Patents

Literature

56results about How to "High quality and purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glassy ganoderm spore powder breeding and collecting technique

This invention relates to lucid ganoderma spore powder culturing and collecting technology. It includes the tree seed choosing, loping, cutting, packaging sterilization, inoculation, hyphae culturing, burying, ganoderma management and spore powder culturing and collecting, and the powder culturing and collecting includes the following procedures: material preparation, film laying, packaging and sleeving, culturing management, powder collecting, drying, sieving and storing. The spore powder of this invention is pure, the turnout is high, the economic effect is evident, and the unit output increases the selling income by more than 32% with low cost. And meanwhile, the heavy metal contents of the lucid ganoderma spore powder of this invention I controlled in the national standard.

Owner:XINGLONG SCI & TECH DEV INST LONGQUANCITY

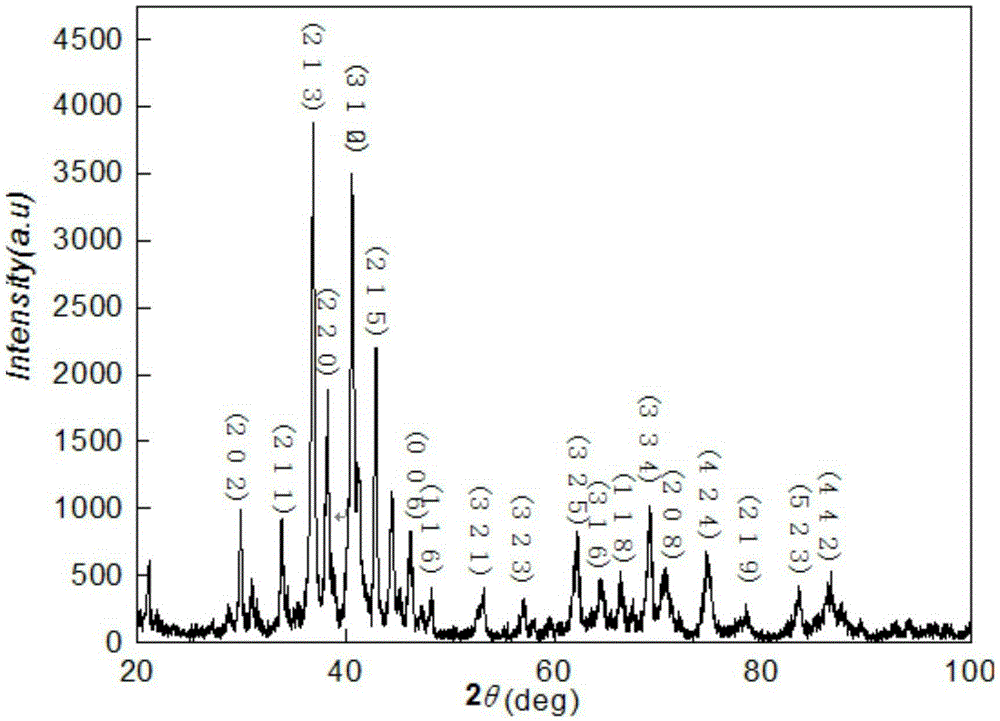

Nb-Si intermetallic compound bar and preparation method thereof

The invention discloses an Nb-Si intermetallic compound bar. The Nb-Si intermetallic compound bar is prepared from, by atomic percentage, 35%-45% of silicon, and the balance niobium and inevitable impurities. The invention further discloses a preparation method of the Nb-Si intermetallic compound bar. The preparation method includes the steps that 1, silicon powder and niobium powder are ball-milled and dried to obtain mixed powder; 2, a blank is formed after compression molding, the blank is sintered, and then an Nb-Si intermetallic compound sintered body is obtained; 3, an Nb-Si intermetallic compound cast ingot is obtained after electric arc melting, and a semi-finished bar is obtained after cutting; and 4, the Nb-Si intermetallic compound bar is obtained after electron beam zone melting. The Nb-Si intermetallic compound bar has the beneficial effects of being high in quality and purity, low in oxygen mass content and uniform in component distribution, the bar is further crushed into powder to serve as a raw material for preparing a high-temperature oxidation-resistant coating and also serve as a strengthening phase of a super-high-temperature oxidation-resistant material, and broad application prospects are achieved in the aerospace field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

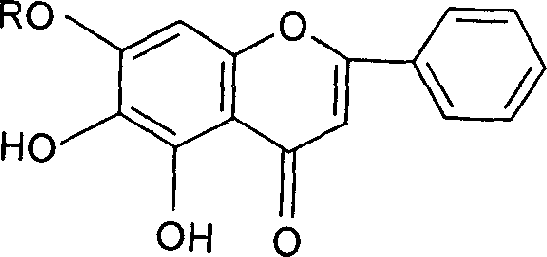

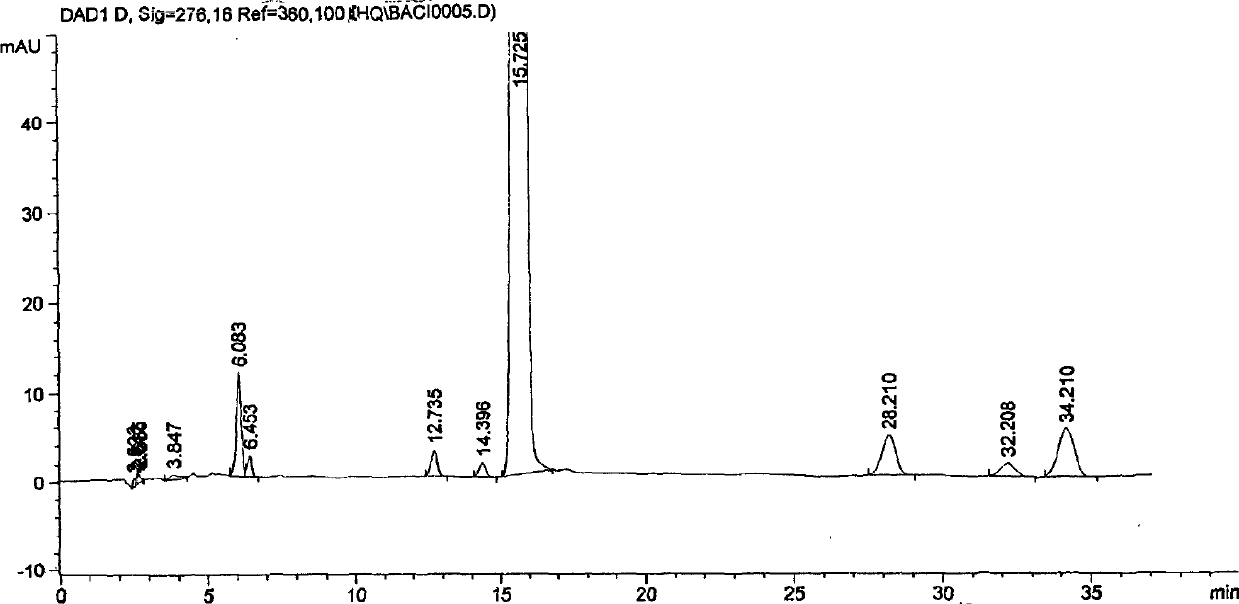

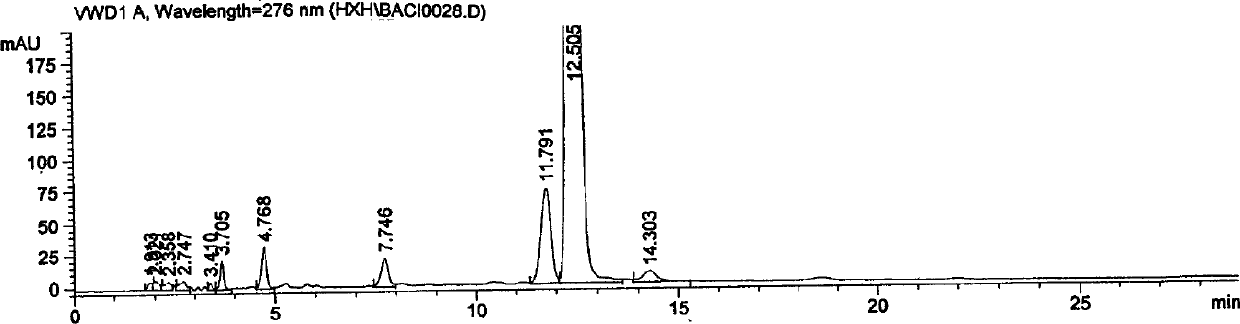

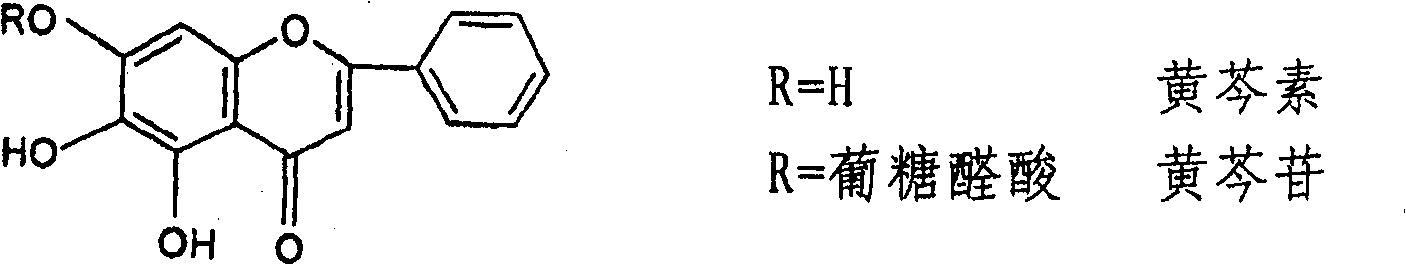

Process for preparing high purity scutellarin

InactiveCN1683356ALow reaction temperatureShort reaction timeOrganic chemistryScutellarinAqueous solution

The present invention discloses preparation process of high purity scutellarin from baicalin. Baicalin is added into water solution of sulfuric acid and reacted at 50-70 deg.c for 10-15 min to obtain separated coarse crystal product; and the coarse product is purified with acetone to obtain high purity scutellarin. Thus prepared scutellarin product, high efficiency liquid phase test process shows, has scutellarin content of 96 % or over. The process has short reaction time, mild reaction condition, simplicity and low cost, and is suitable for industrial production.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

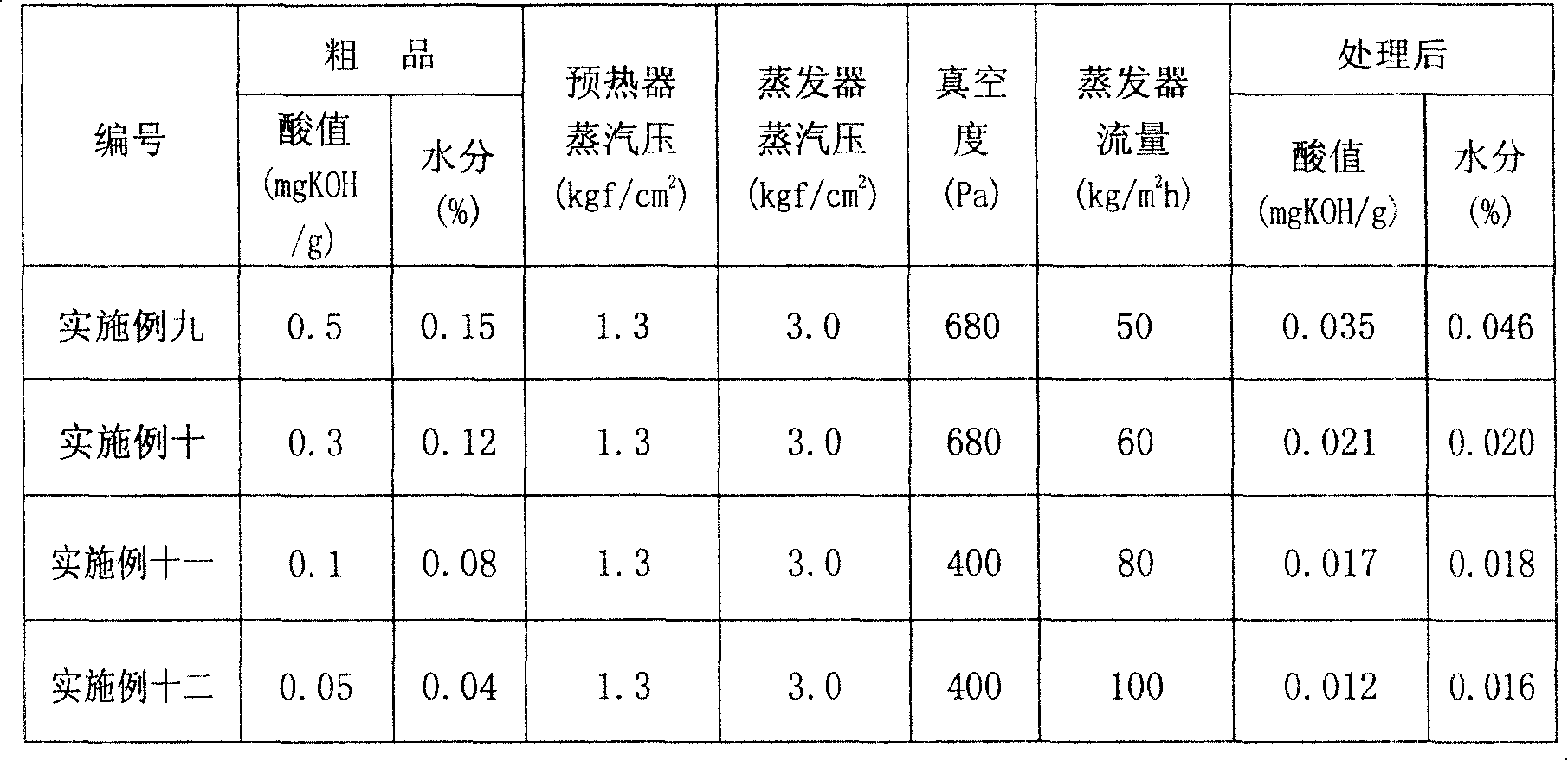

Method for purifying glyceryl triacetate

ActiveCN101205184AHigh quality and purityReduce acidityOrganic compound preparationCarboxylic acid esters preparationChemical industrySteam pressure

A method for purifying the glyceryl triacetate belongs to the field of the separation and purification in the chemical industry and comprises the following steps: (1) the crude products of the glyceryl triacetate are first prepared and the acidity of the crude products is controlled to range from 0.003 per cent to 1 per cent; (2) the crude products are subject to the secondary treatment utilizing a film evaporator, the vacuum degree is controlled to range from 100Pa to 13,300Pa and the flow of the film evaporator ranges from 2 to 200kg / m<2> h; the film evaporator and the preheater are heated by the steam or heat conduction oil; when the steam is used for heating, the heating steam pressure of the preheater is controlled to range from 0.5 kgf / cm<2> to 1.5kgf / cm<2> and the steam pressure of the evaporator ranges from 2.0kgf / cm<2> to 4.0kgf / cm<2>; when the heat conduction oil is used for heating, the temperature of the heat conduction oil ranges from 120 to 160 DEG C. The process delivers high treatment efficiency, the quality purity of the obtained glyceryl triacetate is obviously enhanced, the acidity can be lowered to be lower than 0.002 per cent without causing any odor.

Owner:江苏雷蒙新材料有限公司

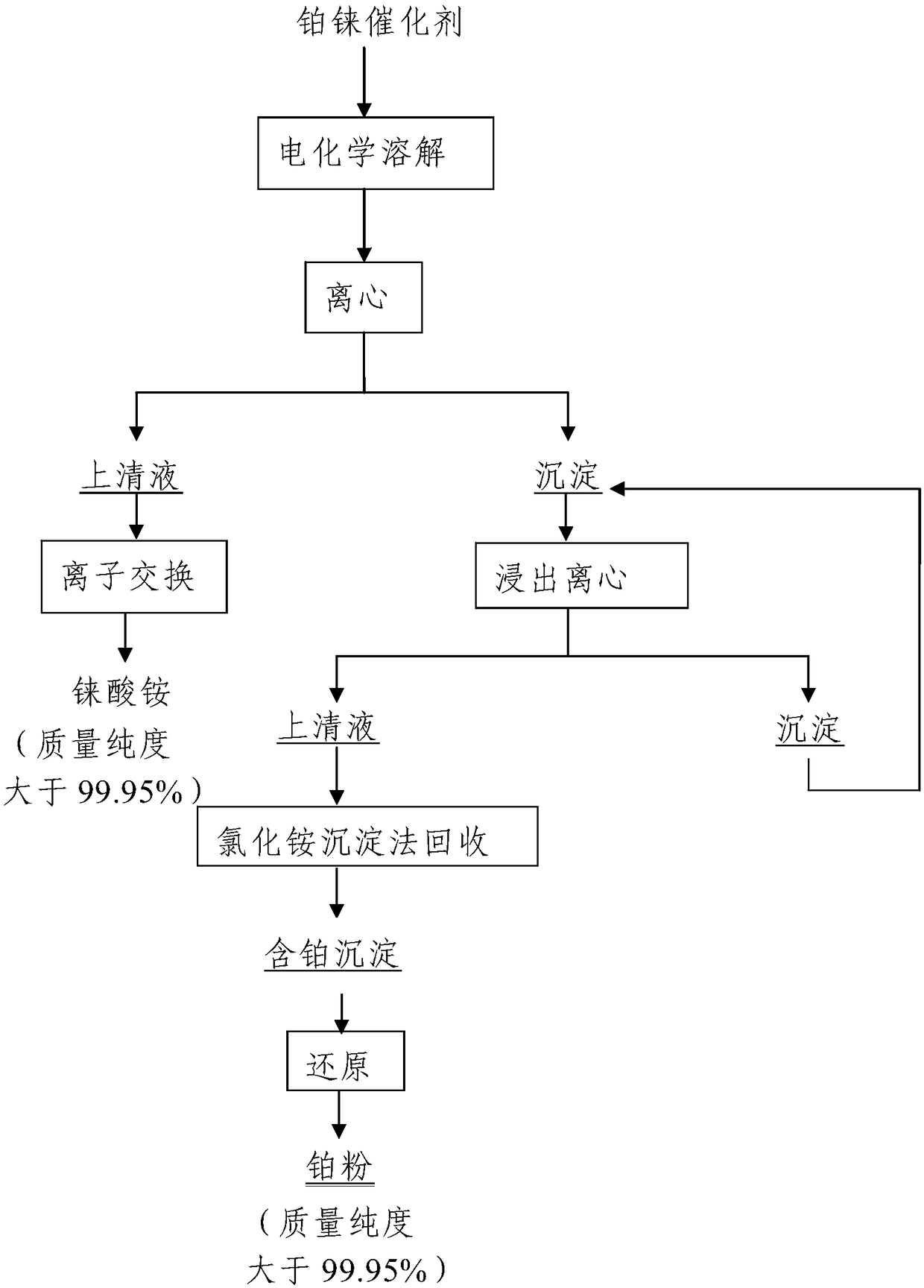

Method for recovering platinum and rhenium from platinum-rhenium catalyst

InactiveCN108277356AEasy to separateImprove leaching rateElectrolysis componentsProcess efficiency improvementRheniumDesorption

The invention discloses a method for recovering platinum and rhenium from a platinum-rhenium catalyst. The method comprises the following steps of 1, carrying out electrodissolution reaction on the platinum-rhenium catalyst so as to obtain slurry; 2, centrifuging the slurry so as to obtain supernatant and precipitates; 3, adjusting the pH value of the supernatant to be 1-4 and then carrying out adsorption with resin; 4, after mixing ammonia water and an ammonium chloride solution, carrying out desorption on the resin subjected to absorption and carrying out evaporation and concentration on anobtained desorption solution so as to obtain ammonium rhenate; and 5, leaching the precipitates by using aqua regia, carrying out centrifuging to obtain supernatant, obtaining platinum-contained precipitates from the supernatant by adopting an ammonium chloride precipitation method and then carrying out hydrazine hydrate reduction so as to obtain platinum powder. The method has the advantages thatthe rhenium in the platinum-rhenium catalyst is selectively dissolved through electrochemical action, so that the rhenium and the platinum are separated and then are recovered separately through an ion exchange method and an aqua regia dissolution-ammonium chloride precipitation method, and therefore the separation efficiency of the rhenium and the platinum can be improved, and the quality and the recovery rate of obtained products are relatively high.

Owner:XIAN RAREALLOYS

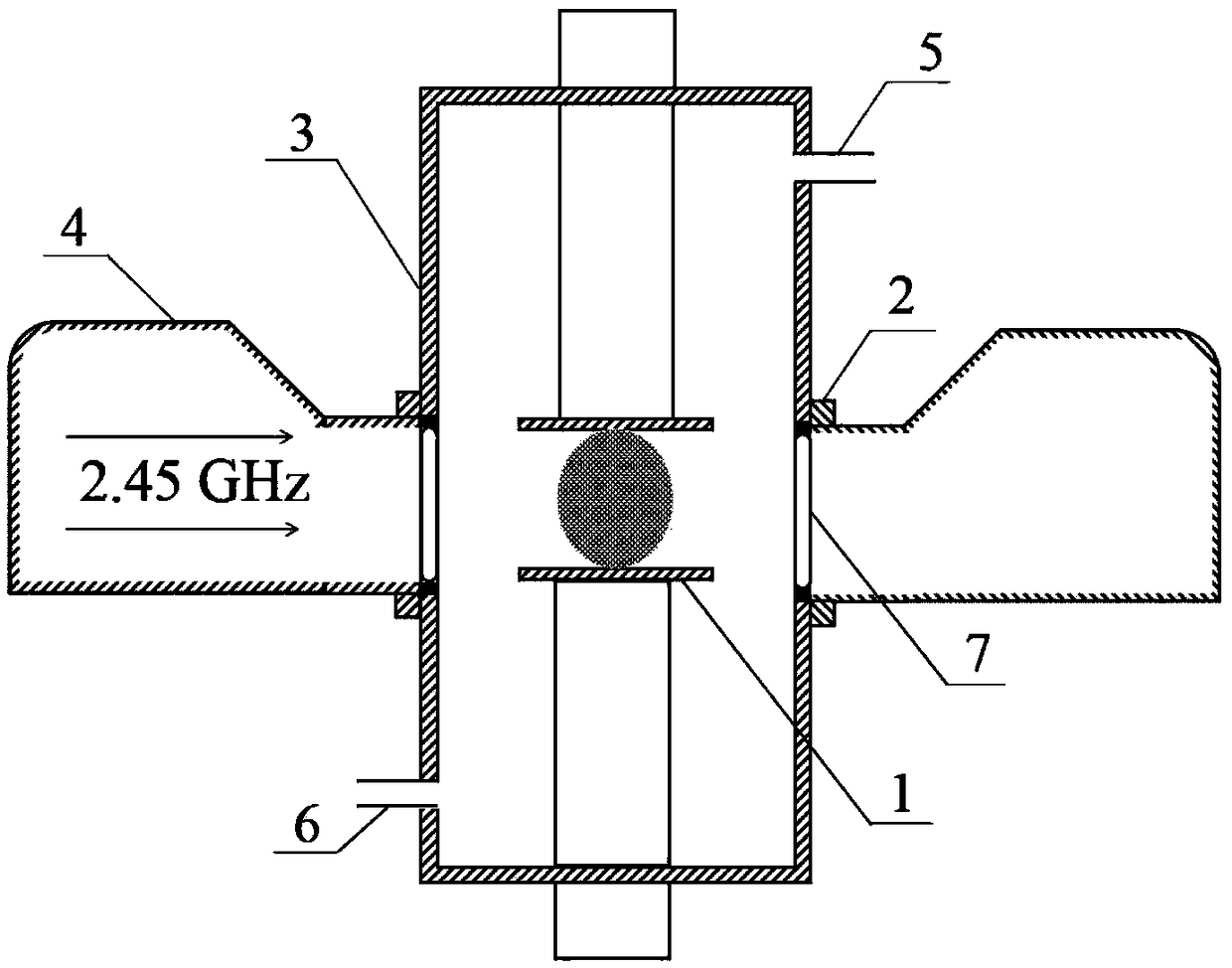

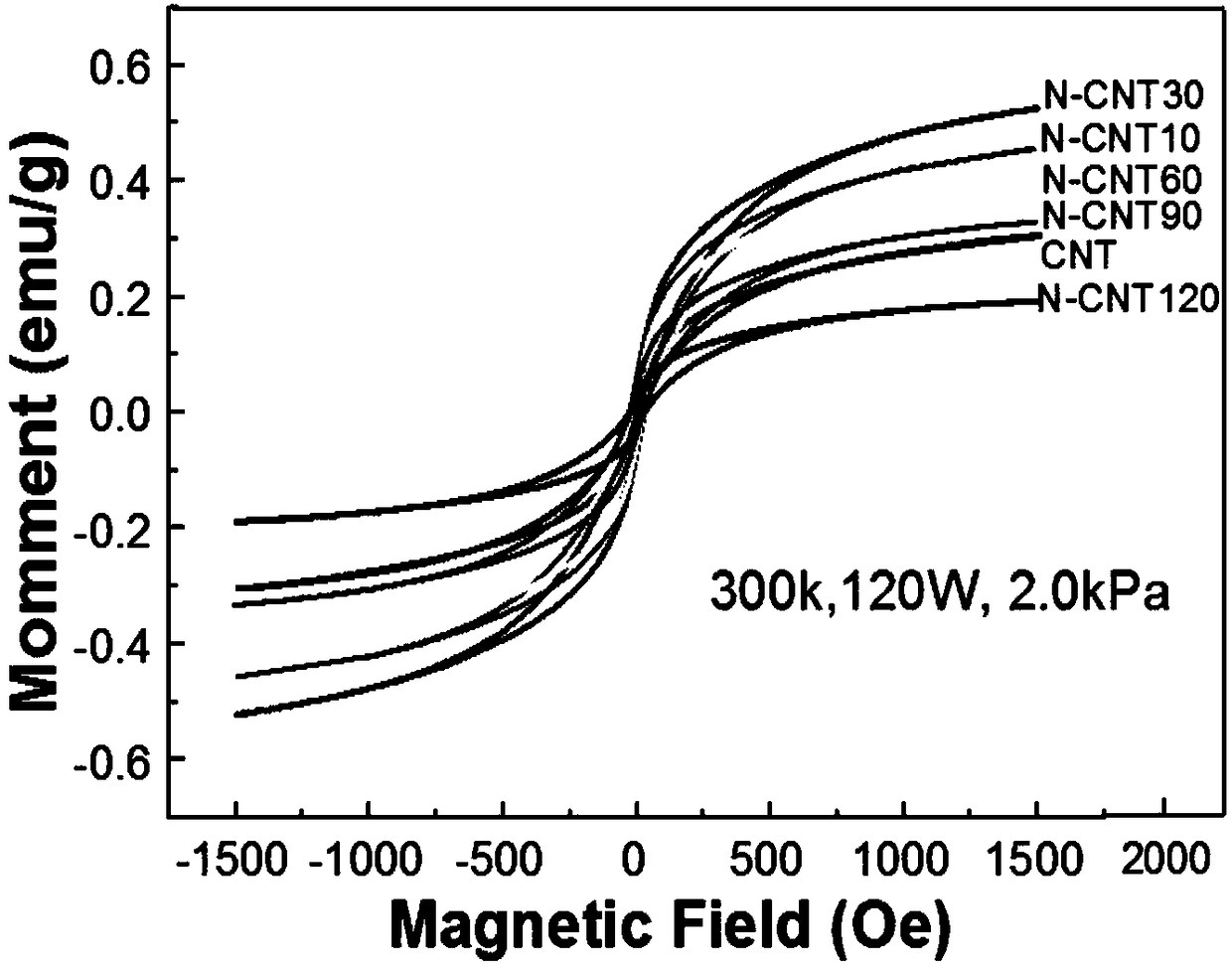

Method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition

InactiveCN108190862AIncrease the chance of ionizationLow deposition pressureCarbon nanotubesNitrogen doped carbon nanotubeChemistry

The invention discloses a method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition. The method comprises the following steps that carbon nanotube powder is placed in a closed cavity, and the cavity is vacuumized; nitrogen gas is introduced to the cavity, the flow rate and air pressure of the nitrogen gas are adjusted, and meanwhile microwave irradiation is conducted to make the gas in the cavity absorb microwave energy and be excited to generate plasma; nitrogen atoms after plasma treatment can be doped into the surfaces and internal structures of carbon nanotubes to form the nitrogen-doped carbon nanotubes, and by controlling the microwave power and nitrogen doping time, the nitrogen carbon nanotubes with different nitrogen contents are obtained.A nitrogen gas source is subjected to plasma treatment by adopting a microwave plasma technology. Since the microwave power and the energy density are high and radical groups have high activity, thegas can be easily dissociated; the nitrogen carbon nanotubes prepared by means of the method are high in quality and purity and facilitates the test and characterization of ferromagnetic properties, optical properties and other properties, and prepared samples show good ferromagnetism.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

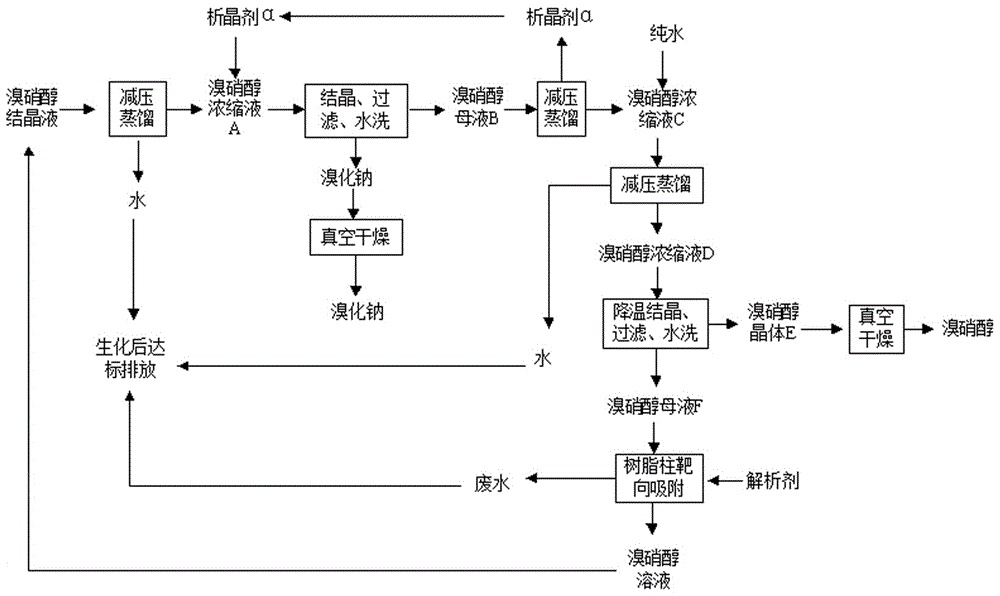

Bronopol refining process

ActiveCN106631813AHigh quality and purityImprove qualityOrganic chemistryOrganic compound preparationBronopolDistillation

The invention discloses a bronopol refining process. The process comprises the following steps: performing reduced pressure distillation on a bronopol crude product crystalline liquid prepared by a conventional method to obtain a concentrate, adding crystallization agent into the concentrate, and crystallizing to obtain a sodium bromide product; further distilling the mother solution, adding pure water, and crystallizing to obtain a bronopol product; and performing resin adsorption on the residual bronopol in the obtained mother solution, resolving, and returning to the bronopol crude product crystalline liquid, wherein in the whole technical process, no loss of bronopol exists, and wastewater is directly subjected to biochemical treatment. According to the invention, sodium bromide and bronopol products with purities of 99% or above can be obtained, and the yield of the bronopol is more than 99%.Compared with the existing one-step reduced pressure distillation and crystallization process, the bronopol refining process increases the bronopol yield and lowers the bronopol and sodium bromide contents in wastewater, so that the wastewater can be directly discharged into a biochemical system, thereby lowering the wastewater treatment cost and reducing environmental pollution.

Owner:河北美邦工程科技股份有限公司

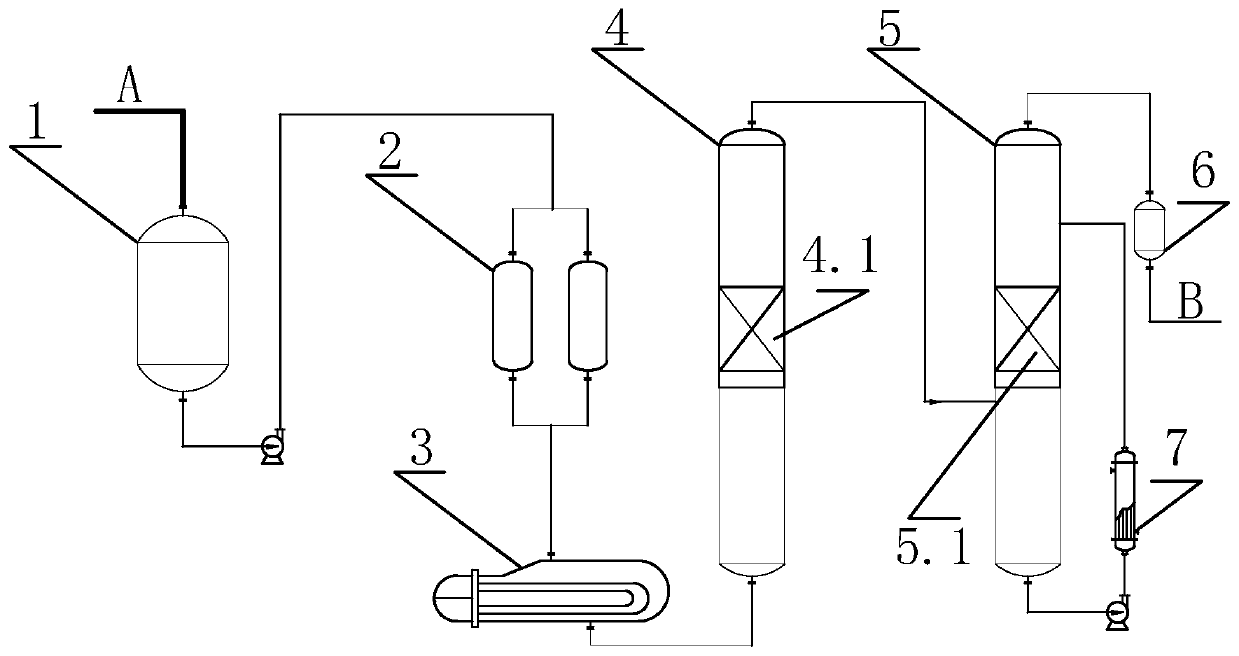

Production system of electronic grade isopropanol

PendingCN111517917AStable chemical structureImprove solubilityOrganic compound preparationOther chemical processesMolecular sieveSpecific surface energy

The invention relates to the technical field of manufacturing of electronic-grade isopropanol. Aiming at solving the problem that the process steps of the isopropanol preparation process are tedious,the invention discloses a production system of electronic grade isopropanol. The production system comprises a raw material conveying unit, a molecular sieve adsorption unit, an evaporation tank, a first rectification unit, a second rectification unit and a filtering unit, which are sequentially connected. A modified adsorption material is arranged in the molecular sieve adsorption unit, a first rectification filler area is arranged in the first rectification unit, a second rectification filler area is arranged between an inlet and an outlet in the inner side of the second rectification unit,the raw material conveying unit is further provided with a feed port A, and the filtering unit is further provided with a discharge port B. One-step dehydration is adopted in the preparation process,the modified adsorption material with magnetic directional adsorption capacity and ultra-large specific surface energy is adopted, electronic-grade isopropanol with high isopropanol purity and low metal ion content is finally obtained, the electronic-grade isopropanol with excellent stability is prepared, and the production process is simple and efficient.

Owner:浙江建业微电子材料有限公司 +1

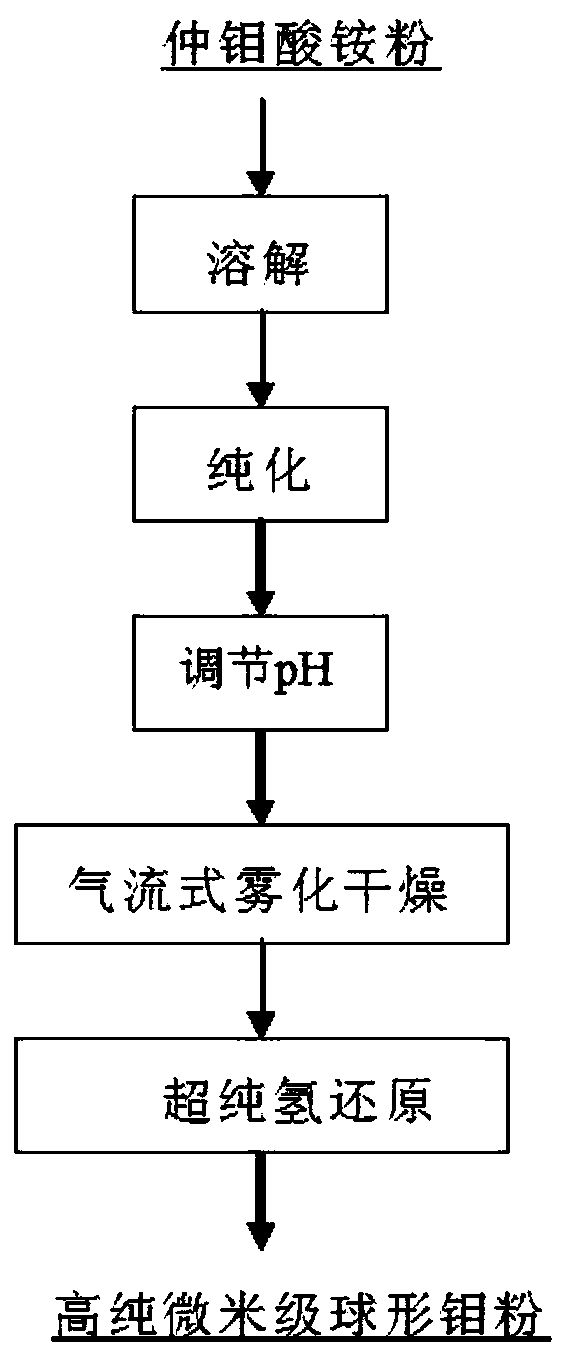

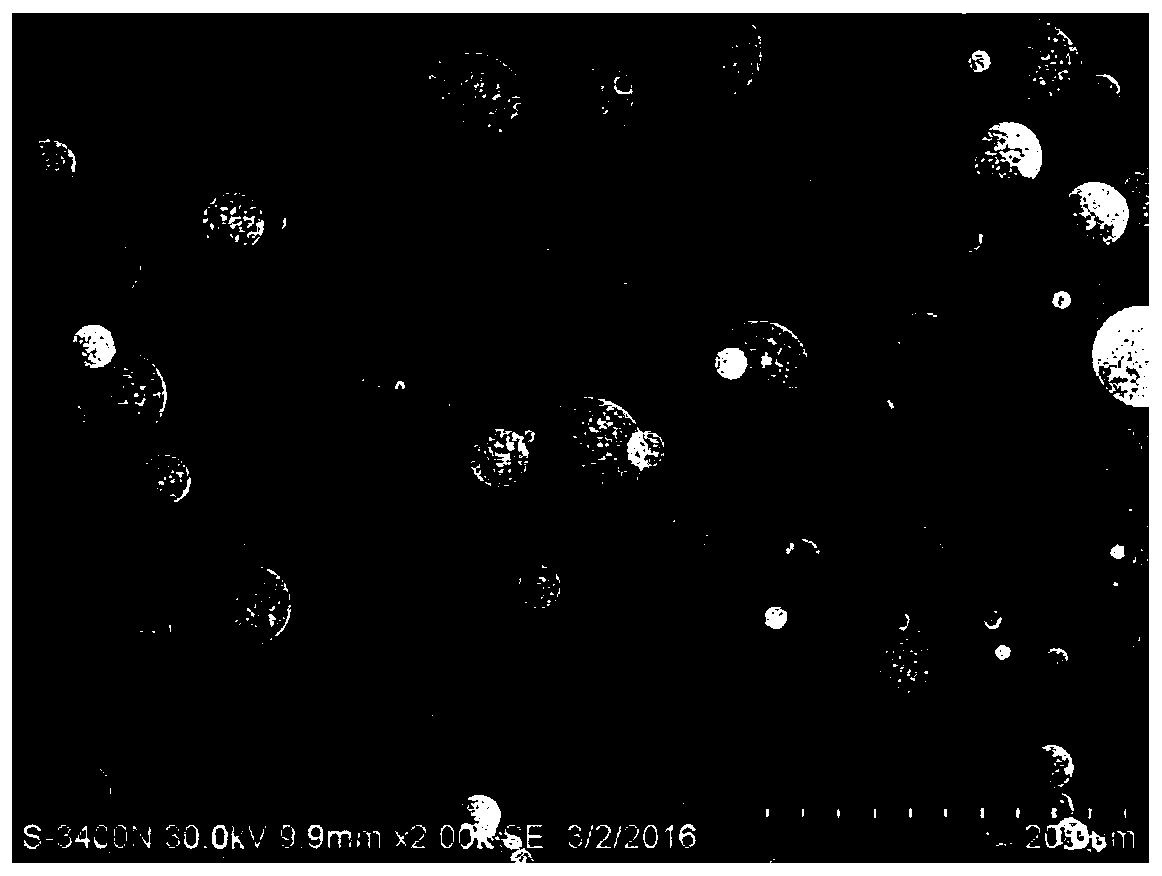

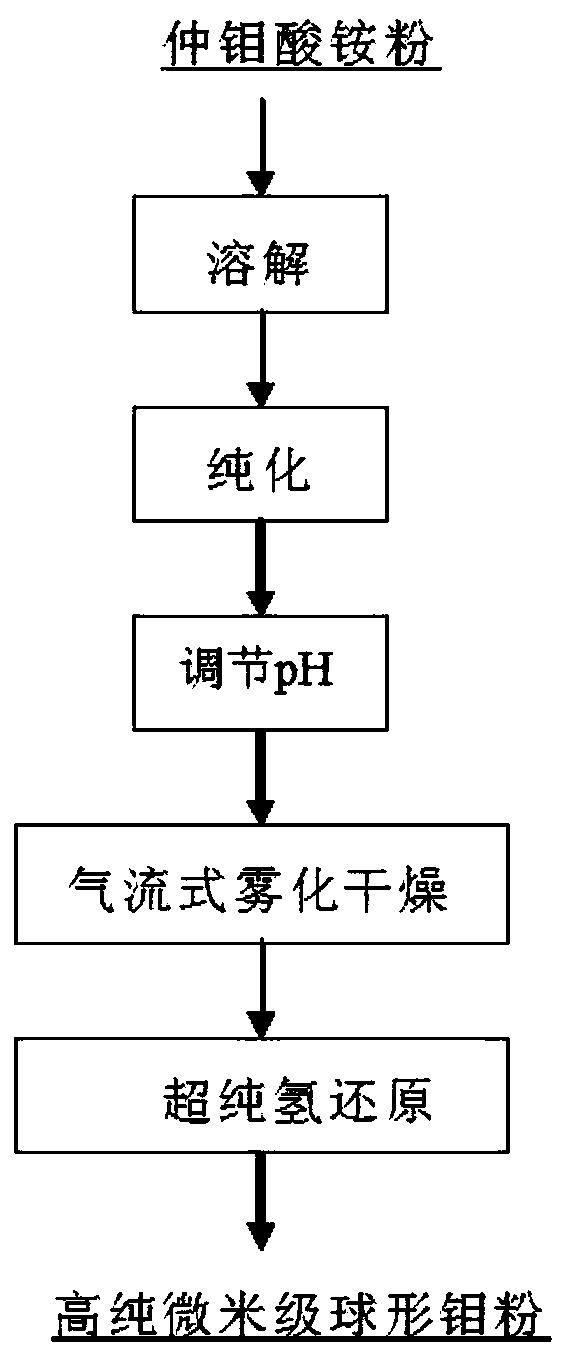

Preparation method of high-purity micron-scale spherical molybdenum powder

The invention discloses a preparation method of high-purity micron-scale spherical molybdenum powder. The preparation method comprises the following steps of S1, sequentially dropwise adding ammoniumhydroxide into ammonium paramolybdate and ageing, carrying out purification by a resin column adsorption to obtain a purified ammonium paramolybdate solution; S2, adjusting the pH of the purified ammonium paramolybdate solution to be neutral, adding citric acid to adjust the pH value to be 1.0; S3, carrying out airflow-type atomization on the purified ammonium paratungstate solution with the pH value of 1.0 to obtain ammonium paramolybdate powder; and S4, placing the ammonium paramolybdate powder in a tubular rotary furnace to be reduced to obtain the molybdenum powder. According to the method, ammonium paramolybdate is prepared into a solution to purify, the quality purity of the molybdenum powder is improved from the source, then the surfactant citric acid is added, the surface tension of the purified ammonium paramolybdate solution is reduced, more uniform drops with higher spherical degree, smaller particle size of the ammonium paramolybdate solution is generated in the airflow type atomization process, so that the spherical degree of the molybdenum powder is improved, molybdenum powder which is high in purity, micron-sized and uniform in particle size distribution is obtained;and meanwhile, the granularity controllability of the molybdenum powder is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for purifying acetyl citrate

ActiveCN101205185ALess impuritiesReduce moistureOrganic compound preparationCarboxylic acid esters preparationAcetic anhydrideCITRATE ESTER

A method for purifying the acetyl citrate relates to the purification technique and comprises the following steps: (1) the citrate reacts with an excessive amount of acetic anhydrides and then is preliminarily dehydrated in a reaction vessel on the vacuum condition after being deacidified, neutralized and washed so as to obtain the crude products of the acetyl citrates; (2) the crude products are subject to the secondary treatment utilizing a film evaporator, the vacuum degree is controlled to range from 100Pa to 13300Pa and the flow of the film evaporator ranges from 2kg / m<2> h to 200kg / m<2> h; the film evaporator and the preheater are heated by the steam or heat conduction oil; when the steam is used for heating, the heating steam pressure of the preheater is controlled to range from 0.5kgf / cm<2> to 1.5kgf / cm<2> and the steam pressure of the evaporator ranges from 2.0 to 5.0kgf / cm<2>; when the heat conduction oil is used for heating, the temperature of the heat conduction oil ranges from 100 to 140 DEG C. The method is very effective for reducing the purities in the acetyl tri-n-butyl citrate and lowering the water and acid value so as to enhance the quality purity of the acetyl citrate.

Owner:江苏雷蒙新材料有限公司

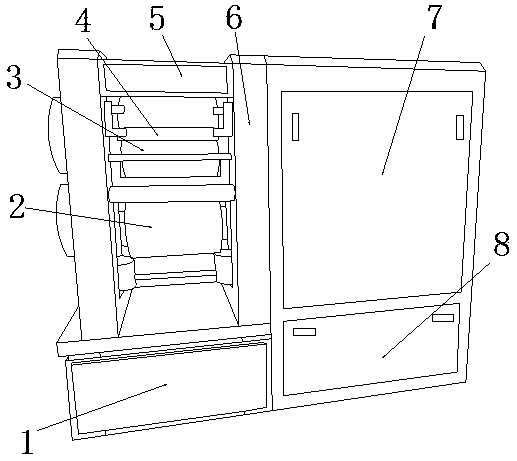

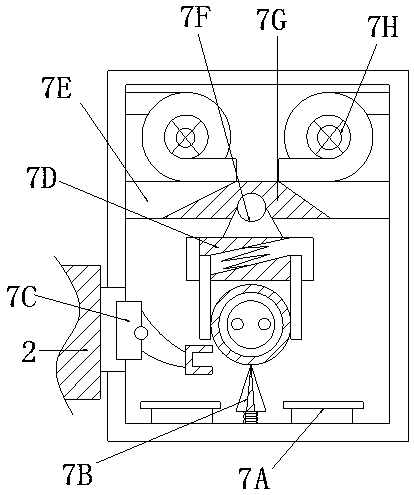

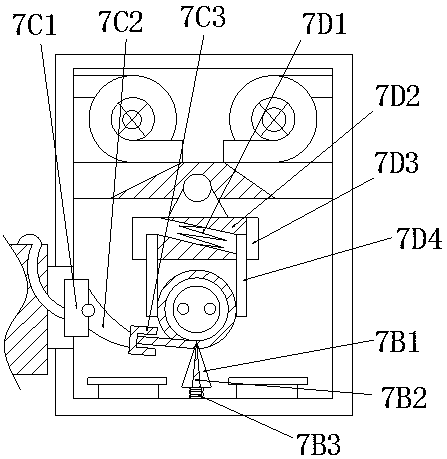

Recovery device for anode and cathode materials of lithium ion battery

ActiveCN110336091AReduced pollutionImprove recycling rateSolid waste disposalWaste accumulators reclaimingEngineeringLithium-ion battery

The invention discloses a recovery device for cathode and anode materials of a lithium ion battery. The structure of the recovery device comprises a motor bottom case groove, a polar plate winding drum, a grinding roller, a clamping shaft frame, a beam plate, a side ring slot vertical plate, a drawer plate cut-off cabinet and a heat exchange bottom groove. The recovery device achieves that the polar plate winding drum and the drawer plate cut-off cabinet are matched to pull out the cathode and anode material rolled plates of the lithium ion battery, the stretched surface enters the polar platewinding drum and the upper and lower sliding surfaces of the grinding roller to press and rotate a surface-grinding cleaning block layer, the effects of eliminating and cleaning the thickness of an upper additive and a lower additive and sweeping powder particles on the surface of an iron-copper incineration plate are formed, a cathode and anode material plate recycling and outputting effect is formed, and after the cathode and anode material plates of the battery are pulled out, the splitting hydrolysis operation of the lithium battery is supported, the free state of organic matters with chemical properties can be decomposed and ionized, the cathode and anode plates of the lithium ion battery taken out from a terminal can be forged, remelted and deformed, the recycling utilization rate is high, the pollution degree of the battery is low, and the environment-friendly treatment is achieved.

Owner:YANGTZE NORMAL UNIVERSITY

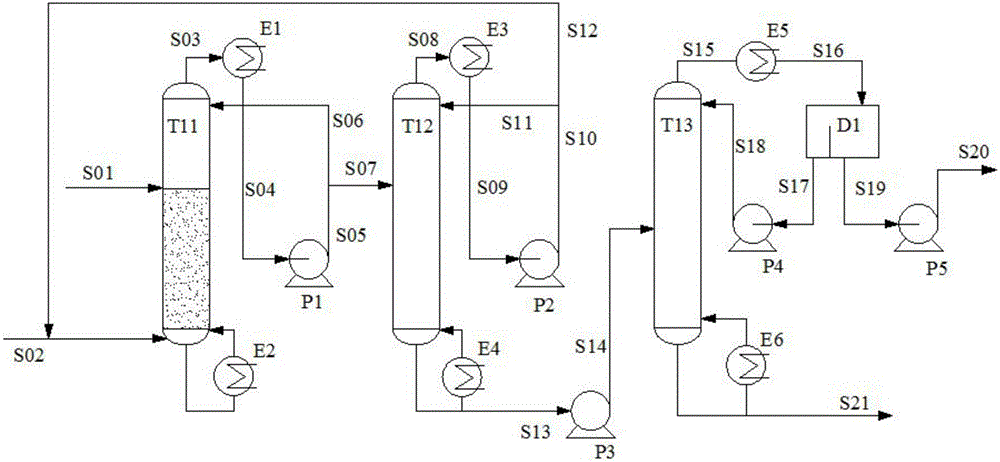

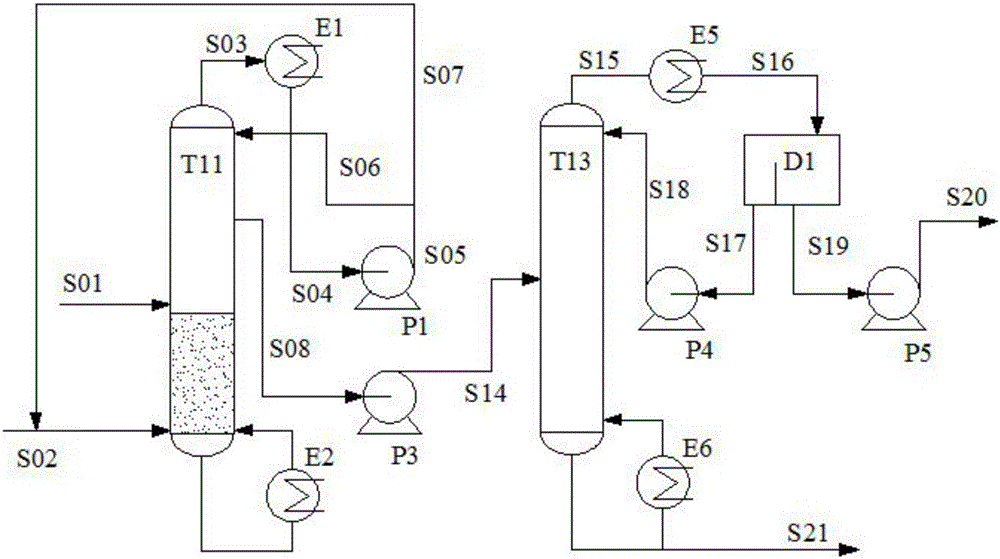

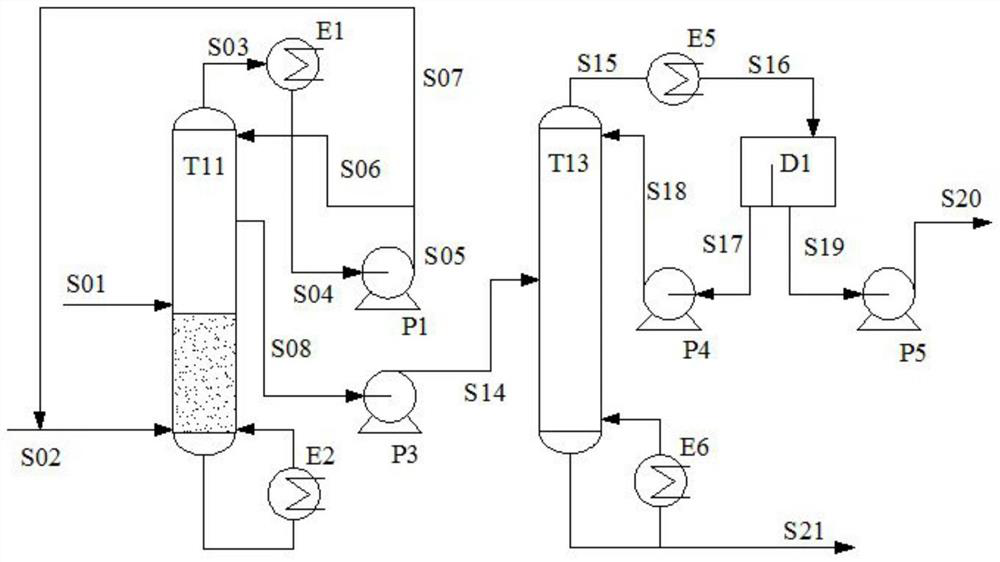

Reactive distillation method and device for 4EMD (4-ethyl-2-methyl-1,3-dioxolame) production

ActiveCN105693686ALess investment in equipmentReduce energy consumptionOrganic chemistryChemical industryEthyl phosphateChemistry

The invention relates to a reactive distillation method and device for 4EMD (4-ethyl-2-methyl-1,3-dioxolame) production. A reactive distillation tower comprises a distillation section and a reactive distillation section, wherein a 1,2-butanediol feed port is formed in the top of the reactive distillation section, acetaldehyde is fed into tower bottom, a reaction product is produced from tower top and enters an acetaldehyde recovery tower for acetaldehyde separation, a 4EMD and water mixture after acetaldehyde separation enters a distillation tower through a tower top phase splitter or one tower plate of the 4EMD distillation tower, by means of the tower top phase splitter, an organic phase flows back, an aqueous phase is produced, and a 4EMD product is obtained from the tower bottom. The method and the device have the advantages that the reaction and the separation coupling are performed in the same equipment simultaneously, so that the equipment investment can be saved, energy consumption can be reduced, the forward reaction is promoted, and a high reaction conversion rate is acquired. By means of the phase splitter arranged at the tower top, water can be removed very well, the 4EMD product with high purity is obtained, and meanwhile, the high recovery rate of the 4EMD product can be guaranteed.

Owner:TIANJIN UNIV

An anti-staining and color-protecting laundry detergent

ActiveCN104450278BGood anti-stick effectAvoid stainsOrganic detergent compounding agentsSurface-active detergent compositionsLaundryFatty acid methyl ester

The invention relates to the technical field of laundry detergent, in particular to an anti-staining and color-protecting laundry detergent, which comprises the following raw materials in percentage by weight: anti-staining agent 2-10%, polyoxyethylene alkyl alcohol ether 5-15%, polyoxyethylene laurel Amide 5‑15%, fatty acid amide 2‑10%, sodium fatty acid methyl ester sulfonate 5‑10%, sodium xylene sulfonate 1‑5%, pigment 0.01‑0.05%, essence 0.1‑0.5%, deionized water quantity. The laundry detergent of the present invention is mainly composed of mild and low-irritation nonionic surfactants, compounded with anionic surfactants with excellent decontamination, emulsification and foaming capabilities, and has better anti-staining and color protection effects. When the clothes are washed together, it can prevent the clothes from staining during washing; low foam and easy to rinse, can effectively remove stubborn stains on the clothes; deep cleansing, making the washed clothes whiter and more colorful; skin care antibacterial, pH value is neutral, Mild and non-irritating, highly effective sterilization, does not hurt the skin.

Owner:东莞市广利行洗涤原料有限公司

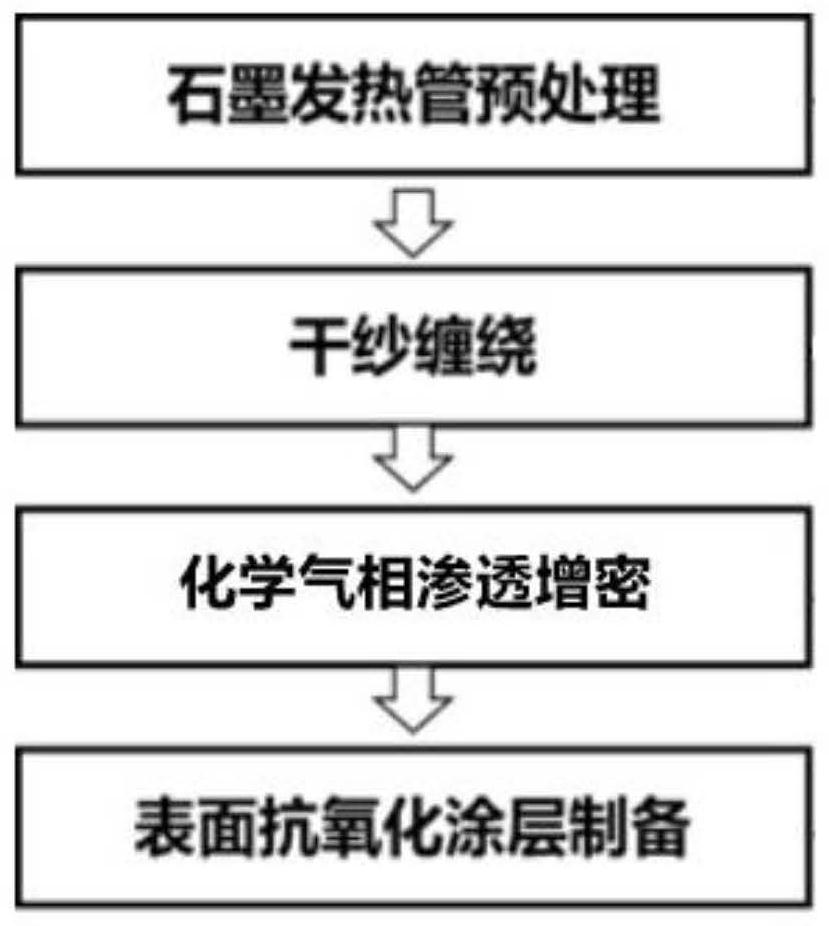

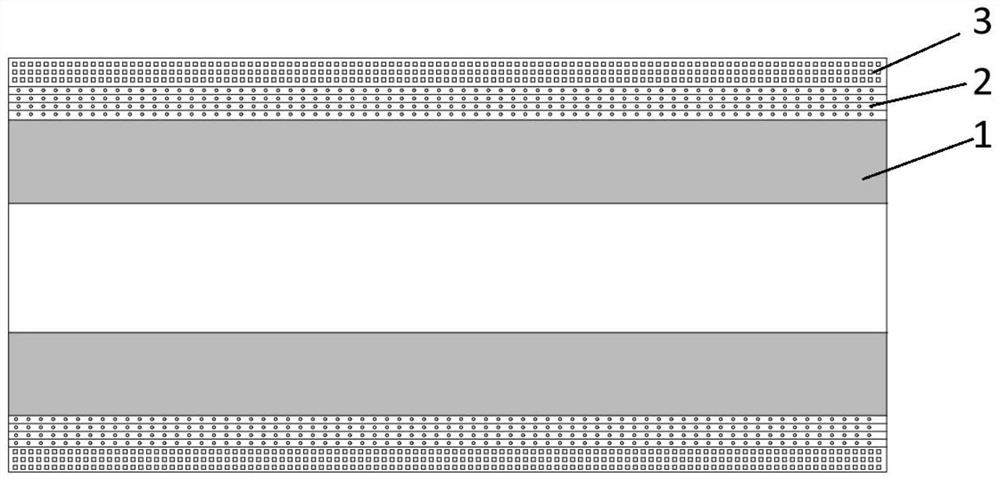

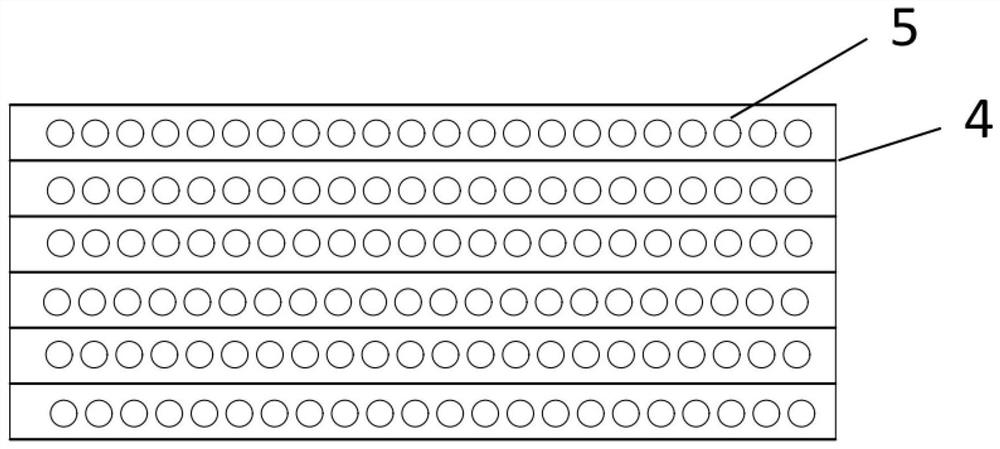

Fiber-wound reinforced graphite heating tube structure and preparation method thereof

The invention discloses a preparation method of a fiber-wound reinforced graphite heating tube structure. The method comprises the following steps: 1, pretreating a graphite heating tube; 2, winding continuous carbon fiber dry yarn onto the pretreated graphite heating tube; 3, forming a dry yarn winding reinforcing layer; 4, preparing an antioxidant coating to obtain a fiber-wound reinforced graphite heating tube structure. The invention also discloses a fiber-wound reinforced graphite heating tube structure prepared by the method. According to the invention, the pretreated graphite heating tube is subjected to dry yarn belt tension winding, and then densification and surface coating treatment are respectively carried out by sequentially combining CVI and CVD processes, so that the fiber winding reinforced graphite heating tube has better breaking strength, tensile strength, thermal shock resistance and oxidation resistance, the service life is obviously prolonged, and the preparationperiod is shortened; in addition, the fiber winding reinforced graphite heating tube is simple and reliable in structure, and meets the application requirements of various types of graphite heating tubes.

Owner:XIAN CHAOMA SCI TECH

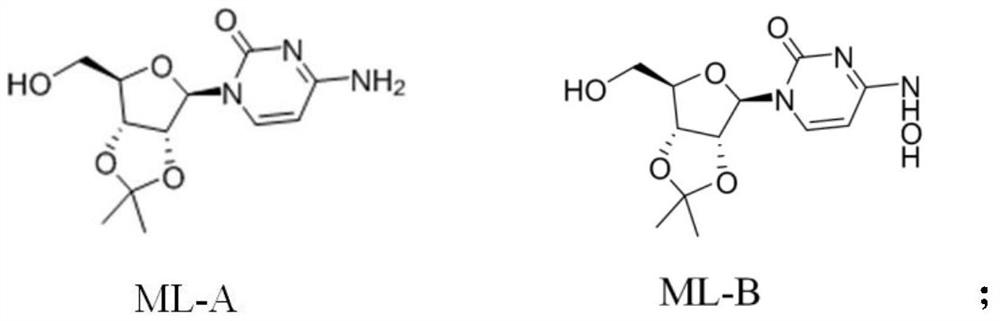

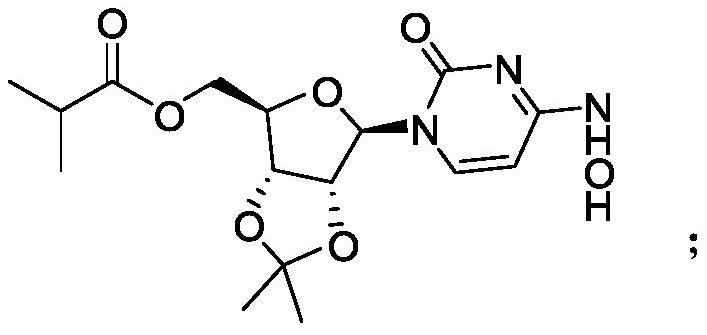

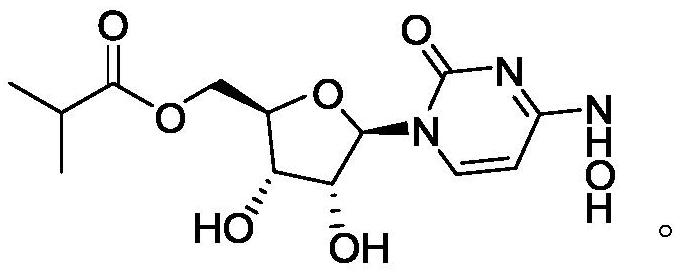

Preparation method of potential anti-new coronavirus drug monaprevir

PendingCN114315933AEasy to operateHigh yieldSugar derivativesSugar derivatives preparationBiotechnologyTrans esterification

The invention relates to a preparation method of a potential anti-new coronavirus drug monaprevir, which comprises the following process steps: step (1) synthesis of an intermediate ML-B: dissolving a material ML-A in an organic solvent, and reacting with hydroxylamine salt to obtain the intermediate ML-B; (2) synthesizing an intermediate ML-C: reacting the intermediate ML-B obtained in the step (1) with anhydride, and carrying out ester exchange to obtain the intermediate ML-C; and (3) synthesis of monaprevir: carrying out a deprotection reaction on the intermediate ML-C obtained in the step (2) to obtain monaprevir. The preparation method is simple to operate and high in yield. According to the embodiment of the invention, the product obtained by the preparation method is quite high in quality and purity, tedious product purification operation is not needed, and the production efficiency of the product is greatly improved. Therefore, the preparation method provided by the invention is a process method particularly suitable for large-scale production, and can effectively meet the current requirements.

Owner:海化生命(厦门)科技有限公司

Method for industrially preparing high-purity ergothioneine

PendingCN113666873AEasy to removeLarge amount of processingOrganic chemistryIon exchangeUltrafiltration

The invention provides a method for industrially preparing high-purity ergothioneine. The method comprises the following steps of: carrying out hot water treatment on mycelium, carrying out solid-liquid separation, and performing collecting to obtain feed liquid containing ergothioneine; carrying out vacuum concentration, filtration, ultrafiltration, decoloration, desorption and concentration on the feed liquid containing ergothioneine; performing chromatographic purification on an ergothioneine desorption concentrated solution, collecting a target peak, performing concentrating until the solution is dry, and dissolving a product in water to obtain an ergothioneine sample solution; desalting and decolorizing the ergothioneine sample solution through ion exchange resin, and performing collecting to obtain a desalted ergothioneine concentrated solution; and carrying out coarse crystallization and recrystallization on the desalted ergothioneine concentrated solution, and performing drying to obtain high-purity ergothioneine crystal powder. According to the method, a large amount of high-purity ergothioneine is prepared from the mycelia of the pleurotus ostreatus CGMCC No.23071, the product quality of the ergothioneine is ensured. The method is particularly suitable for large-scale production of the ergothioneine, so that the requirements of the product in the fields of food, cosmetics, health care, medicine and the like are met.

Owner:天津富麦生物科技发展有限公司

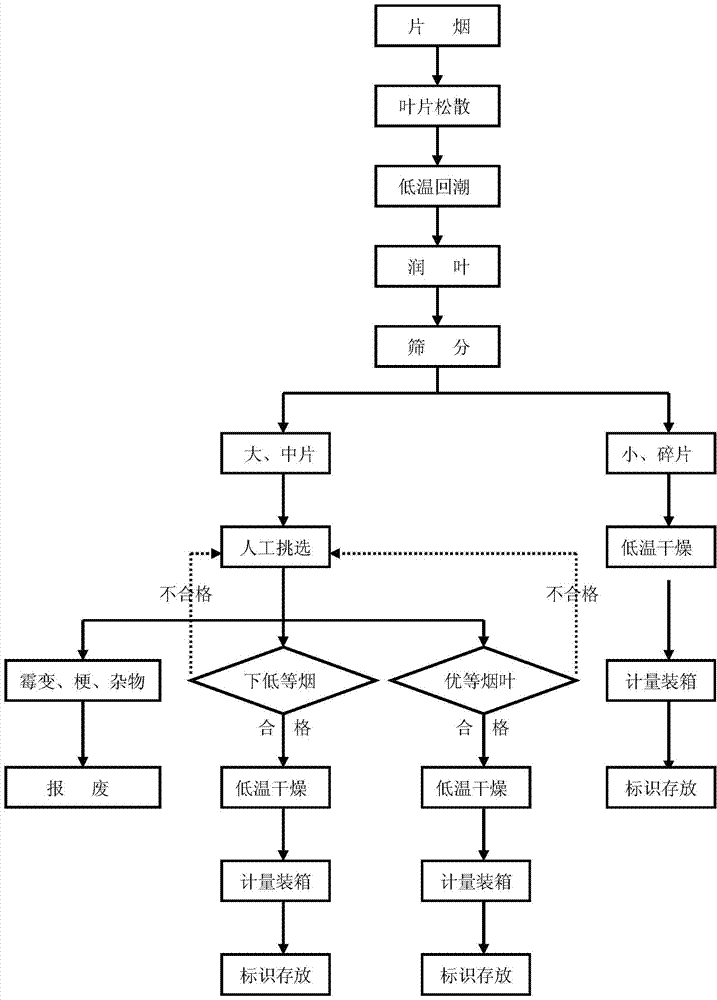

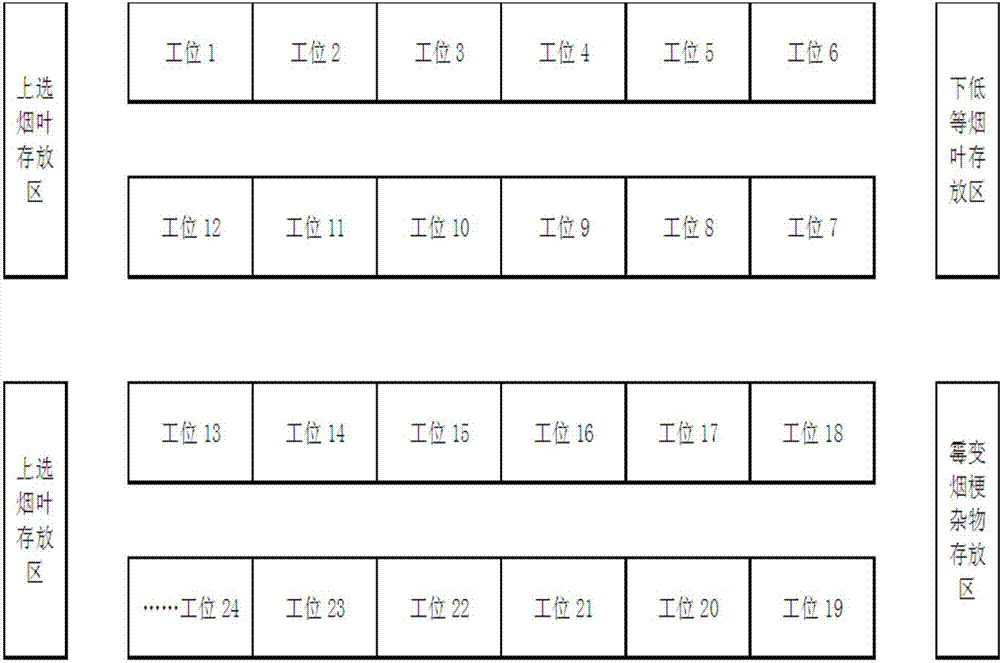

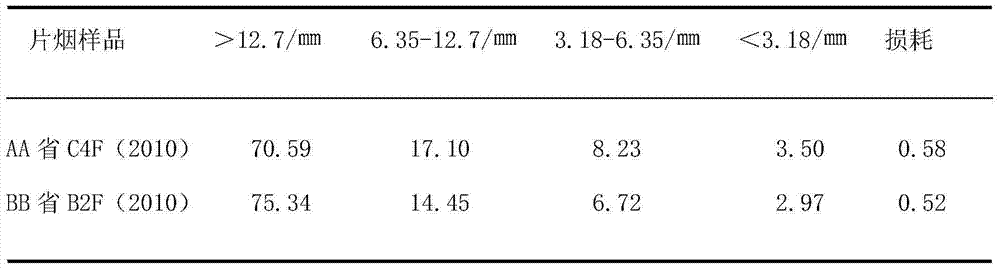

Upgrading process of strips

ActiveCN103689779BEasy to classify and useEfficient removalTobacco preparationMaterials scienceRaw material

The invention relates to an upgrading process of strips. The upgrading process comprises the following steps of preparing materials, loosening, carrying out low-temperature vacuum resurgence, moistening leaves, sieving, sifting in an ad hoc area, classifying and storing, repeatedly baking leaves, and metering and packaging, wherein sieving comprises a step of sieving the strips to three different specifications d of not more than 3.18 mm, d of more than 3.18 mm and less than 12.7 mm, and d of not less than 12.7 mm according to the sieve mesh number; sifting in the ad hoc area comprises a step of manually sifting the sieved strips with the specification of d of not less than 12.7 mm in the ad hoc area; classifying and storing comprises a step of respectively storing the strips with the specifications of d of not more than 3.18 mm and d of more than 3.18 mm and less than 12.7 mm, and tobacco leaves, which are sorted out from sifting; repeatedly baking leaves comprises a step of respectively carrying out low-temperature drying treatment on the sieved strips or the manually sifted strips. According to the upgrading process, the strips can be divided into raw materials with different specifications and be convenient for classification and use, and the application range is widened; through sifting, the use value is improved, and the upgrading process is convenient for precise application of the raw materials.

Owner:CHINA TOBACCO SHANDONG IND

Glassy ganoderm spore powder breeding and collecting technique

Owner:XINGLONG SCI & TECH DEV INST LONGQUANCITY

Fine-silver integrated kettle standard manufacturing method

InactiveCN108202120AImprove antioxidant capacityExtended shelf lifeGrinding machinesHollow articlesWater leakageWorkmanship

The invention discloses a fine-silver integrated kettle standard manufacturing method. The fine-silver integrated kettle standard manufacturing method comprises the following operation steps that a silver sheet is prepared, and the thickness of the silver sheet is 0.9-1.1 mm; a steel hollow circular sleeve is prepared, the diameter of the circular sleeve is 7-11 cm, the thickness of the wall of the circular sleeve is 2-4 cm, and the height of the circular sleeve is 8-12 cm; a circular concave body silver blank is manufactured; a circular kettle body is manufactured through beating based on thesilver blank; a spout is manufactured on one portion of the circular kettle body through hammering and made of an iron bar in the shape like the arabic number 7. According to a fine-silver integratedkettle manufactured by the method, the stereoscopic impression of a kettle body is high, the body shape is manufactured through repeated hammering, the workmanship is exquisite and ingenious, the kettle body is free of water leakage, and the integrated kettle is free of welding spots, high in quality and fineness, resistant to oxidation and long in guarantee period.

Owner:丹寨县国春银饰有限责任公司

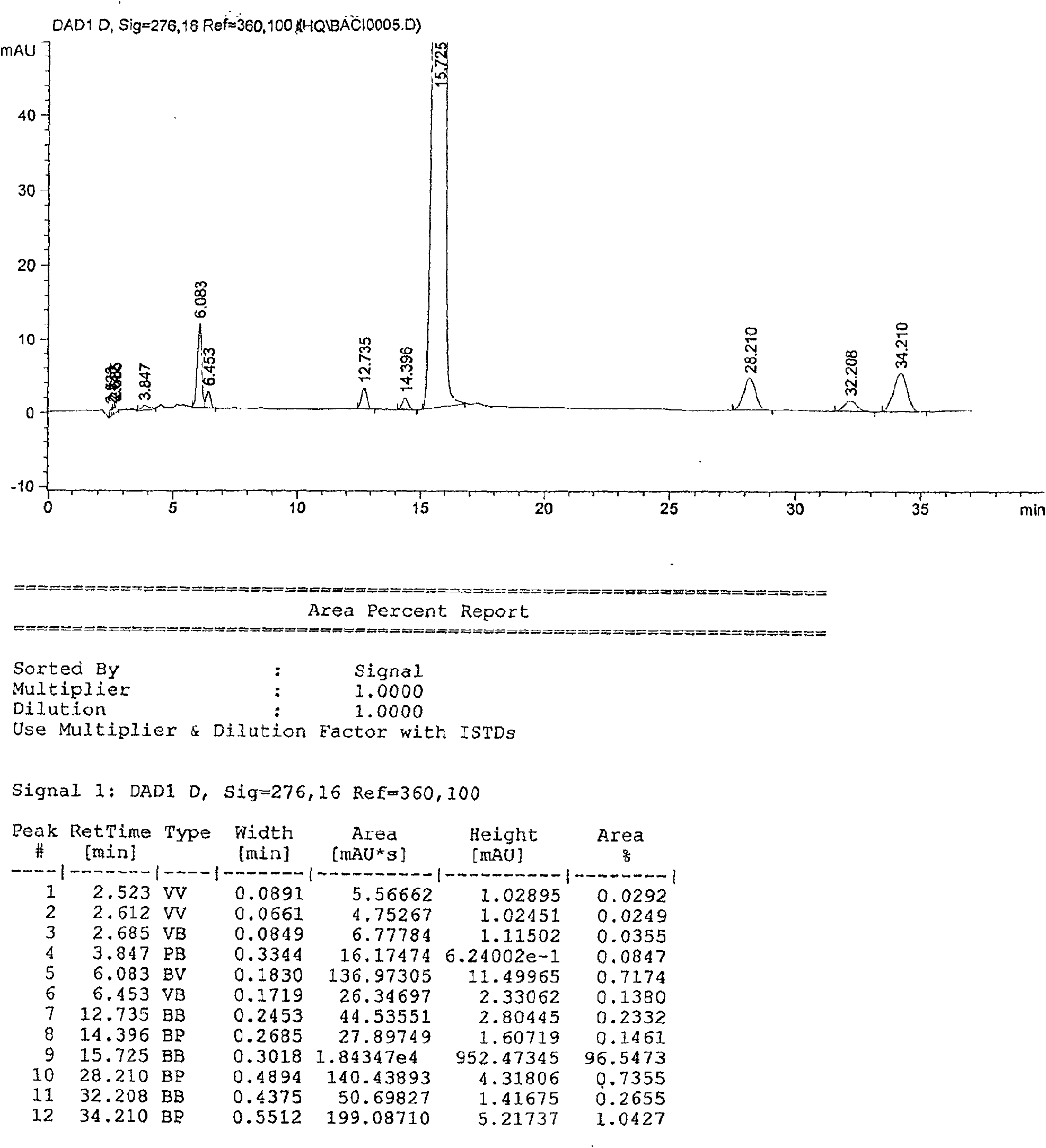

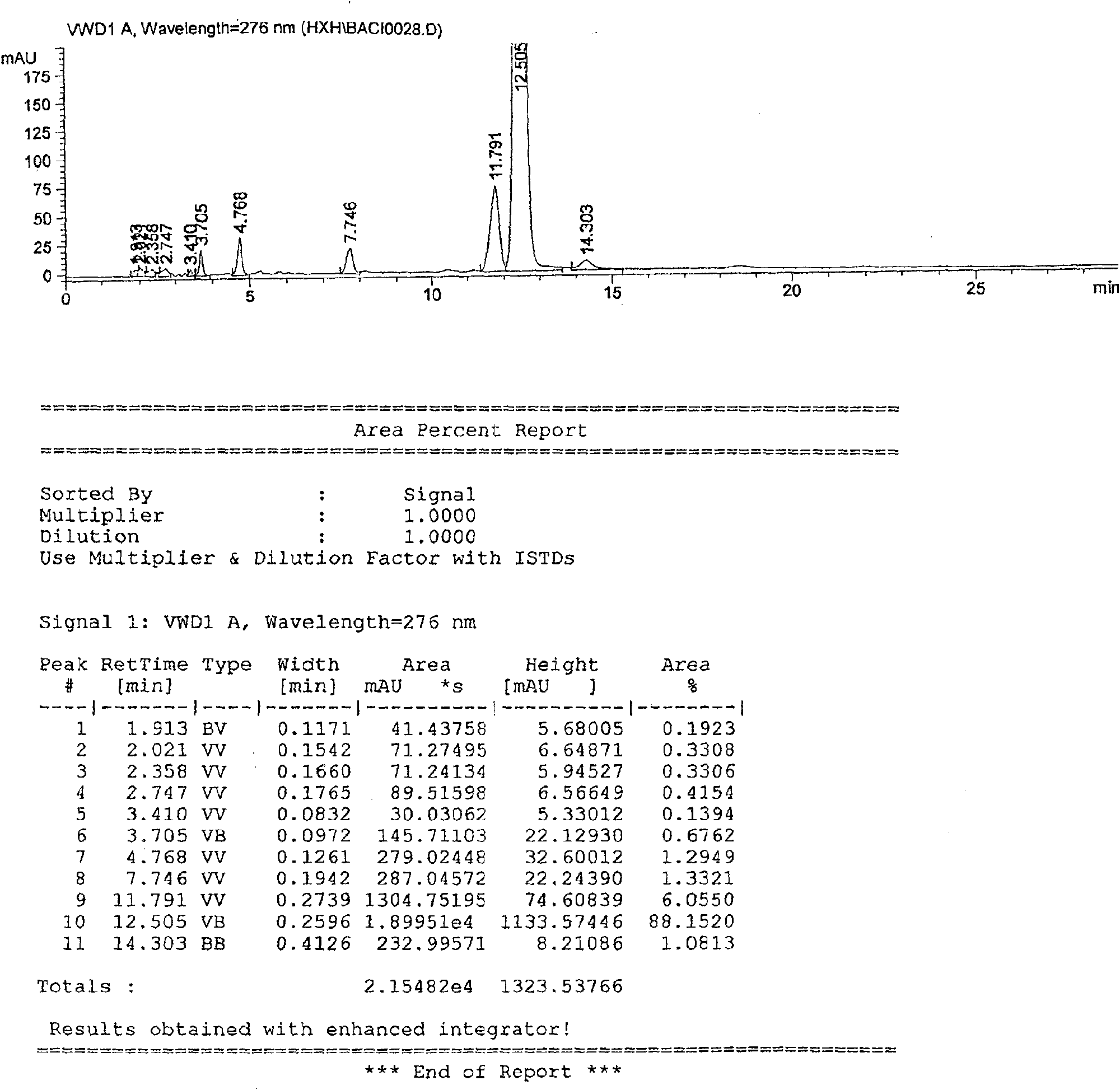

Process for preparing scutellarin

InactiveCN100572373CLow reaction temperatureShort reaction timeOrganic chemistryBaicaleinAqueous solution

The invention discloses a method for preparing high-purity baicalein from baicalin. Add baicalin into sulfuric acid aqueous solution, react for 10-15 minutes at 50-70°C, crystals are precipitated to obtain a crude product, and then purified with acetone to obtain high-purity baicalein. Purity Baicalein. The obtained baicalein was determined by high performance liquid phase method, and the normalized method content was 96% or above. The method provided by the invention prepares finished products with high quality, high purity and light color, short reaction time, mild reaction conditions, simpler process and low cost. It is more suitable for industrial production.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

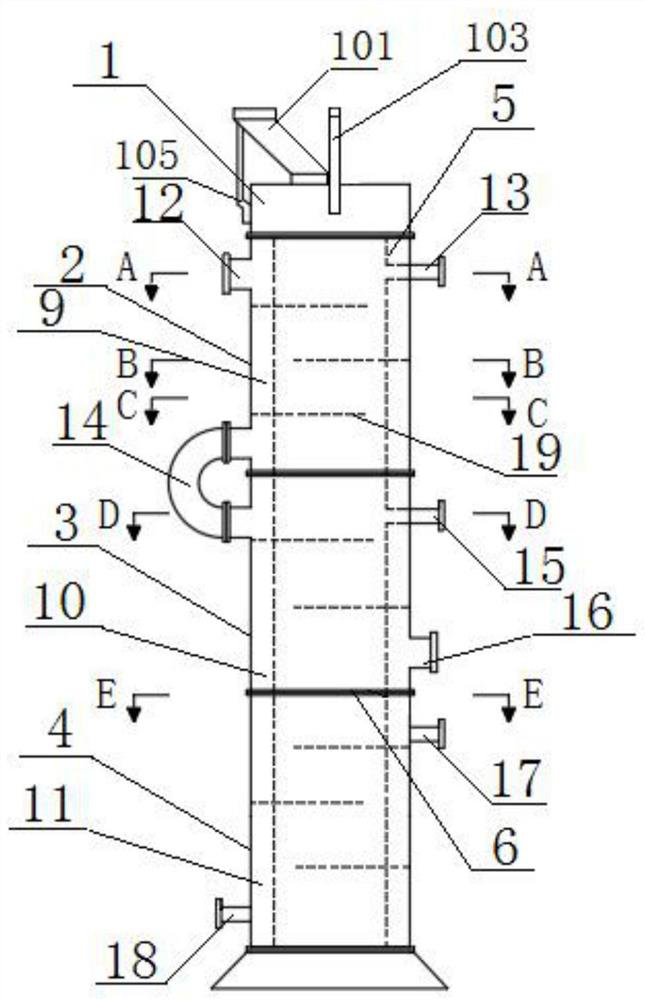

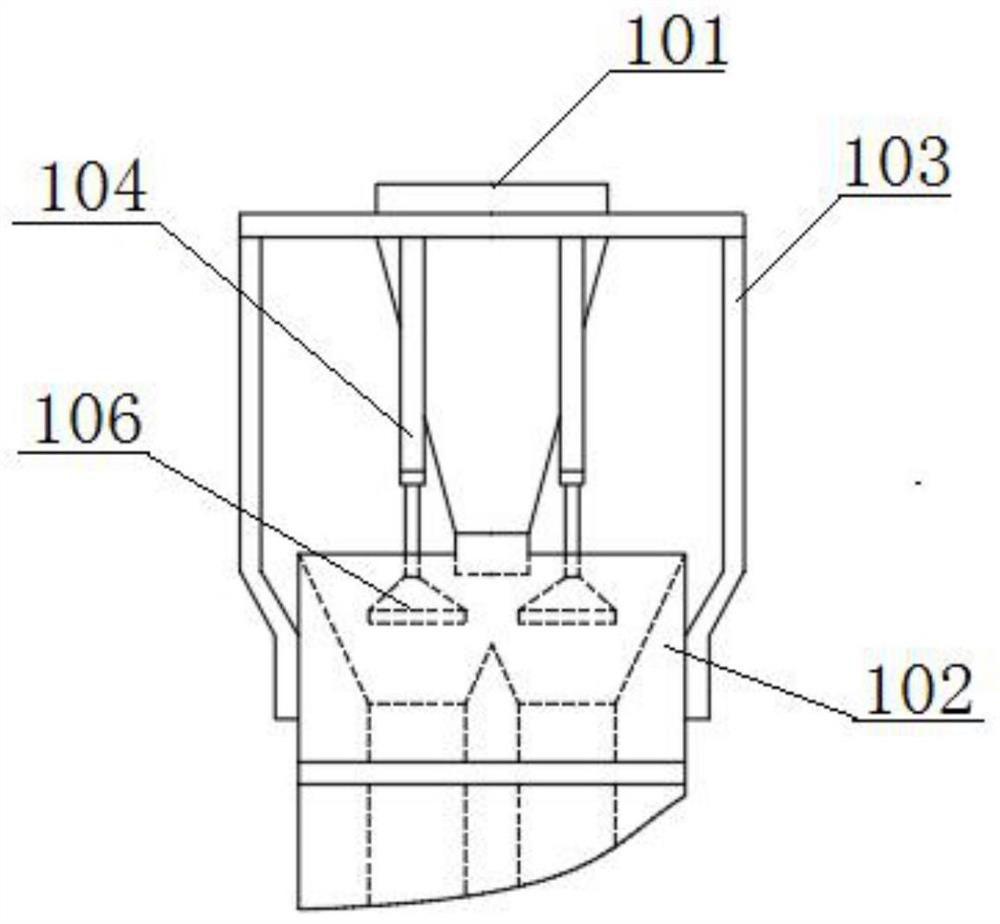

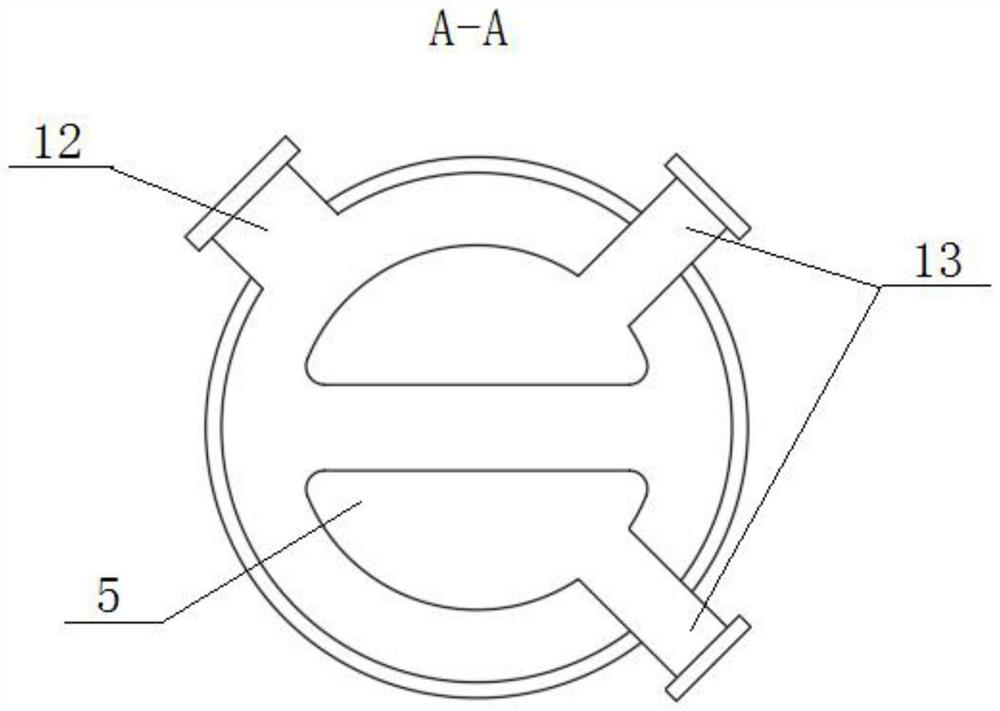

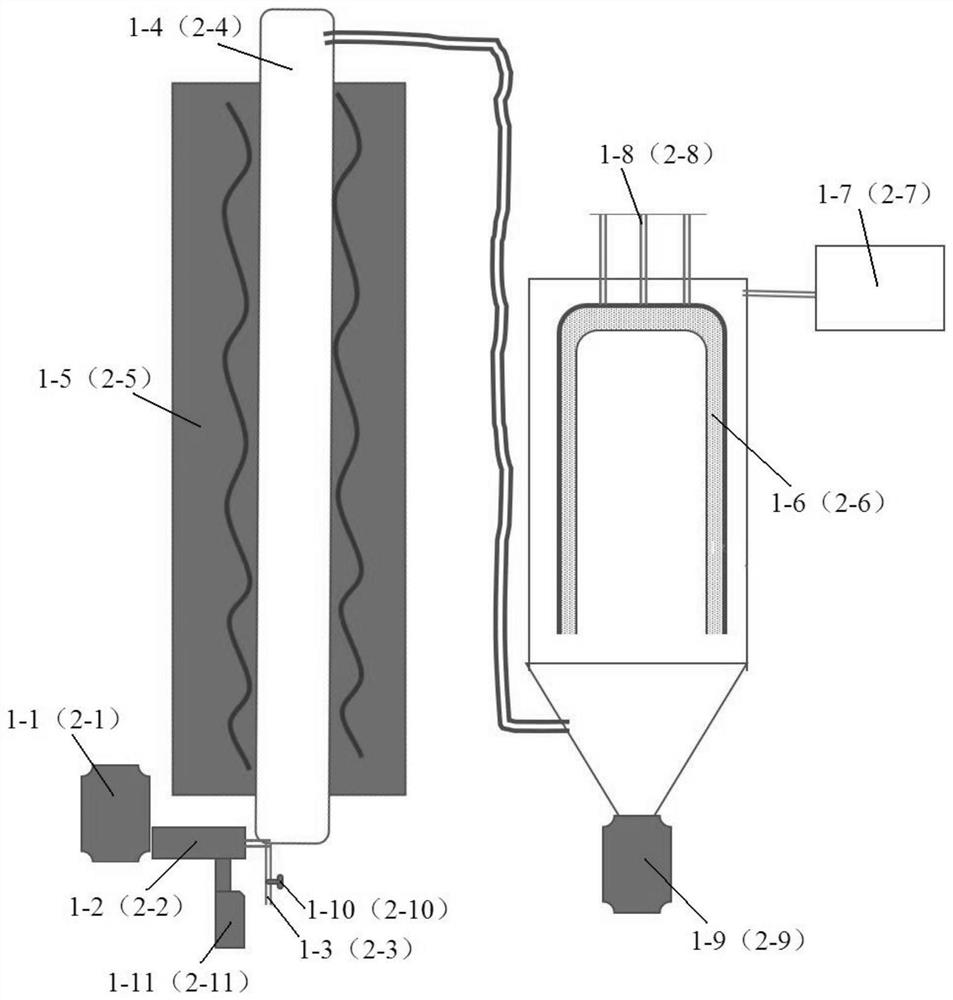

A biomass pyrolysis furnace with detachable vertical semicircular tube body

ActiveCN110257091BQuality improvementHigh quality and purityEnergy inputSpecial form destructive distillationVertical tubeMechanical engineering

The invention discloses a biomass pyrolysis furnace with detachable vertical semicircular tubes, and relates to the technical field of biomass pyrolysis furnaces. The biomass pyrolysis furnace comprises a feeding zone, a preheating zone, a carbonizing zone and a cooling zone which are sequentially arranged from top to bottom in the vertical direction. The two opposite semicircular vertical tubes, which vertically penetrate the pretreating zone, the carbonizing zone and the cooling zone, are arranged in the pretreating zone, the carbonizing zone and the cooling zone. Horizontal internal semicircular furnace pore plates are arranged at joints among the feeding zone, the preheating zone, the carbonizing zone and the cooling zone and at the bottom of the cooling zone. Pneumatic stop valves are arranged at positions, corresponding to the joint between the carbonizing zone and the cooling zone and to the bottom of the cooling zone, in the two semicircular vertical tubes. A preheating flame path, a carbonizing flame path and a cooling water path are sequentially arranged at positions, corresponding to the preheating zone, the carbonizing zone and the cooling zone, of a zone between the inner wall of a furnace body and the outer walls of the two semicircular vertical tubes. Two preheated air outlets communicated with the semicircular vertical tubes are arranged on the upper portion of one side of the preheating zone. The preheating flame path and the carbonizing flame path are communicated through a U-shaped pipe arranged on the outer wall of the furnace body. Two carbonized gas outlets communicated with the semicircular vertical tubes are arranged at the top of one side of the carbonizing zone. Baffle plates are arranged in the preheating flame path, the carbonizing flame path and the cooling water path. The biomass pyrolysis furnace has the advantages that the preheating zone and the carbonizing zone are arranged independently, the purity of target products can be improved, and high-quality biochar can be obtained through the semicircular vertical tubes and the baffle plates.

Owner:北京燕泰博嘉科技有限公司

Reactive distillation method and device for 4emd production

ActiveCN105693686BHigh purityHigh recovery rateOrganic chemistryChemical industryReactive distillationEthyl group

Owner:TIANJIN UNIV

A method for preparing bi-2212 precursor powder by suspension sintering

ActiveCN110817957BInhibition of segregationHigh quality and purityBismuth compoundsOxalateHigh volume manufacturing

The invention discloses a method for preparing Bi-2212 precursor powder through a suspension sintering method. The method comprises the specific processes: mixing Bi2O3, Ca(OH)2, SrCO3 and CuO, then preparing oxalate mixed powder by adopting an oxalate coprecipitation method, and then sequentially carrying out heating and heat preservation, preliminary sintering, high-temperature sintering and phase-forming sintering to obtain the Bi-2212 precursor powder. The oxalate mixed powder prepared by the coprecipitation method is used as raw material powder, the quality purity of a Bi-2212 phase in the Bi-2212 precursor powder is effectively improved, and a step-by-step suspension sintering method is combined; through phase formation is effectively promoted, the problem of powder segregation caused by melting of a low-melting-point phase is solved, the problem of incomplete final phase formation caused by too low local temperature due to large heat absorption of the Bi-2212 phase directly generated from oxide powder is avoided, the uniformity and quality of the Bi-2212 precursor powder are greatly improved, and the method is suitable for mass production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

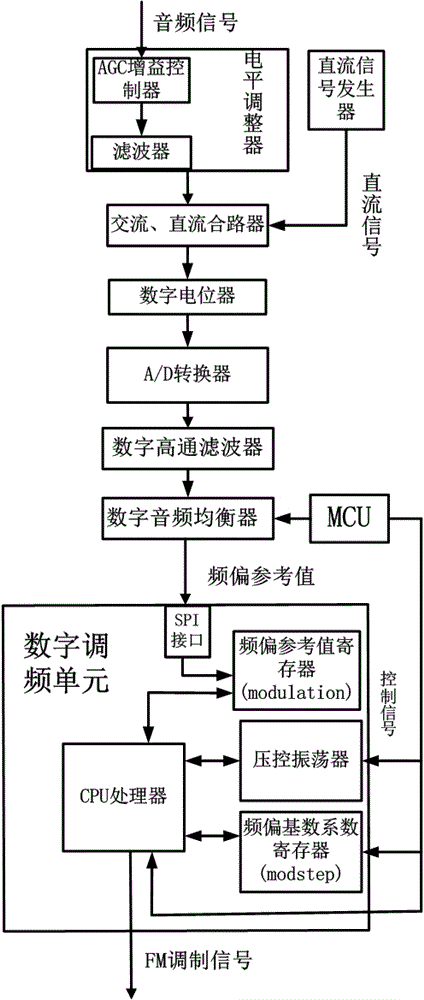

Digital audio fm modulation circuit of handheld ultrashort wave air-to-air radio

ActiveCN103825853BFlexible FM processingSmooth FM ProcessingFrequency-modulated carrier systemsMicrocontrollerVoice communication

Owner:CHENGDUSCEON TECH

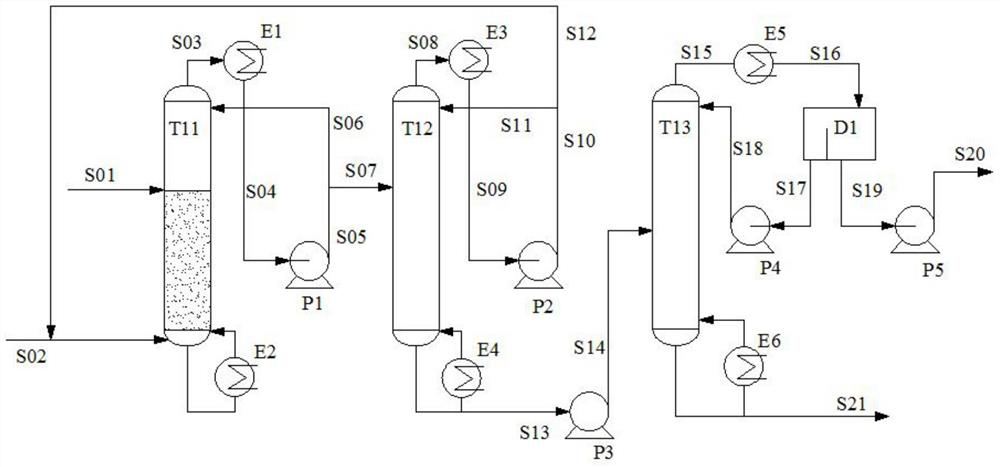

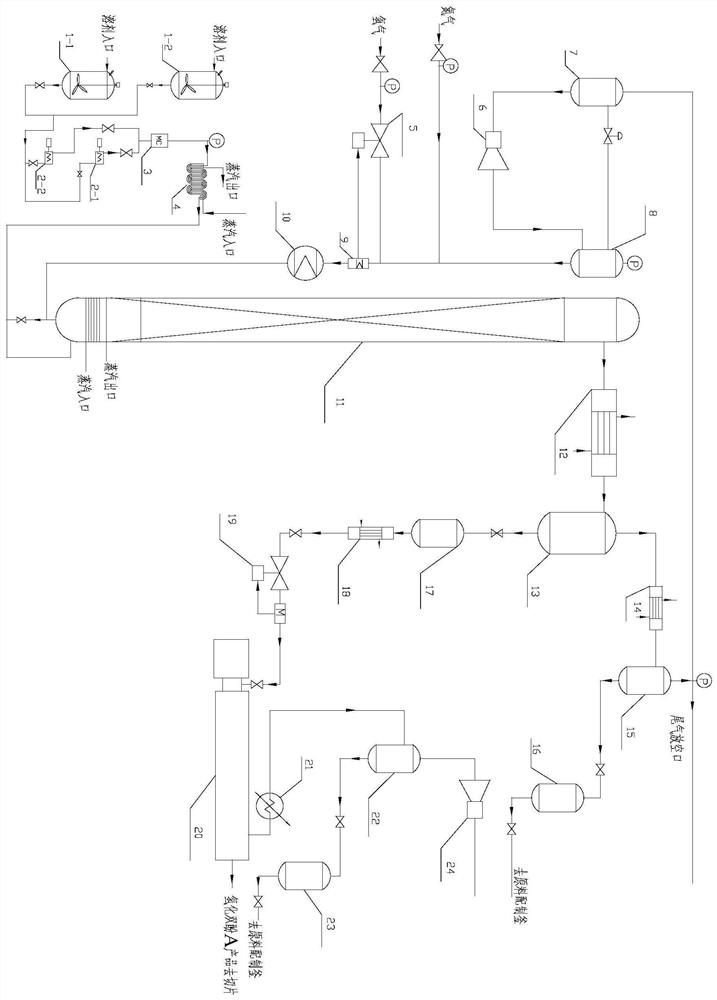

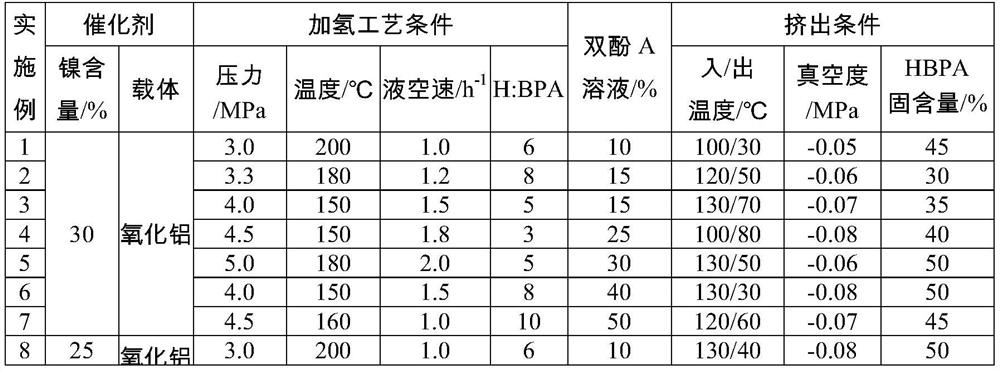

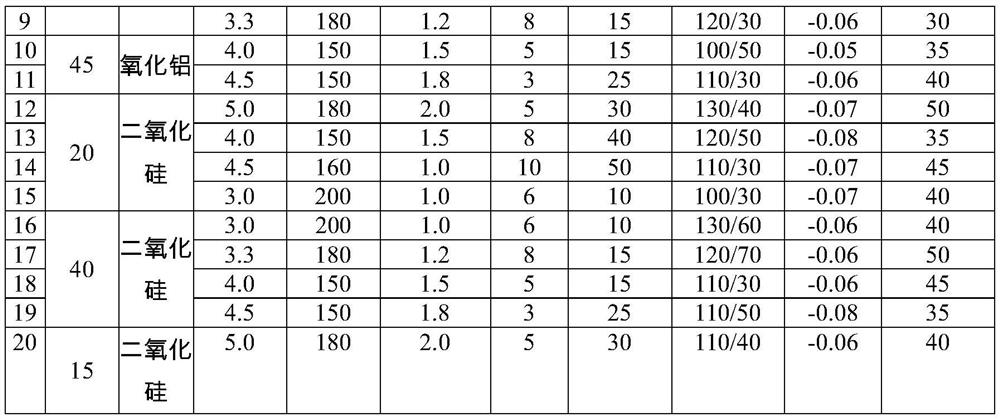

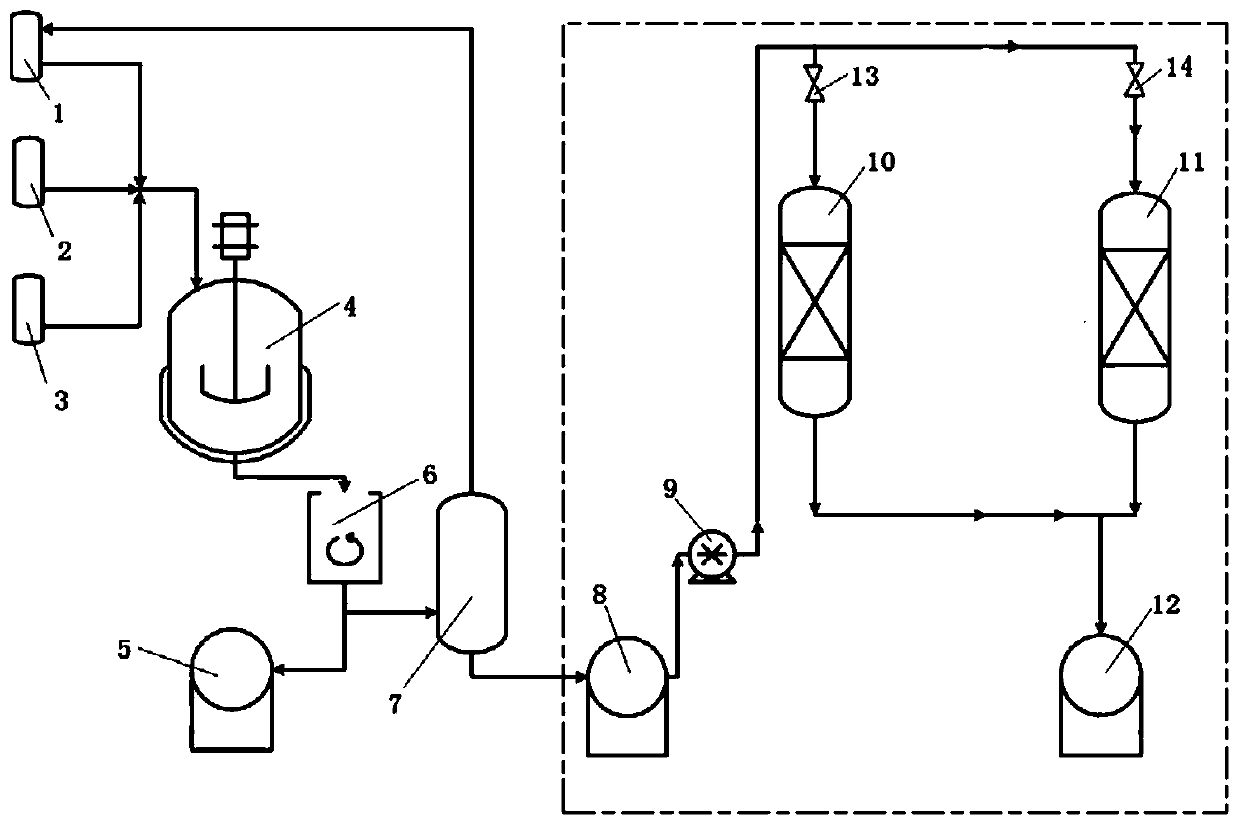

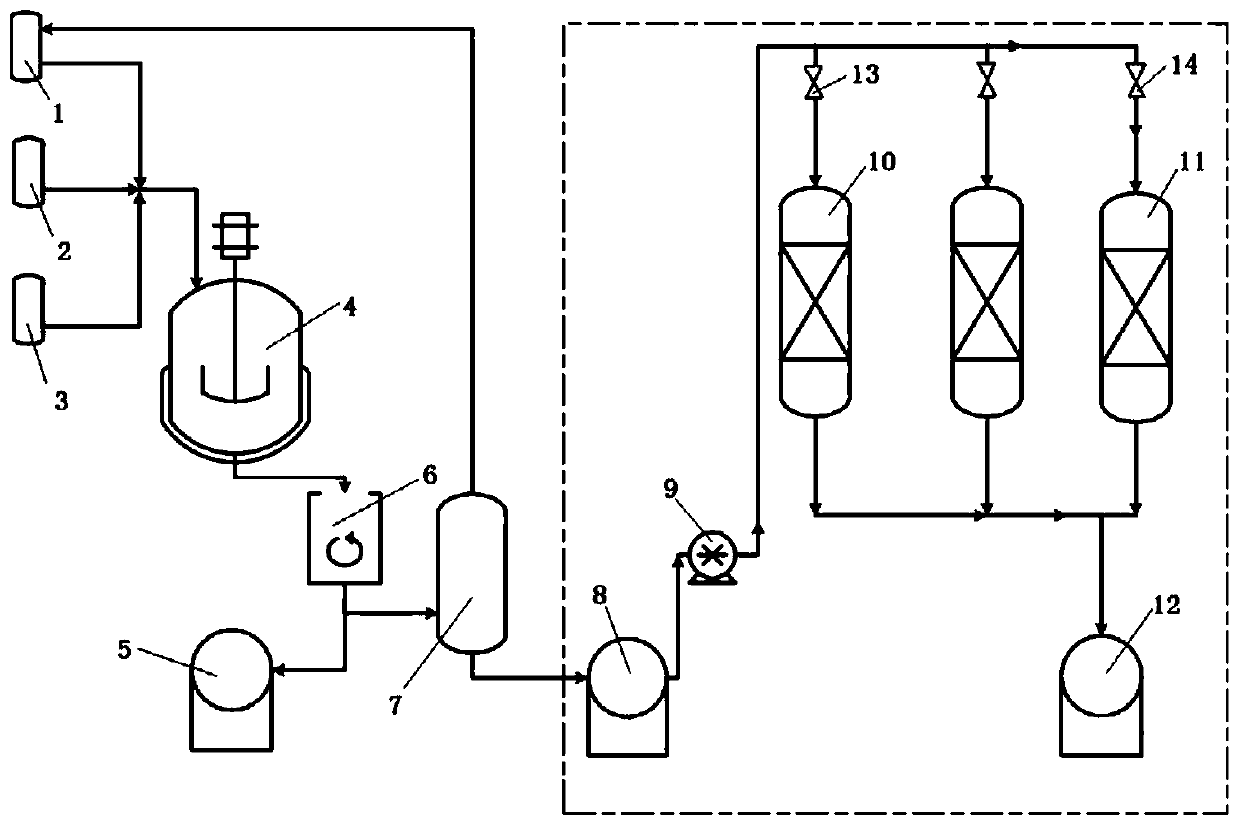

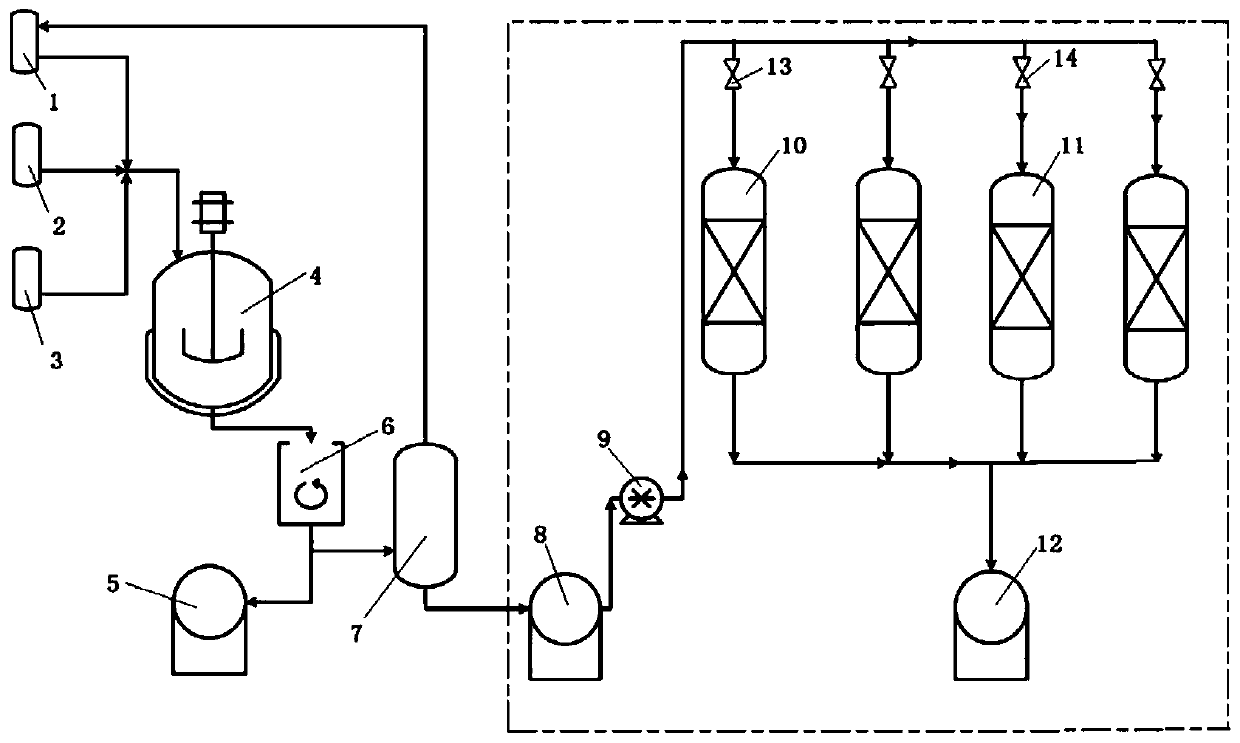

Equipment for continuous preparation of hydrogenated bisphenol a and continuous preparation method of hydrogenated bisphenol a

ActiveCN109678661BExtended stayRaise the ratioPreparation by hydrogenationHydroxy compound separation/purificationPtru catalystHydrogenation reaction

Owner:CHANGZHOU UNIV

Method for extracting high-purity resveratrol from wild blueberry of Great Khingan by enzymolysis

InactiveCN105695516AHigh yieldHigh quality and purityOrganic chemistryOrganic compound preparationAlcoholOrganic solvent

The invention belongs to the field of natural organic chemistry, and relates to a method for enzymatically extracting high-purity resveratrol from Daxinganling wild blueberries. The invention uses the blueberry fruit picked in Daxing'an Mountains as a raw material, and obtains a high-purity resveratrol crystal powder product through a simplified process of biological enzymolysis reaction, water extraction, alcohol precipitation, deep extraction, separation, concentration and drying. The method of the invention has the characteristics of sufficient biological enzymolysis, short time consumption, low energy consumption cost, high operation safety, full use of raw materials and organic solvents, waste liquid mainly being water, good for environmental protection, and easy industrialization and application. The resveratrol crystal powder product prepared by the method of the invention has a high purity, which can reach more than 98 percent; and a high yield, which can reach 1.40 percent.

Owner:DAXINGANLING PERFECTION NOBILITY FRIGID ZONE BIO TECH CO LTD

Method for purifying glyceryl triacetate

ActiveCN101205184BHigh quality and purityReduce acidityOrganic compound preparationCarboxylic acid esters preparationChemical industrySteam pressure

Owner:江苏雷蒙新材料有限公司

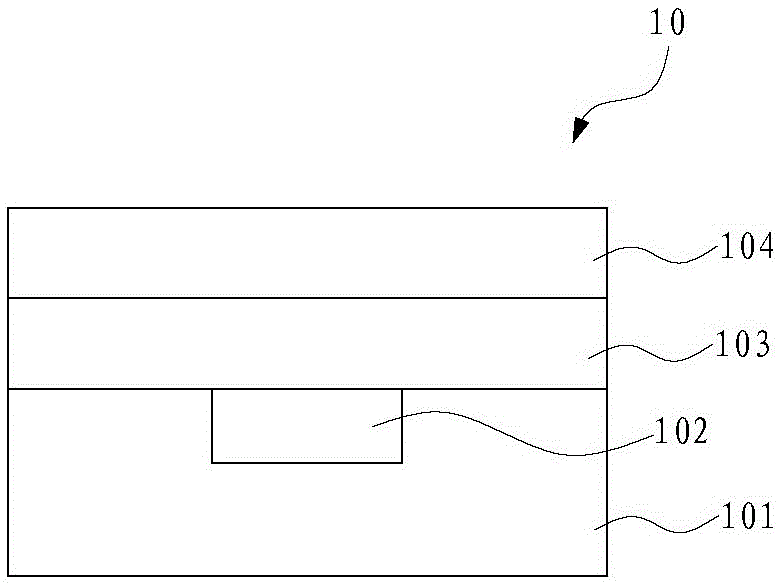

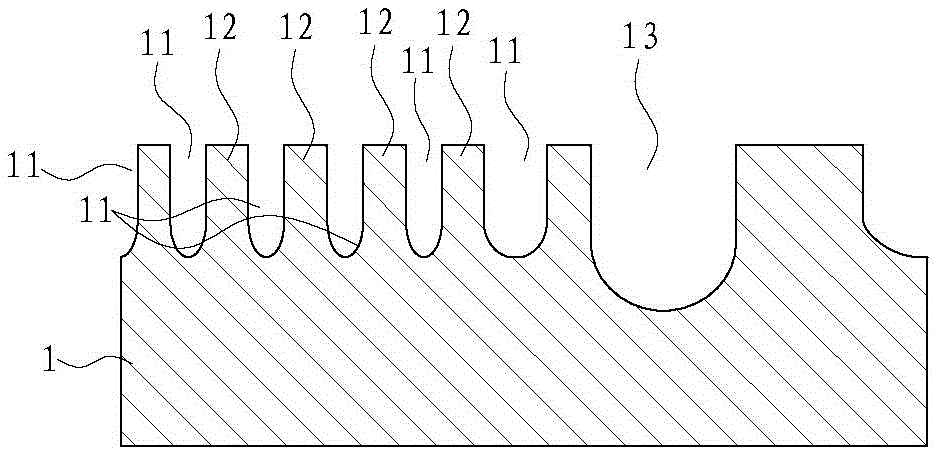

A diode selection element array structure and manufacturing method

InactiveCN103972172BHigh quality and purityImprove structural qualityTransistorSemiconductor/solid-state device manufacturingInsulation layerEngineering

The invention discloses a diode selection element array structure manufacturing method. The diode selection element array structure manufacturing method includes forming shallow isolation grooves on a P-type semiconductor substrate at intervals, and forming blank posts among the shallow isolation grooves, wherein one of the blank posts is a P-tie blank post, and the rest are N-tie blank posts; filling the insulation layer in the shallow isolation grooves; forming an N trap on the P-type semiconductor substrate; burying a first P-type diffusion layer on the N trap; forming N-type diffusion layers on the N-tie blank posts, forming wolfram plugs on the N-type diffusion layers, and connecting the wolfram plugs with the N-type diffusion layers to form a first electrode of a diode; extending the P-tie blank posts to form second P-type diffusion layers, forming wolfram plugs on the second P-type diffusion layers, and connecting the wolfram plugs with the second P-type diffusion layers to form a second electrode of the diode; forming an N-type diffusion layer on the upper layer of one side of the N trap and forming another wolfram plug on the upper layer of the N-type diffusion layer and connecting the wolfram plug with the N-type diffusion layer to form a contact electrode of the N trap. The diode selection element array structure manufacturing method is simple in process, and manufacturing cost is saved; a diode selection element array structure formed by the manufacturing method is good in quality.

Owner:陈秋峰

Purifying method of biodiesel

ActiveCN109810735ARich capillary channelsRich pore size range distributionBiofuelsFatty-oils/fats refiningBiodieselPurification methods

The invention discloses a purifying method of biodiesel. The purifying method is characterized by purifying crude biodiesel by adopting a percolation system, thus obtaining the biodiesel, wherein thepercolation system at least comprises one percolation tower taking thermal activated bauxite as filler. According to the purifying method disclosed by the invention, the percolation tower taking the thermal activated bauxite as the filler is adopted for percolating and purifying the crude biodiesel, and the adsorption ability on impurities such as polar molecular water, methanol, sterol, glycerinum, phospholipid, acid-base catalyst residue and free fatty acid in the crude biodiesel is increased by utilizing strong adsorption and filtering functions and high purifying resolution of the thermalactivated bauxite on the impurities, so that the biodiesel with higher quality and higher purity is obtained; meanwhile, the acid value of the biodiesel is reduced, mixing of poor impurities is avoided, the quality of the biodiesel is increased, and the purifying efficiency is high.

Owner:CHANGAN UNIV

Spirodiol dienoic acid ester and preparation method thereof

The invention discloses spirodiol dienoic acid ester and a preparation method thereof. A spirodiol dienoic acid ester substance is prepared in a mixed solvent system, reactants adopt spirodiol and olefine acid monomers and includes but is not limited to acrylic acid and methacrylic acid, and the spirodiol dienoic acid ester is characterized in that the structure has a carboxyl group and a double bond. The esterification reaction between the two reactants is carried out in a mixed solvent, two hydroxyl groups at two ends of the reactant spirodiol respectively react with carboxyl groups on the reactant olefine acid to form ester bonds, and the obtained product is the spirodiol diolefine acid ester. The spirodiol is dihydric alcohol with an alicyclic structure; the resin prepared by the spirodiol is superior to fatty diol in the aspects of heat resistance, solvent resistance and the like, and has the advantage that aromatic diol is difficult to reach in the aspect of yellowing resistance,and the macromolecule obtained by reaction has carbon-carbon double bonds at two ends, can be used as a cross-linking agent in polymerization reaction, has a spiro ring in the molecule, and can alsoprovide excellent mechanical properties.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com