Equipment for continuous preparation of hydrogenated bisphenol a and continuous preparation method of hydrogenated bisphenol a

A technology for hydrogenating bisphenol and hydrogen, which is used in hydrogenation preparation, separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of high production energy consumption and high catalyst products, and achieve higher purity, higher product purity, and higher evaporation rate. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

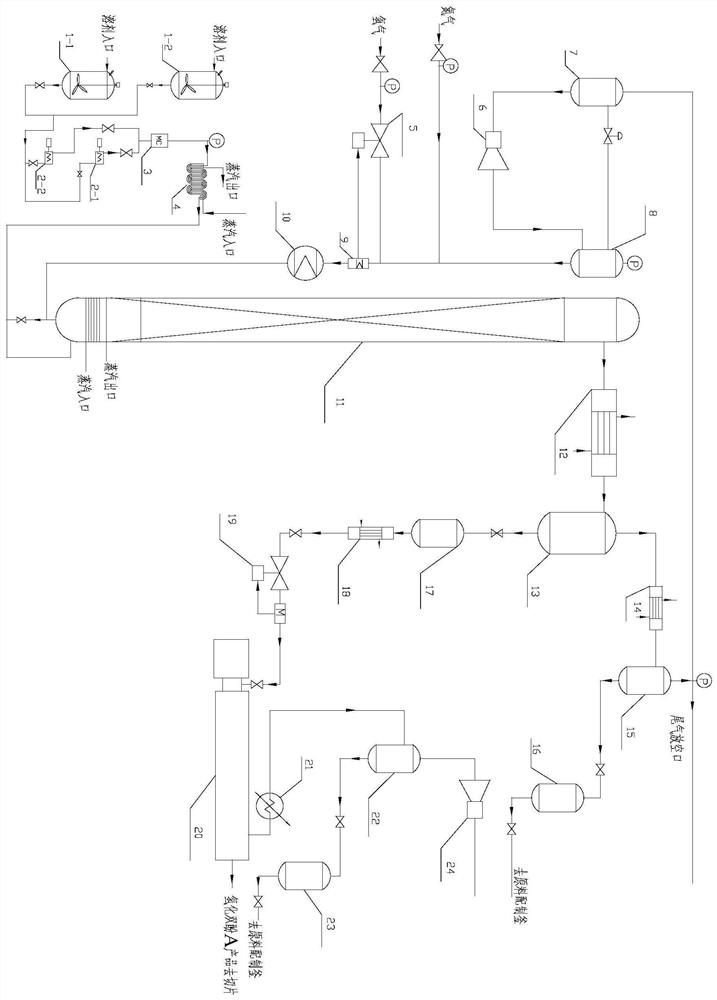

Method used

Image

Examples

Embodiment 1~20

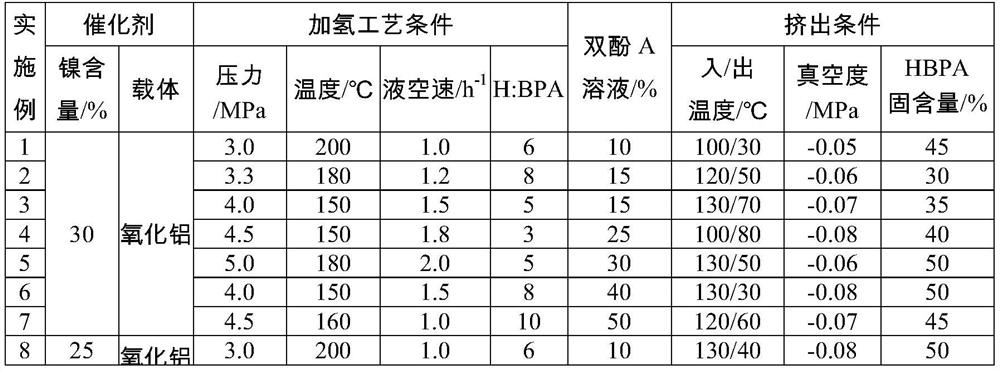

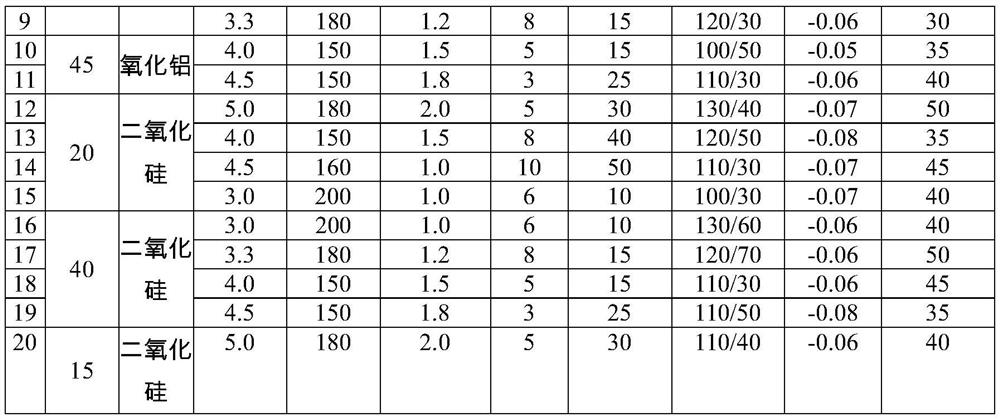

[0048] In order to further illustrate this invention, the operations such as hydrogenation reaction, solvent separation, product extrusion are carried out below according to the above-mentioned implementation method, the test of the purity of hydrogenated bisphenol A product when carrying out different hydrogenation process conditions, extrusion conditions, hydrogenated bisphenol A After A product is completely dissolved with solvent isopropanol, then utilize gas chromatography to adopt external standard method to carry out the analysis of product purity and impurity analysis and isomer, and the analysis data of concrete implementation condition and product are shown in Table 1 and Table 2:

[0049] Table 1 embodiment process data

[0050]

[0051]

[0052] Table 2 embodiment product data

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com