Front suspension bracket for cab of heavy duty truck

A cab front suspension and front suspension technology, which is applied to the upper structure of the truck, vehicle parts, upper structure, etc., can solve the problems of front suspension bracket fracture, etc., and achieve the prevention of falling and good energy absorption capacity , The effect of protecting the safety of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

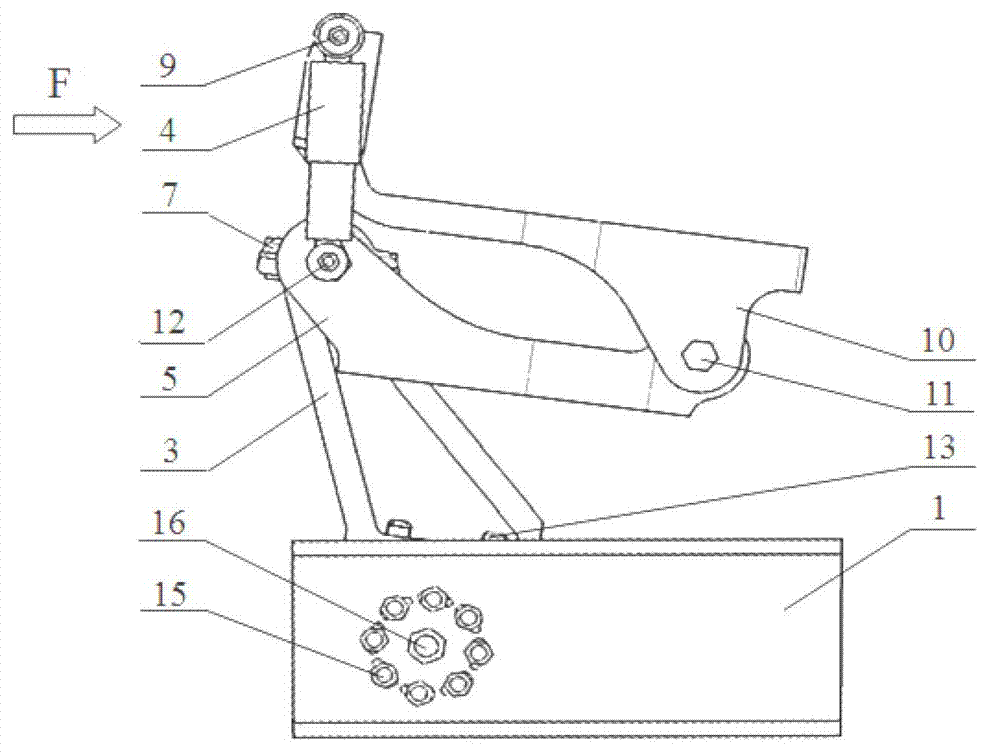

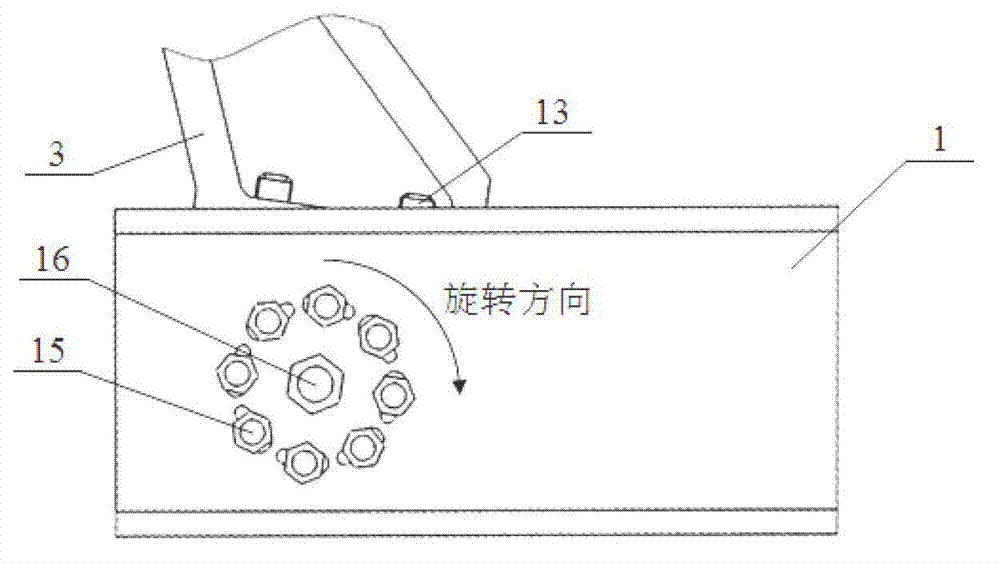

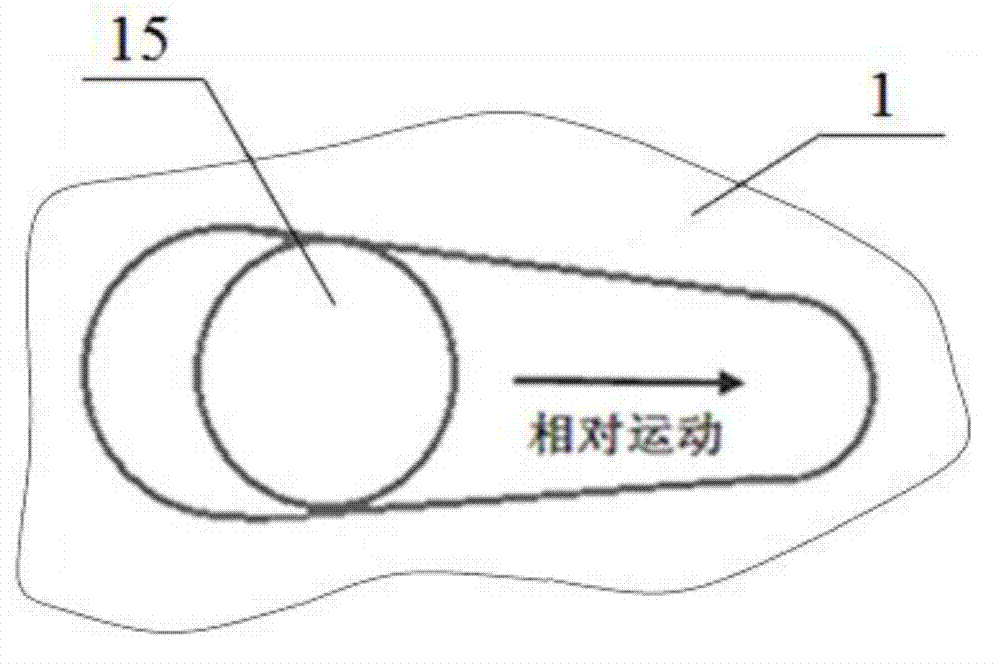

[0052] The present invention is described in detail below in conjunction with accompanying drawing:

[0053] The front suspension bracket of the cab of the heavy-duty truck according to the present invention is intended to ensure the integrity of the front suspension bracket of the truck when the truck collides head-on, and prevent the damage caused by the fracture of the front suspension bracket. The cab of the truck falls while absorbing part of the collision energy to effectively protect the occupants in the truck.

[0054] refer to Figure 6 , the structure of the front suspension bracket of the heavy truck cab according to the present invention is shown in the figure. The front suspension bracket of the heavy truck cab consists of a front suspension right bracket, a front suspension left bracket and a front suspension bracket. Support balance bar 8 is formed, and front suspension right support and front suspension left support are installed on the right end of front susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com