Process for preparing high purity scutellarin

A baicalein, high-purity technology, applied in the field of preparing baicalein, can solve the problems of high requirements for reaction conditions, troublesome refining process, high industrial cost, etc., and achieve the effects of reducing production costs, low cost, and short reaction time

Inactive Publication Date: 2005-10-19

HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this process can produce baicalein with higher purity, there are still problems such as deep color (many impurities), long reaction time, high requirements for reaction conditions, troublesome refining process, etc. of the product, which will cause poor quality and industrial cost too high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

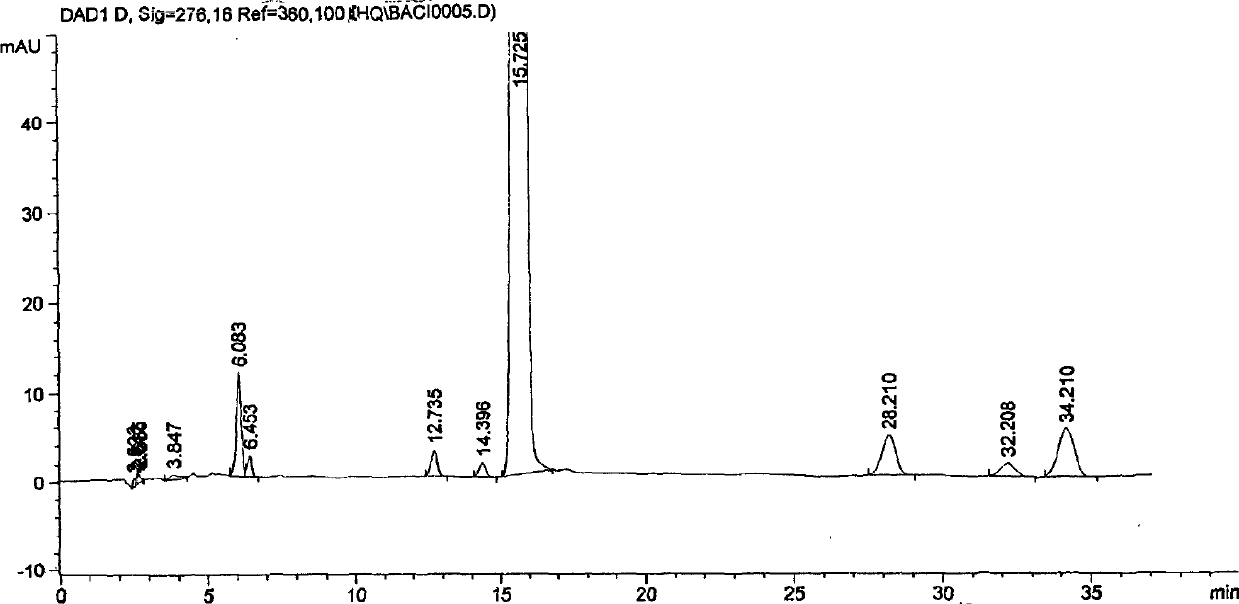

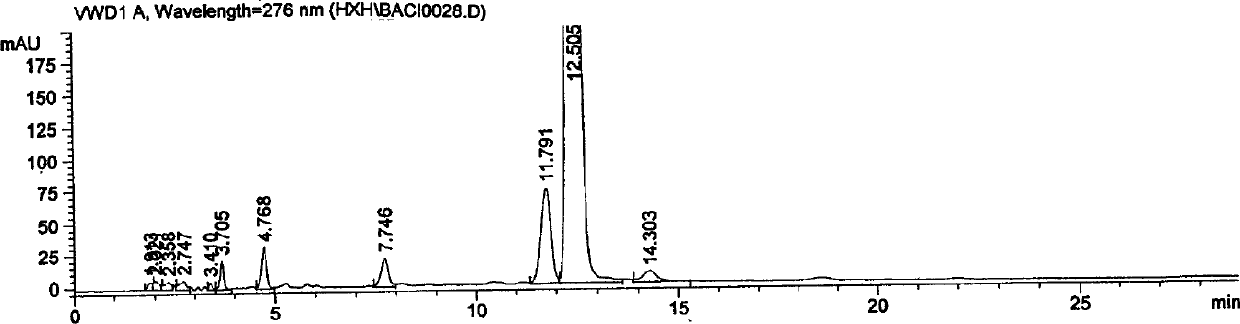

Login to View More Abstract

The present invention discloses preparation process of high purity scutellarin from baicalin. Baicalin is added into water solution of sulfuric acid and reacted at 50-70 deg.c for 10-15 min to obtain separated coarse crystal product; and the coarse product is purified with acetone to obtain high purity scutellarin. Thus prepared scutellarin product, high efficiency liquid phase test process shows, has scutellarin content of 96 % or over. The process has short reaction time, mild reaction condition, simplicity and low cost, and is suitable for industrial production.

Description

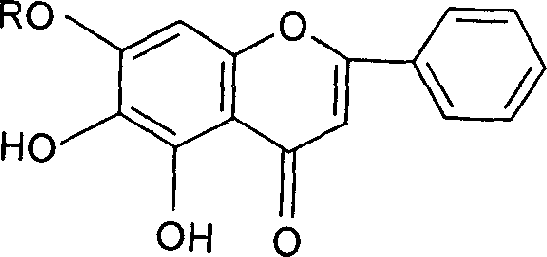

technical field The invention belongs to the extraction method of traditional Chinese medicine, in particular to the method for preparing baicalein from baicalin. Background technique Scutellaria baicalensis is the dry root of Scutellaria baicalensis Georgi, which has the functions of clearing away heat and dampness, purging fire and detoxification, stopping bleeding and preventing miscarriage. Baicalein and Baicalin are the main components of Scutellaria baicalensis. They have exact chemical structures, and their structural formulas are: R=H baicalein R=glucuronic acid baicalin Studies in recent years have found that these two extracts of Scutellaria baicalensis have antibacterial and antiviral effects, especially baicalein has more liver protection, gallbladder diuresis, free radical scavenging and antioxidant effects, anticoagulant and antithrombosis, and inhibition of pancreatic enzymes. Activity, effect on biofilm, anti-cancer, dual regulation on smooth muscle, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07D311/30

Inventor 潘福生叶杉

Owner HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com