Recovery device for anode and cathode materials of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in the field of recycling devices, can solve the problems of low recycling efficiency, low power distribution and recycling rate, corrosion and burns, etc., and achieve the effect of high recycling utilization rate and low battery pollution degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

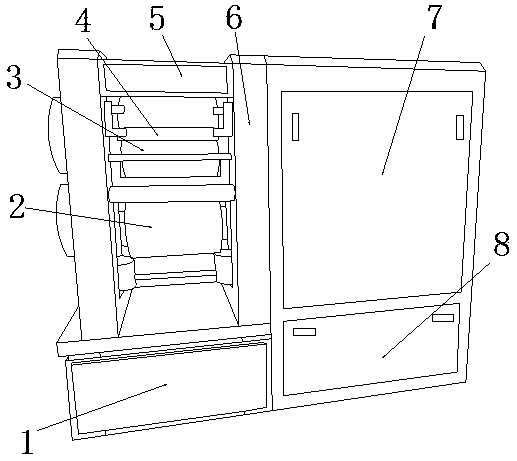

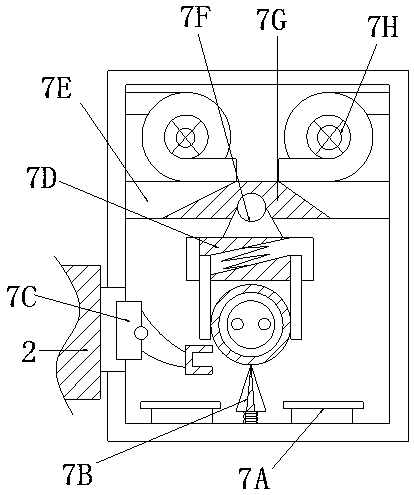

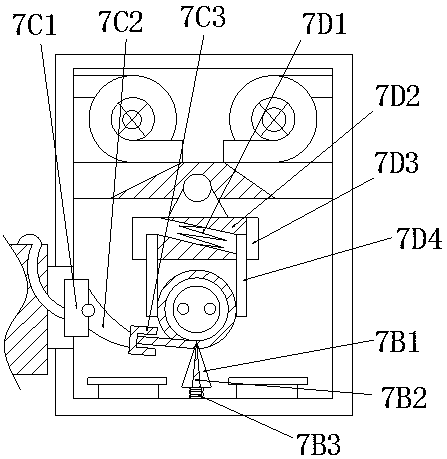

[0031] see Figure 1-Figure 7 , the present invention provides a recycling device for positive and negative materials of lithium-ion batteries, the structure of which includes: motor bottom tank 1, pole plate winding drum 2, grinding roller 3, clamping shaft frame 4, beam plate 5, The side ring groove vertical plate 6, the pumping plate cutting box 7, and the heat exchange bottom groove 8, the pumping plate cutting box 7 is close to the top surface of the heat exchange bottom groove 8 and the right side of the side ring groove vertical plate 6 And on the same vertical plane, the grinding roller 3 and the clamping shaft frame 4 are buckled together, the electrode plate winding drum 2 and the grinding roller 3 adopt clearance fit, and the side ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com