Self-balancing supercritical foaming method and self-balancing supercritical foaming device for multicomponent multiphase complex system

A foaming device and supercritical technology, applied in the field of pressure relief foaming after self-equilibrium swelling, can solve the problems of unstable foaming effect, fluctuation of material foaming effect, etc., and achieve the improvement of foaming ratio, uniform cell structure, The effect of improving the foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

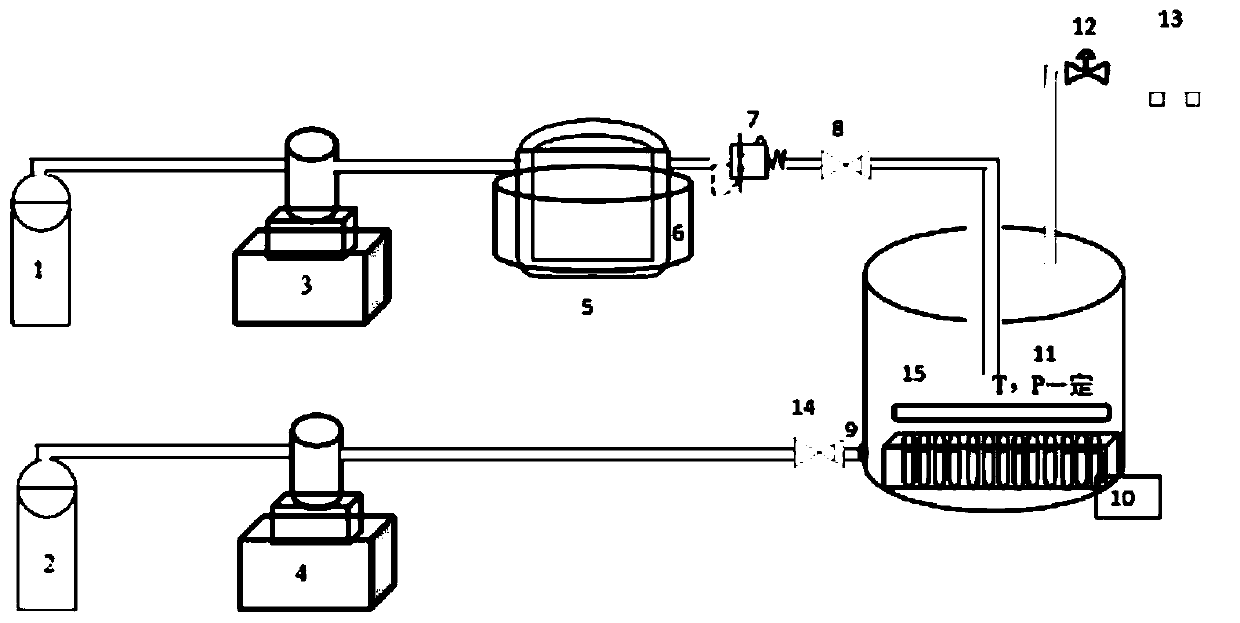

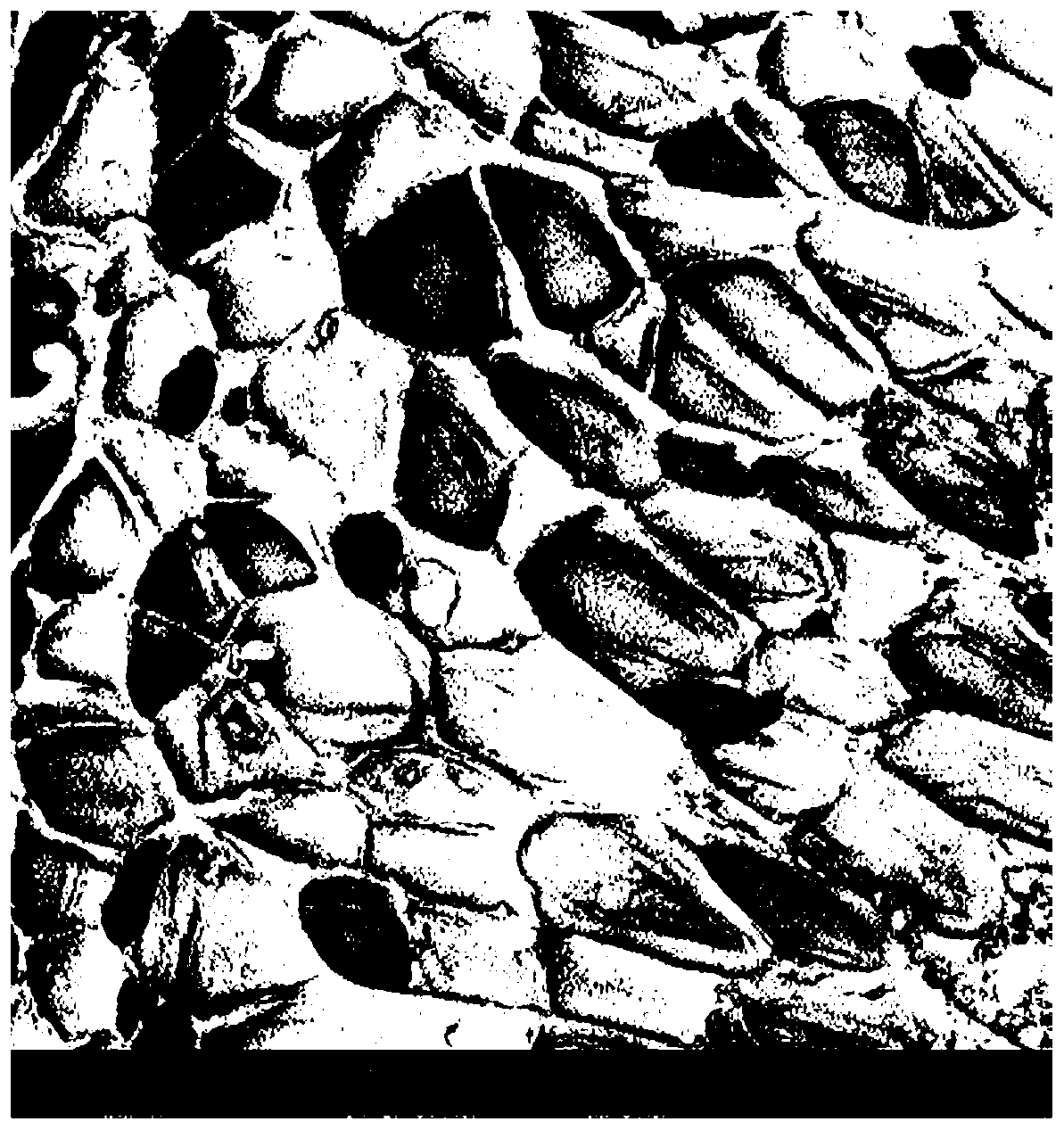

[0117] Such as figure 1In the device shown, the production of polypropylene foamed polymer material is taken as an example. First, polypropylene (the shape of the raw material is a block, the size is about 600 cm³, a total of 2 samples) is added to the high-pressure container (volume is about 5L), Use a liquid pump to transport excess n-hexane to the high-pressure vessel through the heated buffer tank, and at the same time raise the temperature of the high-pressure vessel to 140°C, and use the ISCO pump to pump 15MPa CO 2 The gas is sent to the high-pressure container through the heated buffer tank, and the ISCO pump is kept on to stabilize the pressure in the container, and the polymer is filled with CO 2 Swell in the atmosphere of n-hexane for 5 hours, so that the polymer can fully absorb CO 2 and n-hexane, then open the valve for 2 seconds to release the pressure, recycle the mixed foaming agent into the recovery device, use the recovery device to separate the phases of th...

Embodiment 2

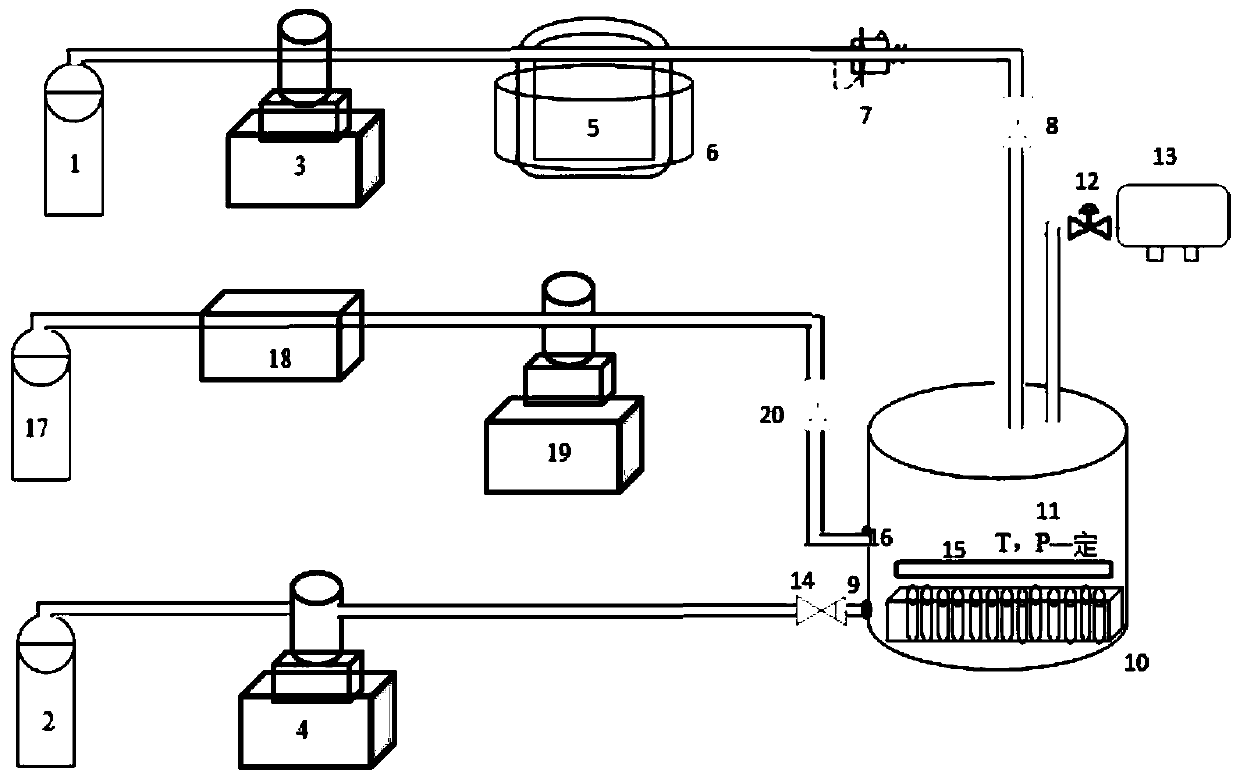

[0129] Taking the production of polyphenylsulfone foamed polymer materials as an example, firstly, the polyphenylsulfone raw material is in the shape of a block, the size is about 600 cm³, a total of 2 samples) into a high-pressure container (volume is about 5L), and the high-pressure container Set the heating cable on the buffer bottle to the required temperature for foaming, use a liquid pump to transport excess distilled water through the buffer bottle to a high-pressure container, and use a booster pump to transfer 20MPa CO 2 The gas is delivered to the high-pressure container through the high-pressure buffer bottle, and the pressure of the high-pressure container is stabilized by the pressure reducing valve, and the PPSU is filled with CO 2 Swell in an atmosphere of distilled water for 5 hours, so that PPSU can fully absorb CO 2 and distilled water, then open the valve for 2 seconds to release the pressure, recycle the mixed foaming agent into the recovery device, use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com