Method and device for preparing nitrogen-doped carbon nanotubes by using microwave vapor deposition

A technology for preparing a device and carbon nanotubes, applied in the field of nanomaterials, can solve the problems of difficult control of reaction time and degree of reaction, many surface defects, small diameter of the tube, etc., and achieves microwave power tunability, low deposition pressure, An effect that increases the chance of ionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

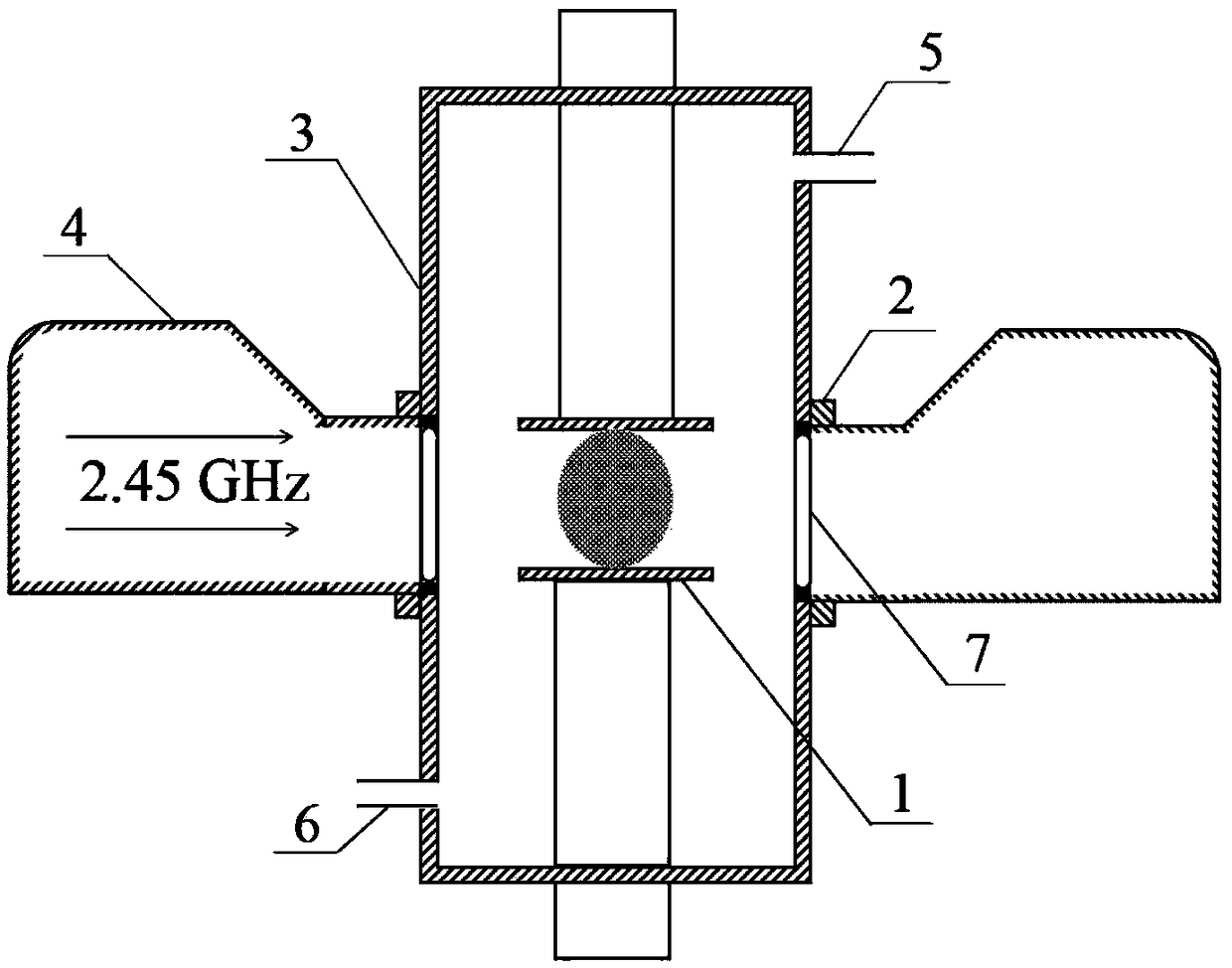

[0029] The schematic diagram of the preparation device of nitrogen-doped carbon nanotubes of the present invention refers to the attached figure 1 As shown, it includes a cavity 3, an air inlet 5, an air extraction port 6, a compressed rectangular waveguide 4, a quartz glass tube 7, and a microwave generator;

[0030] Inside the cavity, a substrate table 1 and a lifting mechanism are provided, and the substrate table 1 is installed on the lifting mechanism;

[0031] There are air inlets 5 and air outlets 6 at the upper and lower ends of the cavity;

[0032] The middle part of the cavity is provided with a quartz glass tube 7, and microwaves are transmitted in the cavity 3 through the quartz glass tube 7;

[0033] The cavity is fixed with a metal flange 2 that can move up and down. The upper metal flange 2 is located above the quartz glass tube 7, and the lower metal flange is located below the quartz glass tube. The cavity 3 is composed of the upper and lower metal flanges 2 ...

Embodiment 1

[0037] (1) Using ethanol and acetone solutions in sequence to ultrasonically clean the substrate to remove surface impurities. Subsequently, an appropriate amount of carbon nanotube powder sample is placed on the substrate at the center of the substrate stage and placed in a closed cavity, and then the metal flange is sealed to exclude air.

[0038] (2) Vacuumize the cavity, and feed nitrogen, adjust the nitrogen flow and air pressure (the air pressure of nitrogen in the cavity), and perform microwave irradiation;

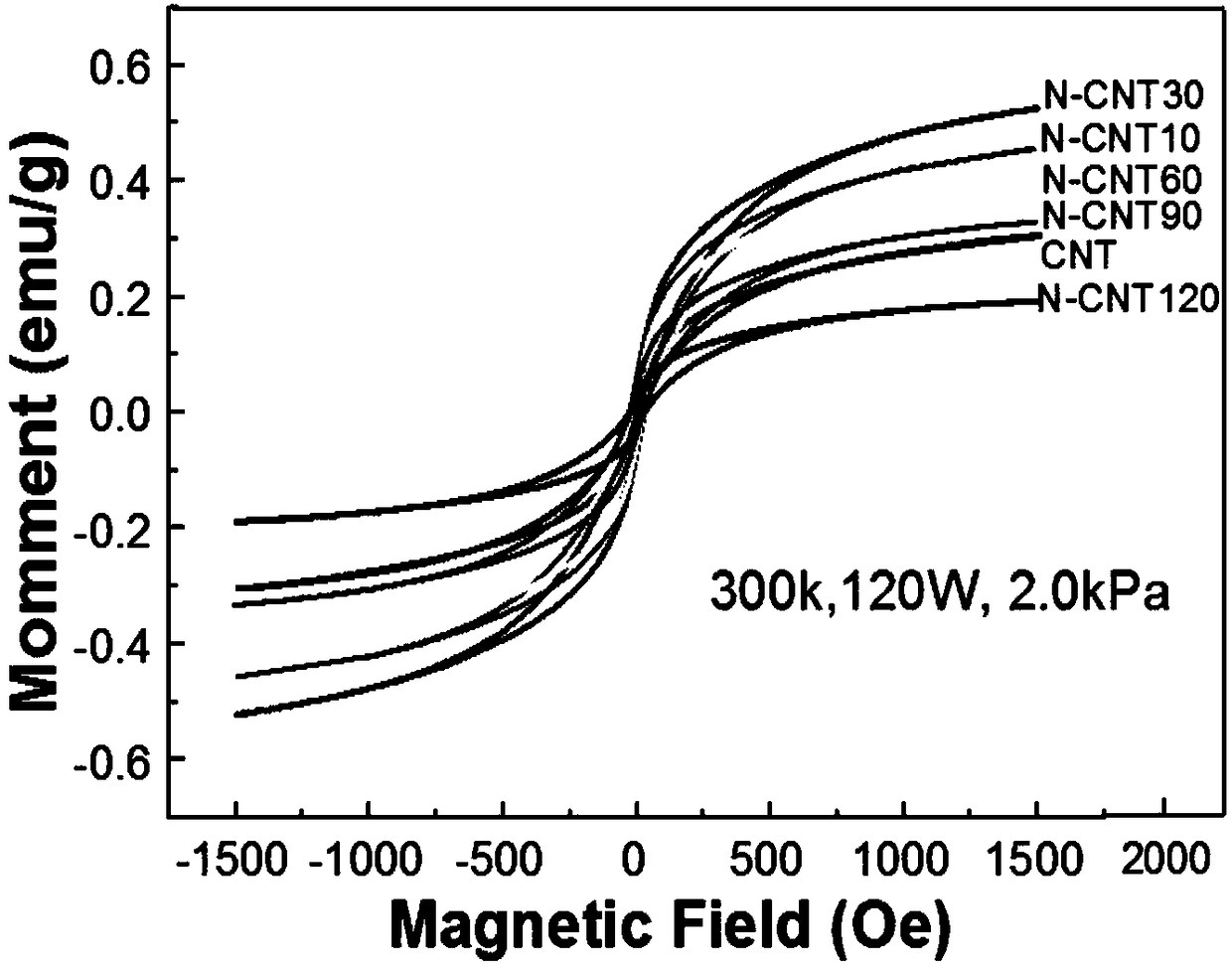

[0039] (3) The gas in the chamber absorbs microwave energy to excite and generate plasma. The process parameters used are: nitrogen flow rate 50sccm, working pressure 2.0kPa;

[0040] (4) Introduce nitrogen gas, adjust the gas flow rate, and wait until the plasma state is stable. After the reaction, the microwave source was turned off, and after the cavity was cooled, the nitrided samples were taken out. The process parameters used in the experiment were: microwav...

Embodiment 2

[0044] (1) Using ethanol and acetone solutions in sequence to ultrasonically clean the substrate to remove surface impurities. Subsequently, an appropriate amount of carbon nanotube powder sample is placed on the substrate at the center of the substrate stage and placed in a closed cavity, and then the metal flange is sealed to exclude air.

[0045] (2) Vacuumize the cavity, and feed nitrogen, adjust the nitrogen flow and air pressure (the air pressure of nitrogen in the cavity), and perform microwave irradiation;

[0046] (3) The gas in the cavity absorbs microwave energy to excite and generate plasma. The process parameters used are: nitrogen flow rate 50 sccm, and working pressure 3.0 kPa.

[0047] (4) Introduce nitrogen gas from the gas inlet, control and adjust the gas flow rate, and wait until the plasma state is stable. After the reaction, turn off the microwave source, wait for the cavity to cool down, and take out the sample. The process parameters used in the experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com