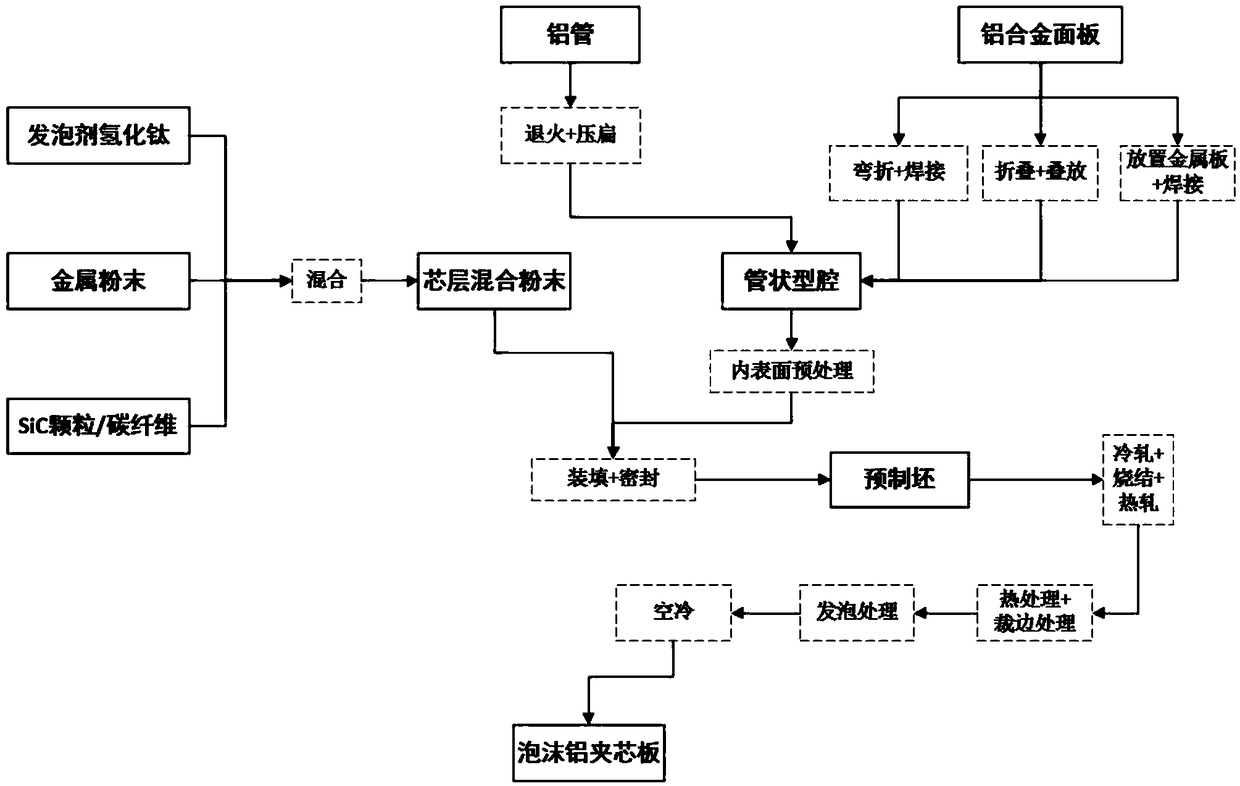

Preparation method for industrial large-size foamed aluminum sandwich panel

A foamed aluminum, large-size technology, applied in the field of layered composite material preparation, can solve the problems of difficulty, unfavorable production control of foaming time, low interface bonding strength, etc., and meet the requirements of reducing heating rate, high stability and High repeatability and high controllability of temperature accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Mix aluminum powder, silicon powder, copper powder, magnesium powder, zinc white copper powder and foaming agent, add additives, and mix evenly to obtain a core layer mixed powder. The mixing time is 1h; the element composition of the core layer mixed powder is Si in mass percentage 5%; Mg 8%, Cu1%, Zn 2%, foaming agent 0.5%, and the rest is Al; the foaming agent is titanium hydride powder; the additive is SiC particles, accounting for the total mass of the core mixed powder ≤8%; when the additive is carbon fiber, the additive accounts for ≤0.5% of the total mass of the core mixed powder; the particle size of aluminum powder, silicon powder and magnesium powder is 100-400 mesh; the particle size of copper powder, zinc white copper powder and titanium hydride powder 400-1000 mesh; the particle size of silicon carbide particles is 50-200 mesh;

[0051] use The 3003 aluminum alloy tube aluminum alloy is used as the tube; the tube is annealed at 400±10°C for 1 hour, then ...

Embodiment 2

[0062] Method is with embodiment 1, and difference is:

[0063] (1) Mix aluminum powder, silicon powder, copper powder, magnesium powder and foaming agent, add additives, and mix evenly to obtain a core layer mixed powder. The mixing time is 2h; the element composition of the core layer mixed powder is Si 10 by mass percentage %; Mg 1%, Cu 6%, foaming agent 2%, and the rest is Al; the additive is carbon fiber; accounting for 0.5% of the total mass of the core mixed powder; carbon fiber diameter ≤ 100um, length ≤ 3mm;

[0064] (2) Use size The 6063 aluminum alloy pipe is used as the pipe; the pipe is annealed at 400±10°C for 3 hours, then flattened with a press, and then rolled into a tubular cavity with a rolling mill; the tubular cavity consists of an upper plate, a lower plate and The connection between the two is formed, the distance between the upper plate and the lower plate is 30mm; the width of the tubular cavity is 210±10mm, and the wall thickness is 4mm;

[0065] (...

Embodiment 3

[0073] Method is with embodiment 1, and difference is:

[0074] (1) Mix aluminum powder, silicon powder, copper powder, magnesium powder, zinc white copper powder and foaming agent without adding additives, and mix evenly to obtain the core layer mixed powder. The mixing time is 3 hours; the element composition of the core layer mixed powder is as follows: The mass percentage is Si 8%; Mg 4%, Cu 3%, Zn 1%, foaming agent 1%, and the rest is Al;

[0075] (2) 6061 aluminum alloy plate is used as the plate; the two sides of the two parallel plates are sealed to form a tubular cavity; the tubular cavity is composed of an upper plate, a lower plate and a connection between the two The upper plate and the lower plate are parallel to each other with a distance of 25mm; the width of the tubular cavity is 500mm and the wall thickness is 4mm; the method of sealing the two sides is: the two sides of the upper plate and the lower plate Bending respectively, the angle between the bending p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com