Gold-plated circuit board manufacturing method

A production method and circuit board technology, which is applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve problems such as burrs on gold-plated boards, achieve the effect of solving burrs and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

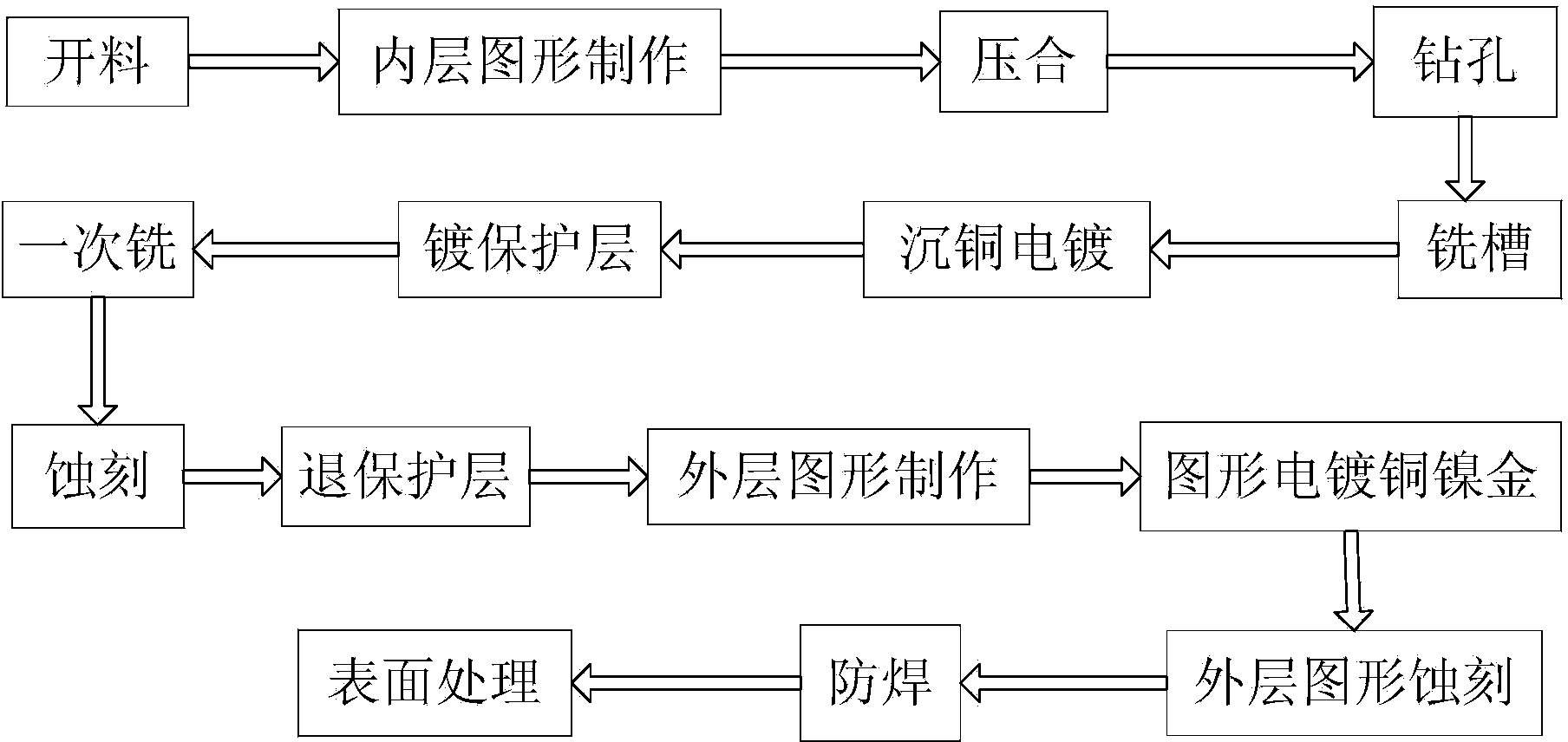

[0036] A method for making a gold-plated circuit board, such as figure 2 As shown, including material cutting, inner layer graphic production, pressing, drilling, milling, copper plating, protective layer plating, one-time milling, etching, protective layer removal, outer layer graphic production, graphic electroplating copper nickel gold, outer layer Layer graphic etching, solder mask, surface treatment process; among them:

[0037] Cutting, inner layer graphic making, pressing and drilling processes are handled according to the conventional process.

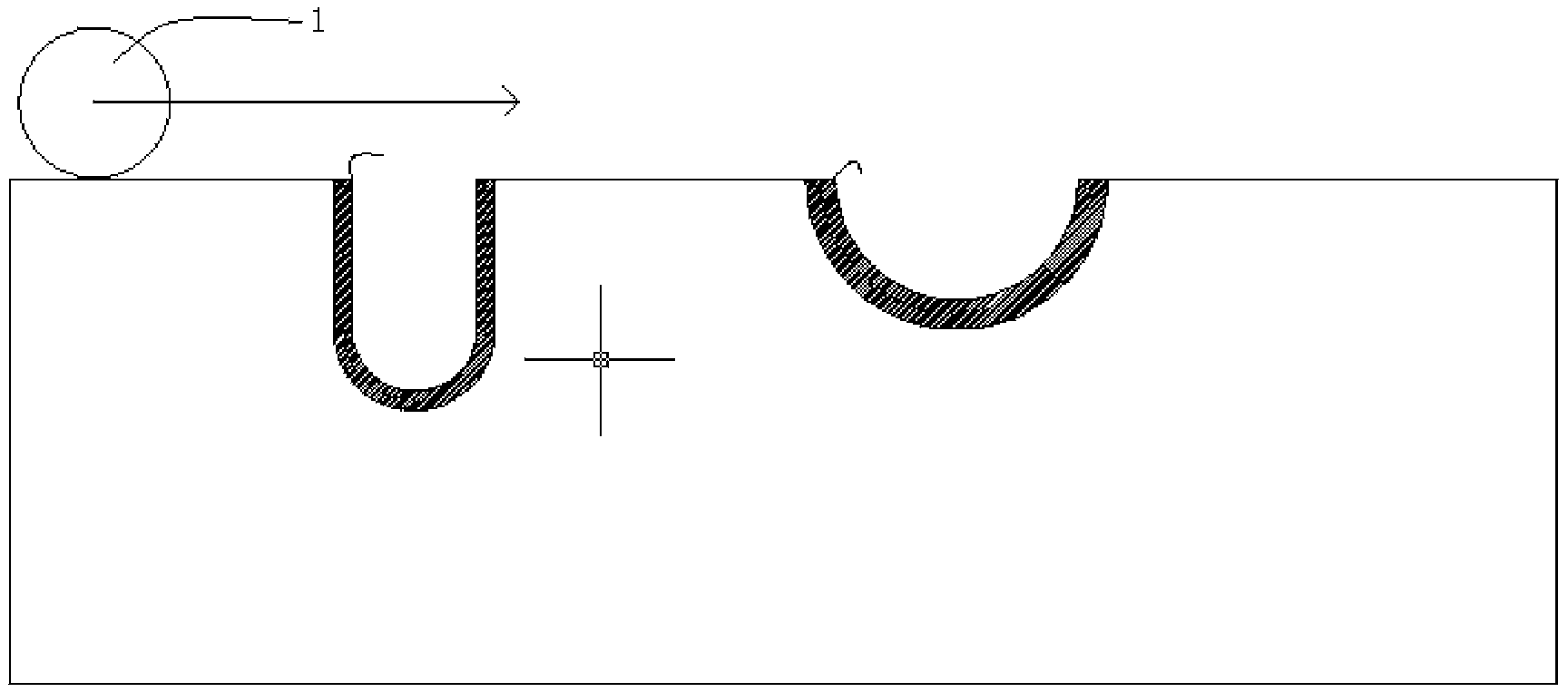

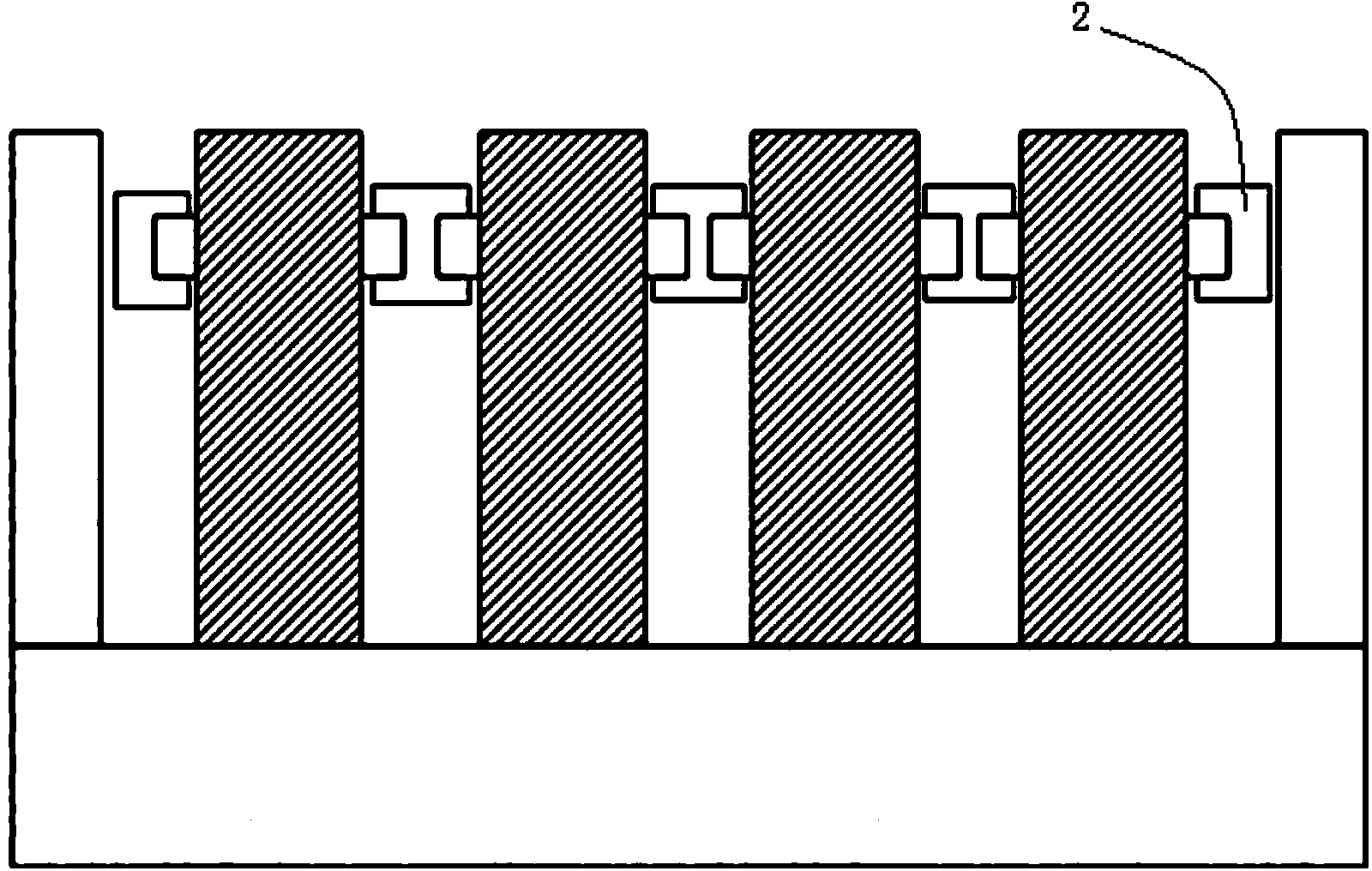

[0038] In the slot milling process, the side wall of the metallized area is processed in the way of slot milling 2, such as image 3 shown.

[0039] In the copper plating process, such as Figure 4 As shown, the milled slots are metallized by sinking copper, the electroplating process controls the current density to 8ASF, and the time is 25min, so that the copper thickness reaches 6μm.

[0040] In the step of plating the p...

Embodiment 2

[0048] The gold-plated circuit board manufacturing method of the present embodiment is basically the same as the manufacturing method in embodiment 1, the difference is:

[0049] In the copper immersion electroplating process, the milled slots are metallized by immersion copper. During the electroplating process, the current density is controlled at 15ASF, and the time is 60min, so that the copper thickness reaches 12μm.

[0050] In the step of plating the protective layer, the protective layer is a tin layer, and the thickness of the tin layer is 10 μm.

[0051] In the outer pattern making process, when the dry film is exposed, the exposed area of the dry film is extended 5 mil into the groove.

[0052] In the graphic electroplating copper-nickel-gold process, copper plating and nickel plating are processed according to conventional processes. The conditions for gold plating are to control the current density to 3ASF for 120 seconds, so that the thickness of the gold layer re...

Embodiment 3

[0054] The gold-plated circuit board manufacturing method of the present embodiment is basically the same as the manufacturing method in embodiment 1, the difference is:

[0055] In the copper immersion electroplating process, the milled slots are metallized by immersion copper. During the electroplating process, the current density is controlled at 10ASF, and the time is 40min, so that the copper thickness reaches 9μm.

[0056] In the step of plating the protective layer, the protective layer is a tin layer, and the thickness of the tin layer is 7 μm.

[0057] In the process of making the outer pattern, when the dry film is exposed, the exposed area of the dry film is extended 3mil into the groove.

[0058] In the graphic copper-nickel-gold plating process, copper plating and nickel plating are processed according to conventional processes. The conditions for gold plating are to control the current density to 2ASF for 90 seconds, so that the thickness of the gold layer reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com