Force-responsive polymer foam particle and preparation method thereof

A technology of foam particles and polymers, applied in the field of force-responsive polymer foam particles and their preparation, to achieve good energy absorption capacity, rich stress monitoring and stress response capabilities, and improve the effect of high and low temperature slow rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

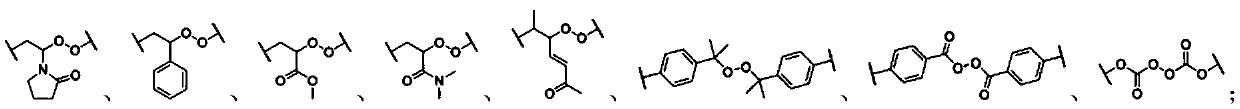

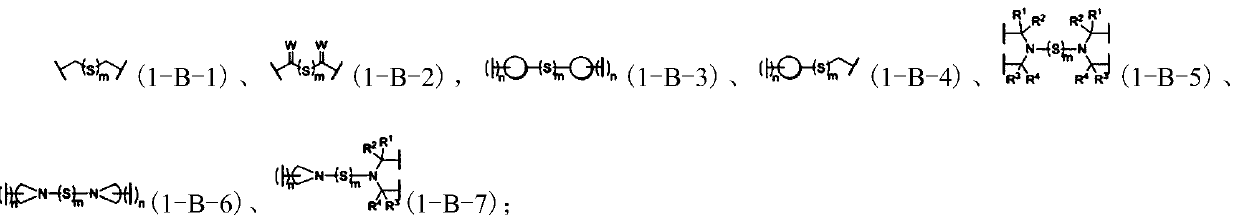

[2053] In the preparation process of force-responsive polymer foam particles, other optional additives are preferably antioxidants, light stabilizers, heat stabilizers, crosslinking agents, chain extenders, compatibilizers, tougheners, plasticizers , Flame retardant.

[2054] In the present invention, the optional fillers in the polymer mainly play the following roles: ①Reduce the shrinkage rate of the molded product, improve the dimensional stability, surface finish, smoothness and flatness or dullness of the product ②Adjust the viscosity of the polymer; ③Meet different performance requirements, such as improving the impact strength and compressive strength, hardness, stiffness and modulus of polymer materials, improving wear resistance, increasing heat distortion temperature, improving electrical conductivity and thermal conductivity Etc.; ④ Improve the coloring effect of the pigment; ⑤ Give light stability and chemical corrosion resistance;

[2055] The optional fillers in...

Embodiment 1

[2119]

[2120] With 1 molar equivalent of boron trifluoride ethyl ether as the initiator and epichlorohydrin as the accelerator, the ring-opening copolymerization of tetrahydrofuran and 2-(tetrahydrofuran-3-yl)acetonitrile is initiated, and water is used as the terminator to obtain the hydroxy-terminated polytetrahydrofuran.

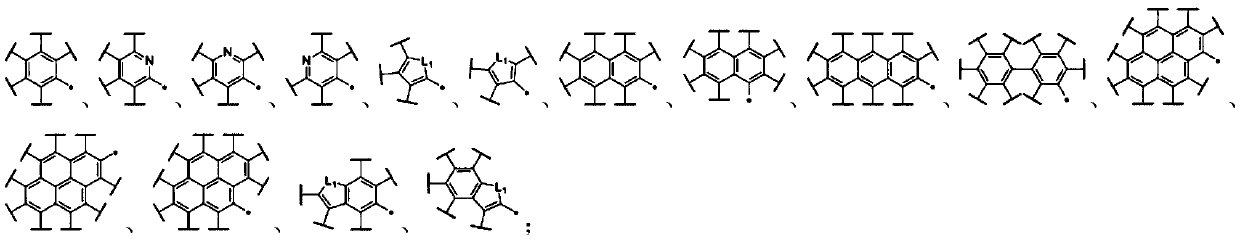

[2121] Take 5.3g of toluene-2,4,6-triyl triisocyanate into a three-necked flask, vacuum dehydrate at 120°C for 2 hours, cool down to 45°C, add 12ml of DMF to dissolve and dilute, protect with argon, and then put 0.8g The diazacycarbene compound (a), 4.05 g of 6-hydroxycoumarin and a small amount of butyltin dilaurate solution were dissolved in 40 mL of DMF and added dropwise to the reaction flask at a constant speed. After heating to 70°C for 3 hours, add 10 g of hydroxyl-terminated polytetrahydrofuran containing pendant nitrile groups, and continue the reaction at 70°C for 6 hours to obtain polyurethane containing coumarin side groups.

[2122] 70 ...

Embodiment 2

[2124]

[2125] Using 9,10-dibromoanthracene and trimethylsilylacetylene as raw materials, Pd(PPh 3 ) 2 Cl 2 , CuI, diisopropylamine as a catalyst, THF as a solvent, react under an argon atmosphere at 60°C to obtain 9,10-bistrimethylsilylethynyl anthracene; 9,10-bistrimethylsilylethynyl Dissolve anthracene and N-(2-hydroxyethyl)maleimide in xylene solvent, and stir at 150°C for reaction 3d to obtain compound (b); dissolve compound (b) in a mixture of THF and methanol In the solvent, potassium carbonate was added, and the reaction was stirred for 2h at room temperature under an argon atmosphere to obtain an intermediate product, and then Pd(PPh 3 ) 2 Cl 2 , CuI, diisopropylamine as a catalyst, THF as a solvent, react 1d with 4-iodophenol at room temperature under argon atmosphere to obtain compound (c).

[2126] Take 3.48g of 1,2-bis(4-phenylisocyanate) disulfide into a three-necked flask, vacuum dehydrate at 120°C for 2h, cool down to 45°C, add 10ml of DMF to dissolve an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com