Purifying method of biodiesel

A technology of biodiesel and purification method, which is applied in the field of biodiesel preparation, can solve the problems of high equipment cost and operation cost, a large amount of manpower and material resources, and is not effective and practical, and achieves strong adsorption and filtration capabilities, low energy consumption, and low operating temperature. Gentle effect with pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

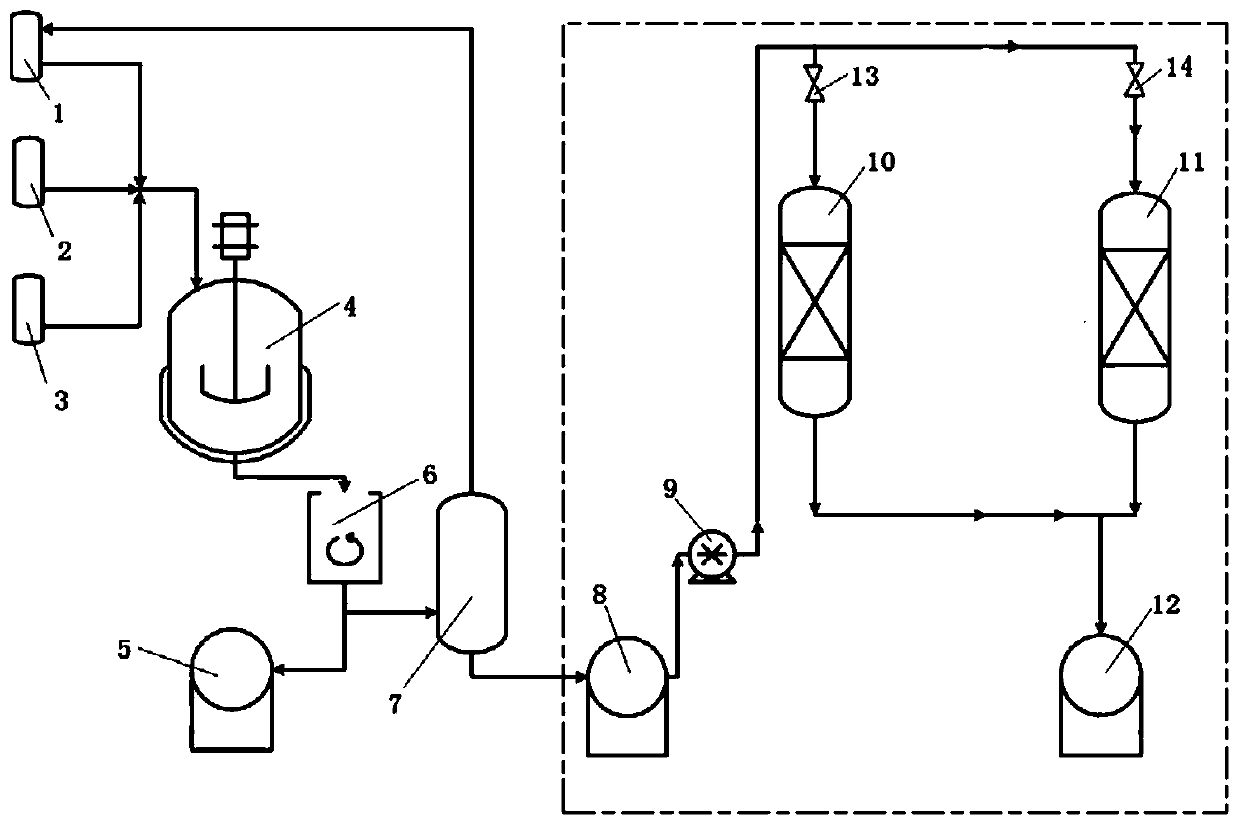

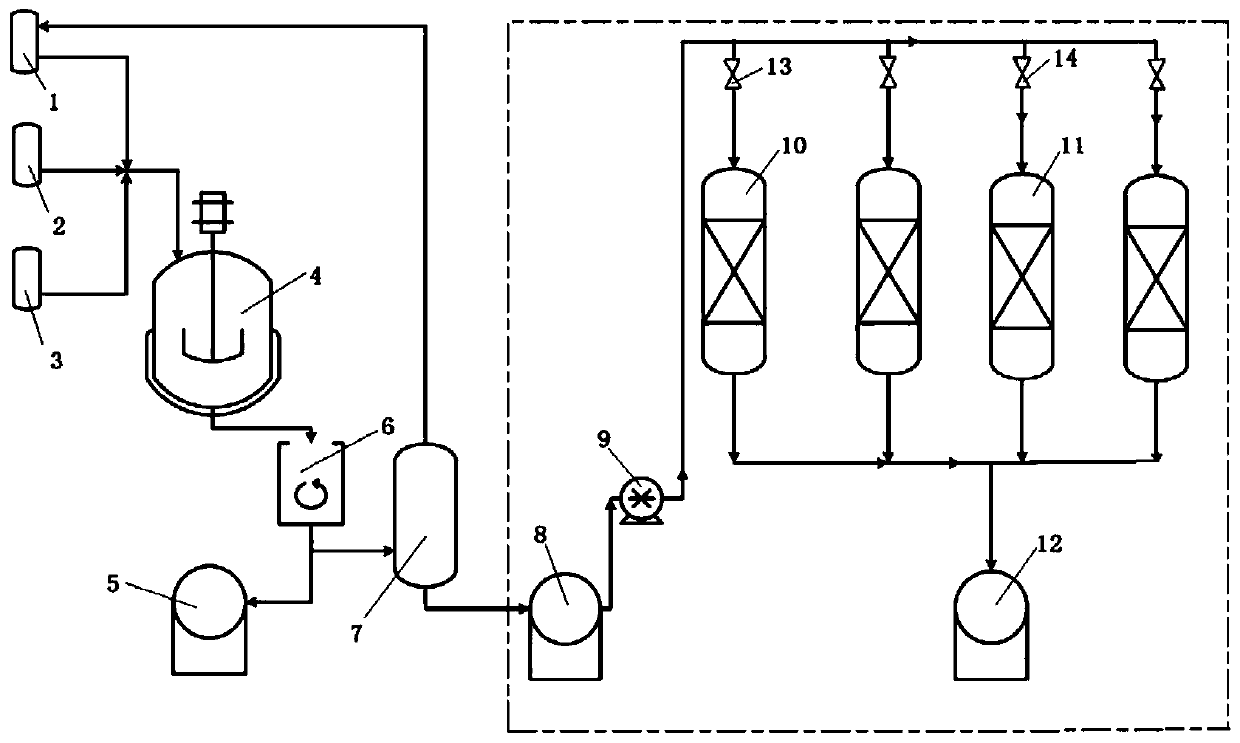

[0041] The purification process of the present embodiment is: open the valve 13 of the main percolation tower, close the valve 14 of the auxiliary percolation tower, and use the crude biodiesel stored in the crude biodiesel storage tank 8 at a flow rate of 50 L / h under the action of the centrifugal oil pump 9 Purify through a diafiltration system composed of a main diafiltration tower 10 to obtain biodiesel with a mass content of fatty acid methyl ester of 99.6%, which is sent to a biodiesel storage tank 12 for storage; the operating temperature is 20° C., and the operating pressure is normal pressure The raw material for the preparation of the crude biodiesel is soybean oil, and the preparation method is an alkali-catalyzed method; 40kg of heat-activated bauxite is filled in the main percolation tower, and the particle size of the heat-activated bauxite is 50 orders. The average diameter of the sieve hole of the heat-activated bauxite is 0.556mm, the azobenzene adsorption amou...

Embodiment 2

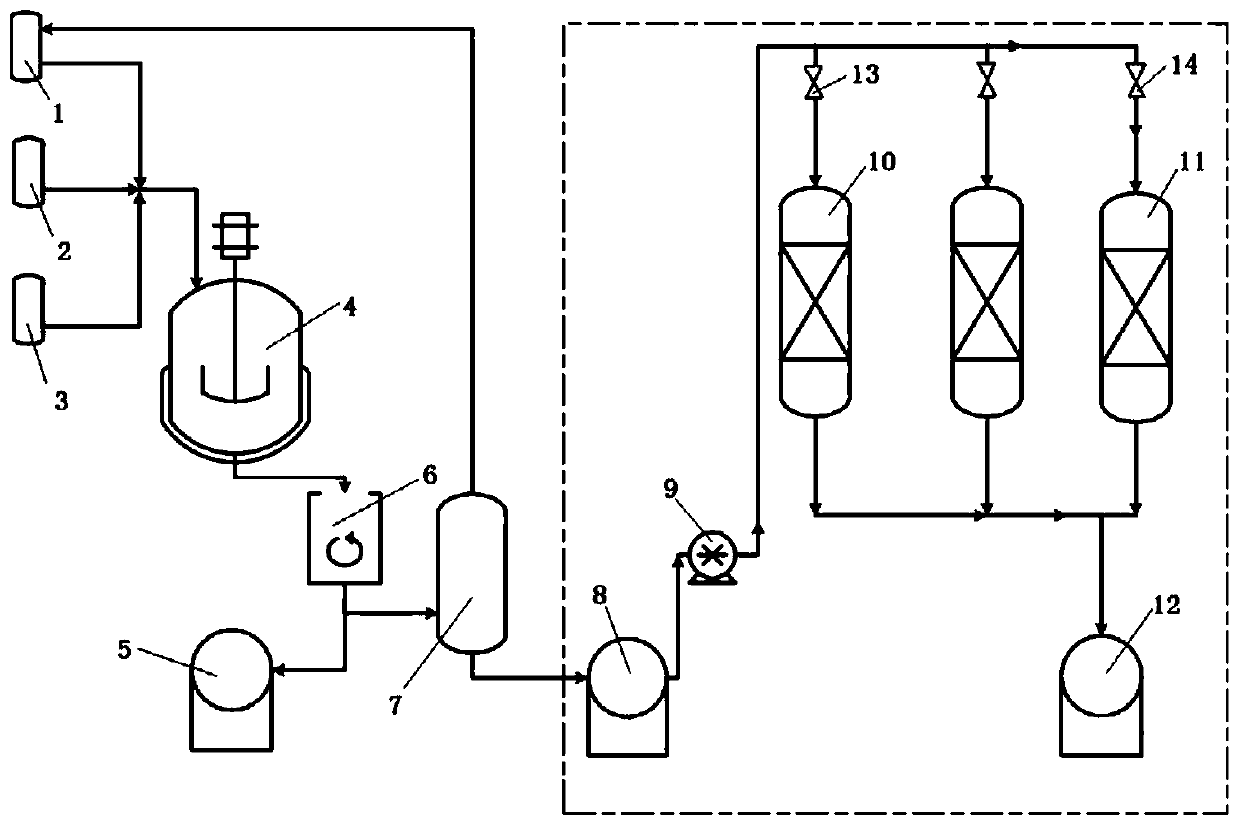

[0044] The purification process of the present embodiment is as follows: open the valve 13 of the main percolation tower, close the valve 14 of the auxiliary percolation tower, and use the crude biodiesel stored in the crude biodiesel storage tank 8 at a flow rate of 100 L / h under the action of the centrifugal oil pump 9 Simultaneous purification is carried out through a diafiltration system composed of two parallel main diafiltration towers 10 respectively to obtain biodiesel with a mass content of fatty acid methyl ester of 99.2%, which is sent to a biodiesel storage tank 12 for storage; the operating temperature is 25°C , the operating pressure is normal pressure; the raw material for the preparation of the crude biodiesel is rapeseed oil, and the preparation method is an acid-catalyzed method; 40kg of heat-activated bauxite has been filled in the two main percolation towers 10, and the heat-activated bauxite The particle size of the activated bauxite is 20 meshes, the avera...

Embodiment 3

[0047] The purification process of the present embodiment is as follows: open the valve 13 of the main percolation tower, close the valve 14 of the auxiliary percolation tower, and use the crude biodiesel stored in the crude biodiesel storage tank 8 under the action of the centrifugal oil pump 9 at a flow rate of 150 L / h Simultaneous purification is carried out through a diafiltration system composed of two parallel main diafiltration towers 10 to obtain biodiesel with a mass content of fatty acid methyl ester of 99.8%, which is sent to a biodiesel storage tank 12 for storage; the operating temperature is 35°C , the operating pressure is normal pressure; the raw material for the preparation of the crude biodiesel is palm oil, and the preparation method is an enzyme-catalyzed method; the two main infiltration towers 10 are all filled with 40kg heat-activated bauxite, and the heat-activated aluminum The particle size of the earth ore is 35 meshes, the average diameter of the siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com