Method and device for manufacturing single-side nickel-plated sheet

A single-sided, electro-nickel technology, which is applied in chemical/electrolytic methods to remove conductive materials, electrical components, printed circuits, etc., can solve the problems of high production cost, achieve low production cost, solve the problem of beautiful appearance and precise hole position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

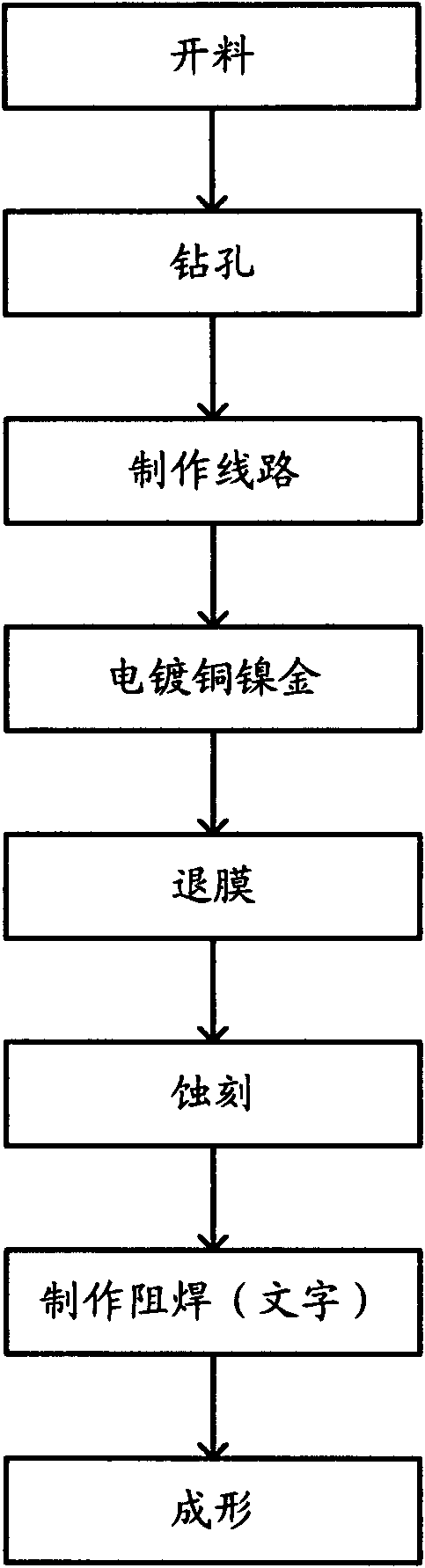

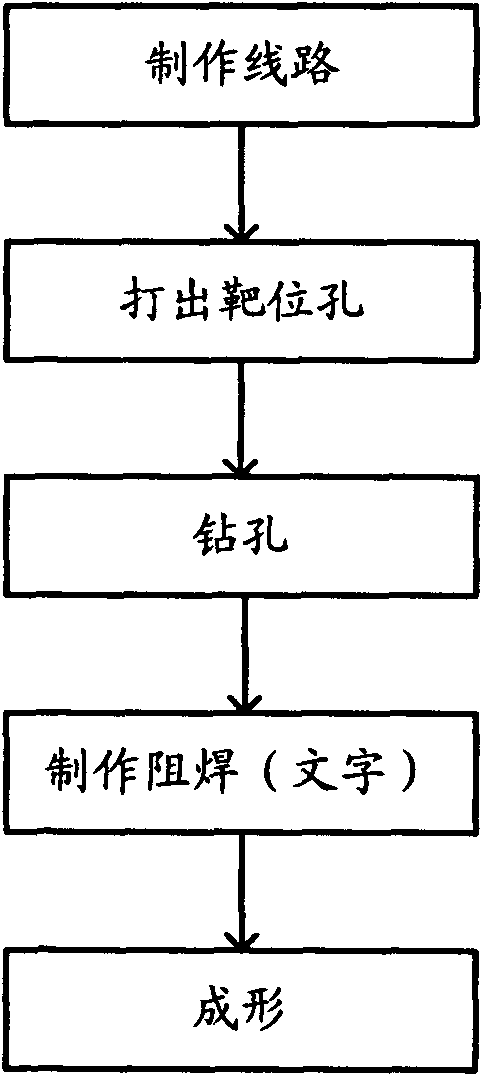

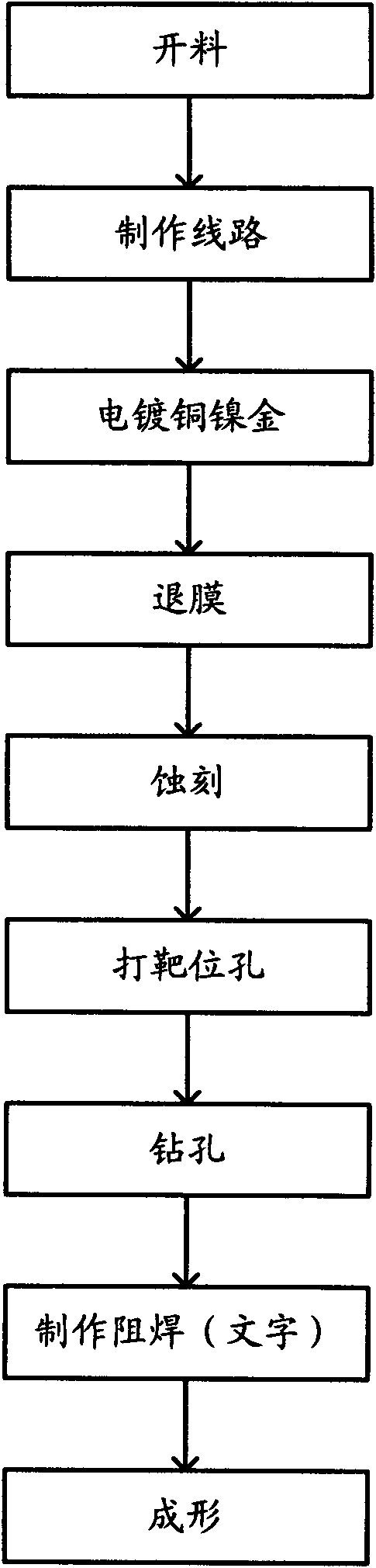

[0042] The present invention provides a method and equipment for manufacturing single-sided electro-nickel-gold plates, which are applied to the technical field of printed circuit boards. The basic idea is: Compared with the prior art, the present invention mainly adjusts the order of drilling holes. After the hole is adjusted to the step of electroplating copper, nickel and gold, the technical problem of the metal circle produced by electroplating is solved. At the same time, in order not to affect the accuracy of drilling, the target hole is designed on the side of the line film process. Punch out the target hole. The drilled target hole is used for drilling positioning, which makes the hole position more precise, thus solving the technical problem of blind holes and solving the problem of crossover of liquid during electroplating which affects the appearance of the gold surface The technical problem of aesthetics: Compared with dry film and film, the present invention only us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com