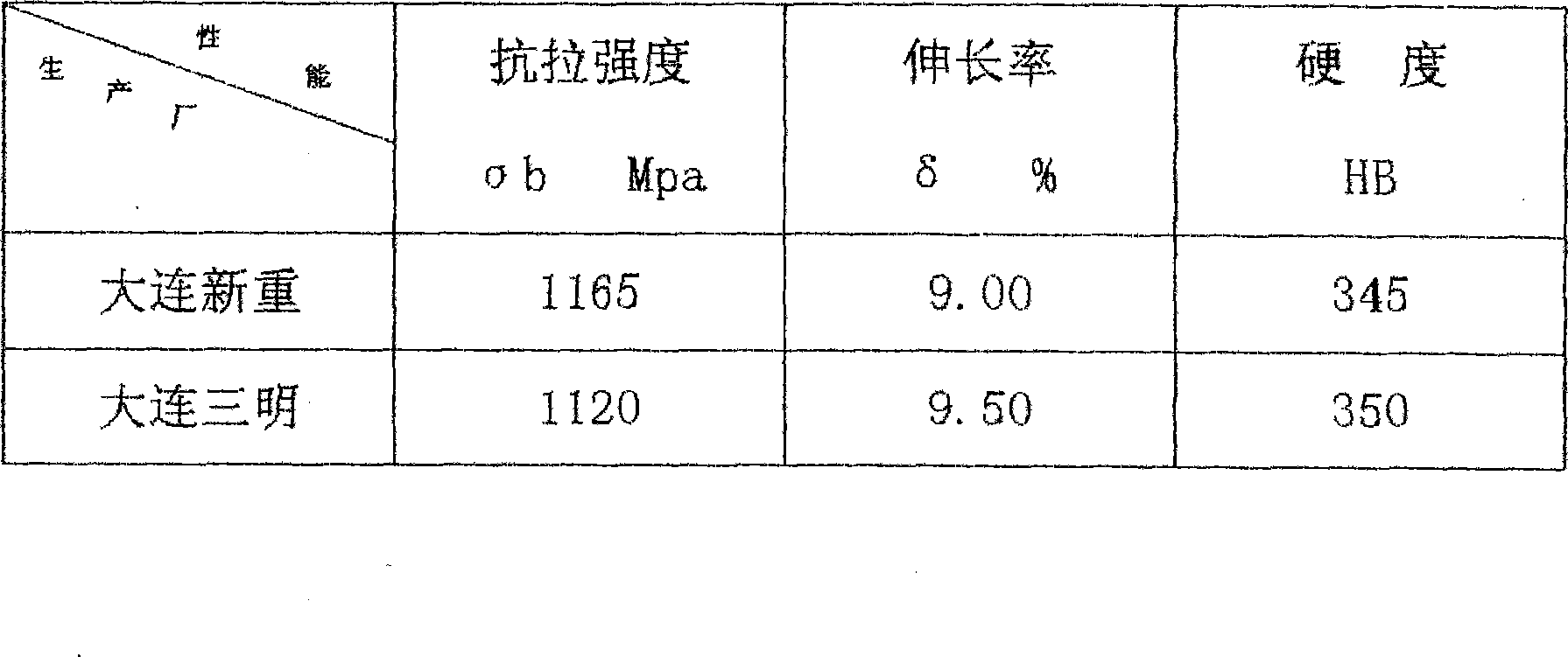

The invention relates to a casting and producing method of a front shaft of a heavy-duty car, which belongs to the enginery. The method adopts copper-nickel alloying isothermal quenching magnesium iron which has higher strength and tenacity compared with the traditional copper-molybdenum alloying isothermal quenching magnesium iron, thereby the service life of the front shaft can be improved; a front shaft blank is cast by adopting a sand-coated iron mould process; the spheroidization of the blank is carried out by adopting a tundish-cover crushing method so that the spheroidization is more stably; a process of mechanical processing firstly and isothermal quenching later ensures that the front shaft does not deform; and the isothermal quenching treatment is performed on a salt bath furnace production line with shielding gas atmosphere to produce an austenite plus acicular ferrite matrix, thereby the tenacity of the front shaft is greatly improved. The method achieves the material revolution that forging is substituted by casting and steel is substituted by iron, saves a heavy forging device or the die investment, shortens the production period, and has obvious economic and social benefits.

Owner:长春怀林机械工程材料科技有限公司

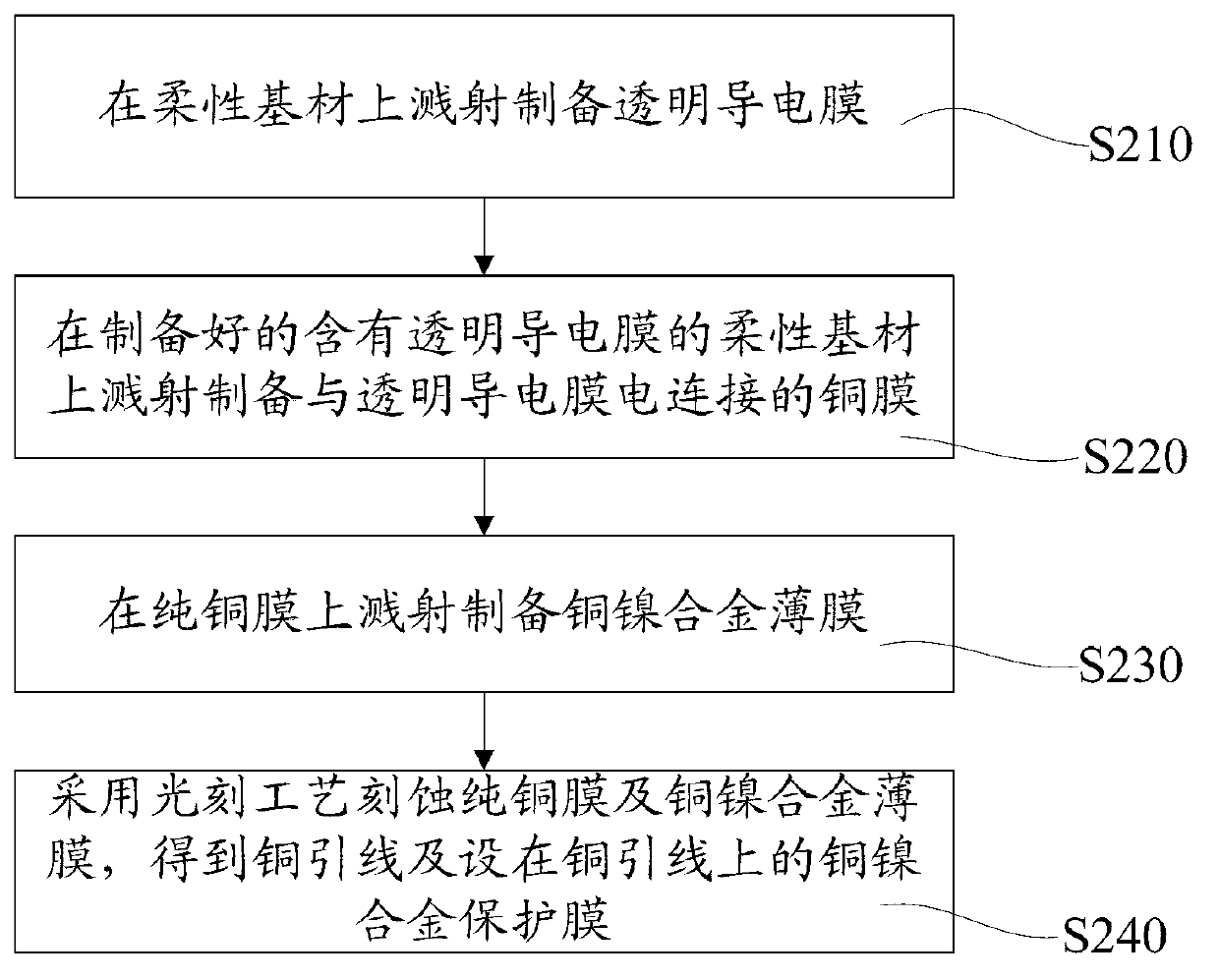

Flexible touch screen and preparation method thereof

ActiveCN103345337APrevent oxidative deteriorationAvoid damageVacuum evaporation coatingSputtering coatingTectorial membraneSputtering

The invention relates to a flexible touch screen, and further relates to a preparation method for the flexible touch screen. The flexible touch screen comprises a flexible substrate, a transparent conductive film arranged on the flexible substrate and electrode leads electrically connected with the transparent conductive film, wherein each electrode lead comprises a copper lead arranged on the transparent conductive film and a copper-nickel alloy protecting film arranged on the copper lead. Copper-nickel alloy is good in oxidation resisting performance under atmosphere and can effectively prevent the copper lead from being oxidized or going bad, sputtering preparation of the copper lead and the copper-nickel alloy protecting film can be directly finished through one process without extra processes, and therefore production efficiency of flexible touch screens can be effectively improved, extra processes are prevented from damaging the transparent conductive film, and the percent of pass of the flexible touch screens is improved.

Owner:深圳南玻显示器件科技有限公司

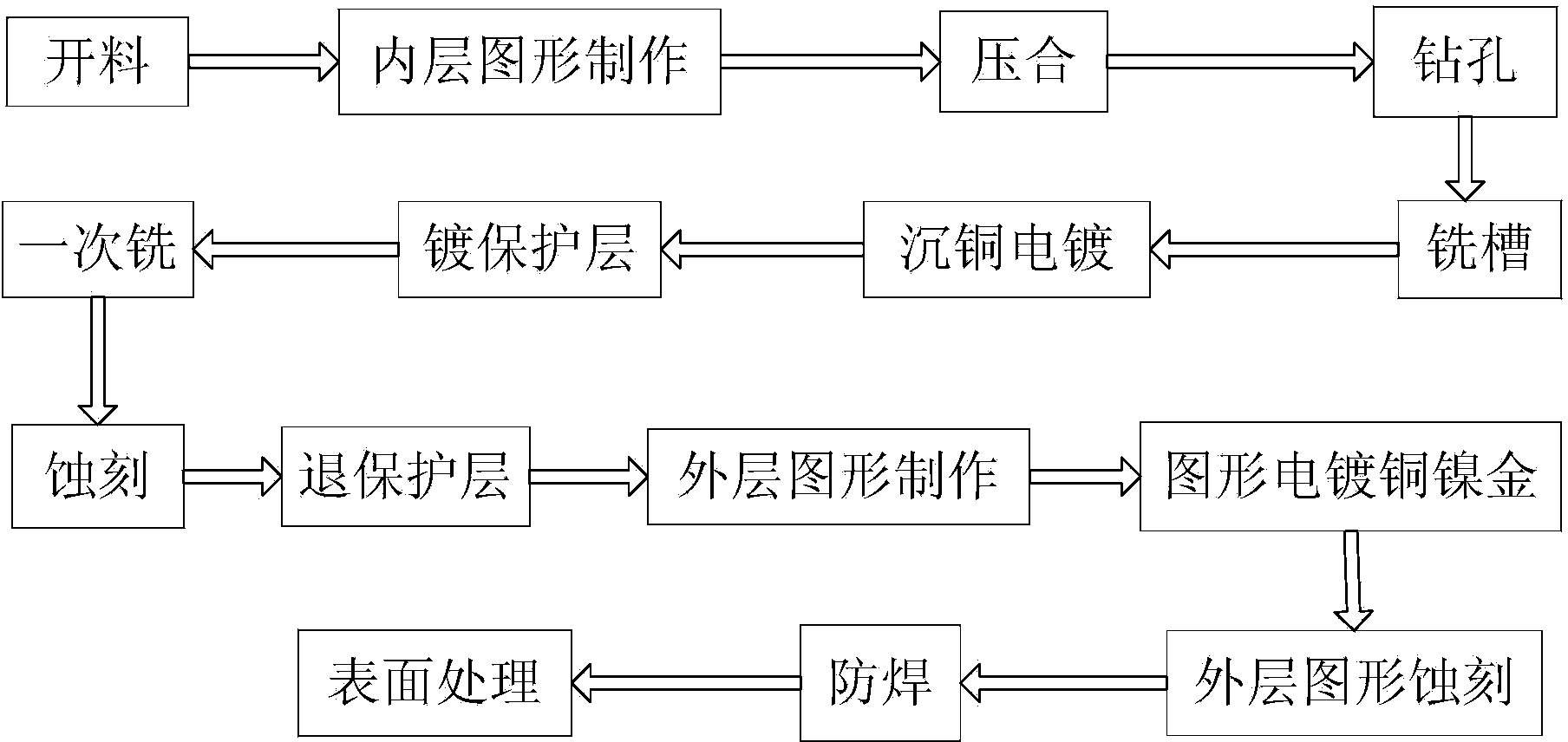

Gold-plated circuit board manufacturing method

ActiveCN103687312AGuaranteed not to be brokenImprove pass ratePrinted circuit manufactureSolder maskProtection layer

The invention discloses a gold-plated circuit board manufacturing method, and belongs to the technical field of the printed circuit board. The manufacturing method includes: cutting material, making an inner layer image, pressing, drilling, milling groove, precipitating copper electroplating, plating a protective layer, an one-time milling, etching, removing the protective layer, making an outer layer image, plating a copper nickel alloy for the image, etching of the outer layer image, a solder mask process, and a surface processing process. The manufacturing method can be used to solve the problem of the gold-plated burr, the artificial trimming is not needed, the simple process and easy control are realized, the labor cost is greatly saved, and the production efficiency is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

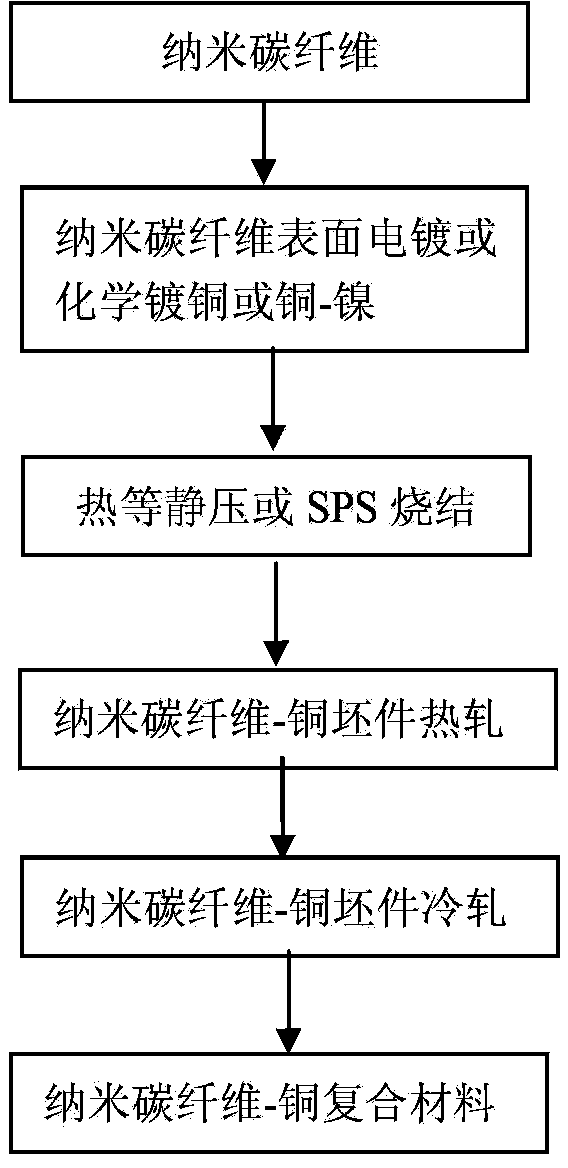

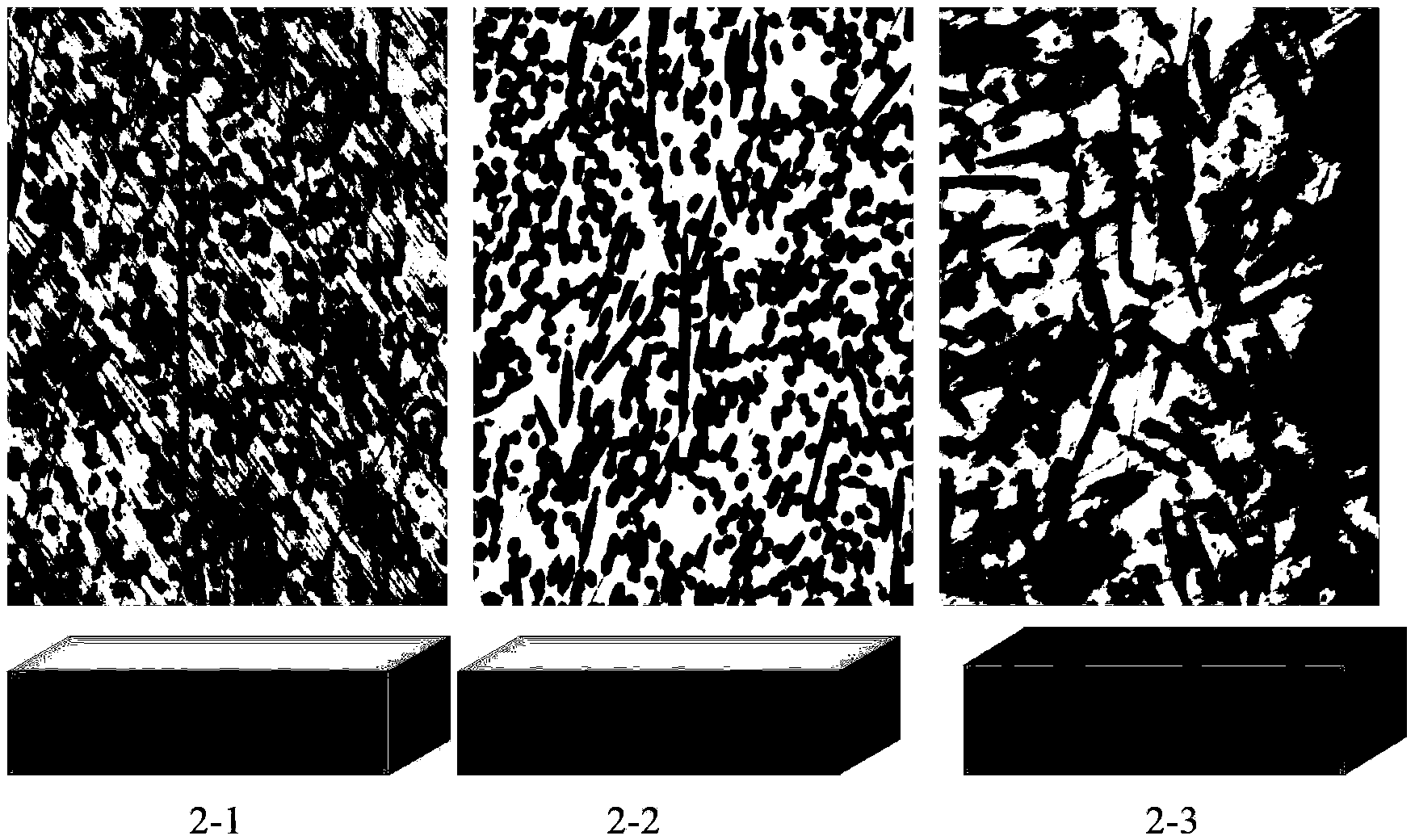

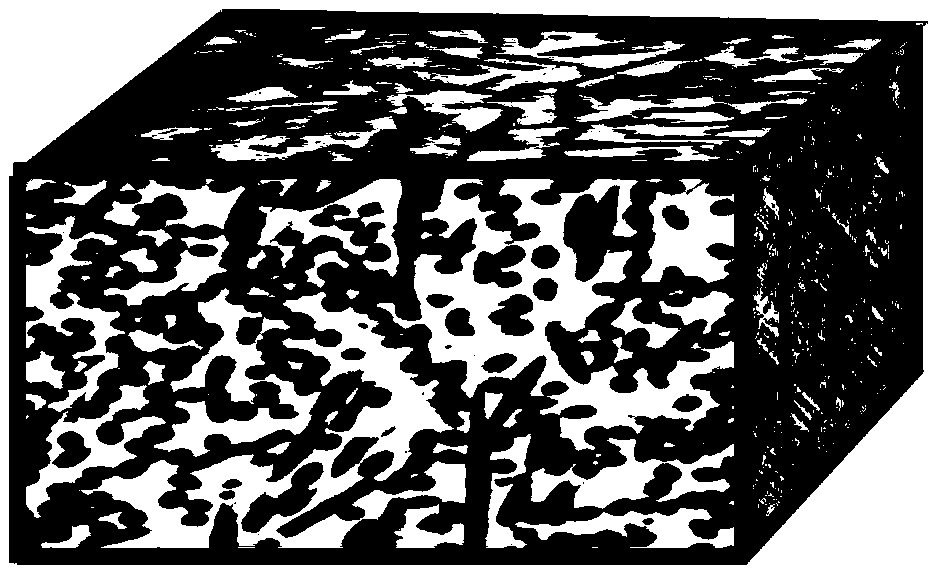

Preparation method of nanometer carbon fiber-copper composite material

The invention discloses a preparation method of a nanometer carbon fiber-copper composite material, which belongs to the technical field of preparation of electronic component composite materials. The method comprises the following steps: plating nanometer carbon fibers with a certain volume fraction of copper or copper-nickel alloy by chemical plating or electroplating, reducing the metalized nanometer carbon fibers in hydrogen, then preparing a nanometer carbon fiber-copper composite material blank by hot isostatic pressing or discharge plasma sintering, finally performing hot rolling cogging, and performing cold rolling to realize oriented arrangement of the nanometer carbon fibers, so as to prepare the nanometer carbon fiber-copper composite material. The prepared nanometer carbon fiber composite material has a density lower than that of copper, is adjustable in thermal expansion coefficient, is high in thermal conductivity in the parallel fiber direction, and is widely used in microelectronic packaging, laser diodes, IGBT and semiconductors, radiating fins, and cover plates.

Owner:GRIMAT ENG INST CO LTD

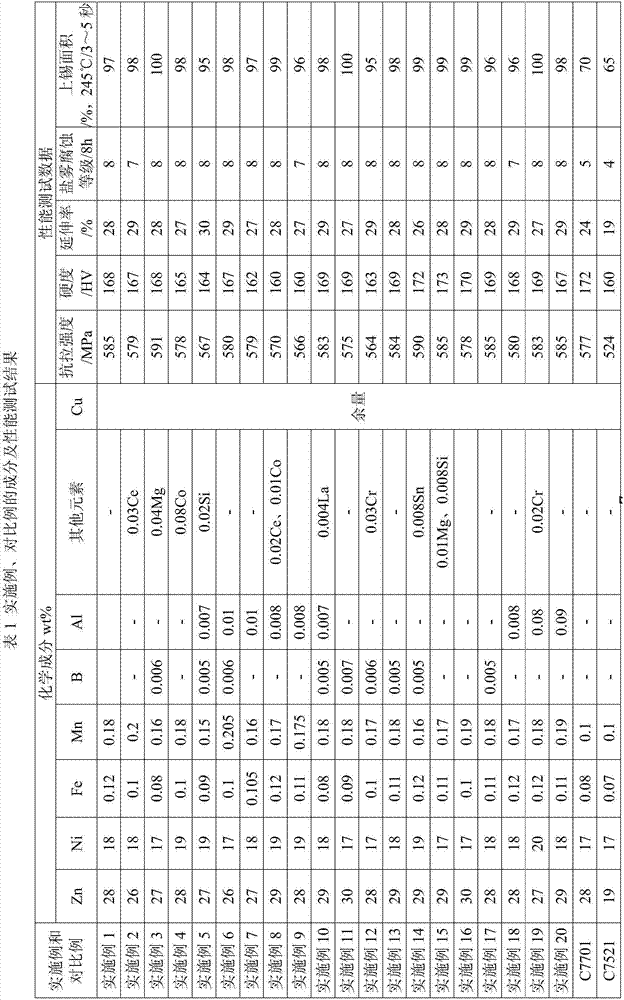

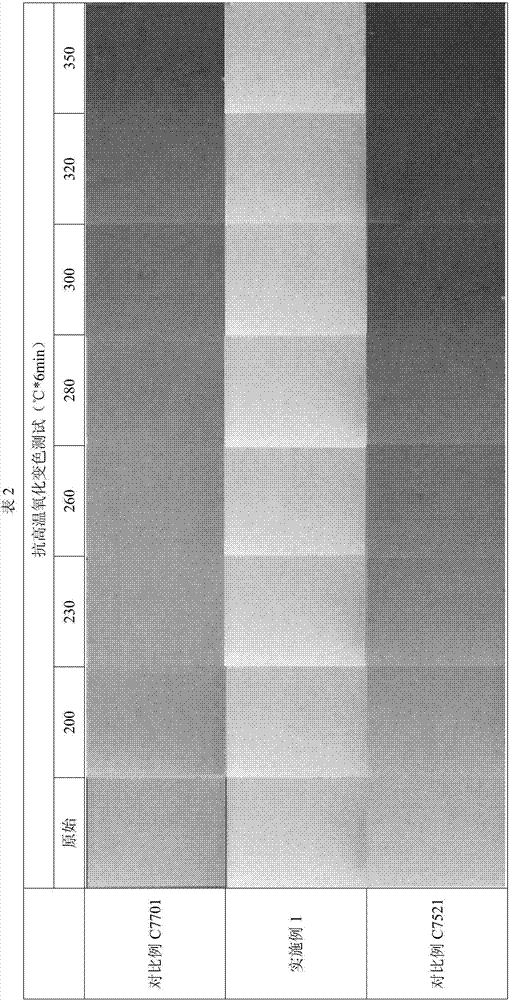

Zinc-copper-nickel alloy and preparation method and application thereof

ActiveCN107151750AImprove high temperature oxidation resistanceImprove solderabilityHot-dipping/immersion processesCupronickelSoldering

The invention discloses a zinc-copper-nickel alloy. The zinc-copper-nickel alloy comprises the following components in percentages by weight: 13-25% of Ni, 15-40% of Zn, 0.01-0.25% of Fe, 0.01-0.5% of Mn and the balance of Cu and inevitable impurities. The zinc-copper-nickel alloy has excellent high-temperature oxidation resistance, salt-spray corrosion resistance and soldering performance. The zinc-copper-nickel alloy cannot oxidize when baked for 5-15 minutes at the high temperature of 280 DEG C; the non-corrosive duration of the zinc-copper-nickel alloy in a 5% NaCl salt mist atmosphere is longer than or equal to 8 hours; and if the zinc-copper-nickel alloy is soaked in tin liquor at the temperature of 245+ / - 5 DEG C and then is taken out 3-5 seconds later, the tinplated area is 95% or above. The zinc-copper-nickel alloy can be applied to electronic and electrical products such as shielding covers, and can also be used as raw materials of other electronic and electrical products with high requirements on comprehensive properties including high-temperature oxidation resistance, salt-spray corrosion resistance and soldering performance.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

Chemical vapor deposition method for preparing graphene

The invention provides a chemical vapor deposition method for preparing graphene, which comprises the following steps: 1. preparing a copper-nickel alloy film on the monocrystalline silicon surface by a copper / nickel double-target magnetron sputtering process; 2. transferring the monocrystalline silicon substrate, of which the surface is deposited with the copper-nickel alloy film, into a chemical vapor deposition reaction furnace, and introducing helium into the reaction furnace to eliminate air in the reaction furnace; 3. heating the substrate to 400-600 DEG C within 20-40 minutes, and introducing helium until the pressure in the reaction furnace is 5-10 Torr; 4. introducing hydrogen into the reaction furnace, and injecting benzene into the reaction furnace; 5. while keeping the pressure in the reaction furnace at 5-10 Torr, after the benzene injection is finished, stopping introducing the hydrogen, introducing helium into the reaction furnace, cooling the monocrystalline silicon substrate with the copper-nickel alloy film to room temperature at the rate of 20 DEG C / minute, and continuing introducing helium for 10 minutes; and 6. taking out the substrate on which the graphene film is grown.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

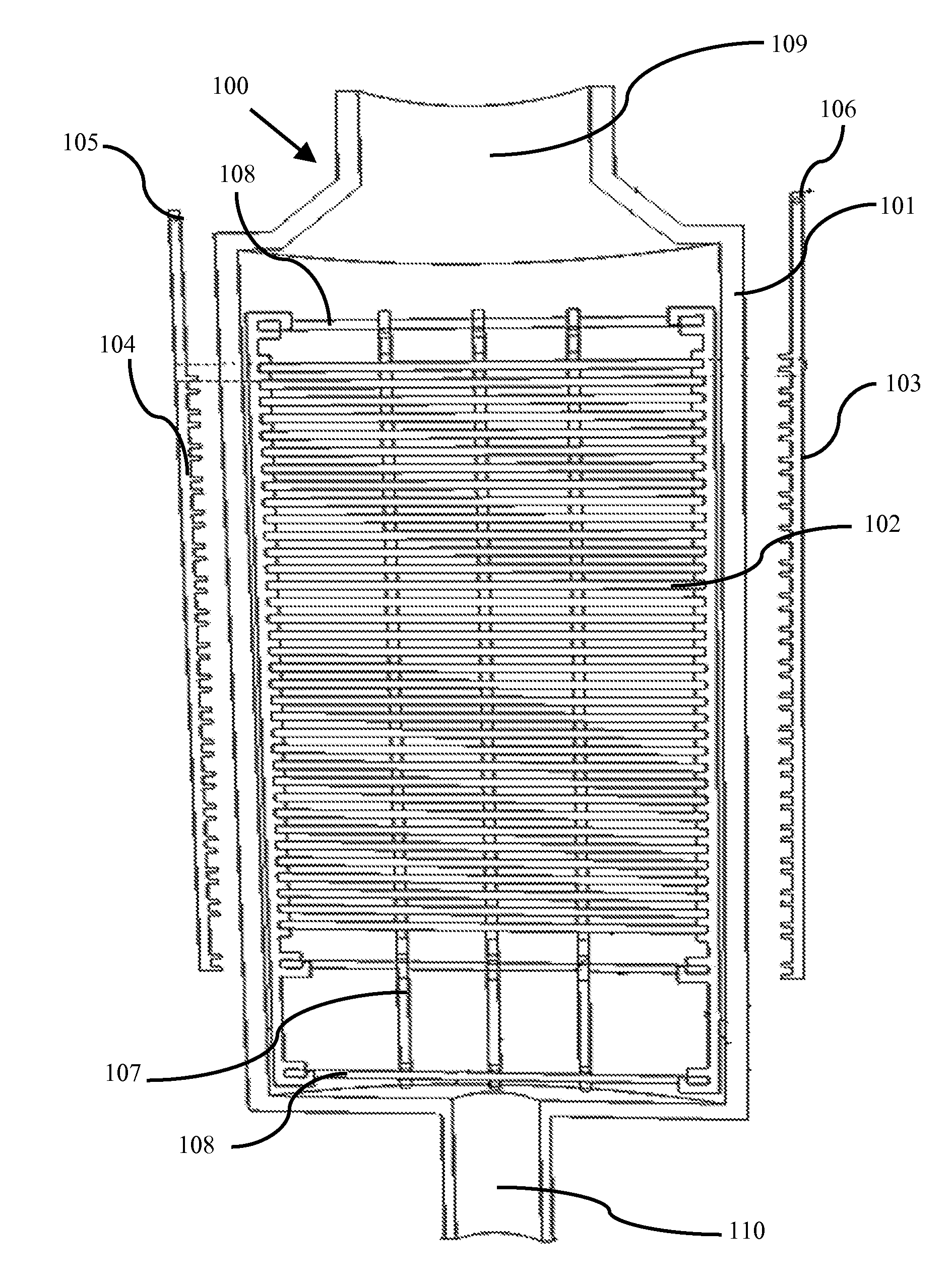

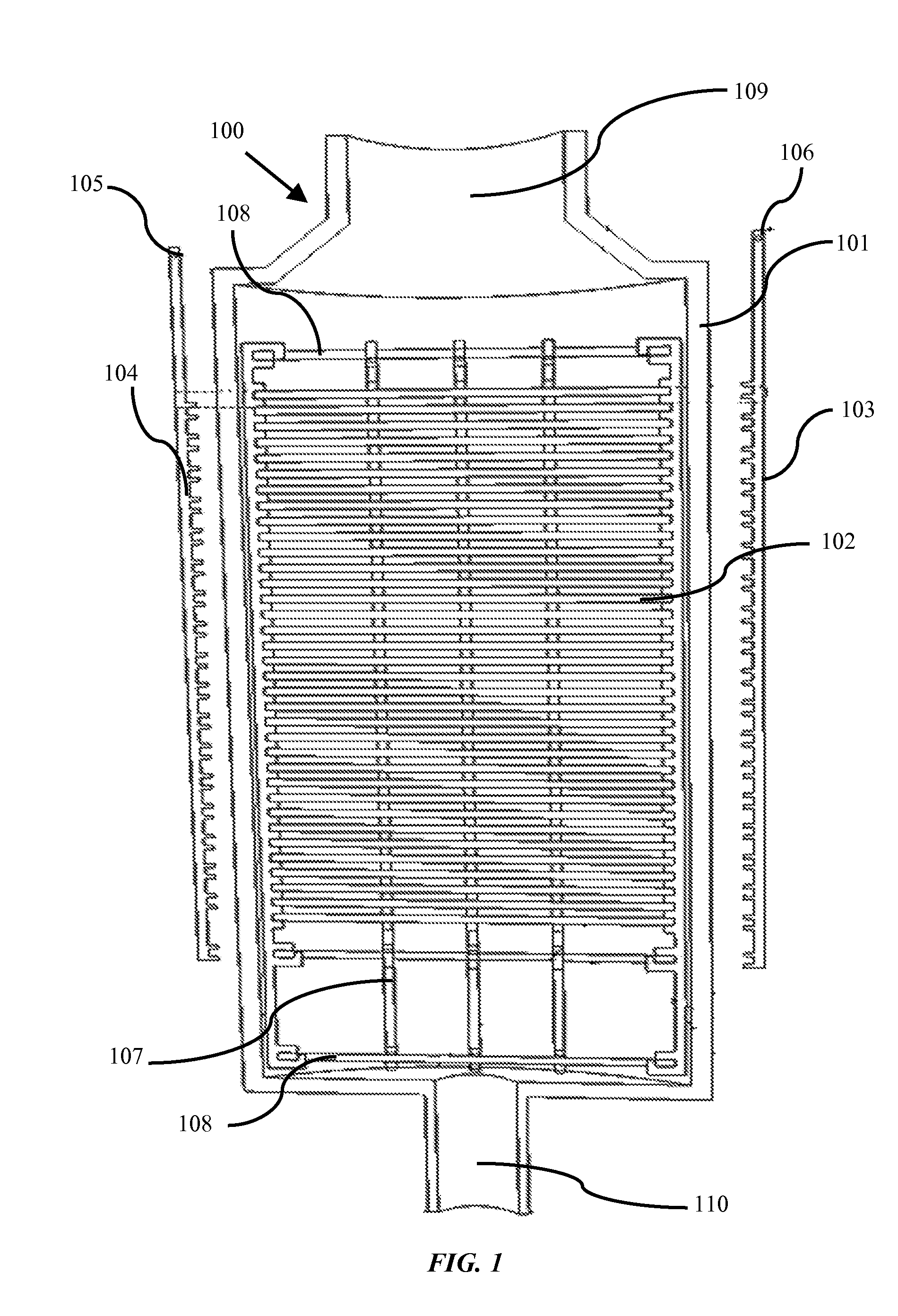

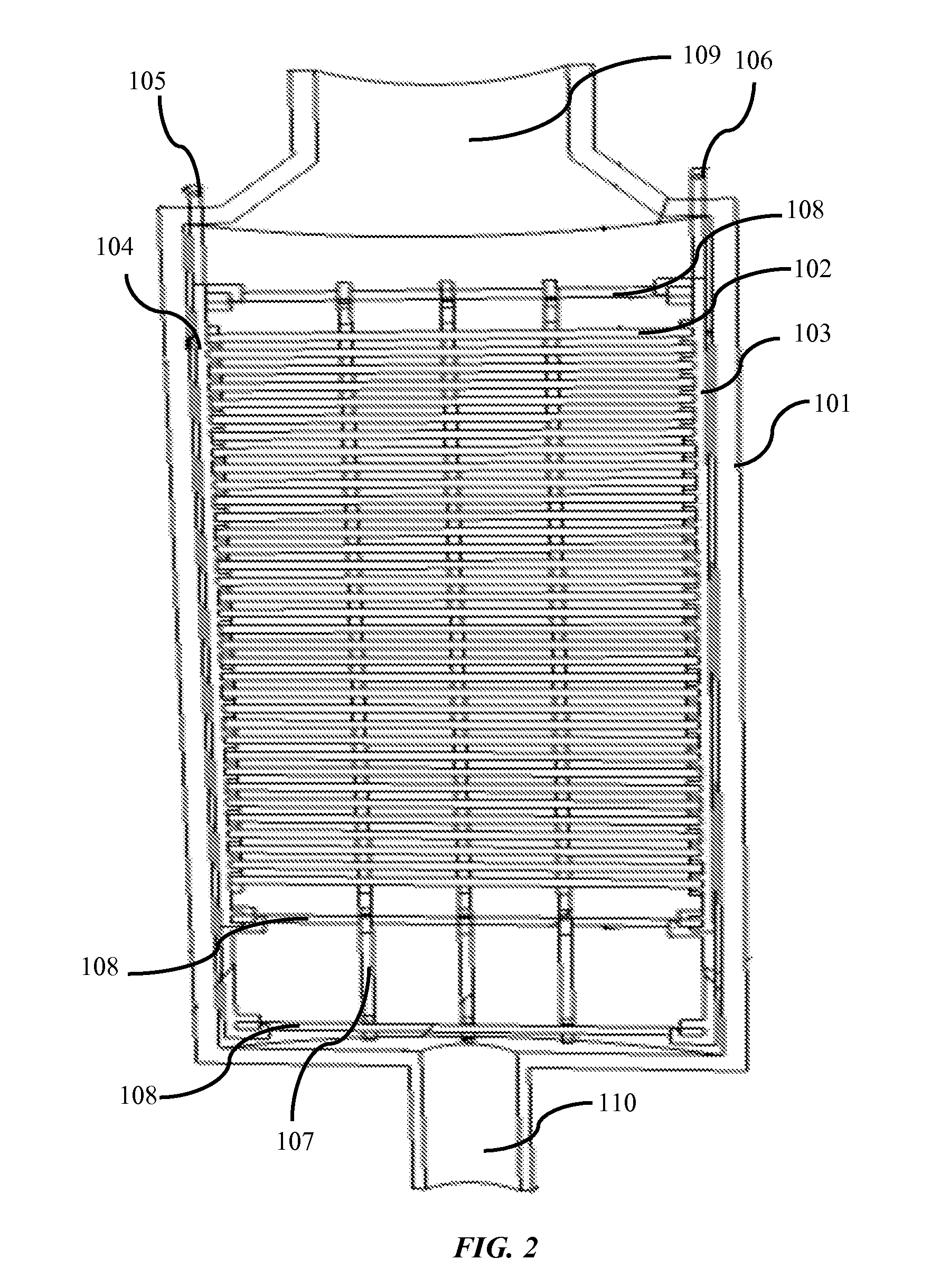

System and method for generating hydrogen and oxygen gases

The embodiments herein provide a HHO generating system and method for generating hydrogen, oxygen and methane. The system adopts electrolysis process to generate a HHO gas from a water-electrolyte solution. The system comprises a reaction tank filled with the water-electrolyte solution, a plurality of disks stacked one above another, a plurality of frames connecting to the disks and an external power supply. The disks comprise a plurality of negatively charged cathode disks and a plurality of positively charged anode disks. The plurality of frames comprises a plurality of conductive frames and a plurality of support frames configured to hold the disks. An electric current is supplied to the conducting frames so as to electrically charge the disks that react with the water-electrolyte solution to produce the HHO gas. The disks are copper-nickel alloy disks in a ratio of 70:30.

Owner:HANSEN DON LEE

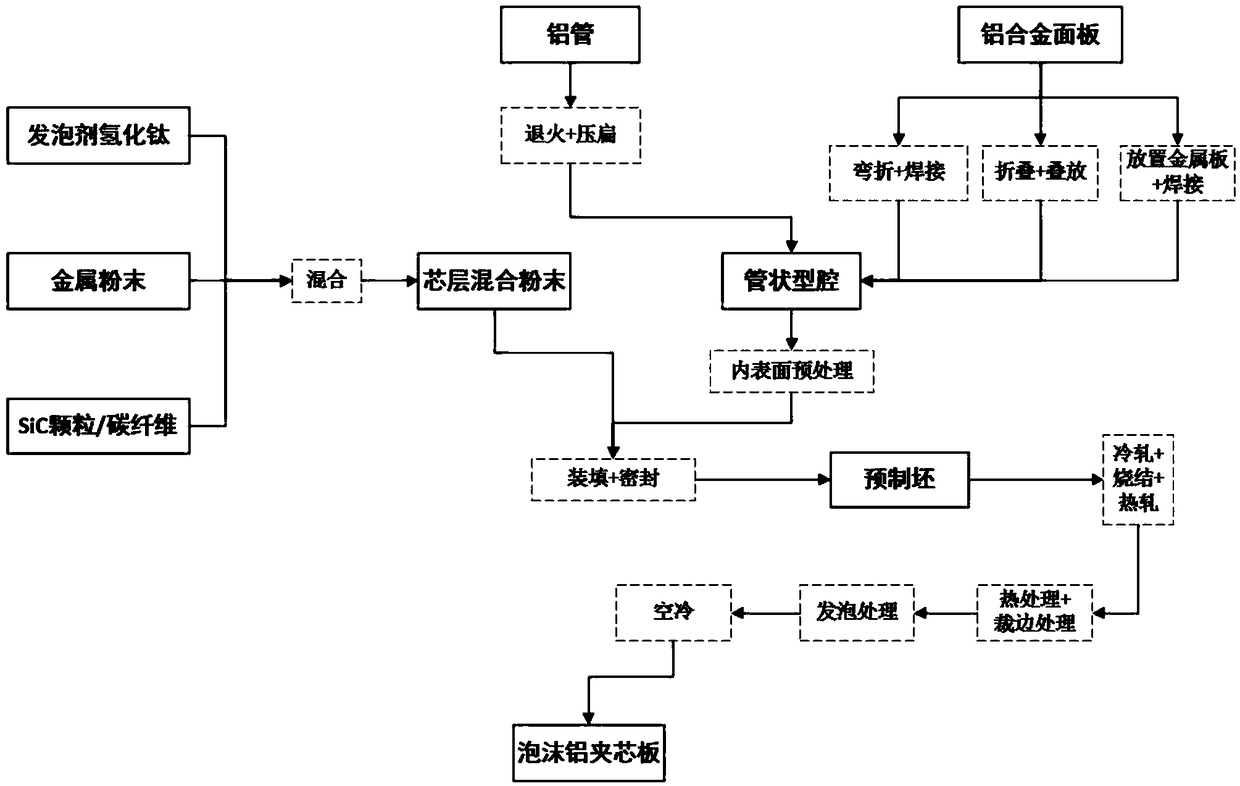

Preparation method for industrial large-size foamed aluminum sandwich panel

ActiveCN108705084ALower the foaming temperatureReduced heating rate requirementsPhysical propertyHeat treating

The invention discloses a preparation method for an industrial large-size foamed aluminum sandwich panel. The preparation method comprises the following steps that (1), aluminum powder / aluminum alloypowder, silicon powder, copper powder, magnesium powder, zinc-copper-nickel alloy powder and a foaming agent are mixed to obtain core mixed powder; (2), aluminum alloy pipes or plates are adopted, andthe pipes are flattened after being annealed and then rolled into a pipe-shaped cavity, or the sides of the two plates are sealed to form a pipe-shaped cavity; (3), the inner surface is pretreated; (4), the front end is sealed and then filled with the core mixed powder, and the tail end is sealed; (5), cold rolling is conducted; (6), sintering is conducted; (7), hot rolling is conducted; (8), edge cutting is conducted after heat treatment; and (9), air cooling is conducted after foaming treatment. According to the preparation method, low-temperature foaming is achieved, oversintering is avoided, and the physical properties of the panel are well kept.

Owner:NORTHEASTERN UNIV

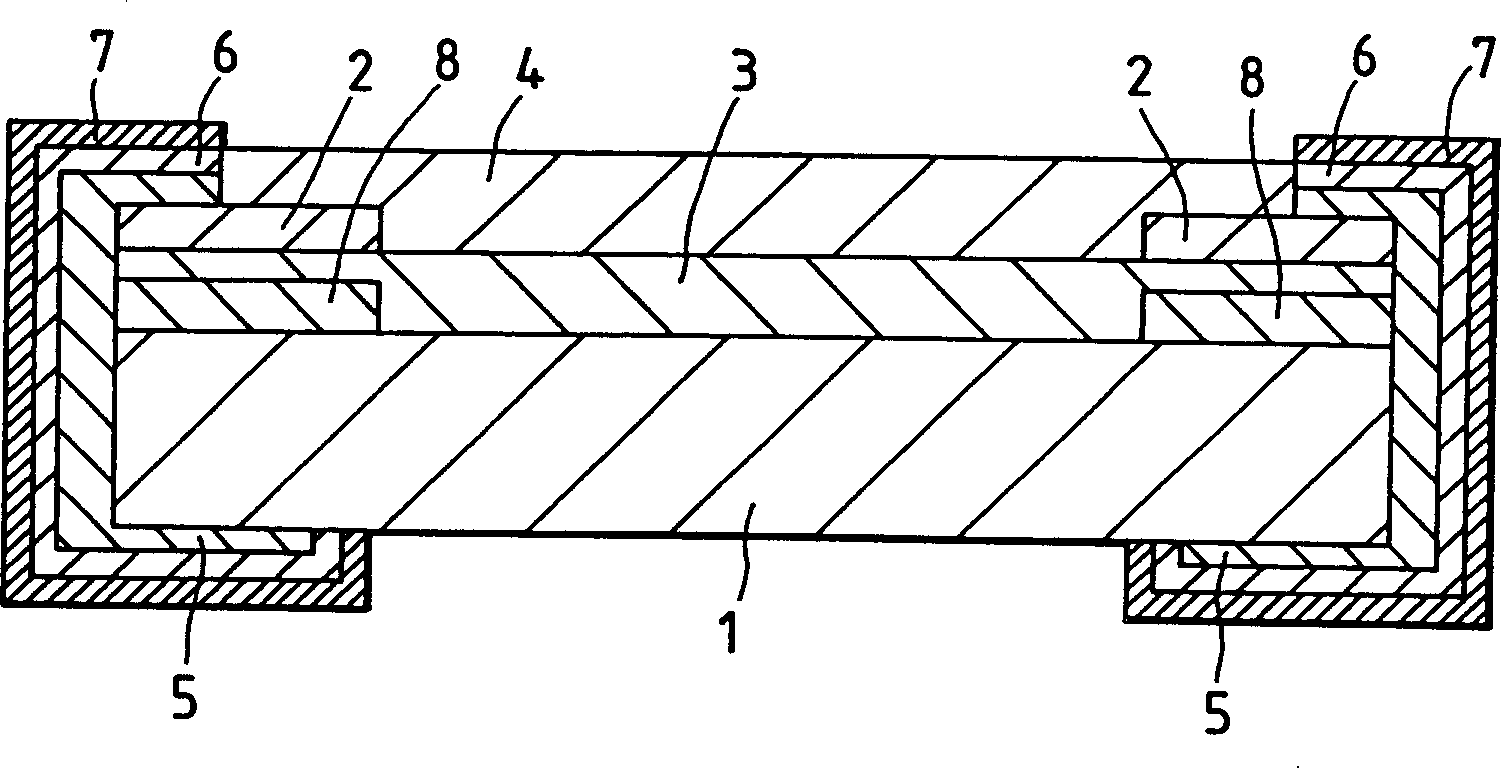

Pellet electrical resistor and producing method thereof

InactiveCN1437201ALower resistanceLow TCRResistor chip manufactureResistors adapted for applying terminalsElectrical resistance and conductanceEngineering

The invention relates to a chip resistor. The object of the invention is to realize a low resistance and a low TCR, and also high accuracy and high reliability. The chip resistor is configured so as to have: a substrate; a resistance layer which is formed on at least one face of the substrate and which is made of a copper nickel alloy; upper-face electrode layers which make surface contact with the upper faces of both the end portions of the resistance layer; and end-face electrodes which are formed so as to cover the upper-face electrode layers. Since the bonding between the resistance layer and the upper-face electrode layers is conducted by metal-to-metal bonding, particularly, impurities which may affect the properties do not exist in the interface.

Owner:PANASONIC CORP

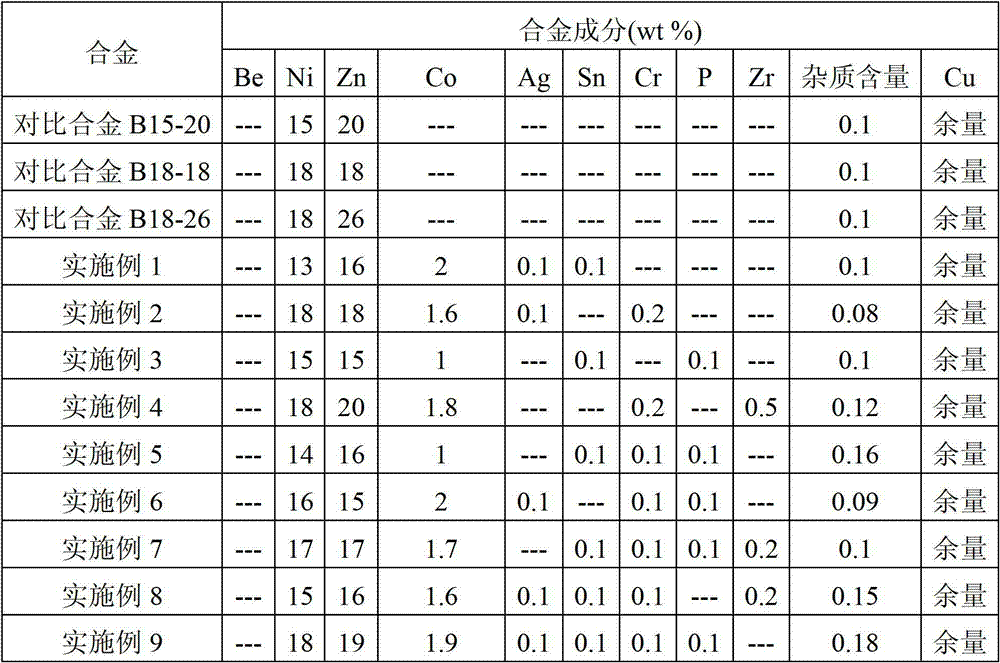

High-strength high-elasticity zinc-copper-nickel alloy and processing method thereof

The invention relates to a high-strength high-elasticity zinc-copper-nickel alloy and a processing method thereof, belonging to the field of nonferrous metal processing. The high-strength high-elasticity zinc-copper-nickel alloy comprises the following components in percentage by weight: 13-18% of Ni, 15-20% of Zn, 1-2% of Co, 0.01-1% of at least one of Ag, Sn, Cr, P and Zr, and the balance of Cu, wherein (a) 15%<=Ni+Co<=20%, and (b) 6.5<=Ni / Co<=15. The high-strength high-elasticity zinc-copper-nickel alloy is subjected to draw casting by a horizontal continuous casting technique. The tensile strength sigma b of the copper alloy is 790-850 MPa, the plastic elongation percentage delta is 4-15%, the electric conductivity is 12-25% IACS, the corrosion resistance is good, and thus, the copper alloy can be widely used for manufacturing precision components and the like in the fields of instruments, meters, medical appliances, daily necessities, communications and the like.

Owner:NINGBO XINGYE SHENGTAI GROUP

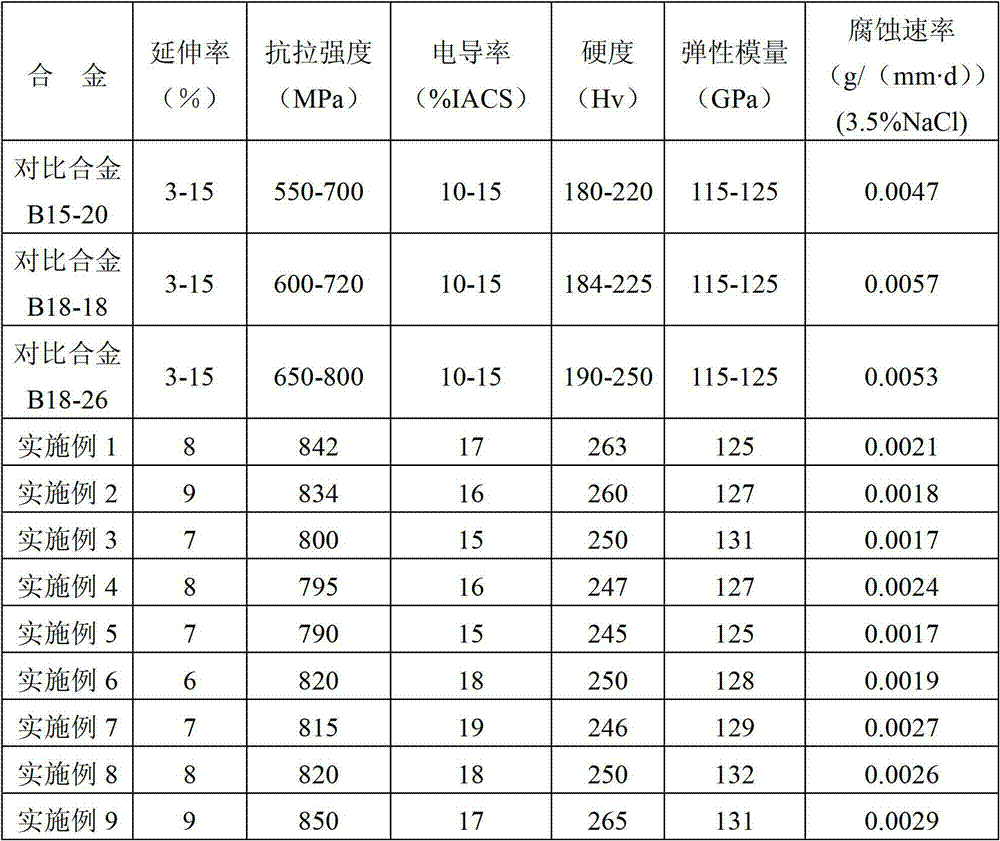

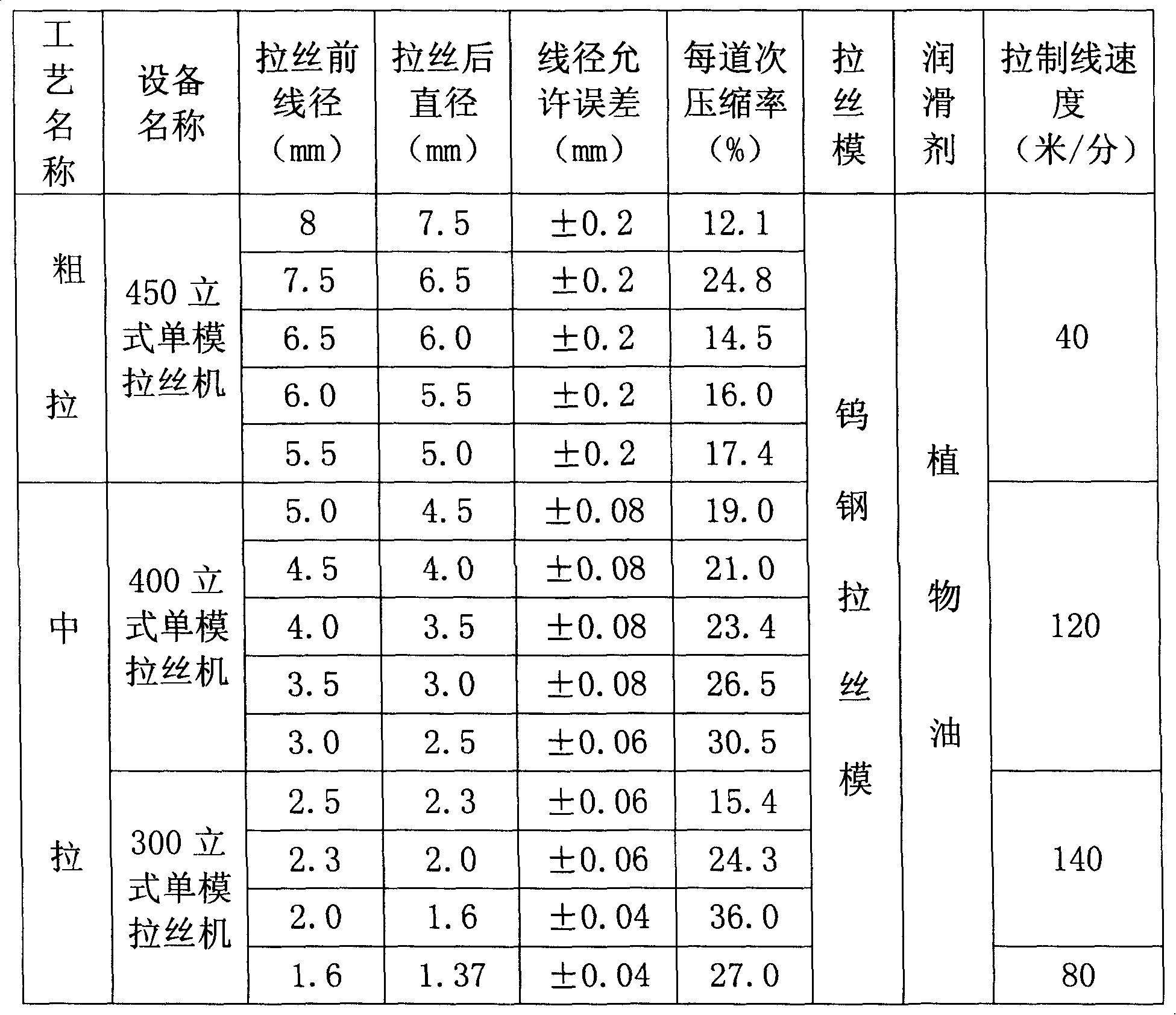

Preparation technique for cuprum peptide-cuprum nickel compensating conductor and alloy wire thereof

ActiveCN101231197AAmbient temperature is high and wideHigh compensation accuracyThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorVacuum fusion

The invention relates to the technical field of temperature-measuring element, in particular to a compensation lead of copper titanic to copper nickel and a preparation process of alloy wires of the compensation lead, wherein, a positive pole conductor of the compensation lead is copper titanic alloy wires, and a weight percentage of the chemical composition is 0.3-1.5 percent of titanic, 0.04-0.06 percent of rare earth, impurities with a percentage no larger than 0.087 percent and excess copper; a negative pole conductor of the compensation lead is copper nickel alloy wires, and a weight percentage of the chemical composition of which is 16-18.5 percent of, 0.3-1.2 percent of manganese, 0.08-0.21 percent of silicon, 0.005-0.015 percent of carbon, 0.04-0.06 percent of rare earth, impurities with a percentage no larger than 0.107 percent and excess nickel. The copper titanic alloy wires and the copper nickel alloy wires have the technical process of raw material preparation, vacuum fusion, hot forging, hot rolling, annealing of hot rolling flan, a process from drawing to annealing with a repetition of three times, and finished product detection and package for leaving factories. The ambient temperature used by the invention is high and wide with a range from -55 DEG C to 300 DEG C, and the invention has the advantages of high precision compensation with a precision level, reduction of raw material cost of 60 percent.

Owner:袁勤华

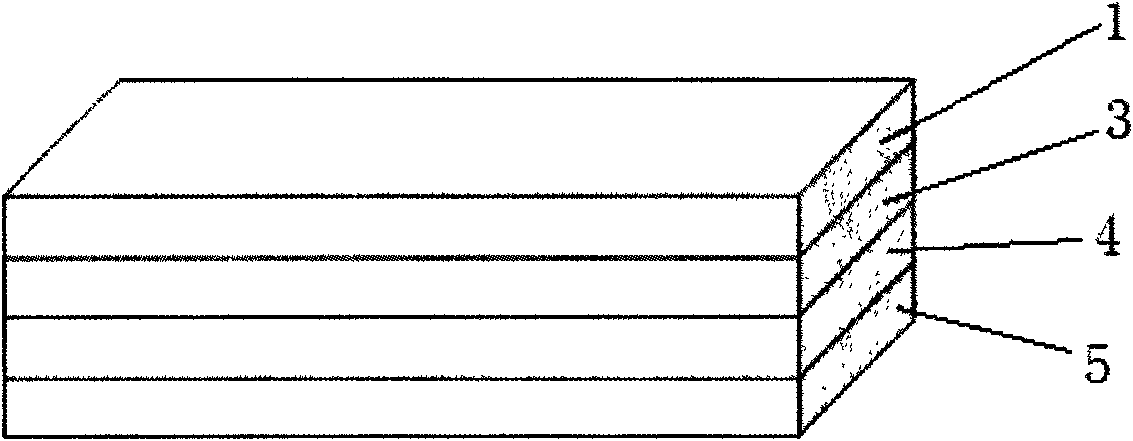

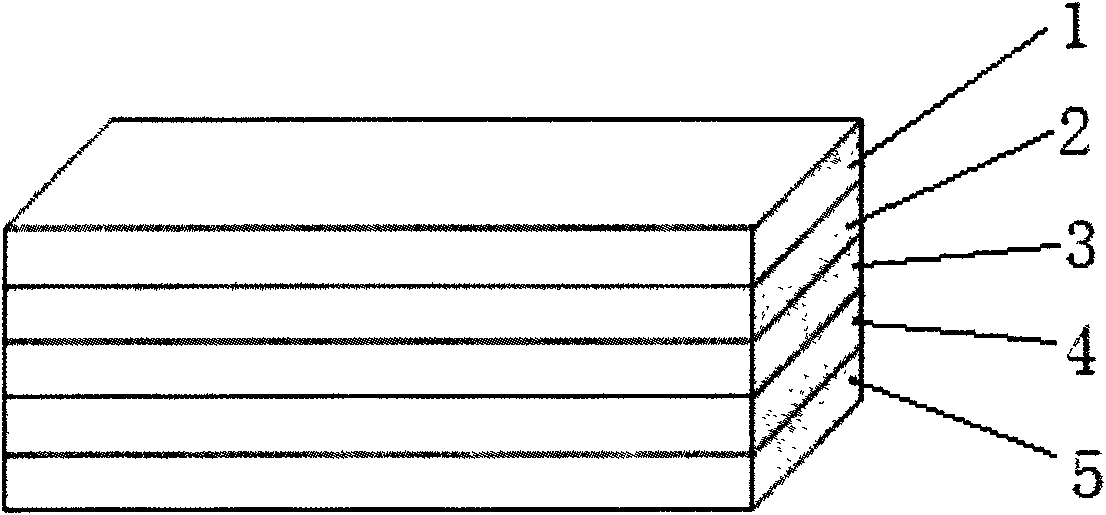

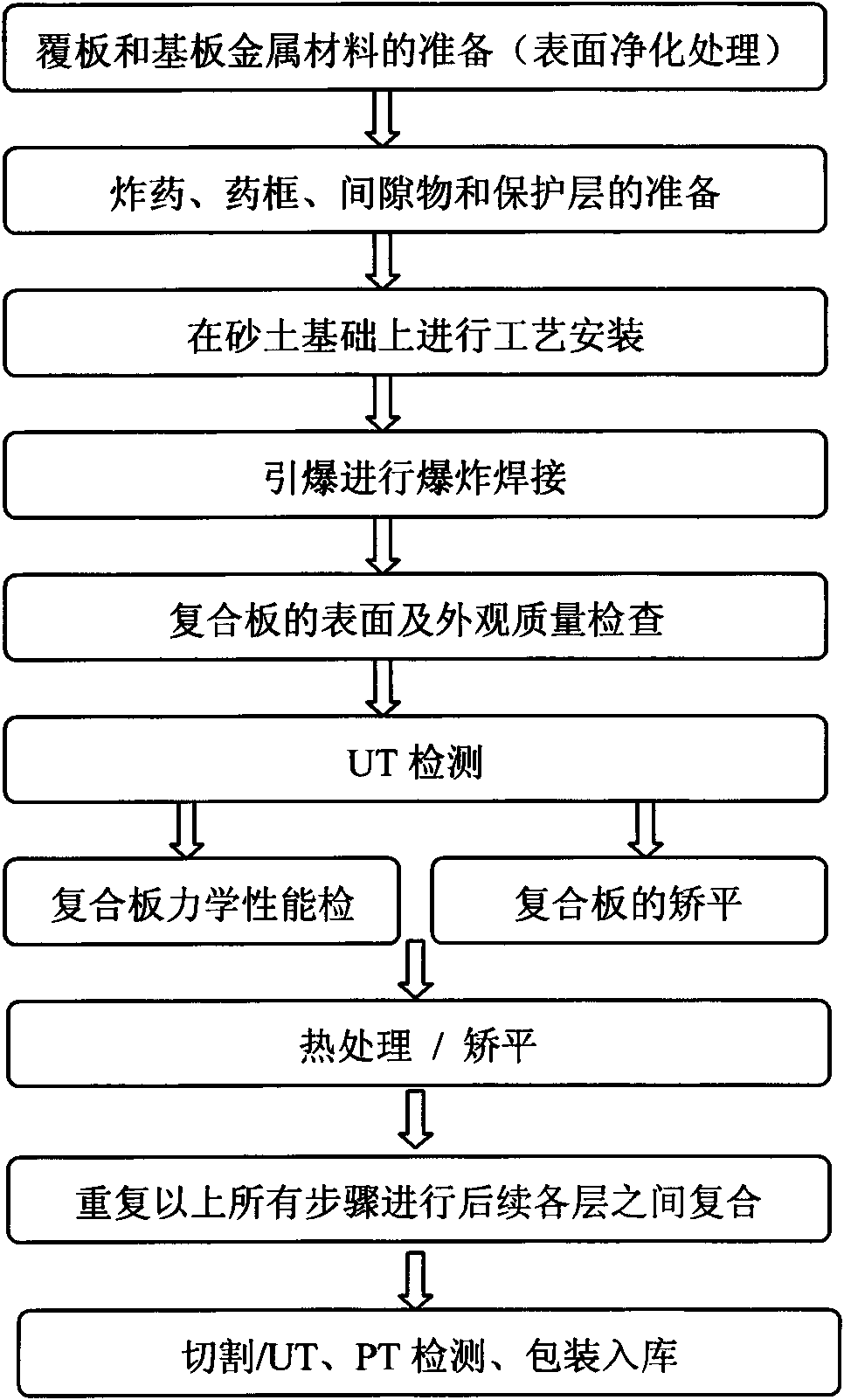

Method for manufacturing multilayer composite aluminum/steel transition joint

InactiveCN101987394AImproved and improved overall performanceImprove toughnessExplosivesNon-electric welding apparatusTitaniumTotal thickness

The invention discloses a method for manufacturing a multilayer composite aluminum / steel transition joint. The transition joint comprises a multilayer composite metal layer, wherein the multilayer composite metal layer sequentially comprises an alloy aluminum layer, a titanium layer, a copper-nickel alloy layer and a steel layer, or an aluminum layer is added between the alloy aluminum layer and the titanium layer, wherein the layers are connected in an explosive welding mode; the thicknesses of the layers are different and range from 0.5 to 20mm and the total thickness of the layers is 10 to 60mm; and the layers are strip, blocky, platy, annular, round or rectangular. Multilayer composite metal is taken as an aluminum / steel transition structural material, and the layers are connected in the explosive welding mode, so that the comprehensive performance of the aluminum / steel transition material is effectively improved.

Owner:安徽钛钴新金属有限公司

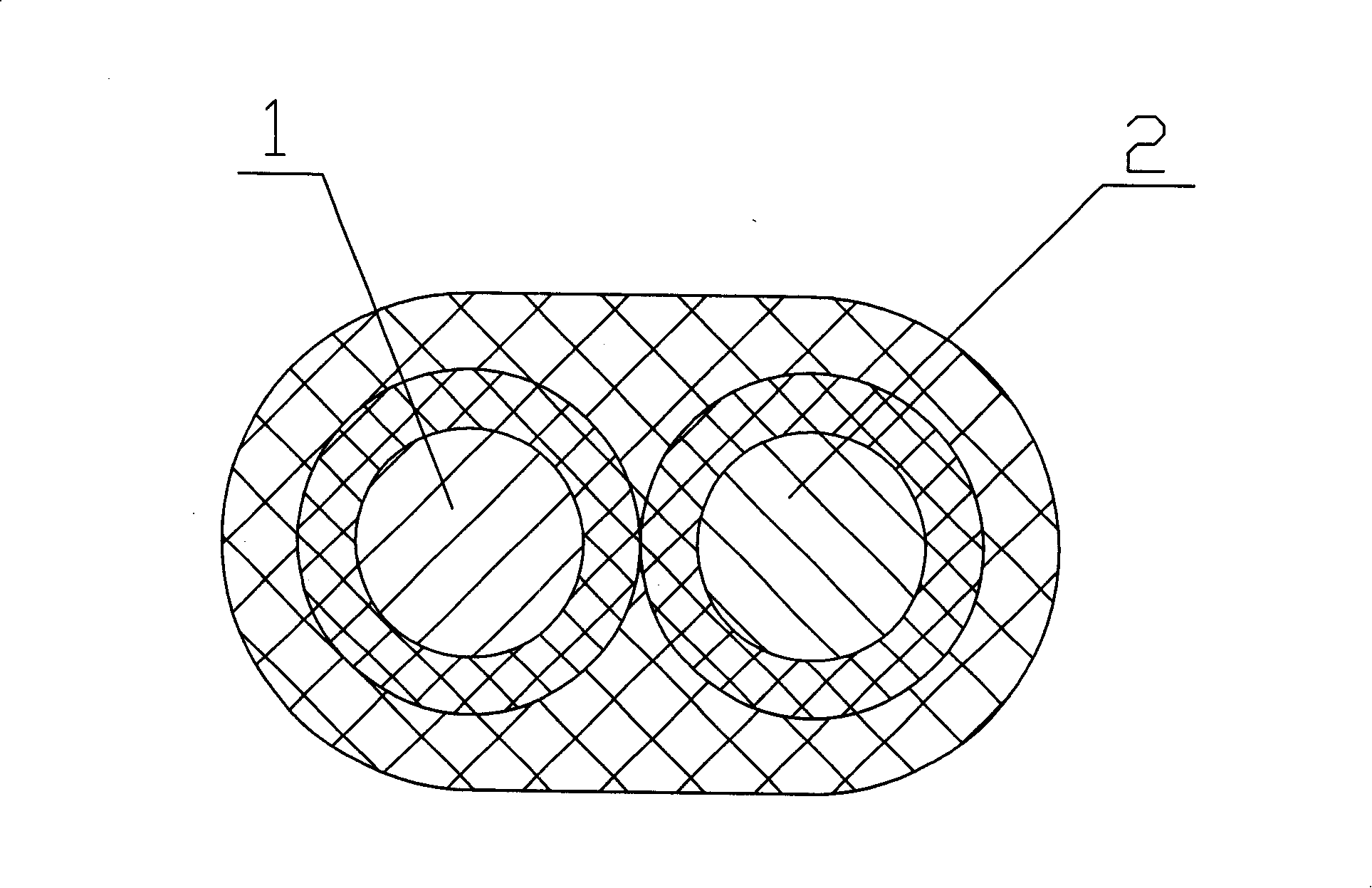

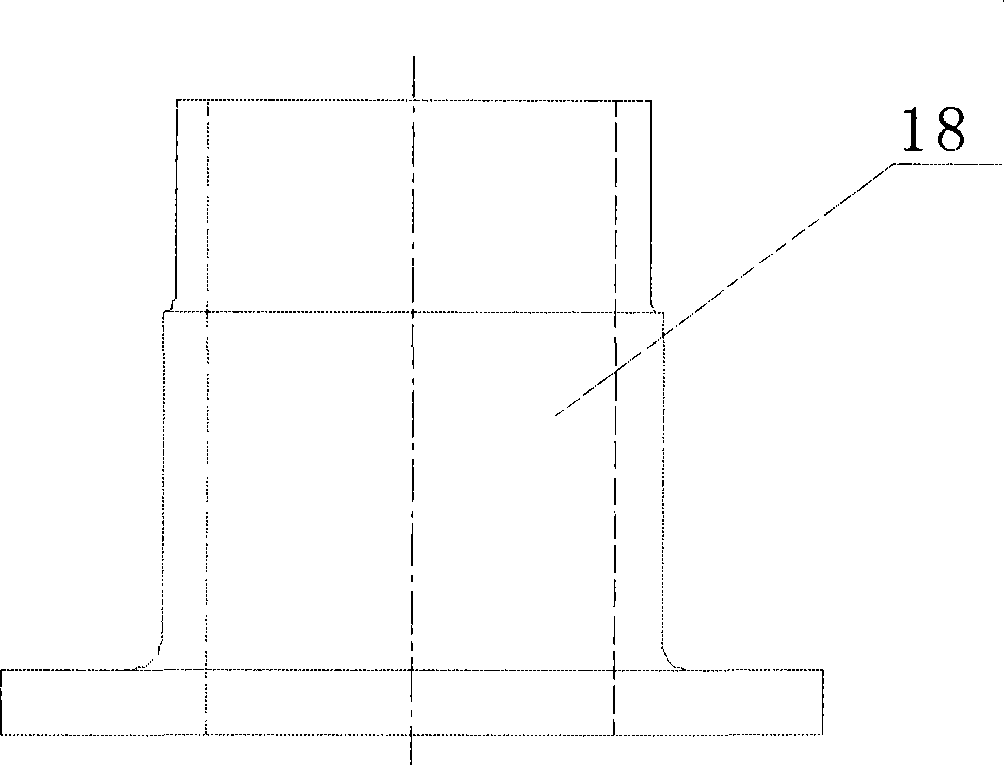

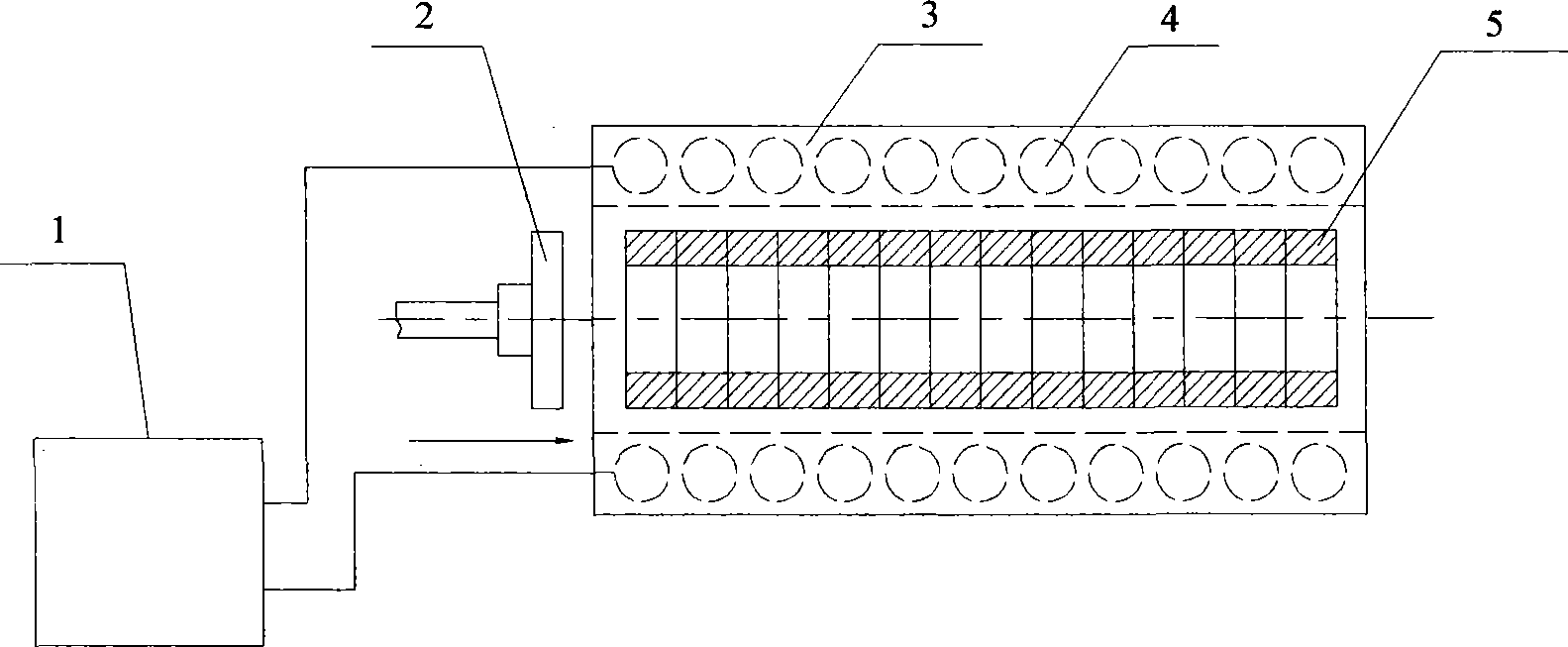

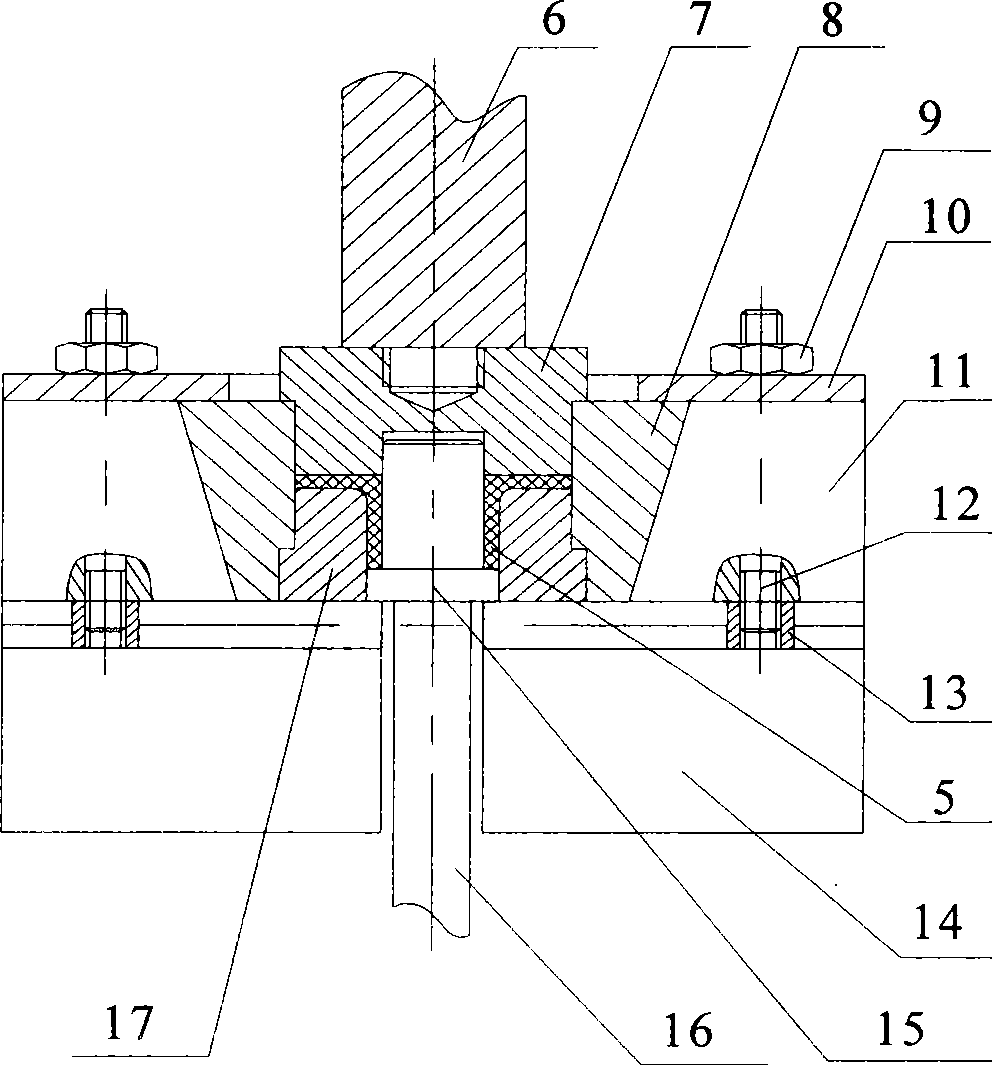

Method for precisely forming copper-nickel alloy flange pipes

ActiveCN101518792AIncrease profitReduce consumptionExtrusion diesExtrusion control devicesSurface roughnessNickel alloy

The invention provides a method for precisely forming copper-nickel alloy flange pipes, comprising the following steps of blanking, heating, forming and machining. Firstly, a tube blank 5 is cut on a sawing machine and then arranged in a heater 3; the power of an induction coil 4 is adjusted between 20KW to 100KW by a power supply 1; and the tube blank 5 is pushed into a sensor with the frequency of 1-2 blanks per minute and heated to the temperature of 900-980 DEG C for 0.5-1 minute. An upper die 7 is fixedly arranged at the lower end of a presser bar 6 of a special oil hydraulic press; a locating ring 11 is arranged on a base 14; a lower die 17 and a core bar 15 are loaded firstly; an external die 8 is positioned; a pressing ring 10 and a nut 9 are fixed; the bottom surfaces of the lower die, the external die and the core bar are closely leaned against the upper end of the base and are connected with the locating ring by a T-shaped block 13 and a bolt 12; the tube blank is sleeved on the lower die; the upper die moves downwards and extrudes the tube blank directly so as to be formed; subsequently, the upper die moves upwards and is disconnected with the tube blank; and the formed tube blank is processed as a qualified copper-nickel alloy flange pipe 18 according to technical requirements and surface roughness. The utilization ratio of the tube blank is improved by 10% and the energy consumption is reduced.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

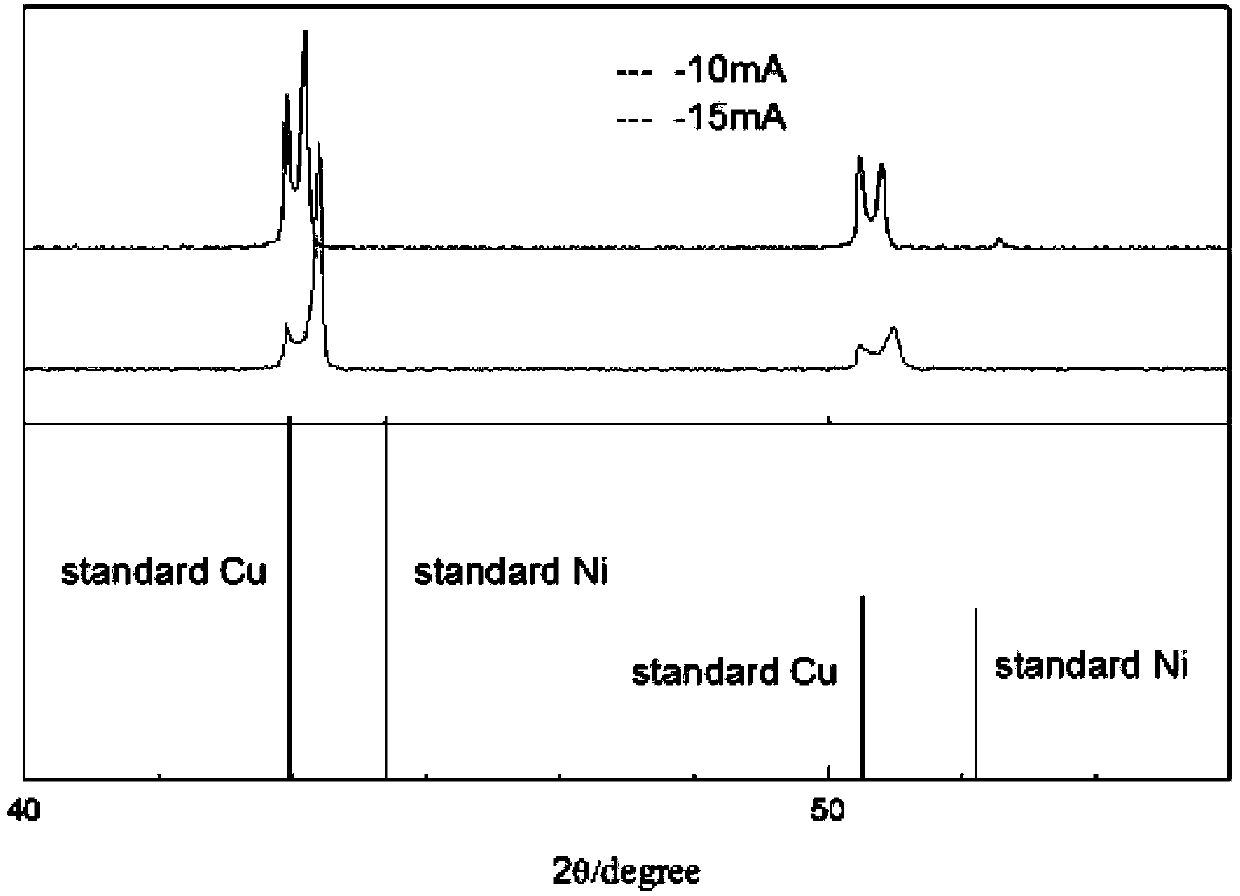

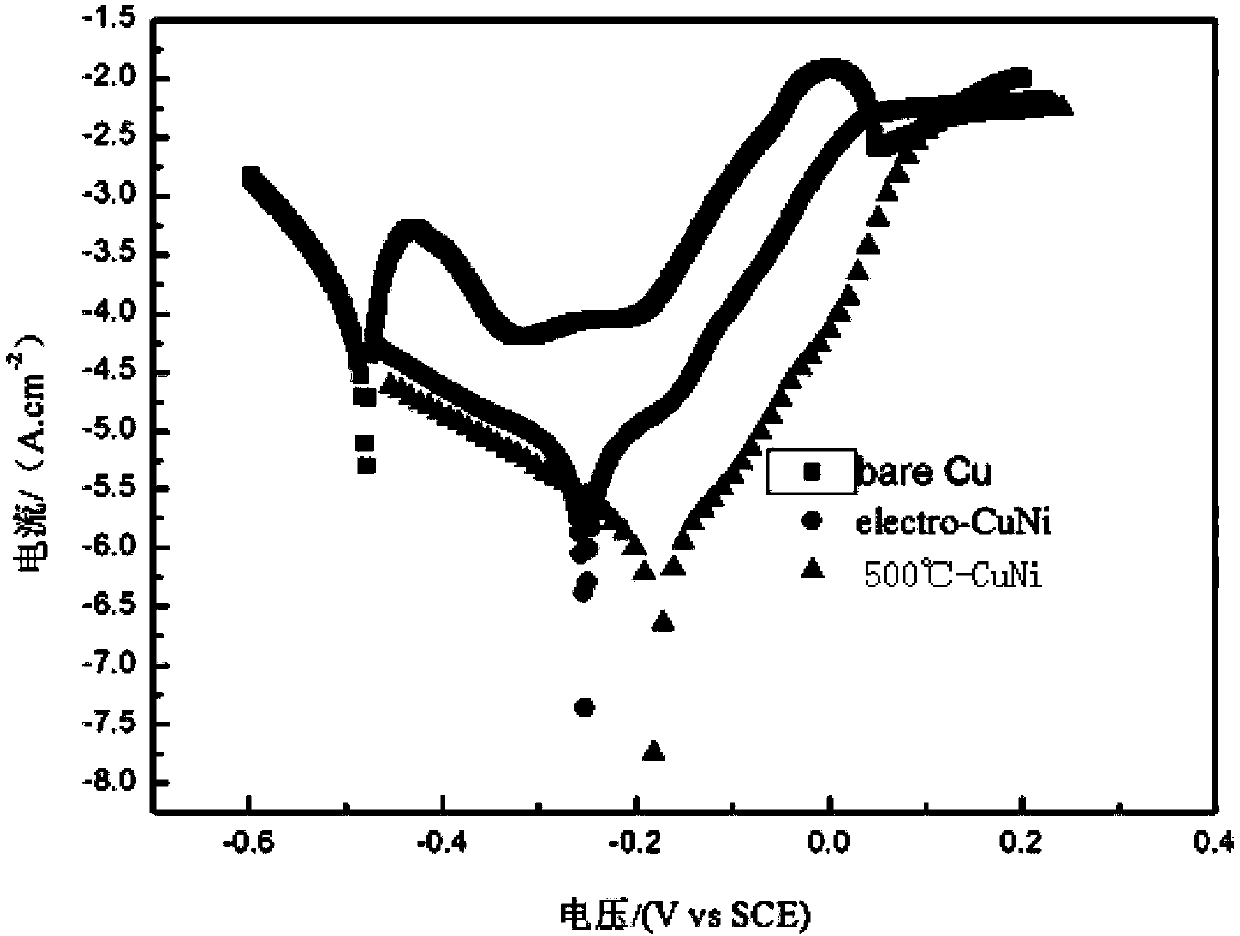

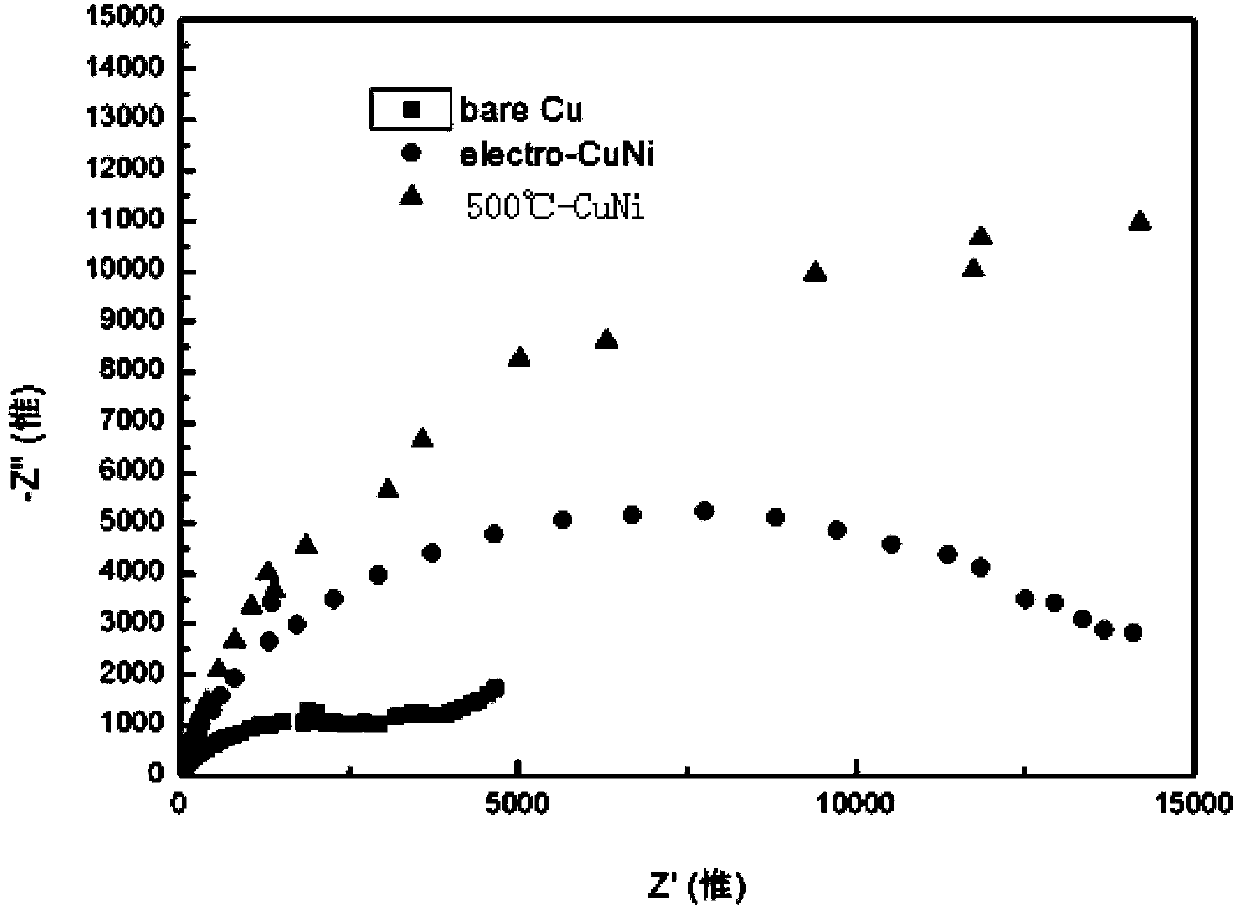

Preparation method of metal surface copper-nickel alloy

The invention discloses a preparation method of a metal surface copper-nickel alloy, which comprises the following steps: (1) metal surface pretreatment; (2) solution preparation; (3) constant-current deposition of copper-nickel alloy; and (4) surface heat treatment. The preparation method has the advantages of simple process, controllable temperature and components, low cost, high efficiency, no pollution and no risk. The electrochemical testing proves that the copper-nickel alloy film has better corrosion resistance than the metal bare sample. The copper-nickel alloy has the advantages of low heat treatment temperature, short holding time and more compact and uniform film; and the electrochemical testing proves that the corrosion resistance is further enhanced.

Owner:OCEAN UNIV OF CHINA

Copper nickel alloy large-size thick-wall seamless pipe manufacturing process

InactiveCN102773303AMeet the design requirementsIncrease the lengthMetal rolling arrangementsThick wallHigh pressure

The invention discloses a copper nickel alloy large-size thick-wall seamless pipe manufacturing process which comprises steps as follows: a B10 alloy cast ingot used as a raw material is subjected to forging or rotary piercing, and then machined to prepare the qualified pipe blank; and the pipe blank is subjected to spin forming to prepare the qualified pipe. The length of the fai270 pipe is more than 3.5m, and the length of the fai340 pipe is more than 1.5m. The prepared pipe has the same mechanical properties and technical properties as the thin-wall pipe, has the average grain diameter of 0.01-0.05mm, has favorable cold / hot working and welding properties, and can be made into elbows, T-joints, reducer pipes and other pipes at low cost. The invention is applicable to the ship sea water pipe system,, fills up the blank in China, and has broad market prospects in the aspects of novel ship sea water pipeline and other high-pressure pipeline materials in future.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for preparing cathode material of tin - copper - nickel alloy in use for batteries

InactiveCN101093884ALow costWide variety of sourcesAlkaline accumulator electrodesLithium electrodeCalcium edetate

The technical scheme includes electroplating and vacuuming steps. Constituents of bath are: disodium calcium edetate, potassium sodium tartrate, potassium pyroborate, nickel sulphate, sodium stannate, and distilled water. Under condition of current density 0.2-1.0A / dm2, copper film electrode covered by tin nickel alloy is prepared after 0.2 -60min electroplating procedures. Vacuuming step includes procedures: placing copper film electrode covered by tin nickel alloy to vacuum drying oven; in vacuum degree 760-380mm mercury column, at 100-180 deg.C, processing 1 - 5h, and preserving heat for 24h. After cooling, cathode material of tin - copper - nickel alloy is prepared. The material possesses excellent discharge performance, and charging and discharging cyclical stability, and high first discharge capacity reached to 600mAh / g active matter. The disclosed cathode material is applicable to lithium ion battery, lithium battery, especially film type battery etc.

Owner:FUJIAN NORMAL UNIV

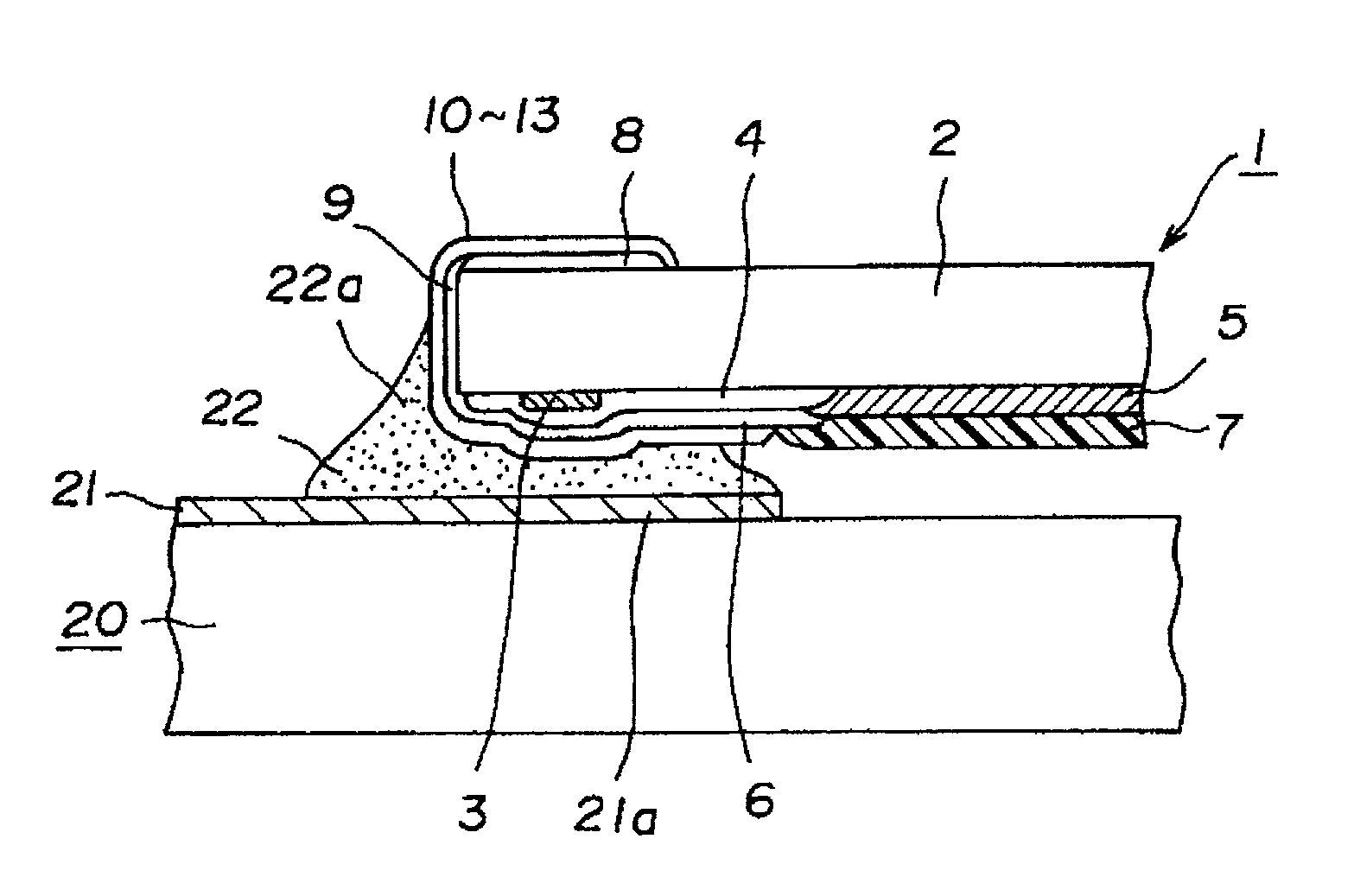

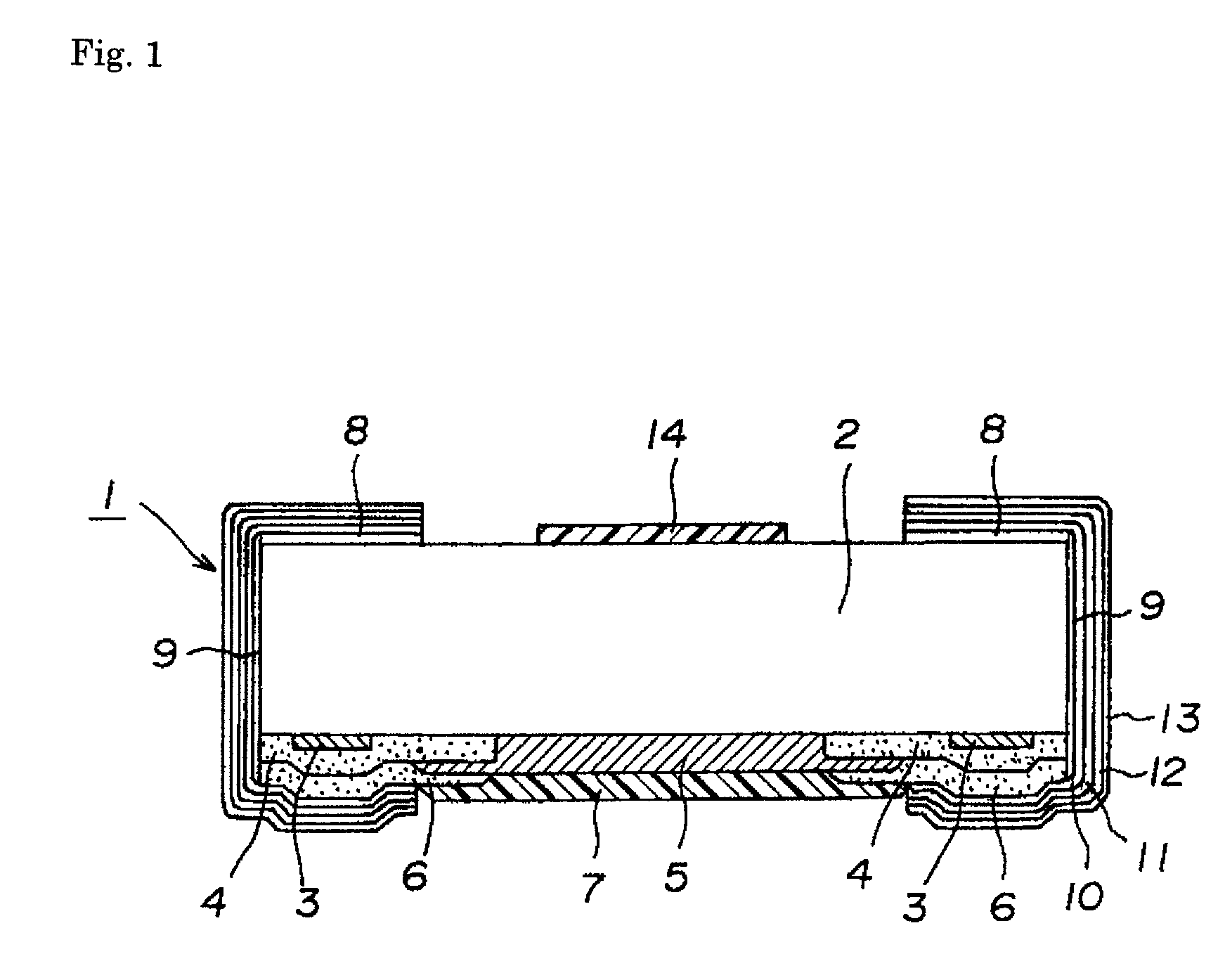

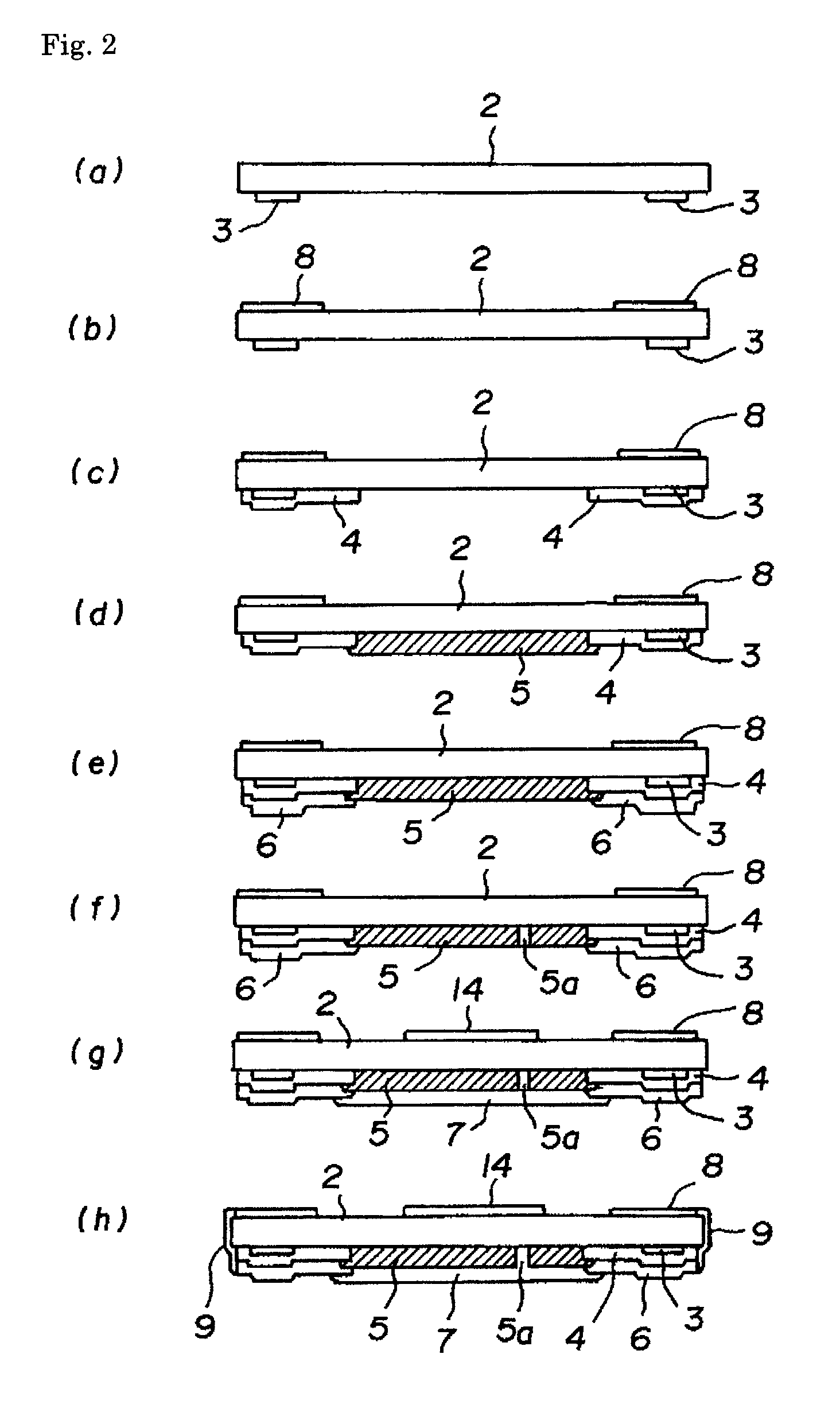

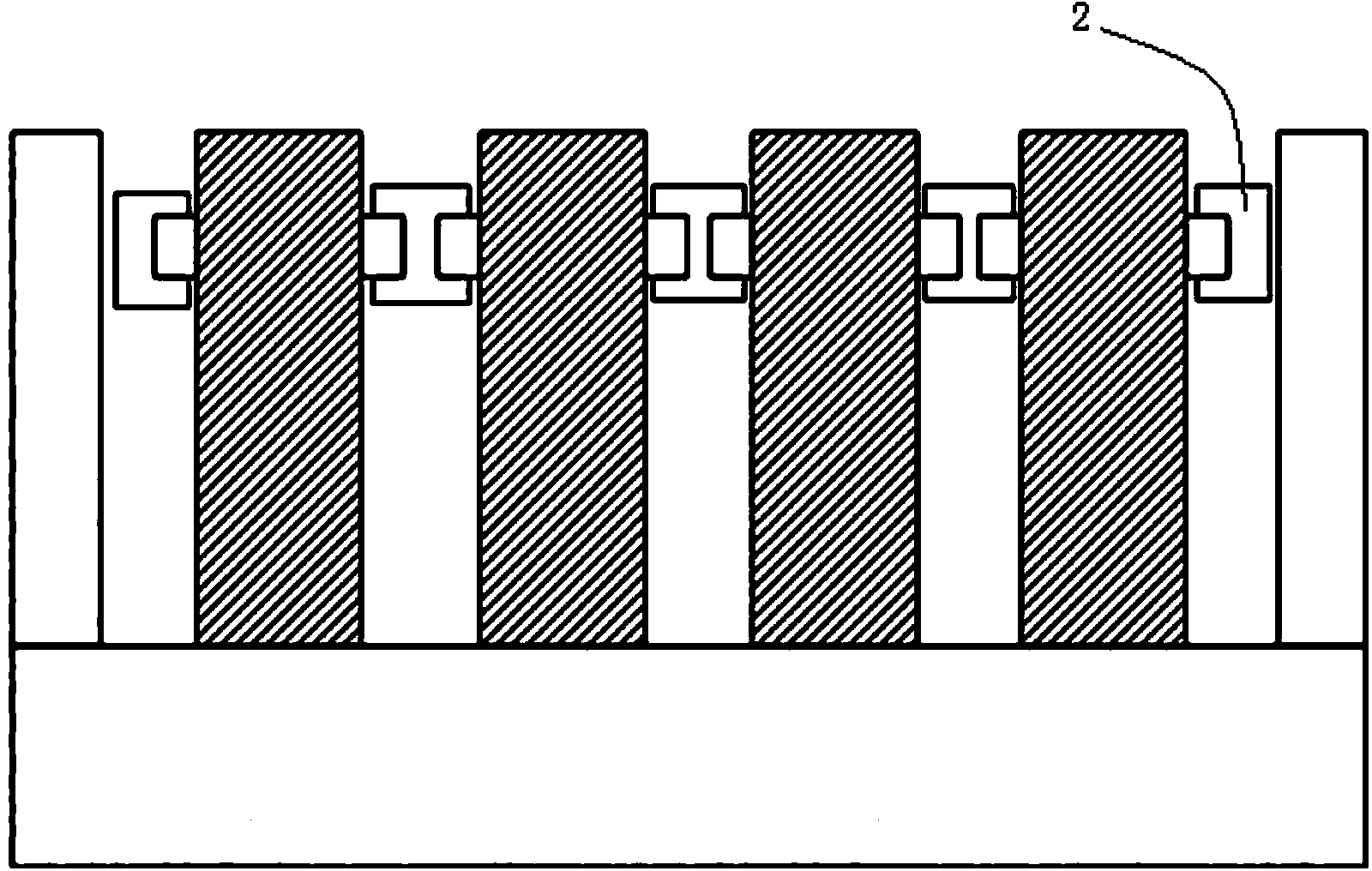

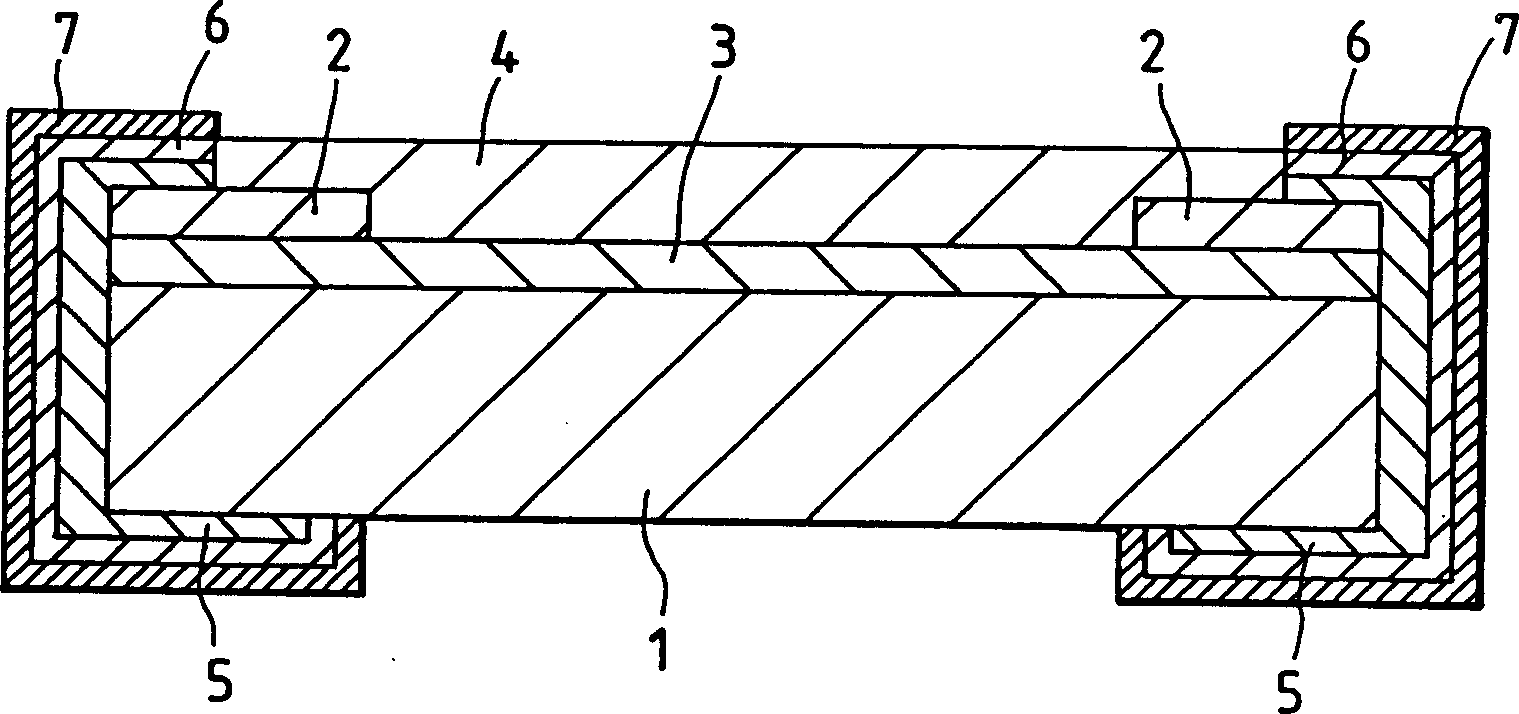

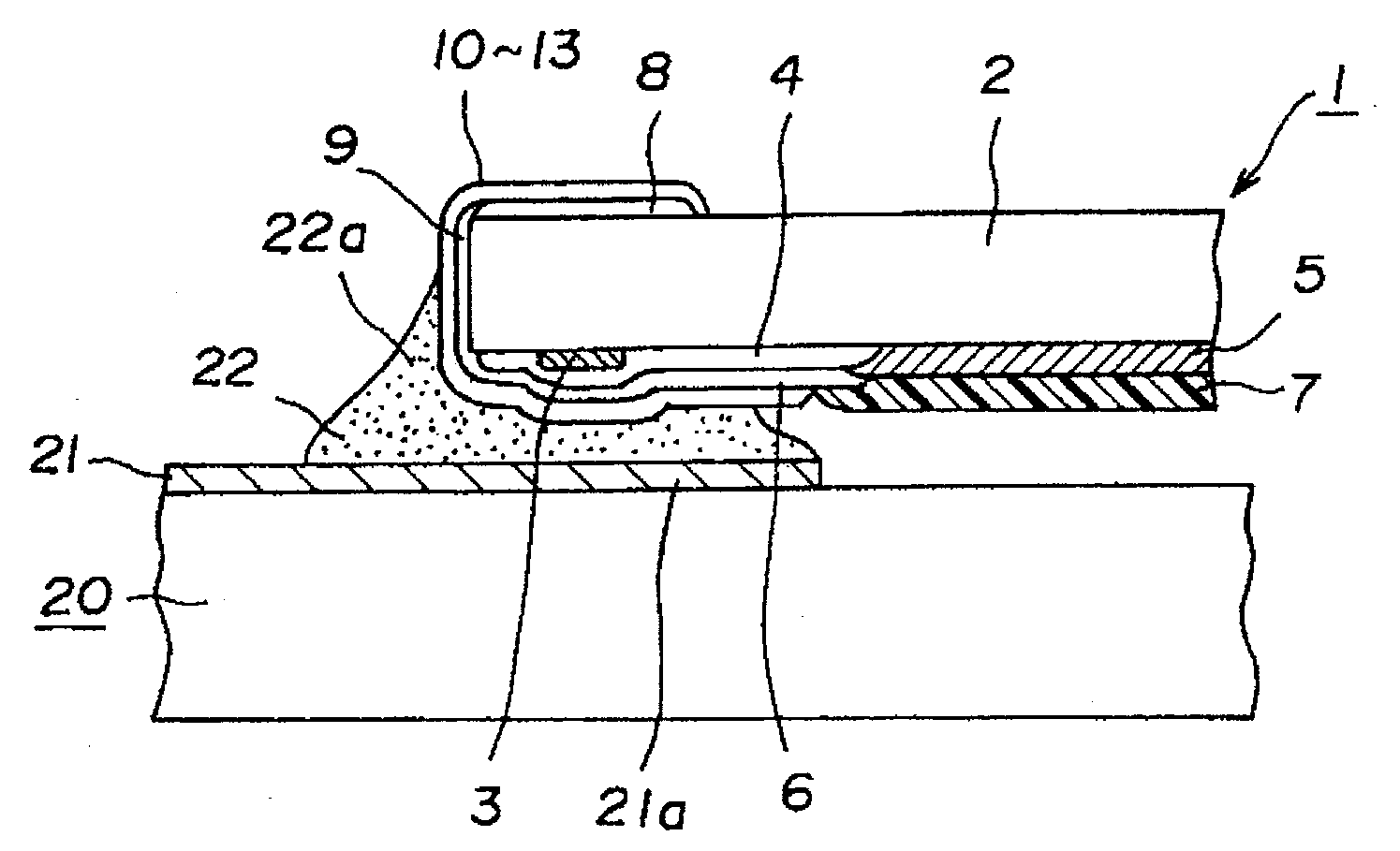

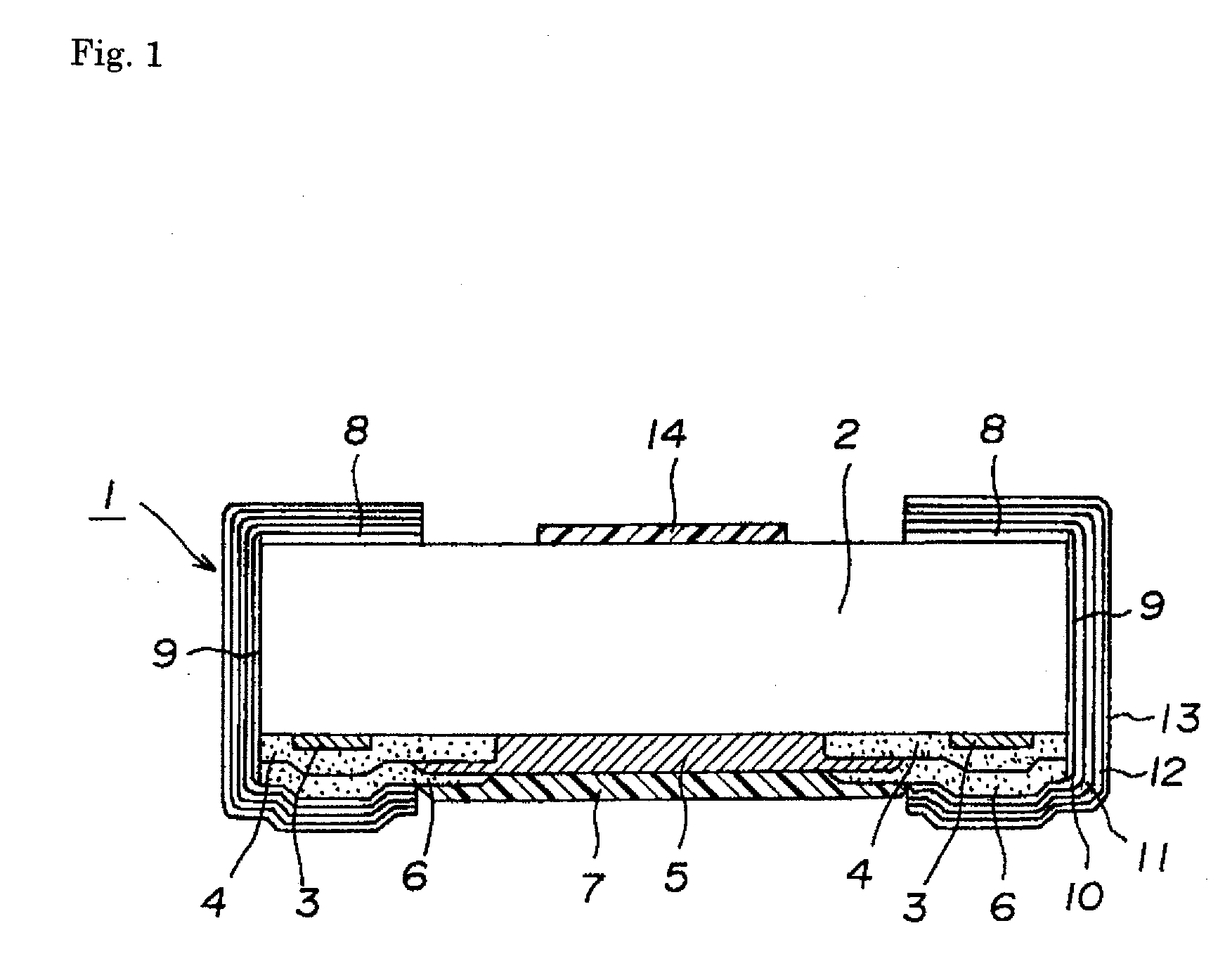

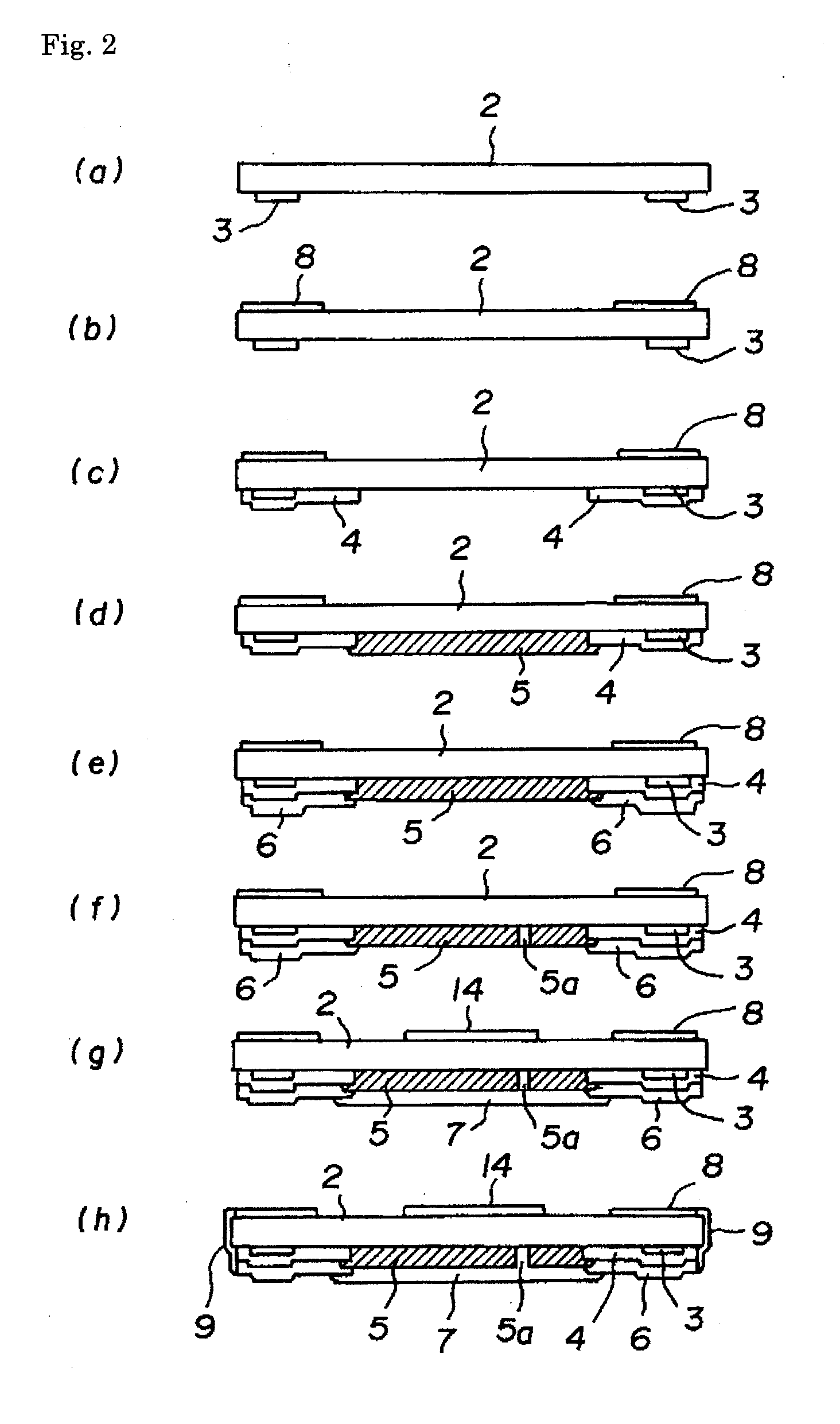

Chip Resistor

InactiveUS20090115569A1Lower resistanceReduce failure rateResistor detailsThick film resistorsCeramic substrateResistive element

[Problem] To provide a chip resistor that is unlikely to suffer from mounting failure and capable of readily lowering its resistance.[Solution] Disclosed is a chip resistor 1 that includes a ceramic substrate 2, a pair of bank-raising foundation sections 3 positioned on both longitudinal ends of the lower surface of the ceramic substrate 2, a pair of first electrode layers 4 that cover at least parts of the bank-raising foundation sections 3 and are positioned at a predetermined distance from each other, a resistive element 5 that is made mainly of a copper-nickel alloy to bridge the first electrode layers 4, a pair of second electrode layers 6 that cover the pair of first electrode layers 4, and an insulating protective layer 7 that covers the resistive element 5. Further, end-face electrodes 9 are positioned on both longitudinal end faces of the ceramic substrate 2. The second electrode layers 6 and end-face electrodes 9 are covered with plating layers 10-13. This chip resistor 1 is to be face-down mounted with the first and second electrodes 4, 6 positioned on a wiring pattern 21 of a circuit board 20.

Owner:KOA CORP

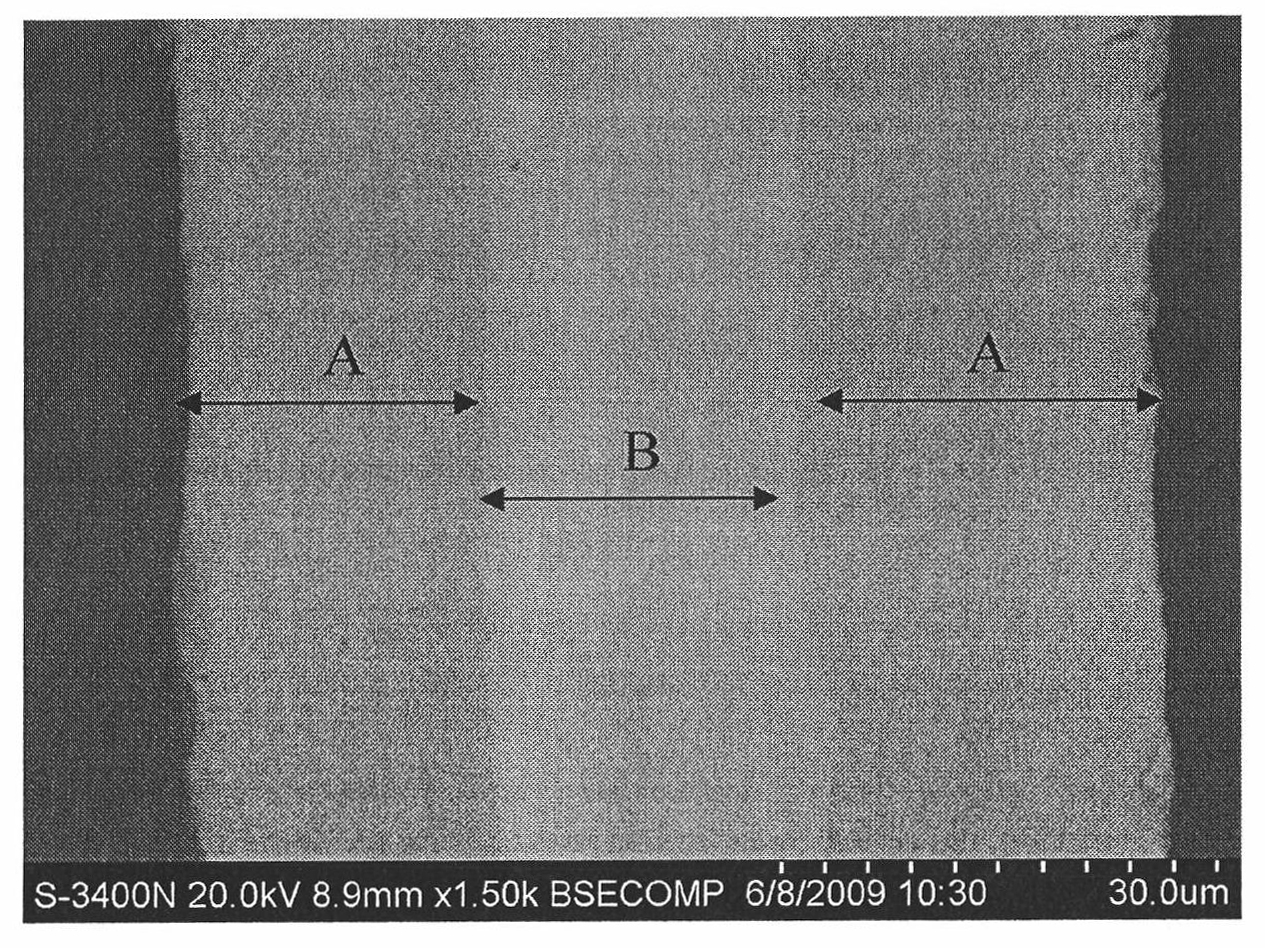

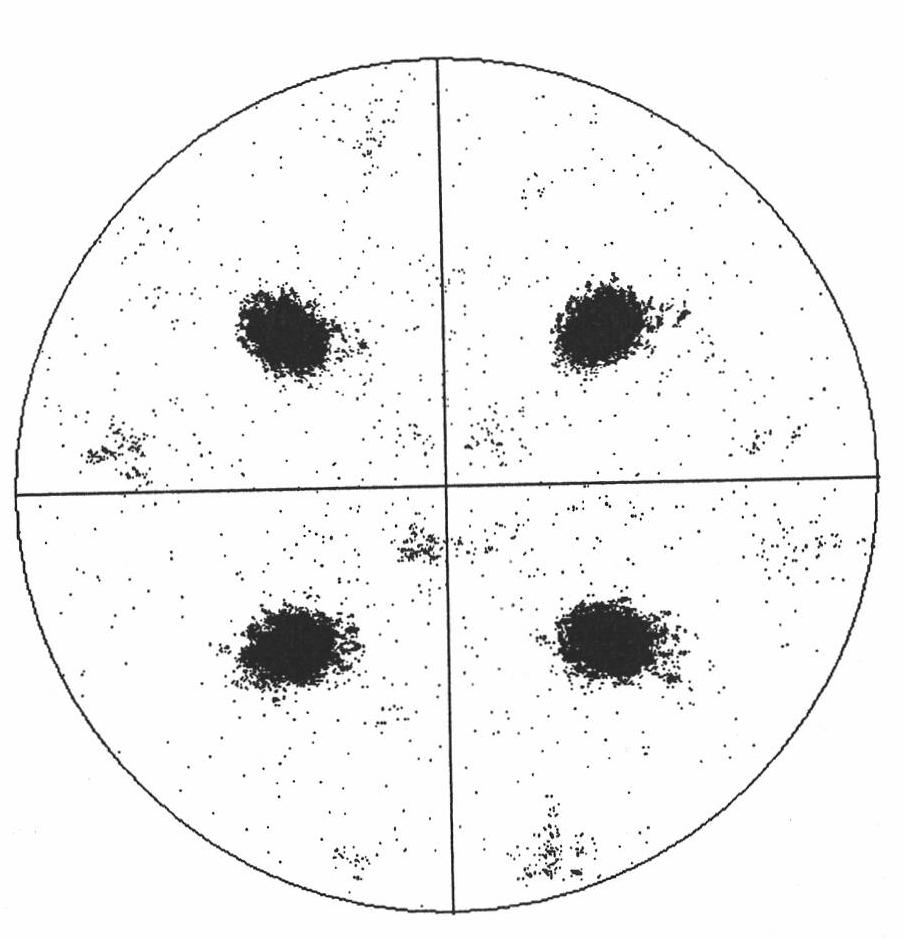

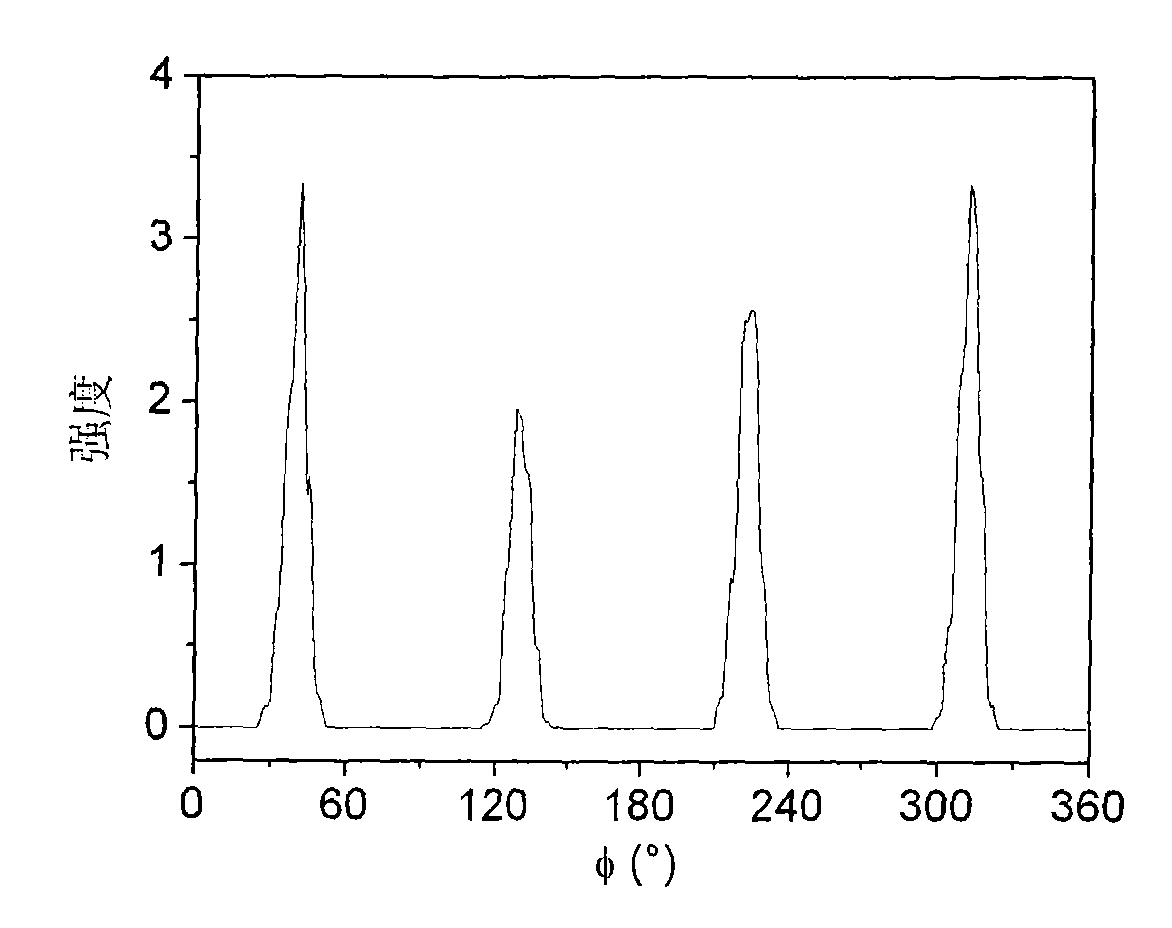

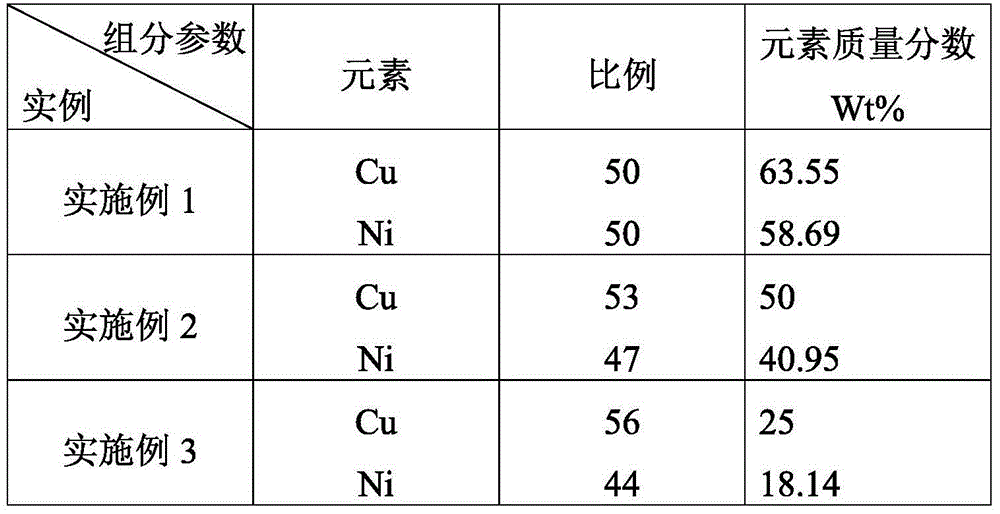

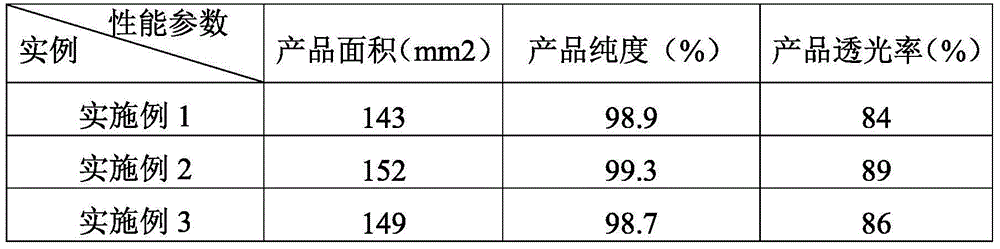

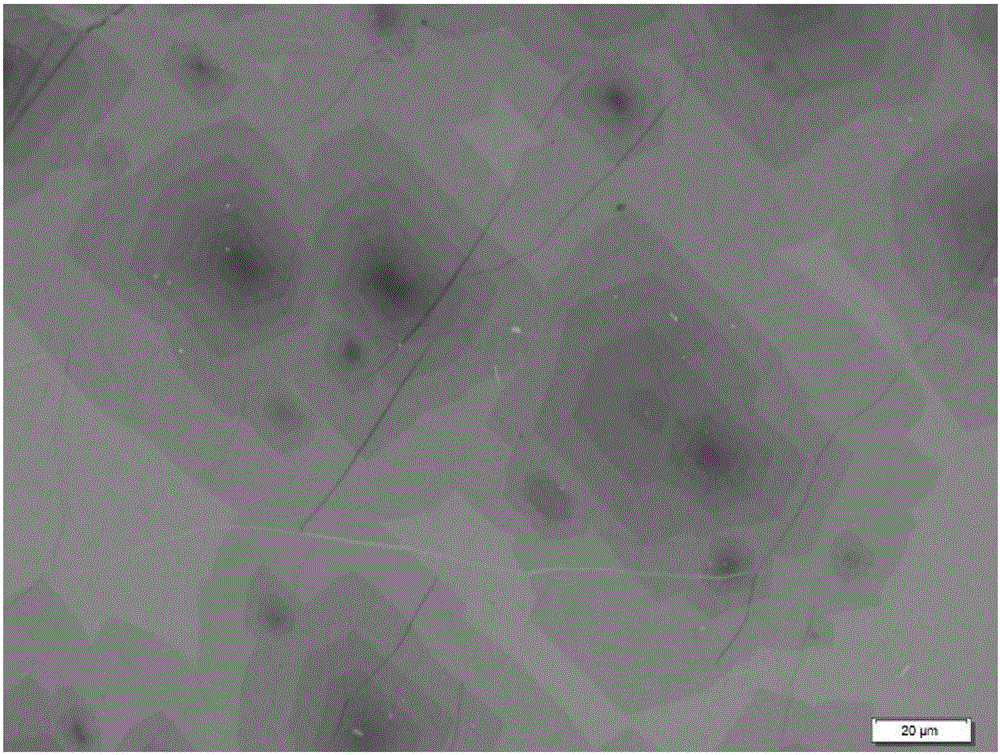

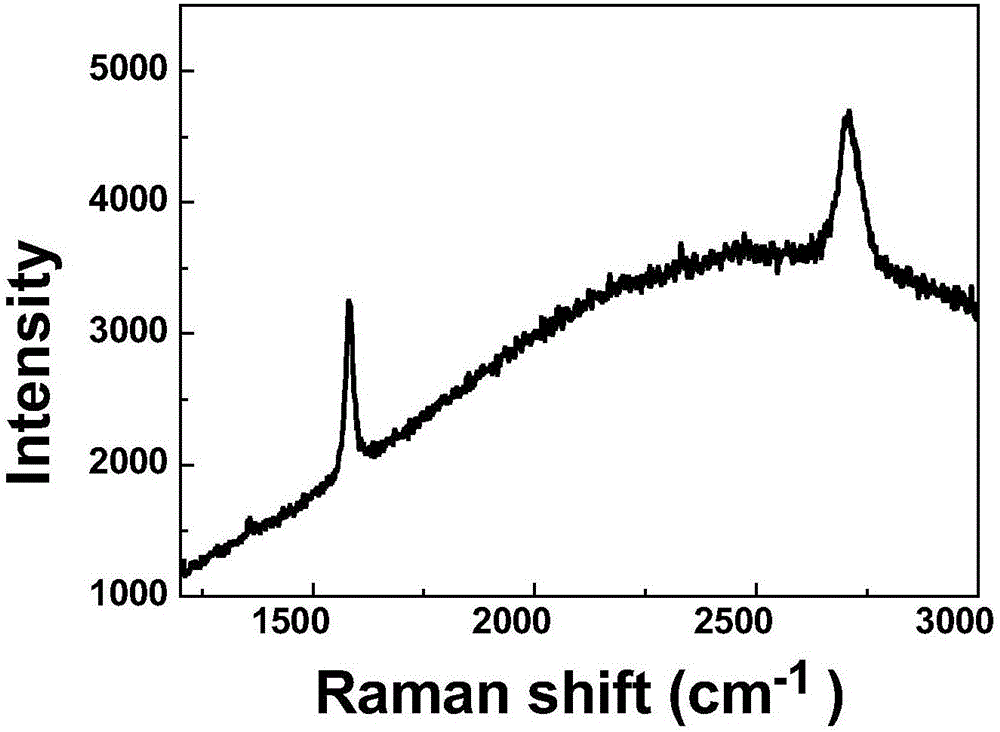

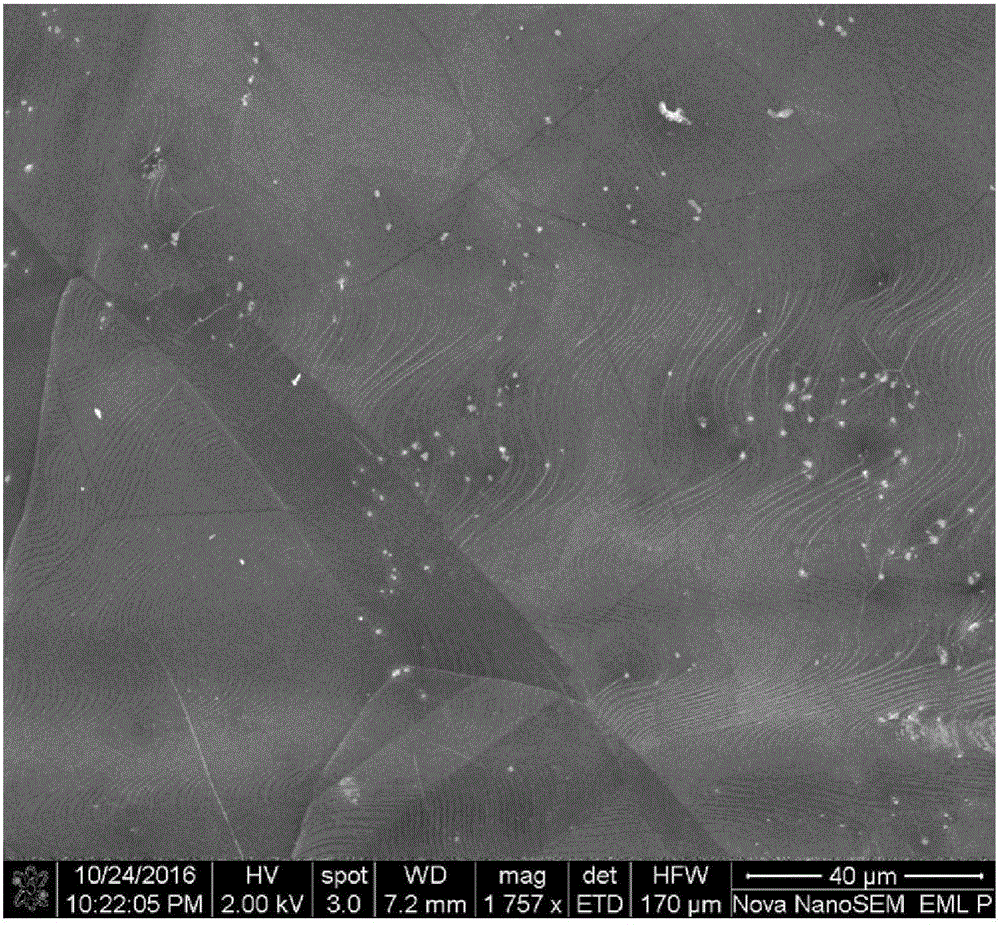

Preparation method for oversized multilayer single crystal graphene and large-size single crystal copper nickel alloy

ActiveCN106835260AQuality improvementAchieve preparationPolycrystalline material growthFrom solid stateCopper foilSingle crystal

The invention provides a preparation method for oversized multilayer single crystal graphene and large-size single crystal copper nickel alloy. The method comprises the following steps: taking nickel plated single crystal copper foil as a raw material; utilizing annealing to prepare oversized single crystal copper nickel alloy; utilizing a normal pressure chemical vapor deposition method and taking the single crystal copper nickel alloy as a substrate, thereby acquiring the oversized high-quality multilayer single crystal graphene. According to the method provided by the invention, the large-size single crystal copper nickel alloy is acquired according to a simple method; the regulating effect of the substrate is utilized to prepare the oversized multilayer single crystal graphene; the technical problems of small single crystal size and complex growth process of the multilayer graphene growth are solved; the preparation for high-quality oversized multilayer single crystal graphene sample and single crystal copper nickel alloy can be realized according to a simple method.

Owner:PEKING UNIV

Corrosion-resistant white copper tube and manufacturing method thereof

InactiveCN103740977AImprove mechanical propertiesImprove conductivityRigid pipesChemical compositionRare earth

The invention relates to the field of copper-nickel alloys, in particular to a corrosion-resistant white copper tube and a manufacturing method thereof. The corrosion-resistant white copper tube comprises the following chemical components in percentage by weight: less than or equal to 0.03 percent of C, 0.10-0.20 percent of Si, 6.0-8.0 percent of Mn, less than or equal to 0.005 percent of S, 0.15-0.20 percent of P, 22.0-24.0 percent of Ni, 2.0-4.0 percent of Co, 2.0-4.0 percent of Zn, 0.20-0.40 percent of Pb, 3.0-4.0 percent of Fe, 0.15-0.20 percent of RE, 0.005-0.010 percent of As and the balance of Cu. The method comprises the following steps: manufacturing a white copper tube blank by performing induction smelting; performing coil stretching production on the white copper tube blank through the procedures of casting, sawing, water seal extrusion, tube rolling, disk stretching, disk blade die peeling, disk stretching, stretching by using a Schumag combined pulling machine, straight bar stretching and annealing. By adopting the corrosion-resistant white copper tube, the problems of limited service life of the conventional copper-nickel alloy material and non-adaptability to coil stretching production due to poor elasticity are solved, and coil stretching is realized.

Owner:江西九星铜业有限公司

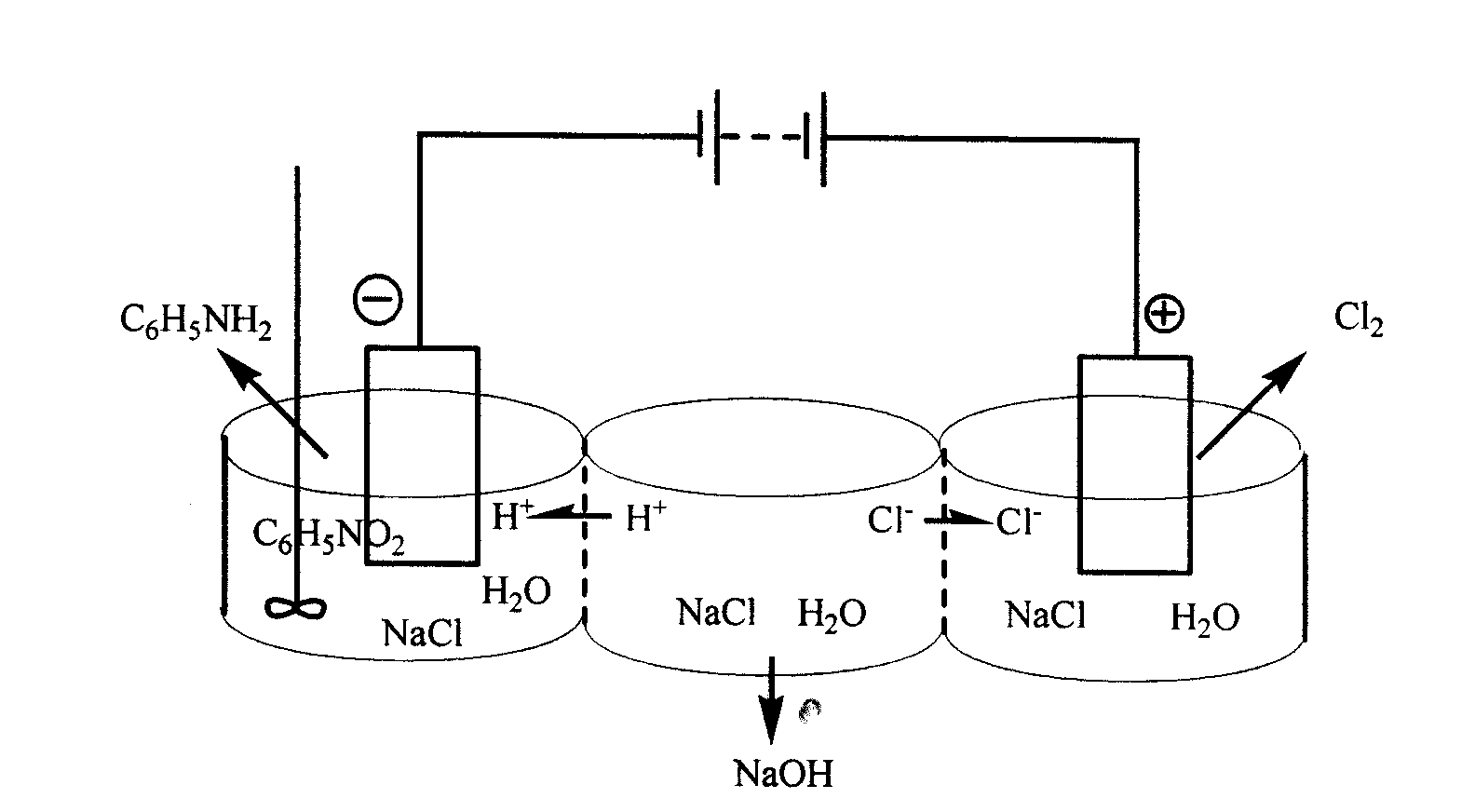

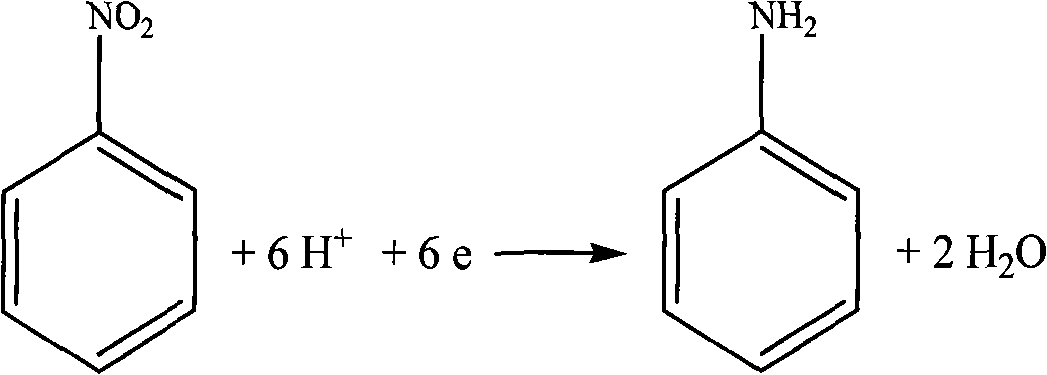

Method for synthesis of aniline and alkali-chloride with electrochemical conjugate synthesis

InactiveCN101492826APairwise synthesisReduce consumptionOrganic chemistryElectrolysis componentsElectrochemical responseSupporting electrolyte

The invention relates to a technical method for synthesizing aniline and chlor-alkali in pair. In the method, an electrochemical reaction is carried out in a three-chamber diaphragm electrolyzer, and three chambers of the electrolyzer are an anode chamber, a cathode chamber and an intermediate chamber, wherein the anode chamber and the intermediate chamber are separated by an anion exchange membrane, and the cathode chamber and the intermediate chamber are separated by a cation-exchange membrane. The anode uses graphite anode, DSA anode or lead anode and other anode materials; and the cathode uses platinum, silver, copper, lead, nickel, copper nickel alloy, copper amalgam, carbon steel, stainless steel, graphite, glass carbon and other materials. Catholyte consists of 1 to 20 percent of nitrobenzene, water (or mixture of water and alcohol), 0 to 5 percent of surface active agent, pH conditioning agent and 0 to 35 percent of supporting electrolyte; while anolyte consists of 5 percent critical saturated sodium chloride solution and trace additive; and solution in the intermediate chamber consists of 5 percent critical saturated sodium chloride. Products of electrolysis are aniline and chlorine with a by-product sodium hydroxide. Synthesis of aniline and chloro-alkali in pair by electrochemistry saves assembly and consumption of all links of hydrogen from production to application on one hand, and reduces pressure of the electrolyzer, electricity consumption and cost on the other hand.

Owner:YANCHENG INST OF TECH

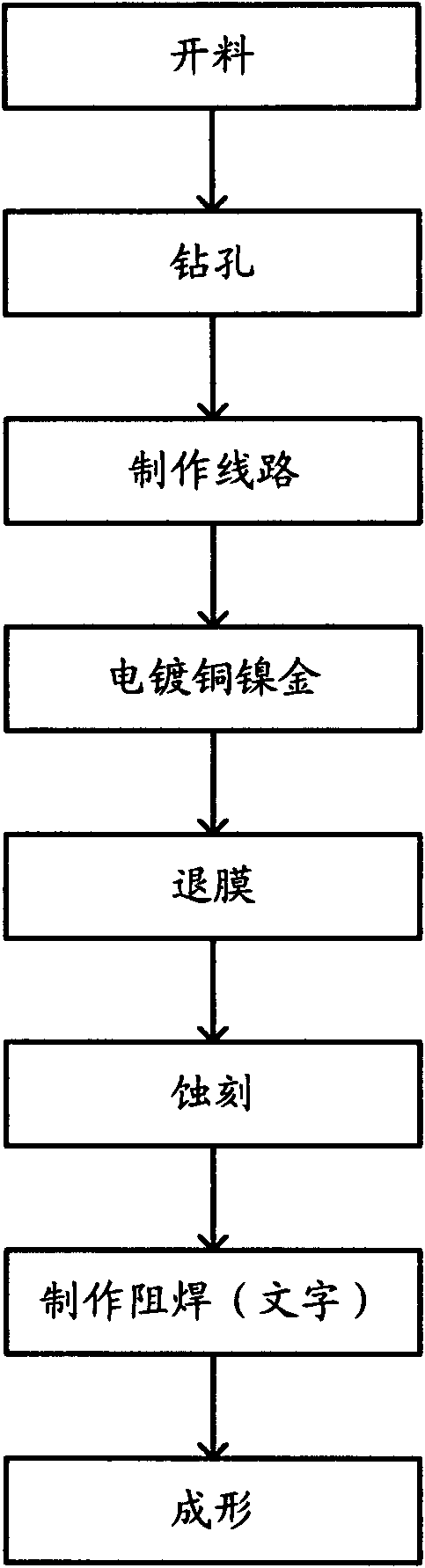

Method and device for manufacturing single-side nickel-plated sheet

InactiveCN101640978ASolve technical problemsSolve the technical problems of aesthetic appearanceConductive material chemical/electrolytical removalElectric resistance weldingElectroplating

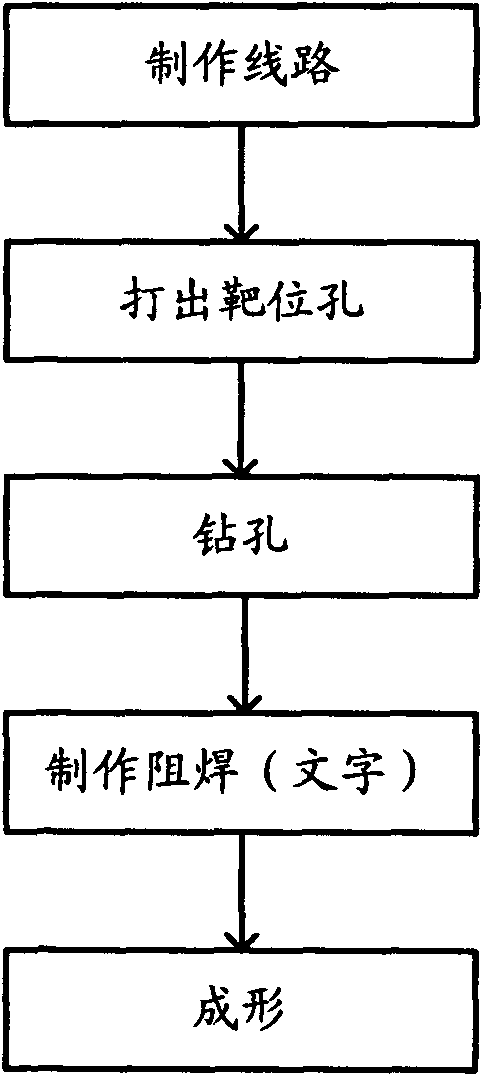

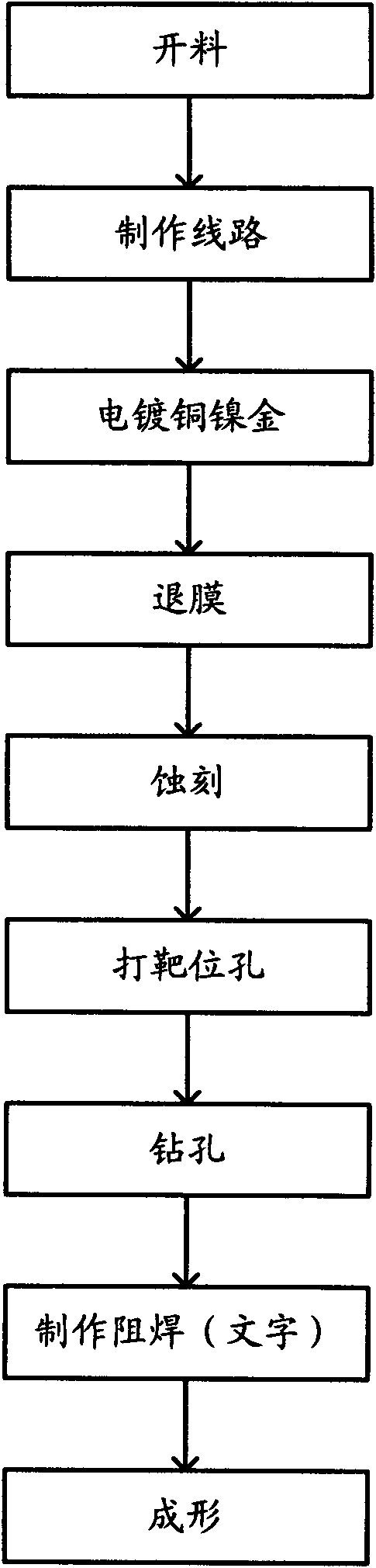

The invention discloses a method and a device for manufacturing a single-side nickel-plated sheet. The method comprises the following steps: manufacturing a circuit, punching target position holes; knocking out target position holes and drilling holes; manufacturing electric resistance welding (characters); and shaping. In the invention, a drilling hole step is adjusted to be behind a copper-nickel alloy plating step so as to solve the technical problem of metal rings generated in plating. In the invention, the target position holes are arranged on a circuit pholin technological edge, and thetarget position holes are knocked out before the holes are drilled for not influencing the accuracy of the drilling holes; the punched target position holes are used for positioning the drilling holesso as to enable the holes to be more accurate and solve the technical problem of blind holes and the technical problem that the attractive appearance of the alloy surface is influenced by liquid medicine cross easily occurring in the plating. Compared with a dry film and a pholin, the invention has lower manufacture cost except for using a little more drilling tip.

Owner:SHENZHEN SUN & LYNN CIRCUITS

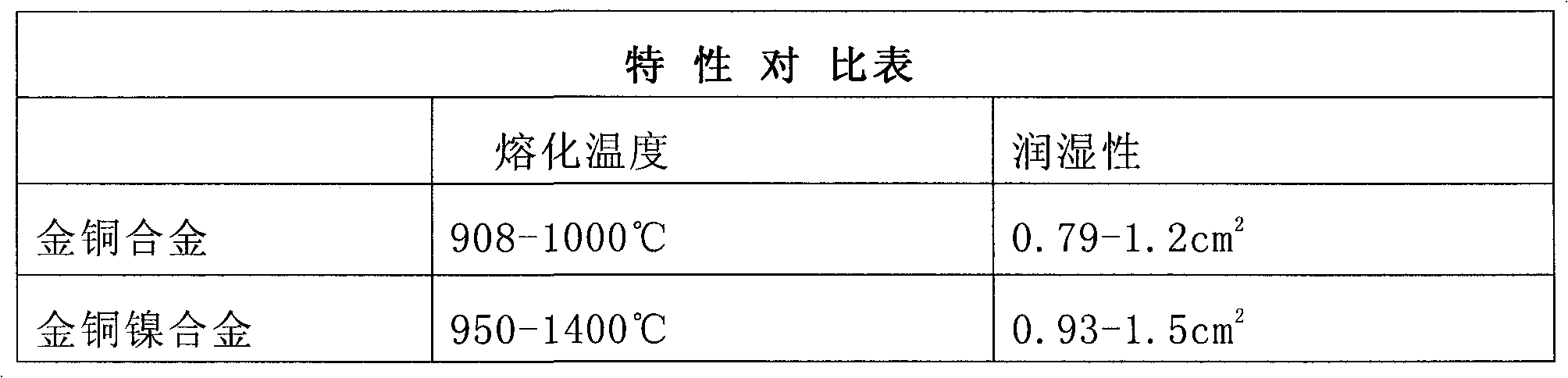

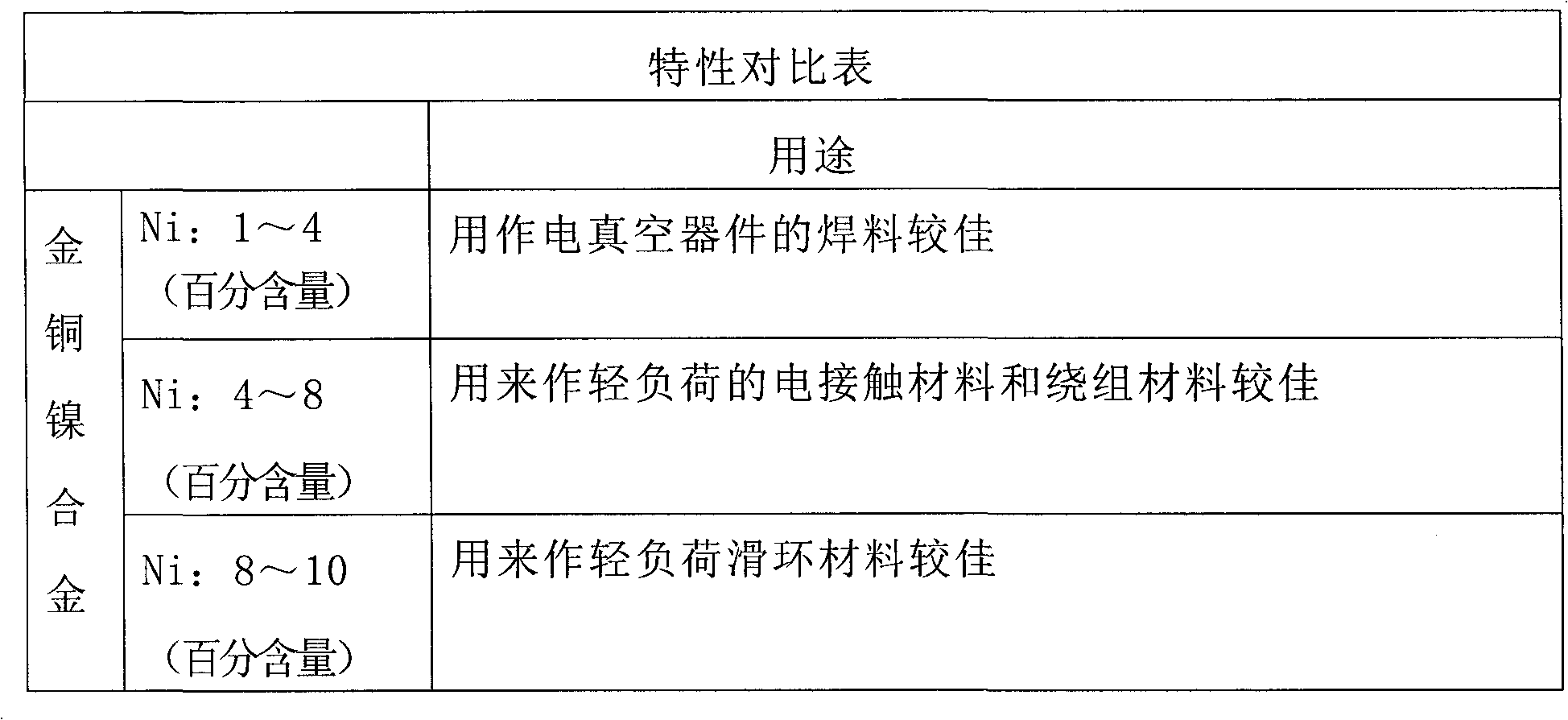

Gold-copper-nickel alloy, preparation method and application thereof

The invention discloses a gold-copper-nickel alloy, a preparation method and applications thereof. The gold-copper-nickel alloy consists of, by weight, 15-60% of Cu, 1-5% of Ni, with the balance being Au. The preparation method comprises the following steps: in accordance with the above-mentioned weight percentage ranges, the high-purity gold, oxygen-free copper and high-purity nickel materials are weighed up; the raw materials are put in a graphite crucible in a vacuum continuous casting machine in order; the continuous casting machine is vacuumized, heated and filled with argon when all materials are melted, then the materials begin to be operated by drawing casting; the obtained wires by drawing casting have a diameter of 8mm; and the size of the finished product is achieved by further drawing operation. The gold-copper-nickel alloy in the invention is widely used as solder for an electric vacuum device, and can be used as light-load electrical contact material, winding material and slidding-ring material. Compared with the gold-copper alloy, nickel element is added in the gold-copper-nickel alloy in the invention, which avoids ordered phase transformation, enables the material to be easy to process, and raises the welding quality when the alloy used as solder.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com