Preparation method of nanometer carbon fiber-copper composite material

A nano-carbon fiber and composite material technology, which is applied in the field of composite material preparation of electronic components, can solve the problems of poor fiber orientation, high equipment requirements, large capillary force, etc., and achieves adjustable thermal expansion coefficient, high thermal conductivity, and copper density. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

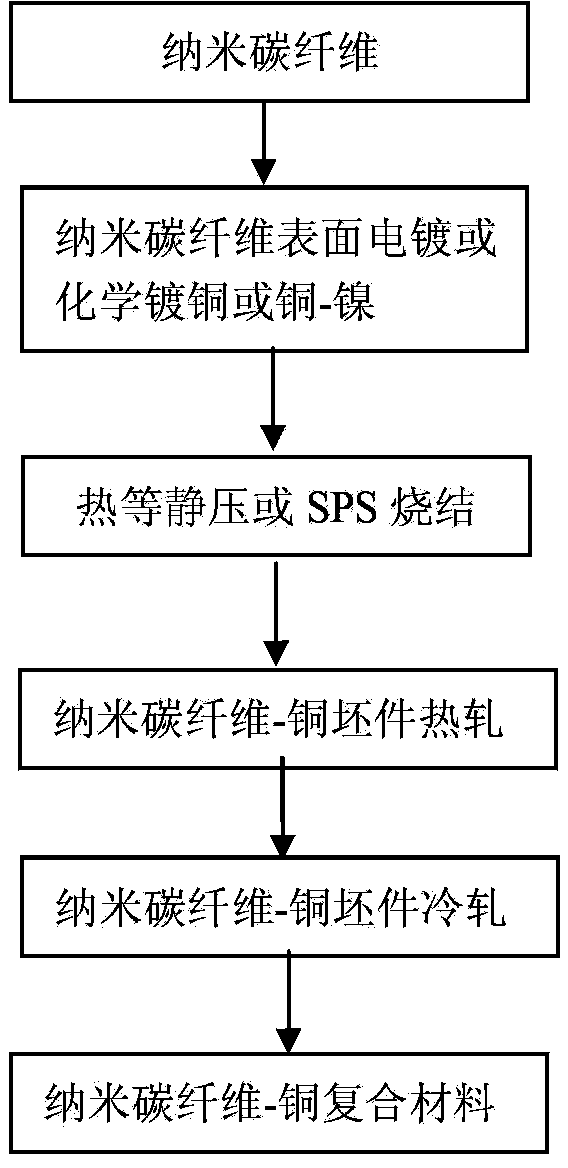

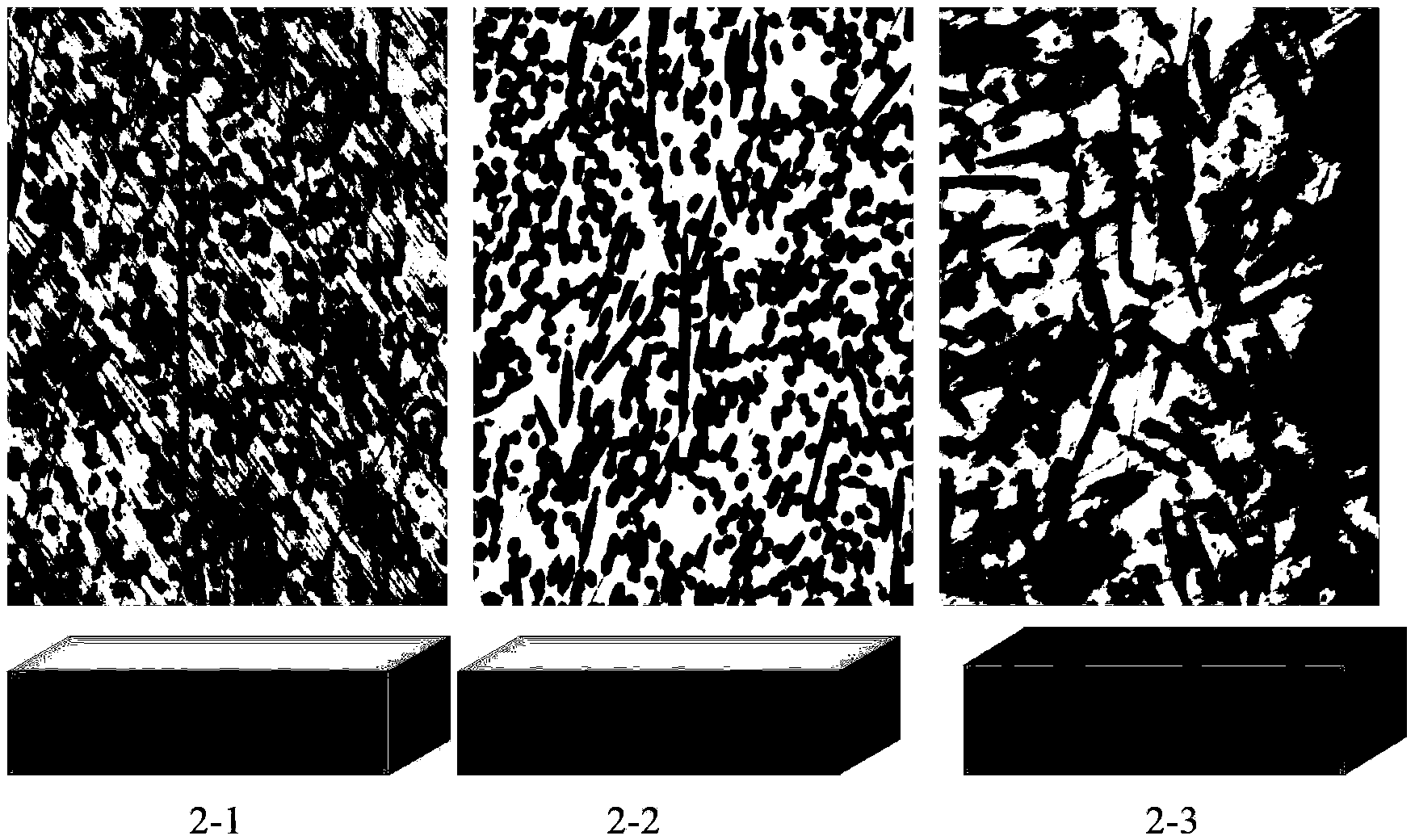

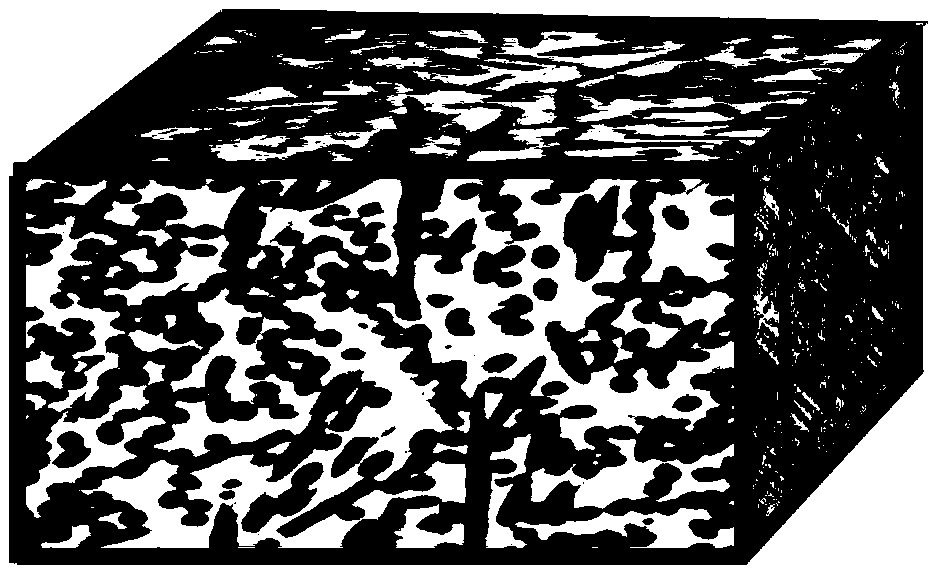

[0018] according to figure 1 In the process shown, the electroless copper plating layer on the surface of carbon nanofibers, the copper layer is 90% of the mass of carbon nanofibers, the hydrogen reduction temperature is 400 ° C, the reduction time is 1 hour, under 90 MPa pressure, 900 ° C hot isostatic pressing for 25 minutes, Obtain nano-carbon fiber-copper blank, then through hot rolling, the reduction ratio is 70%, and the reduction ratio of cold rolling is 10%, obtain nano-carbon fiber-copper composite material, such as Figure 2-3 shown. The density of the material is 8.2g / cm 3 , the thermal conductivity parallel to the fiber x-y direction is 250W / mK, the thermal expansion coefficient is 8ppm / ℃, the thermal conductivity perpendicular to the fiber z-axis direction is 120W / mK, and the thermal expansion coefficient is 17ppm / ℃.

Embodiment 2

[0020] according to figure 1 In the process shown, the electroless copper plating layer on the surface of carbon nanofibers, the copper layer is 80% of the mass of carbon nanofibers, the hydrogen reduction temperature is 400 ° C, the reduction time is 1 hour, under 95 MPa pressure, 950 ° C hot isostatic pressing for 25 minutes, Obtain the carbon nanofiber-copper blank, then through hot rolling, the reduction ratio is 65%, and the cold rolling reduction ratio is 8%, so as to obtain the carbon nanofiber-copper composite material, such as Figure 2-3 shown. The density of the material is 7.5g / cm 3 , the thermal conductivity parallel to the fiber x-y direction is 280W / mK, the thermal expansion coefficient is 10ppm / ℃, the thermal conductivity perpendicular to the fiber z-axis direction is 150W / mK, and the thermal expansion coefficient is 16.5ppm / ℃.

Embodiment 3

[0022] according to figure 1 In the process shown, the electroless copper-nickel layer on the surface of carbon nanofibers is 65% of the mass of carbon nanofibers, the hydrogen reduction temperature is 400°C, the reduction time is 1 hour, and the pressure is 100MPa, 1000°C hot isostatic pressing for 30min, Obtain the carbon nanofiber-copper blank, control the reduction rate at 60% through hot rolling, then cold rolling, the reduction rate is controlled at 5%, obtain the carbon nanofiber-copper composite material, such as Figure 2-3 shown. The density of the material is 6.5g / cm 3 , the thermal conductivity parallel to the fiber x-y direction is 300W / mK, the thermal expansion coefficient is 9ppm / ℃, the thermal conductivity perpendicular to the fiber z-axis direction is 180W / mK, and the thermal expansion coefficient is 16ppm / ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com