A preparation method of high-performance nylon porous material that can be prepared on a large scale

A technology for large-scale preparation of porous materials, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. Simple and easy, large specific surface area, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

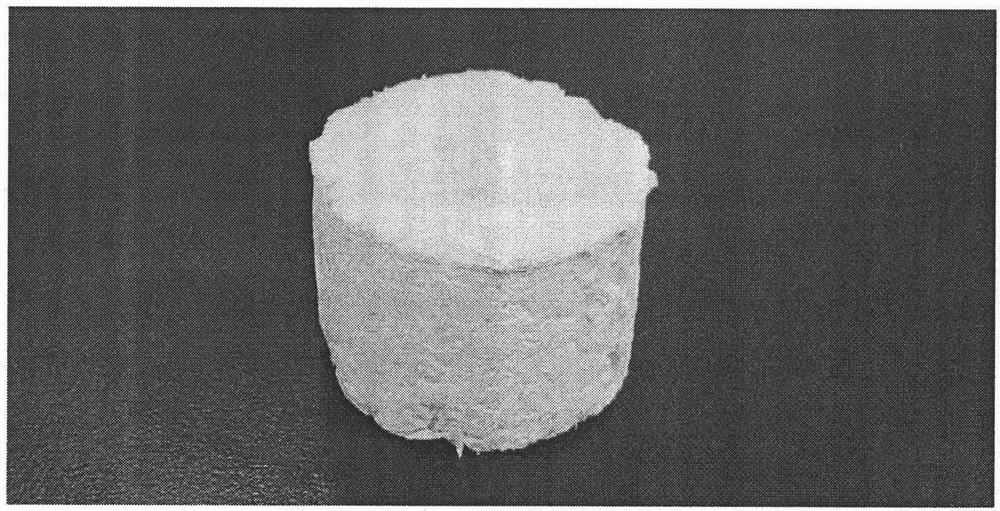

Embodiment 1

[0030] A kind of nylon porous material is characterized in that it is made of the raw material of following parts by weight (g): nylon 6 (PA6) 16, anhydrous formic acid 84, sodium bicarbonate 3, distilled water 97

[0031] A kind of preparation method of nylon porous material as claimed in claim 2, is characterized in that comprising the following steps:

[0032] (1) Nylon 6 and anhydrous formic acid were weighed and mixed according to a certain mass ratio, and stirred with a magnetic stirrer at room temperature for 3 hours until completely dissolved.

[0033] (3) A certain quality of sodium bicarbonate is mixed with water to form a solution with a mass concentration of 3%.

[0034] (4) Take 6ml of nylon / formic acid solution and put it into a mold with a capacity of 14ml, inject NaHCO 3 aqueous solution, producing a large amount of CO 2 A porous material is formed, and the porous material is taken out after the reaction is complete.

[0035] (5) After washing with water, pu...

Embodiment 2

[0038] A kind of nylon porous material is characterized in that it is made of the raw material of following parts by weight (g): nylon 6 (PA6) 16, anhydrous formic acid 84, sodium bicarbonate 4, distilled water 96

[0039] A kind of preparation method of nylon porous material as claimed in claim 2, is characterized in that comprising the following steps:

[0040] (1) Nylon 6 and anhydrous formic acid were weighed and mixed according to a certain mass ratio, and stirred with a magnetic stirrer at room temperature for 3.5 hours until completely dissolved.

[0041] (2) A certain quality of sodium bicarbonate is mixed with water to form a solution with a mass concentration of 4%.

[0042] (3) Take 7ml of nylon / formic acid solution and put it into a mold with a capacity of 14ml, inject NaHCO 3 aqueous solution, producing a large amount of CO 2 A porous material is formed, and the porous material is taken out after the reaction is complete.

[0043] (5) After washing with water, ...

Embodiment 3

[0046] A kind of nylon porous material is characterized in that it is made of the raw material of following parts by weight (g): nylon 66 (PA66) 16, anhydrous formic acid 84, sodium bicarbonate 4, distilled water 96

[0047] A kind of preparation method of nylon porous material as claimed in claim 1, is characterized in that comprising the following steps:

[0048] (1) Nylon 66 and anhydrous formic acid were weighed and mixed according to a certain mass ratio, and stirred with a magnetic stirrer at room temperature for 3 hours until completely dissolved.

[0049] (3) A certain quality of sodium bicarbonate is mixed with water to form a solution with a mass of sodium bicarbonate of 4%.

[0050] (4) Take 6ml of nylon / formic acid solution and put it into a mold with a capacity of 14ml, inject NaHCO 3 aqueous solution, producing a large amount of CO 2 A porous material is formed, and the porous material is taken out after the reaction is complete.

[0051] (5) After washing wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com