Solvent extraction method for acquiring alloy with magnetic separation copper bessemer matte

A leaching, copper-nickel technology, applied in the direction of improving process efficiency, can solve the problems of increasing environmental pollution, polluting the atmosphere, high energy consumption, etc., and achieve the effect of simple, efficient and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The alloy composition is shown in Table 1

[0035] The raw material composition is shown in Table 1:

[0036] Table 1 The composition of the coarse-grained alloy is as follows (%, g / t):

[0037] Ni (%)

co

Cu

Fe

S

Si0 2

Pt(g / t)

PD

Au

69

1.28

14.23

8.5

3.5

1.36

123.22

56.19

48.8

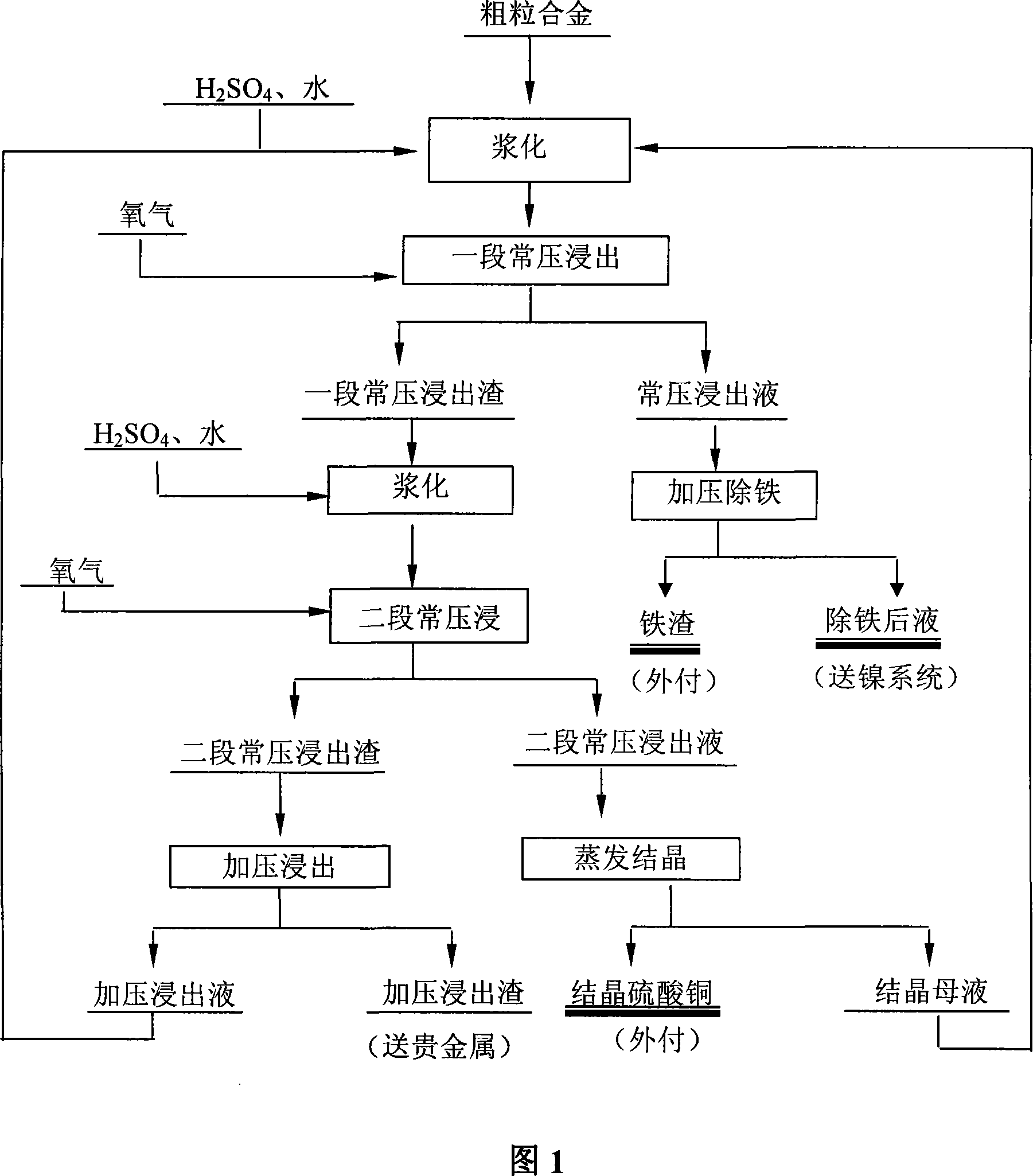

[0038] The coarse-grained alloy is quantitatively and evenly added to the batching slurry tank, and at the same time, the pressurized leaching return liquid, crystallization mother liquor, a certain amount of water and sulfuric acid are added to the batching slurry tank, and the slurry liquid-solid ratio is controlled to be 11:1m 3 / ton, the initial concentration of sulfuric acid is 60g / l, after pulping, the slurry is subjected to a normal pressure leaching oxidation section, the reaction temperature of the oxidation section is controlled at 80°C, and the reaction time is 1h; T...

Embodiment 2

[0044] The composition of the coarse-grained alloy is shown in Table 1

[0045] The coarse-grained alloy is uniformly added to the batching slurry tank in a quantitative manner, and at the same time, the pressurized leaching return liquid, crystallization mother liquor, a certain amount of water and sulfuric acid are added to the batching slurry tank, and the slurry liquid-solid ratio is controlled to be 12:1m 3 / ton, the initial concentration of sulfuric acid is 55g / l, after pulping, the pulp is subjected to a normal pressure leaching oxidation section, the reaction temperature of the oxidation section is controlled at 85°C, and the reaction time is 1.5h; The prepared slurry is pumped into a section of atmospheric pressure oxidation tank, and oxidation leaching is carried out under the condition of passing oxygen. After oxidation leaching, it is pumped into a section of normal pressure replacement tank through the middle tank for replacement and leaching of copper precipitati...

Embodiment 3

[0051] The composition of the coarse-grained alloy is shown in Table 1

[0052] The coarse-grained alloy is quantitatively and evenly added to the batching slurry tank, and at the same time, the pressurized leaching return liquid, crystallization mother liquor, a certain amount of water and sulfuric acid are added to the batching slurry tank, and the slurry liquid-solid ratio is controlled to be 13:1m 3 / ton, the initial concentration of sulfuric acid is 50g / l, after pulping, the pulp is subjected to a normal pressure leaching oxidation section, the reaction temperature of the oxidation section is controlled at 85°C, and the reaction time is 2h; The prepared slurry is pumped into a section of atmospheric pressure oxidation tank, and oxidation leaching is carried out under the condition of passing oxygen. After oxidation leaching, it is pumped into a section of normal pressure replacement tank through the middle tank for replacement and leaching of copper precipitation. The rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com