Non-magnetic cube texture Cu-based alloy composite base band and preparation method thereof

A composite baseband and cubic texture technology, applied in metal rolling, chemical instruments and methods, metal layered products, etc., can solve the problems of low mechanical strength and inability to meet high texture and high strength at the same time, and achieve Improve mechanical strength and ensure non-magnetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

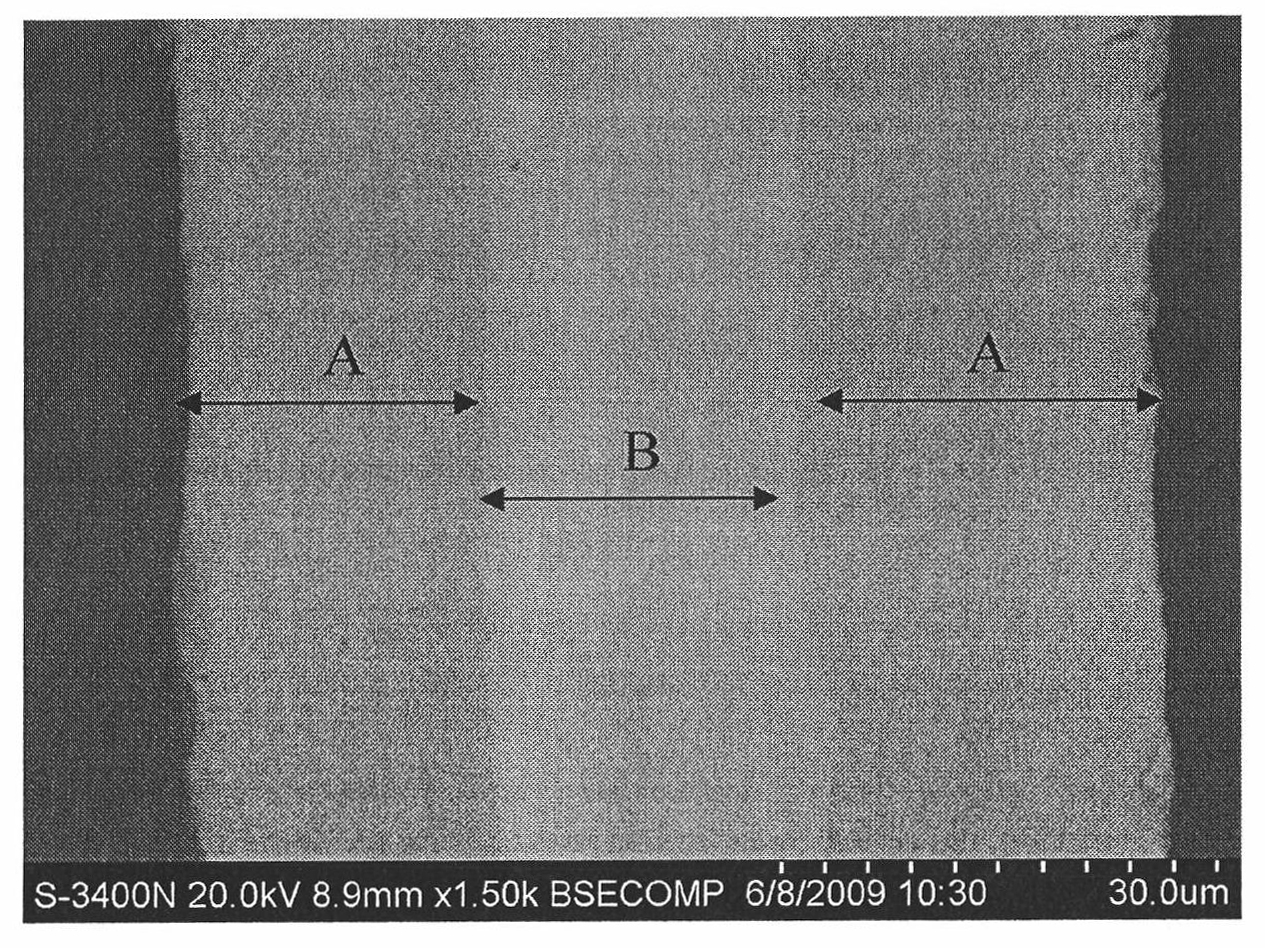

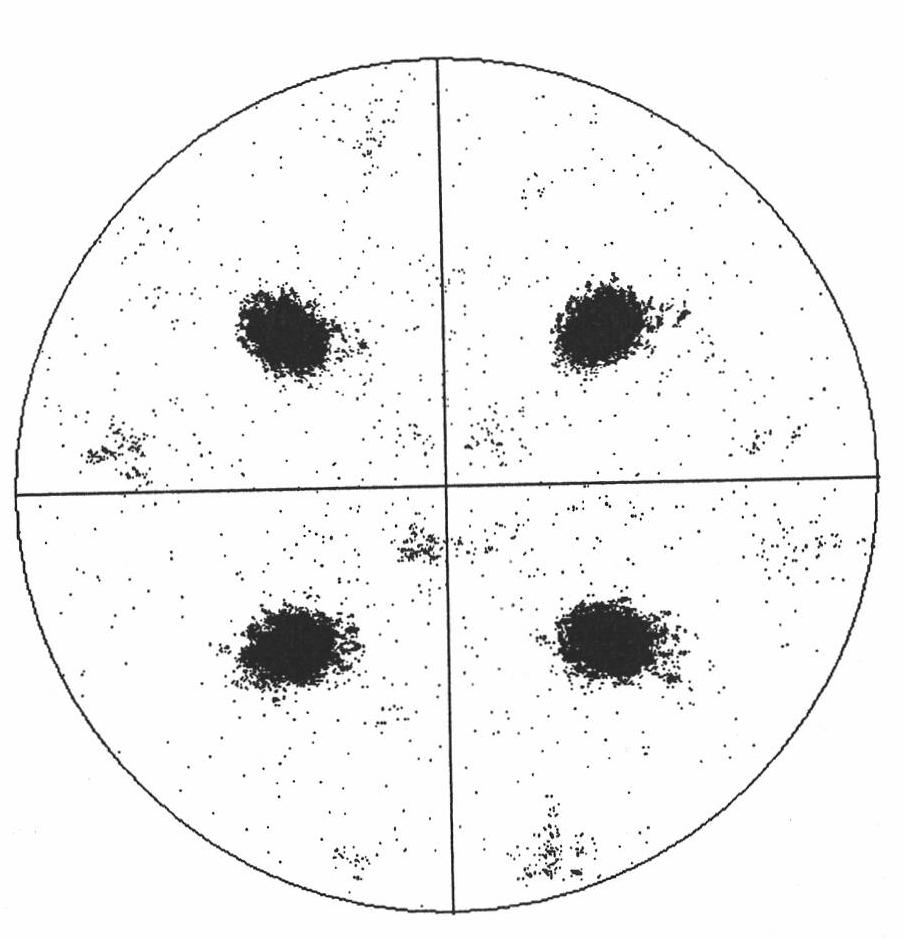

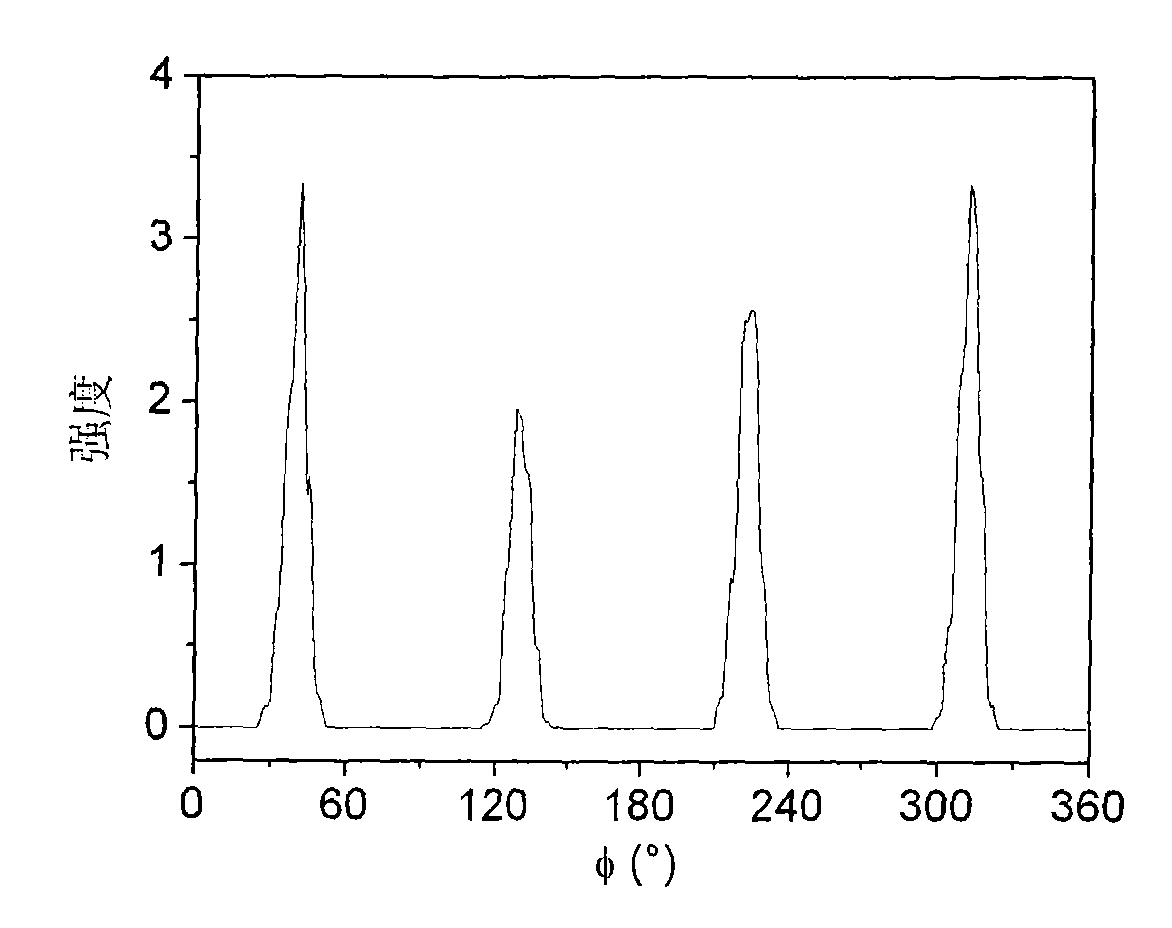

[0023] The NiW powder (code B powder) with a W atomic percentage of 9% and the CuNi powder (code A powder) with a Ni weight percentage of 40% were subjected to high-energy ball milling respectively, and the ground powder was in the order of A-B-A Layered into the mold; using spark plasma sintering technology, put the mold filled with layered powder into the sintering equipment (SPS-3.20-MV spark plasma sintering equipment made in Japan), and pressurize it under vacuum conditions. Sintering, wherein, the sintering pressure is 30Mpa, the sintering temperature is 800°C, and the holding time is 30min; the sintered composite billet is cold-rolled, the deformation of each pass is 5-15%, and the total deformation is greater than 95%, and the thickness is obtained It is 80um cold-rolled base strip; the cold-rolled base strip is annealed at 850°C for 1h, and the protective atmosphere is Ar / H 2 , to obtain the final product Cu-based alloy composite substrate. The yield strength of the ...

Embodiment 2

[0025] Carry out high-energy ball milling with NiW powder (code name B powder) with a W atomic percentage content of 10% and Ni with a weight percentage content of 40% (code name A powder), and divide the ground powder in the order of A-B-A The layer is placed in a rubber mold, and then the rubber mold filled with powder is put into a cold isostatic press for compression molding, wherein the pressure is 250MPa, and the pressure is maintained for 5min. Subsequently, the formed compact is placed in an Ar / H2 protective atmosphere Sintering at 1000°C for 10h, cold-rolling the sintered composite ingot, the deformation of each pass is 5-15%, the total deformation is greater than 95%, and the thickness of the cold-rolled base strip is 100um; the cold-rolled base strip is at 800°C, Insulation annealing for 1h, the protective atmosphere is Ar / H 2 , to obtain the final product Cu-based alloy composite substrate. The yield strength of the composite base belt is shown in Table 1.

Embodiment 3

[0027] The NiW powder (code name B powder) with a W atomic percentage of 12% and the CuNi powder (code name A powder) with a Ni weight percentage of 40% are respectively subjected to high-energy ball milling, and the ground powder is in the order of A-B-A Layered into the mold; using spark plasma sintering technology, put the mold filled with layered powder into the sintering equipment (SPS-3.20-MV spark plasma sintering equipment made in Japan), and pressurize it under vacuum conditions. Sintering, wherein, the sintering pressure is 50Mpa, the sintering temperature is 850°C, and the time is 30min; the sintered composite ingot is cold-rolled, the deformation of each pass is 5-15%, and the total deformation is greater than 95%, and the obtained thickness is 100um cold-rolled base strip; the cold-rolled base strip is annealed at 800°C for 1 hour, and the protective atmosphere is Ar / H 2 , to obtain the final product Cu-based alloy composite substrate. The yield strength of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com