Preparation device and preparation method of high-orientation two-dimensional nanometer material macroscopic body

A two-dimensional nanomaterial and a technology for preparing a device, which are applied in the field of a preparation device for a macroscopic body of a highly oriented two-dimensional nanomaterial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

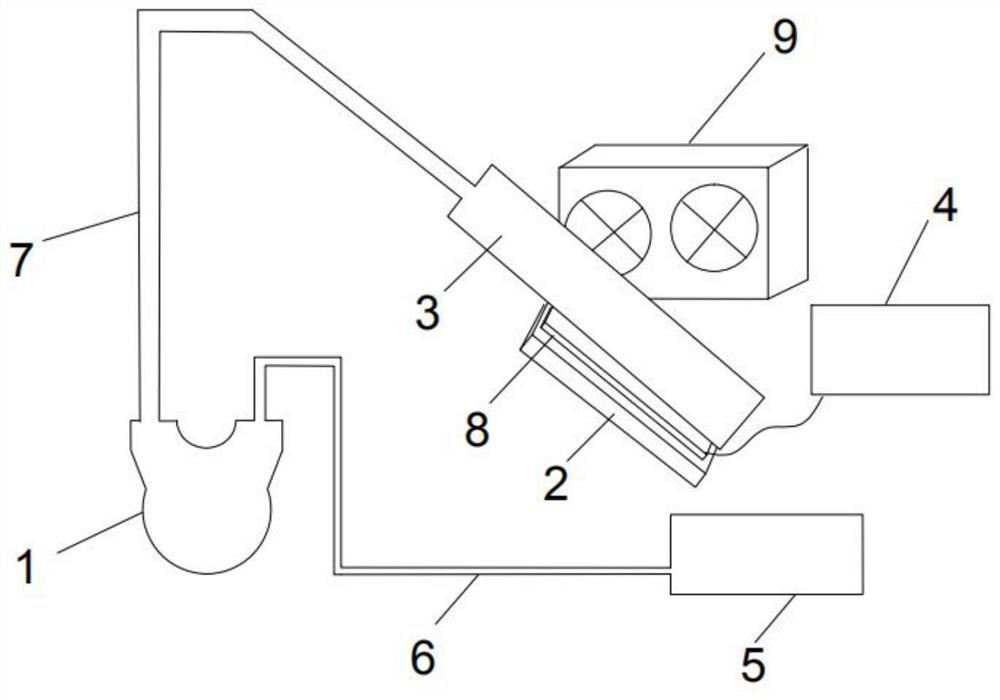

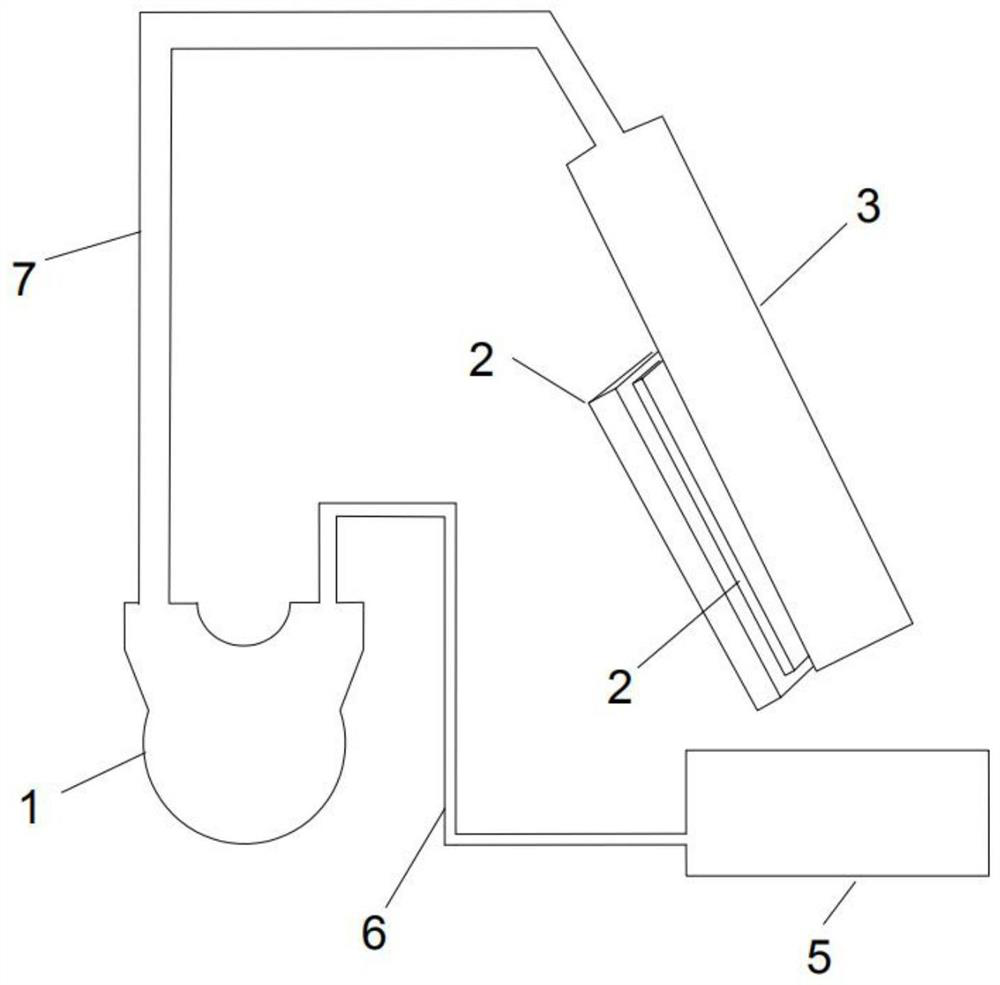

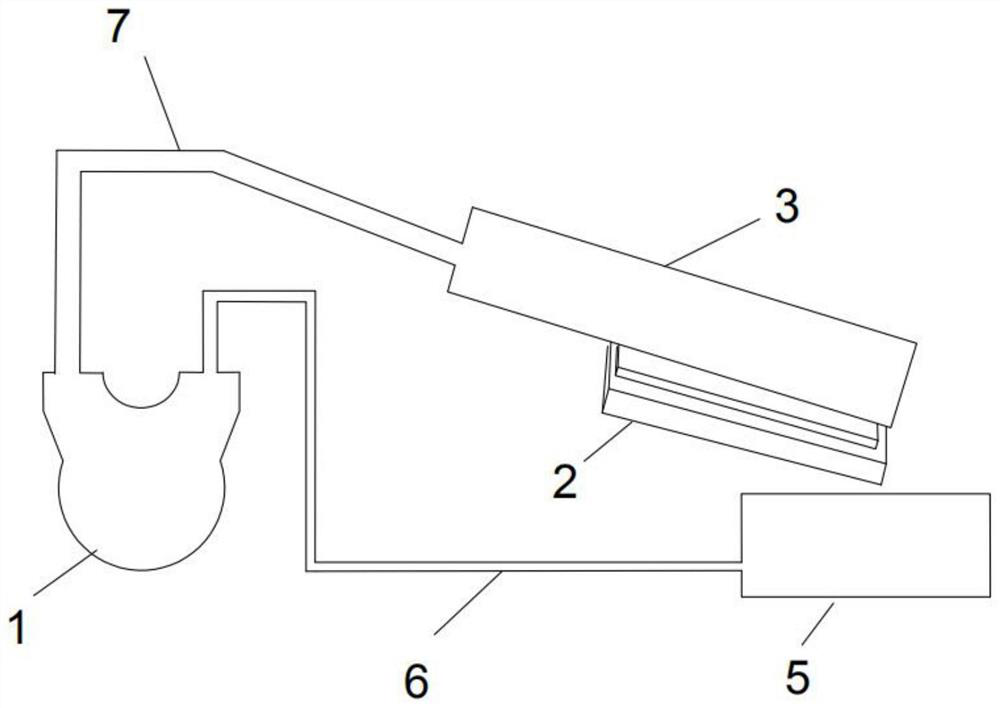

[0037] A preparation device for a highly oriented two-dimensional nanomaterial macroscopic body, including a pump body 1, a refrigerator 2, a freezing chamber 3, a temperature control system 4, and a solution tank 5, and the solution tank 5 passes through the inlet of the pipeline I6 and the pump body 1 The outlet end of the pump body 1 communicates with the front end of the freezing chamber 3 through the pipeline II7. The freezing chamber 3 is set with a high front and a low slope, and the rear end of the freezing chamber 3 is arranged above the solution tank 5 and It communicates with the solution tank 5 , the refrigerator 2 is arranged below the freezing chamber 3 close to or in contact with the bottom surface of the freezing chamber 3 , and the temperature control system 4 is electrically connected with the refrigerator 2 . The refrigerator 2 is a semiconductor refrigeration chip or a liquid nitrogen refrigeration device. Preferably, the semiconductor cooling chip is two d...

specific Embodiment approach 2

[0044] A method for preparing a highly oriented two-dimensional nanomaterial macrobody using the preparation device described in Embodiment 1, comprising the following steps:

[0045] Step 1: Prepare a two-dimensional nanomaterial dispersion, and place the prepared two-dimensional nanomaterial dispersion in an environment of 0-20°C for thermal equilibrium;

[0046] Step 2: Under the temperature environment where the solution is thermally balanced, the pump body 1 continuously transports the two-dimensional nanomaterial dispersion in the solution tank 5 to the freezing chamber 3, and flows from the front end of the freezing chamber 3 to the rear end, and the refrigerator 2 is used for freezing Chamber 3 continues to cool down, and the gradient temperature field provided by refrigerator 2 (the temperature gradually decreases from top to bottom) realizes the stable growth of ice crystals, and the action of fluid shear force realizes the directional arrangement of two-dimensional n...

specific Embodiment approach 3

[0051] A method for preparing a graphene macrobody using the device described in Embodiment 1. Firstly, the preparation and thermal balance of the graphene oxide dispersion are carried out, and then the graphene oxide macrobody is prepared by using a preparation device for a highly oriented two-dimensional nanomaterial macrobody. The orderly assembly of , followed by freeze-drying, and finally chemical vapor reduction to obtain highly oriented graphene macroscopic bodies, the specific steps are as follows:

[0052] Step 1: Preparation and heat balance of graphene oxide dispersion: disperse graphene oxide solution with sheet size of 5-10 μm and concentration of 10-20 mg / ml in deionized water to prepare graphene oxide of 5-15 mg / ml Dispersion liquid, the graphene oxide dispersion liquid is ultrasonically treated at a frequency of 10KHz to 100KHz for 30 to 60 minutes, and then placed in an environment of 0 to 20°C for heat balance;

[0053] Step 2: Under the temperature environme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com