Method for preparing two-dimensional hafnium carbide nanosheets

A technology of hafnium carbide and nanosheets, which is applied in the field of preparation of two-dimensional hafnium carbide nanosheets, can solve the problems of unreported preparation process, increased energy consumption and cost, and high equipment requirements, and achieves simple and easy-to-operate process methods and reduced preparation costs. The effect of low cost and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

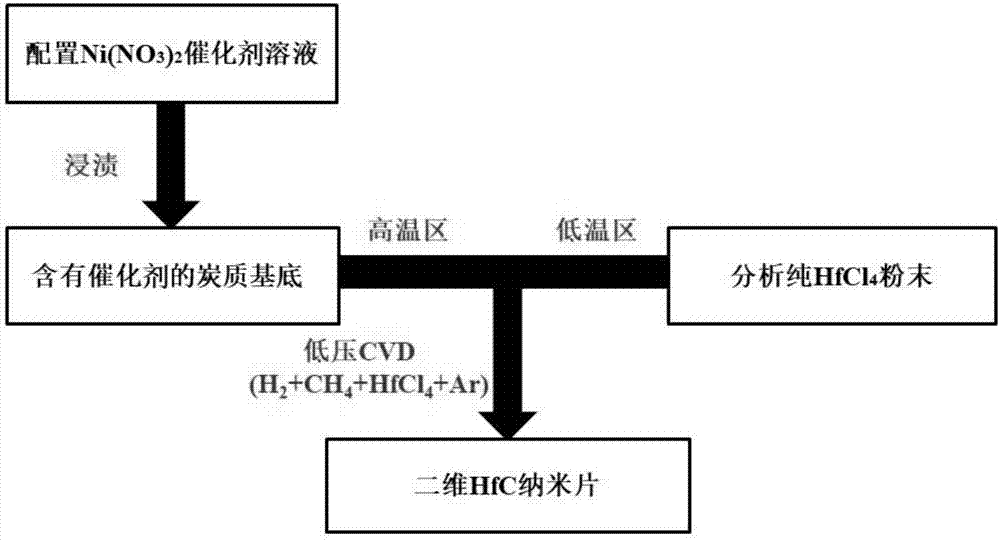

[0026] The preparation method of the two-dimensional hafnium carbide nanosheet provided in this embodiment comprises the following steps:

[0027] (1) Place the carbonaceous substrate on Ni(NO 3 ) 2 After soaking in the solution for 5h-10h, take it out and dry it to prepare Ni(NO 3 ) 2 carbonaceous substrate;

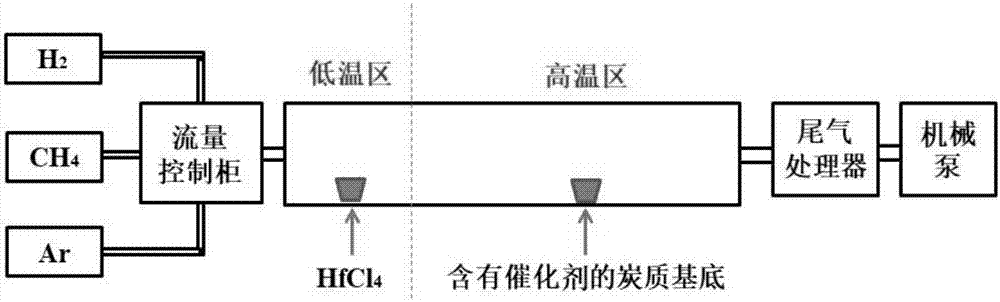

[0028] (2) The Ni(NO 3 ) 2 The carbonaceous substrate is placed in the high temperature zone of the dual temperature zone CVD tube furnace, and 2g-50g HfCl 4 The powder is placed in the low temperature zone of the dual temperature zone CVD tube furnace, and then the dual temperature zone CVD tube furnace is evacuated to 2kPa, wherein, Ni(NO 3 ) 2 carbonaceous substrate and HfCl 4 The powder is placed in the alumina crucible first, and then placed in the high temperature zone and the low temperature zone respectively;

[0029] (3) Feed H into the dual temperature zone CVD tube furnace at a flow rate of 15ml / min-100ml / min 2 At the same time, the temperature in the...

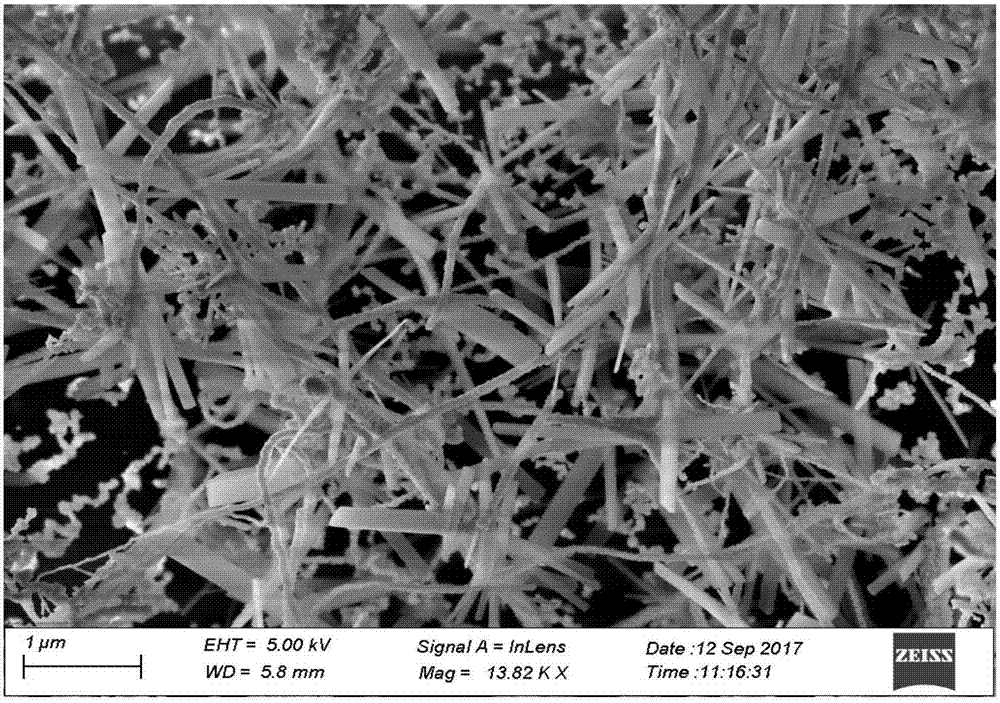

Embodiment 1

[0044] In this embodiment, the following steps are included:

[0045] (1) The cleaned 2D needle-punched carbon felt substrate with a size of 10mm×10mm×5mm was placed in a concentration of 0.20mol / L Ni(NO 3 ) 2 After soaking in ethanol solution for 5h, take it out and dry it in a drying oven at 50°C to prepare Ni(NO 3 ) 2 carbonaceous substrate;

[0046] (2) The Ni(NO 3 ) 2 The carbon substrate is placed in the alumina crucible A, and then the crucible A is placed in the high temperature zone of the double temperature zone CVD tube furnace, and 4g HfCl 4 The powder is placed in an alumina crucible B, and then the crucible B is placed in the low temperature zone of the dual temperature zone CVD tube furnace, and then the dual temperature zone CVD tube furnace is evacuated to 2kPa;

[0047] (3) Feed H into the double temperature zone CVD tube furnace at a flow rate of 50ml / min 2 At the same time, the temperature in the high temperature zone is raised to 1100°C at 8°C / min, ...

Embodiment 2

[0050] The preparation method of the two-dimensional hafnium carbide nanosheet provided in this embodiment comprises the following steps:

[0051] (1) Place the cleaned graphite paper substrate with a size of 10mm×10mm×10mm in 0.05mol / LNi(NO 3 ) 2 After soaking in ethanol solution for 5h, take it out and dry it in a drying oven at 45°C to prepare Ni(NO 3 ) 2 carbonaceous substrate;

[0052] (2) The Ni(NO 3 ) 2 The carbon substrate is placed in the alumina crucible A, and then the crucible A is placed in the high temperature zone of the double temperature zone CVD tube furnace, and 3g HfCl 4 The powder is placed in an alumina crucible B, and then the crucible B is placed in the low temperature zone of the dual temperature zone CVD tube furnace, and then the dual temperature zone CVD tube furnace is evacuated to 2kPa;

[0053] (3) Feed H into the double temperature zone CVD tube furnace at a flow rate of 15ml / min 2 At the same time, the temperature in the high temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com