Denitration catalyst drying apparatus

A technology of denitration catalyst and drying device, which is applied in the direction of drying gas arrangement, local stirring dryer, static material dryer, etc., can solve the problems of energy consumption, hot air is not recycled, waste, etc., to reduce production costs and improve The effect of recycling utilization and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

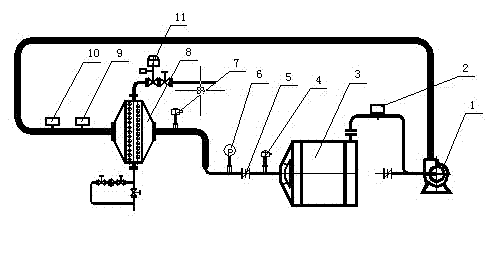

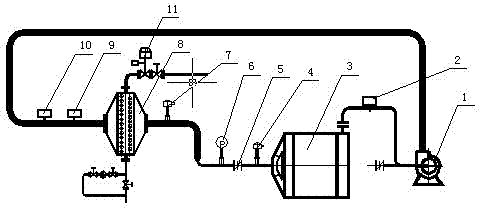

[0011] The present invention comprises drying box 3, heat exchanger 8 and connecting pipeline, and the air inlet of drying box 3 is connected with a blower fan 1, and the air outlet of drying box 3 is connected with heat exchanger 8, and heat exchanger 8 is connected with a hot steam pipeline, heat The outlet of the heat exchanger 8 is connected to the blower fan 1; a pressure detection device three 9, a humidity detection device one 10, a temperature detection device one 4 are set between the heat exchanger 8 and the blower fan 1, and the pipeline is provided with a damper adjustment device 5; A pressure detection device 2 6 and a temperature detection device 2 7 are set between the drying box 3 and the heat exchanger 8 ; a pressure detection device 1 2 is set between the fan 1 and the drying box 3 .

[0012] The present invention is provided with heating device 11 on steam pipeline.

[0013] Working principle of the present invention: the present invention uses steam to heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com