Patents

Literature

49results about How to "Realize environmentally friendly processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

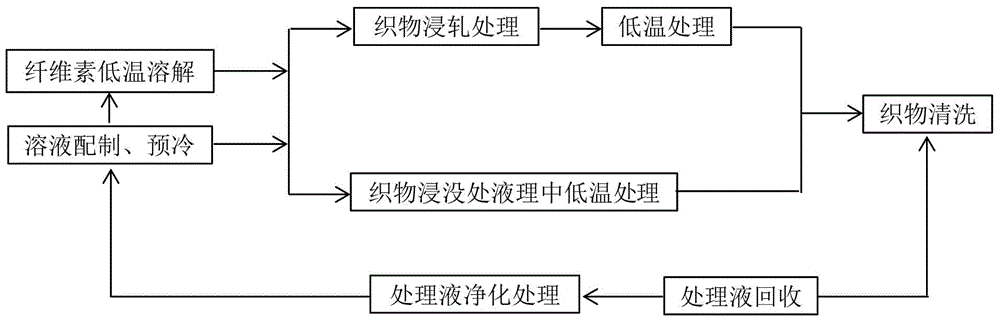

Non-slurry self-sizing method for cellulosic fiber containing yarns

ActiveCN104480722AAchieve repeated useRealize environmentally friendly processingVegetal fibresYarnHydrogen

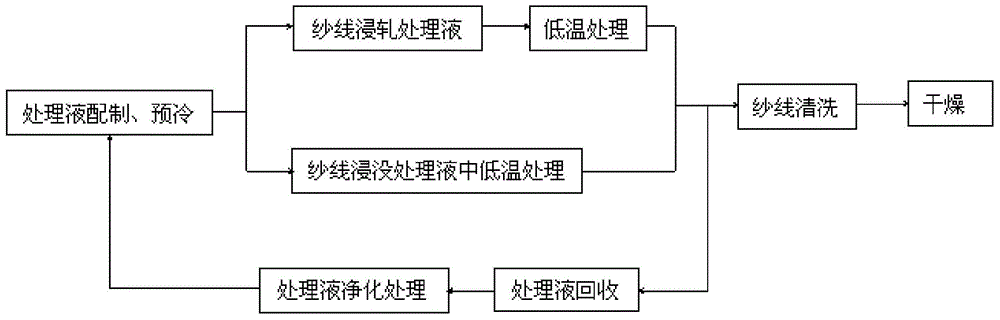

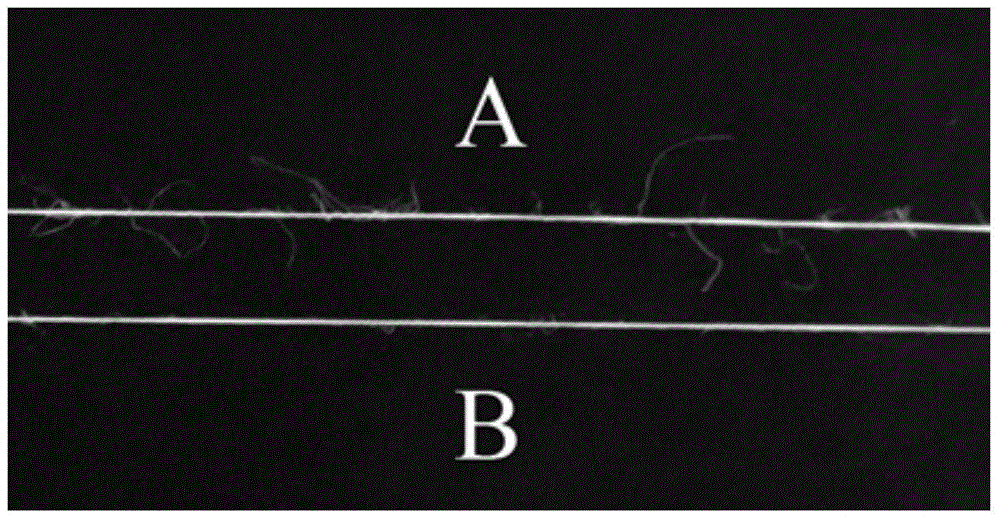

The invention relates to a non-slurry self-sizing method for cellulosic fiber containing yarns. The non-slurry self-sizing method for the cellulosic fiber containing yarns comprises the following steps: mixing alkali, components effectively breaking hydrogen bonds among polysaccharide molecules and water to obtain a dissolved solution, and pre-cooling the solution to be 5 DEG C to 15 DEG C below zero; at 5 DEG C to 80 DEG C below zero, processing cellulosic fiber containing yarns in the dissolving solution or a padding solution for 10 seconds to 15 minutes, washing, and processing the yarns for once to ten times, drying and obtaining self-sized yarns. According to the non-slurry self-sizing method for the cellulosic fiber containing yarns, no slurry is consumed, the utilized various solutions and washing liquids can be recycled, the production cost is low, the energy and water consumption is reduced, the dependency of the textile industry on non-degradable or high-cost traditional slurry is reduced, and the transformation of the textile industry is beneficial of transforming to the low-carbon environment protection industry.

Owner:DONGHUA UNIV

Nutritional foliage fertilizer for plants and preparation method of foliage fertilizer

InactiveCN107673904AEffective and harmless treatmentAvoid pollutionBio-organic fraction processingAnimal corpse fertilisersMicroorganismTrace element

The invention belongs to the technical field of microbial fertilizer and particularly relates to nutritional foliage fertilizer for plants and a preparation method of the foliage fertilizer. The nutritional foliage fertilizer for the plants is prepared from components as follows: 5%-8% of oyster meal, 9%-15% of edible mushrooms, 0.1%-0.5% of a radix sophorae flavescentis extracting solution and 78%-85% of an animal nutrient solution. The nutritional foliage fertilizer for plants contains nutritional essence of plants and animals, contains rich organic selenium and various trace elements and also has the sterilization and fertility increasing efficacy.

Owner:禹玉勇

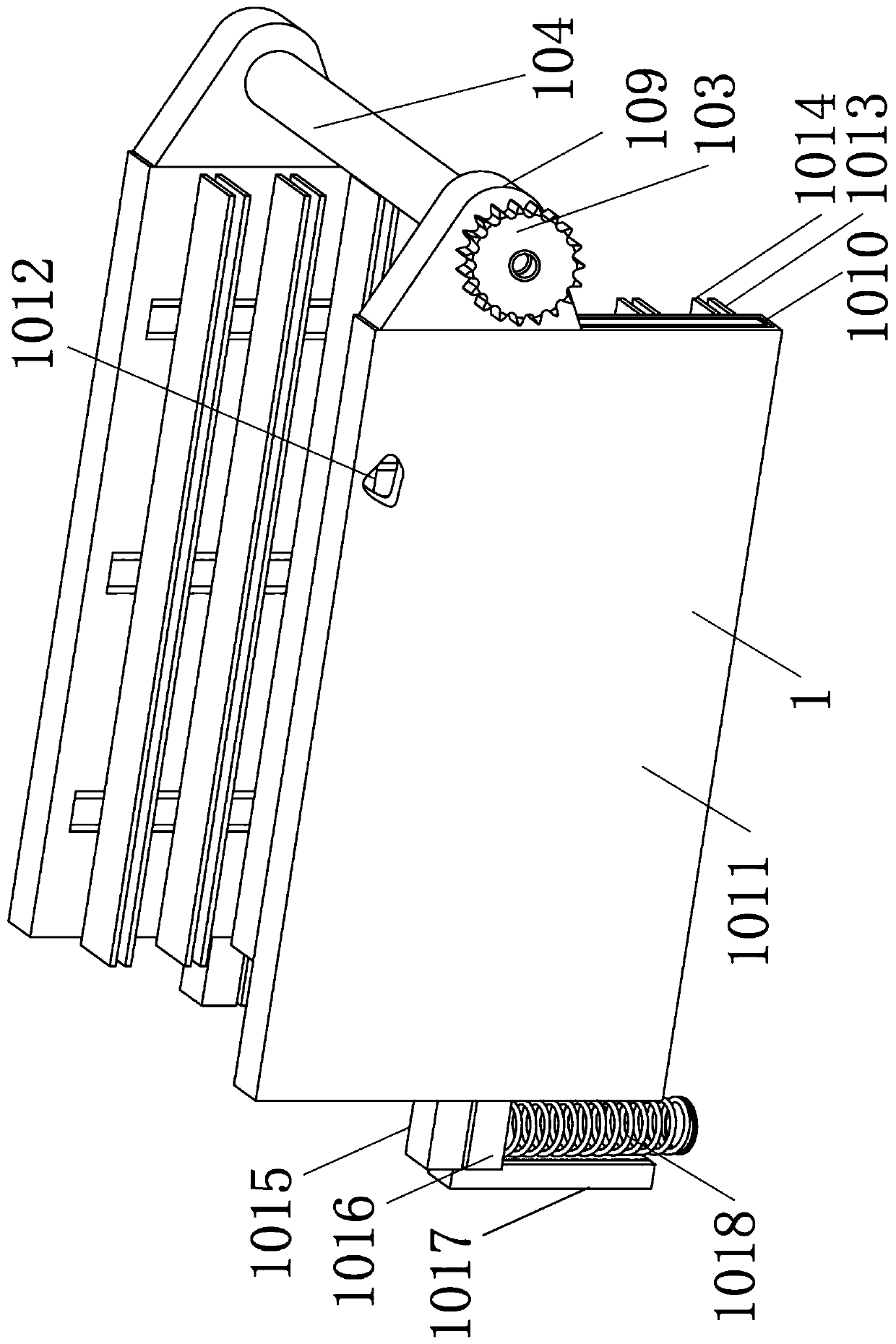

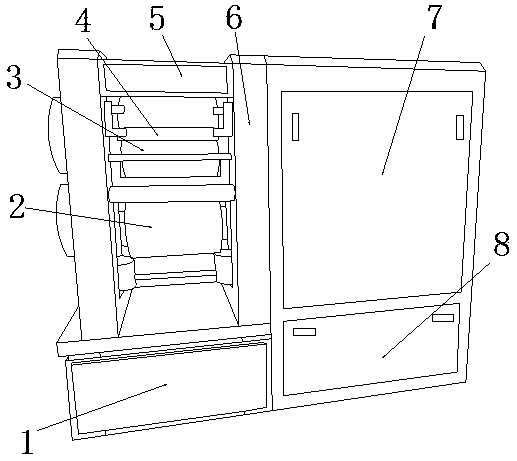

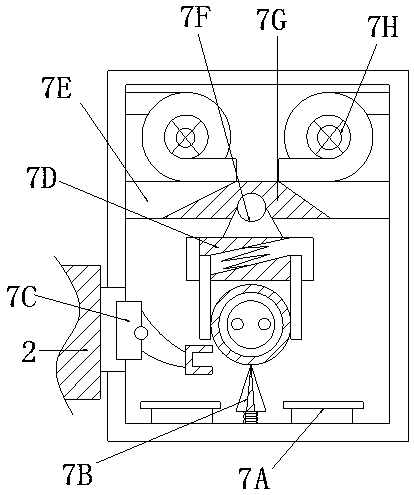

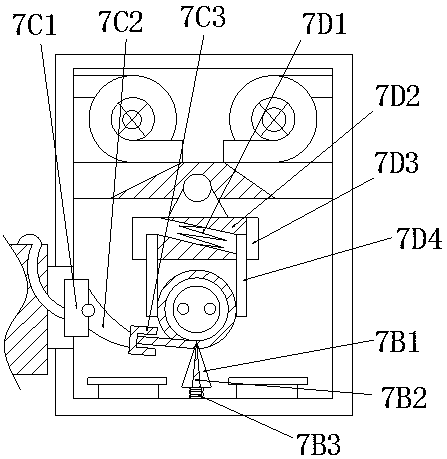

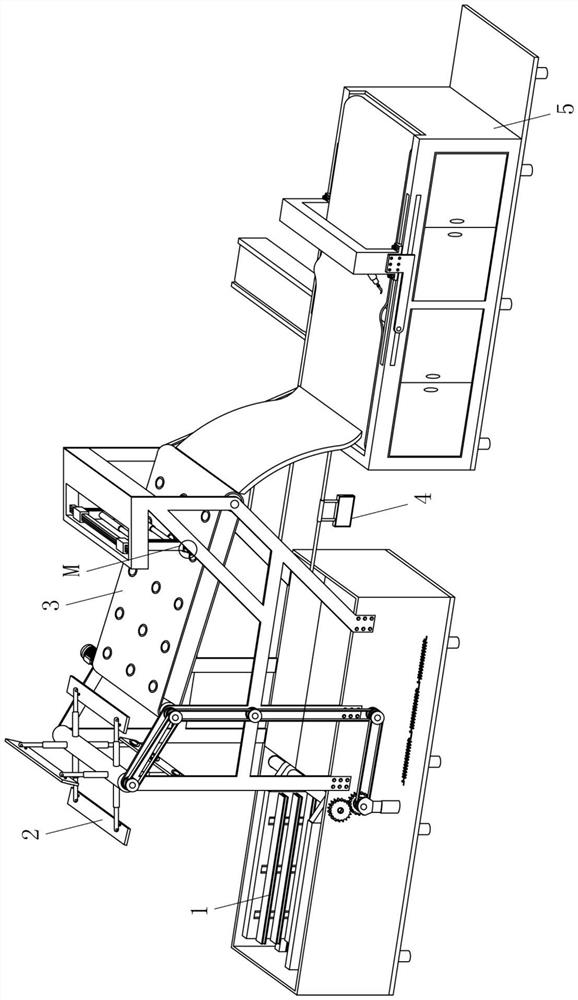

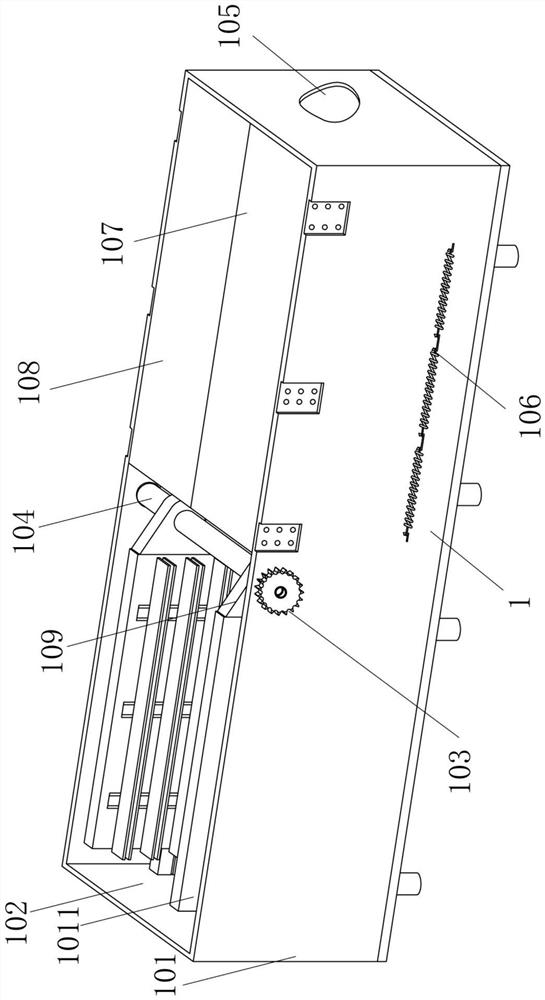

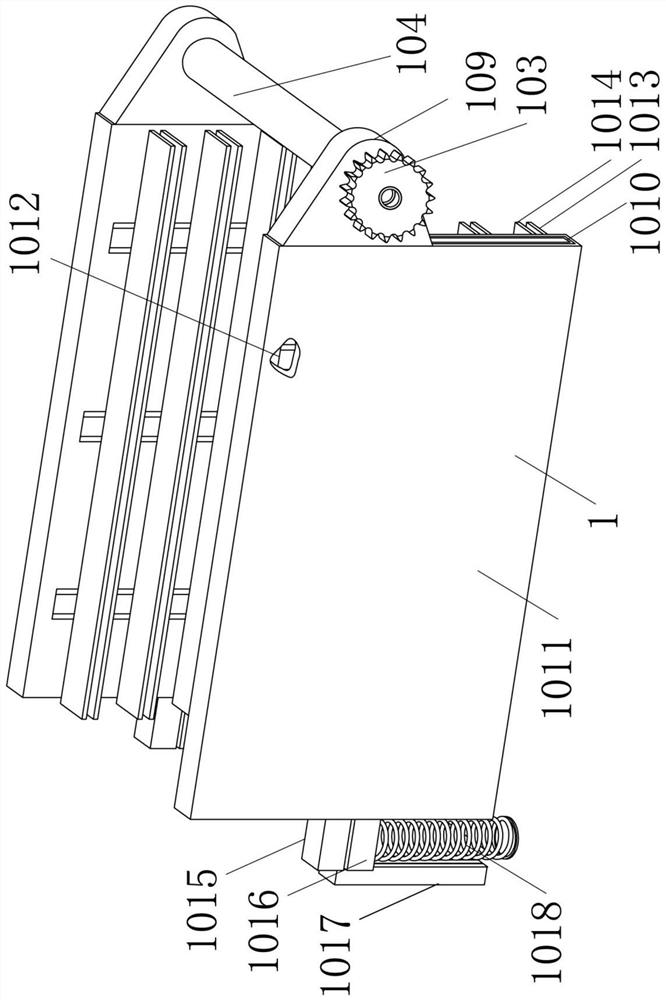

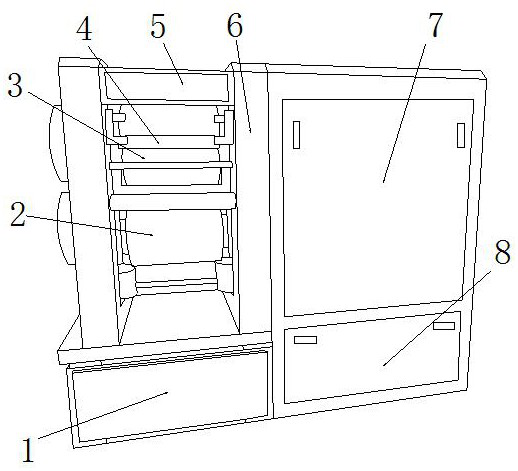

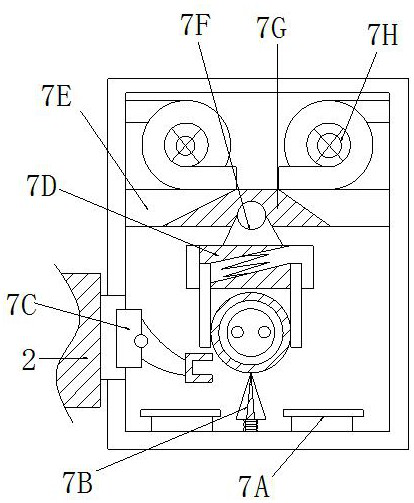

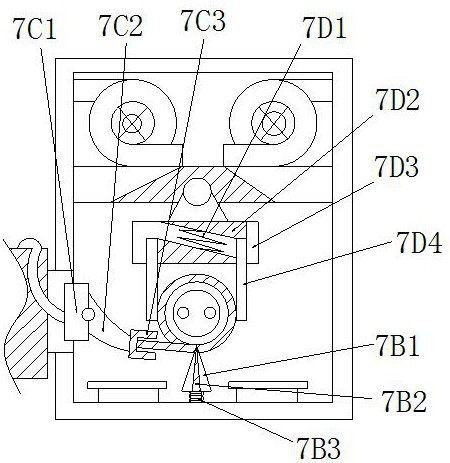

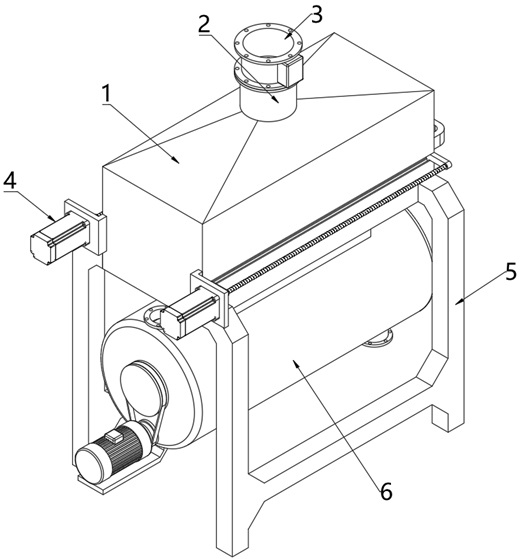

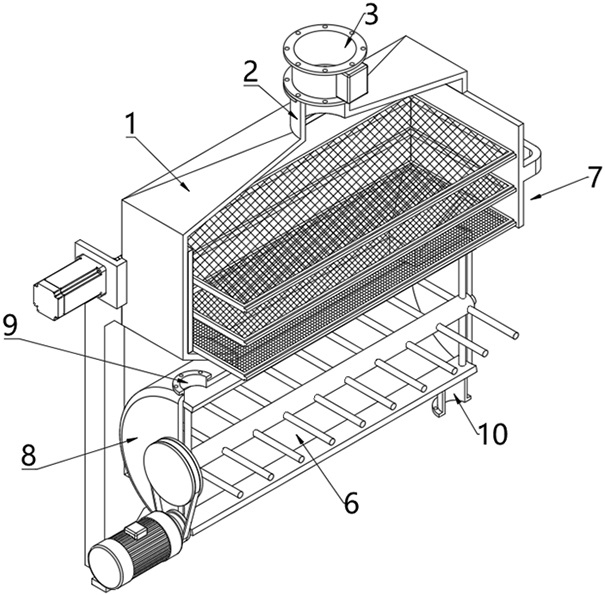

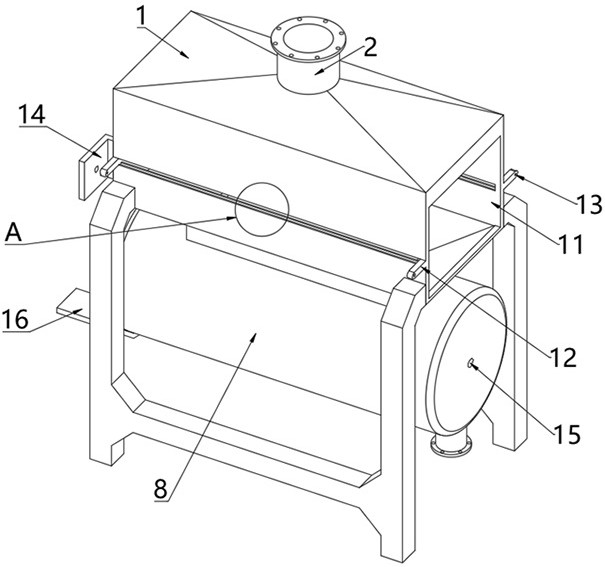

Bamboo product recycling device

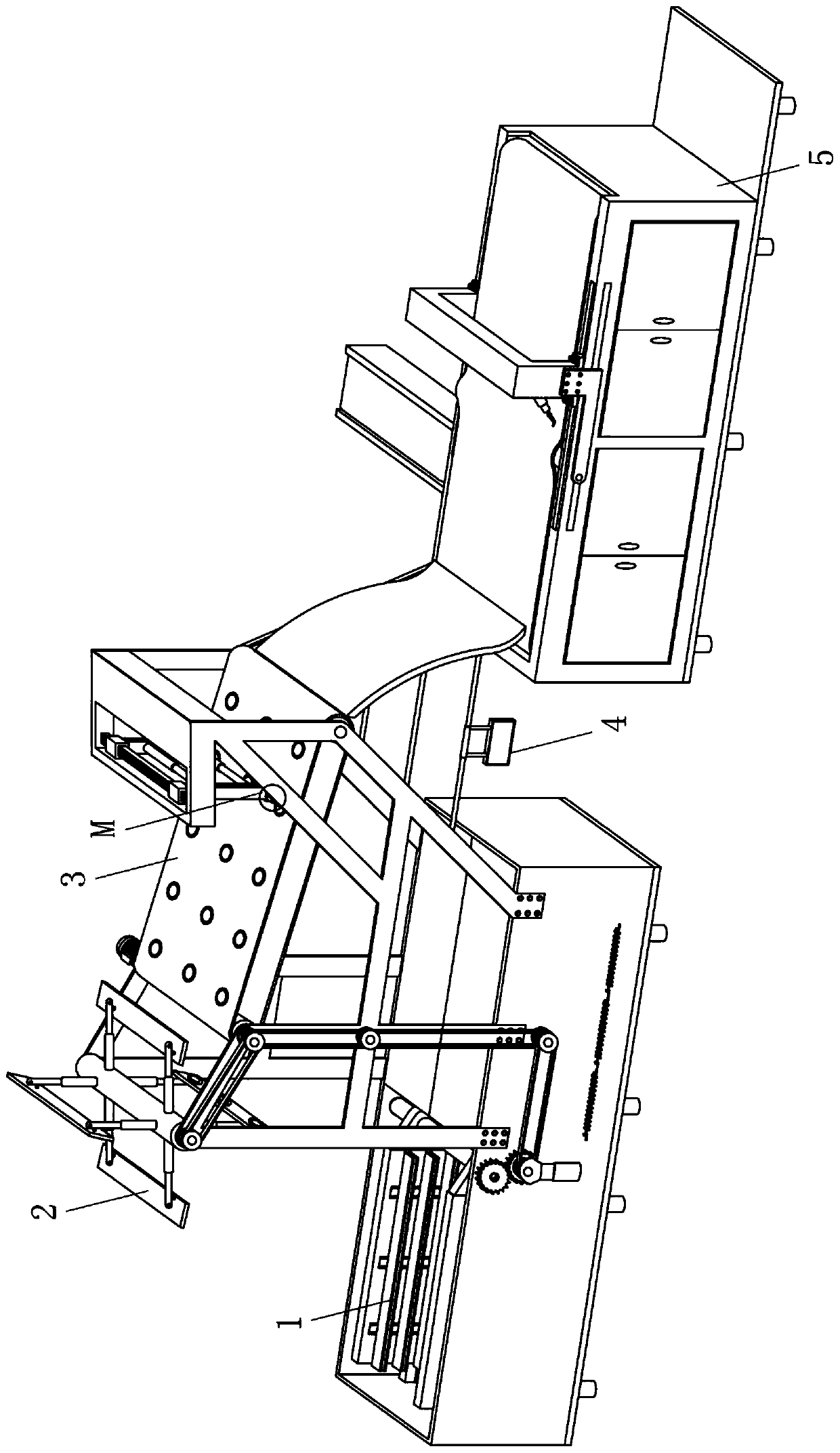

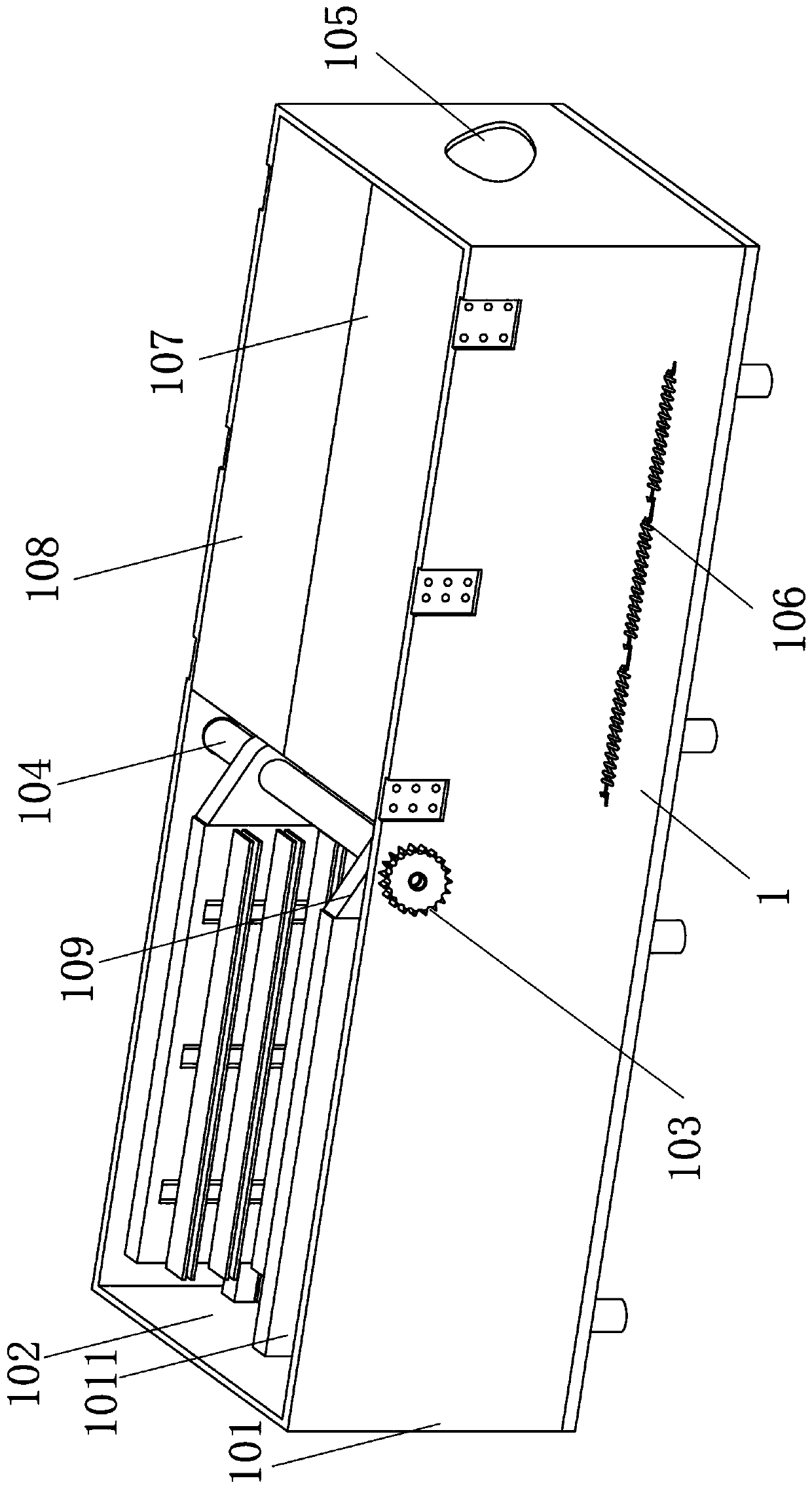

ActiveCN111530889ARealize environmentally friendly processingQuality improvementSolid waste disposalTransportation and packagingTransfer mechanismAgricultural engineering

The invention relates to the field of plant processing and recycling, in particular to a bamboo product recycling device. The technical problem to be solved is to provide the bamboo product recyclingdevice. The bamboo product recycling device comprises a deoiling and softening mechanism, a lifting transferring mechanism, a wire removing mechanism, a control screen and a hooking picking mechanism;the wire removing mechanism is arranged on the right side of the top of the outer surface of the deoiling and softening mechanism; the lifting transferring mechanism is arranged at the upper left part in the wire removing mechanism; and the control screen is arranged in the front right middle of the wire removing mechanism. According to the device, after summer sleeping mats are subjected to deoiling and heating softening, braided wire rubbing off is carried out, and then bamboo chips are recycled one by one; and the quality of the recycled bamboo chips is greatly improved, and meanwhile, bottom fabric and covered edges can be recycled in a unified manner, so that the summer sleeping mats are treated in an environment-friendly manner, and the discarded summer sleeping mats have beneficialusage.

Owner:益阳和祥竹业有限公司

Ecological fruit and vegetable planting and cultivation method

InactiveCN110741864ARealize ecological plantingIncrease incomeAnimal corpse fertilisersExcrement fertilisersEcological environmentWater storage tank

The invention belongs to the technical field of agriculture and discloses an ecological fruit and vegetable planting and cultivation method. The method is characterized in that land is separated intoa fish pond, a vegetable planting garden and a fruit tree planting garden, the vegetable planting garden and the fruit tree planting garden are arranged on the outer side of the fish pond, the fish pond is provided with a draining pipe, and the draining pie is connected with a water storage tank; water in the water storage tank is used for watering the vegetable planting garden and the fruit treeplanting garden; a poultry cultivation area is arranged in the fruit tree planting garden; a fermentation tank is arranged outside the poultry cultivation area, and manure from the poultry cultivationarea is fermented in the fermentation tank and then is used as the fertilizer for the vegetable planting garden and the fruit tree planting garden. The method has the advantages that fish cultivation, fruit and vegetable planting and poultry cultivation are combined, land utilization value is increased, agricultural waste and poultry manure generated during cultivation are comprehensively utilized and fermented into organic fertilizer applied to fruit and vegetable planting and fish cultivation, the use of chemical fertilizer and feed is reduced greatly, ecological environment protection is achieved, and economic benefits are increased.

Owner:绵阳市安州区开创农业开发有限责任公司

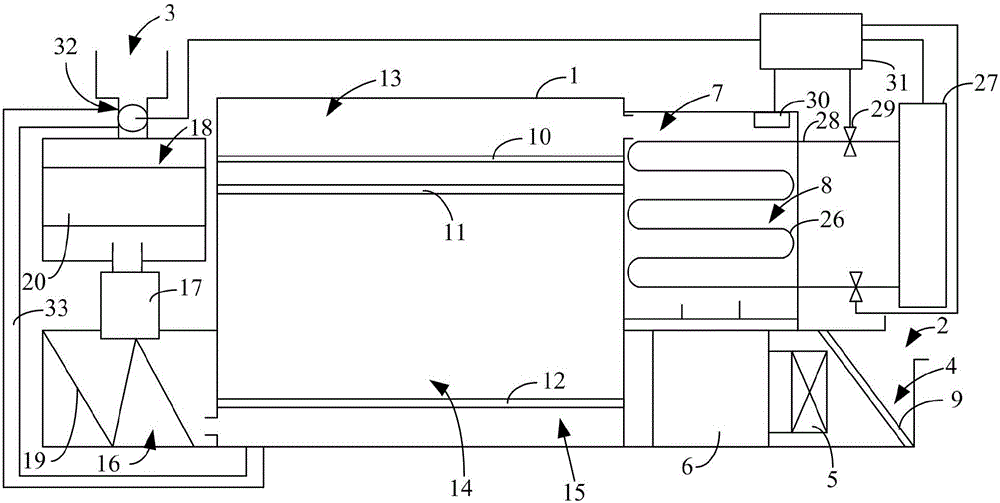

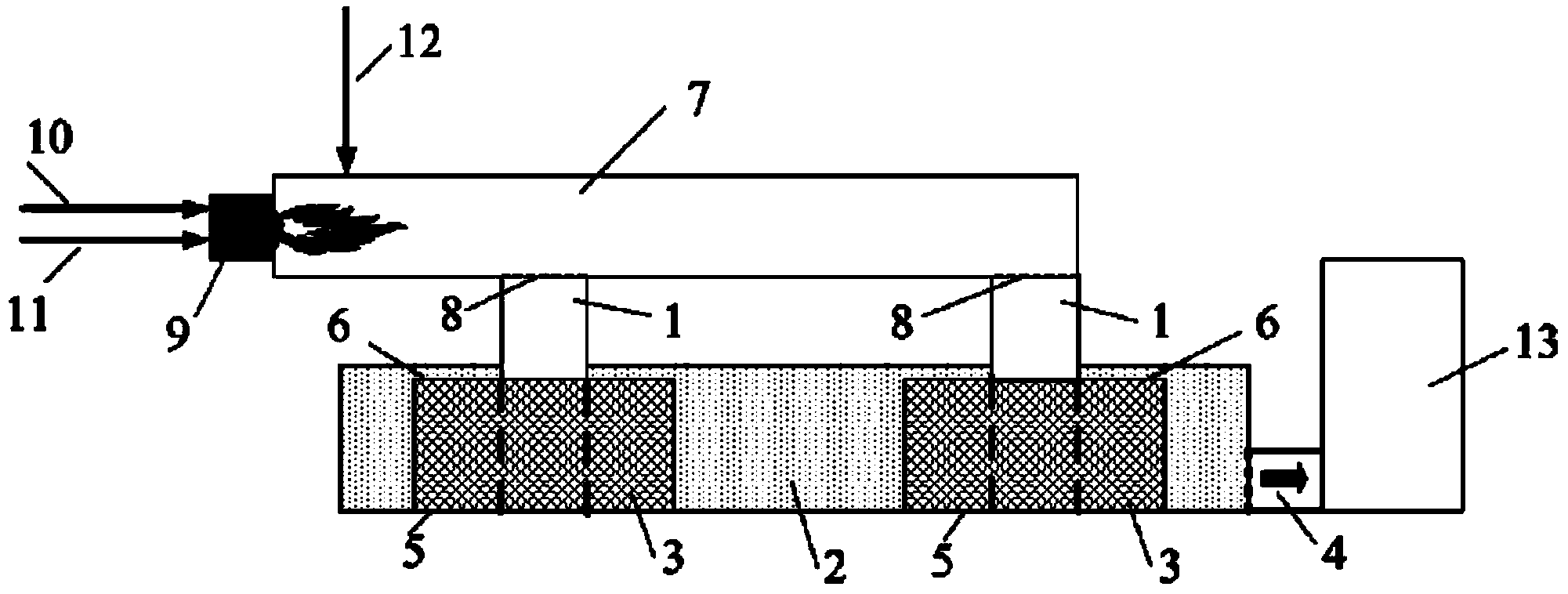

Automobile baking finish house

InactiveCN106694293AReduce pollutionSimple structureLiquid surface applicatorsCoatingsTemperature controlGrating

The invention relates to the technical field of automobile baking finish and provides an automobile baking finish house. A baking finish operation space is formed in a house body of the automobile baking finish house. The house body is provided with an air inlet and an air outlet. A temperature control mechanism is installed in an air supply cavity. A first filtering device is arranged in a first filtering cavity. An air supply fan communicates with the first filtering cavity. A filtering hole plate, a second filtering device and a grating plate are arranged in the baking finish operation space. A static pressure chamber is formed between the second filtering device and a top plate of the house body. An automobile operation space is formed between the second filtering device and the grating plate. A waste gas channel is formed between the grating plate and a bottom plate of the house body. A precipitation cavity communicates with the waste gas channel. A third filtering device is arranged in the precipitation cavity. An exhaust cavity communicates with an air outlet of an exhaust fan. A fourth filtering device is arranged in the exhaust cavity. Air in the exhaust cavity is discharged to the air outlet after passing the fourth filtering device. The automobile baking finish house provides stable and clean airflow for automobile baking finish, the paint spraying effect can be improved, waste gas is subjected to dust removal and filtering treatment, and environmental protection reaches the standard.

Owner:YANTAI SMITHDE ELECTROMECHANICAL EQUIP MFG

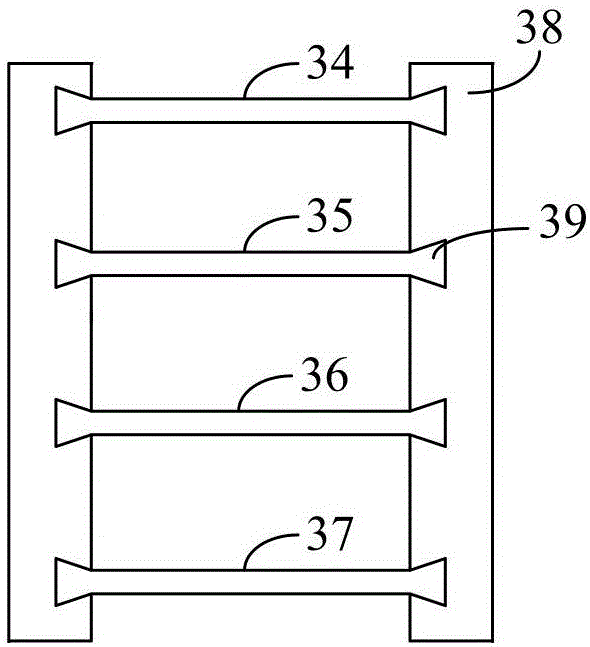

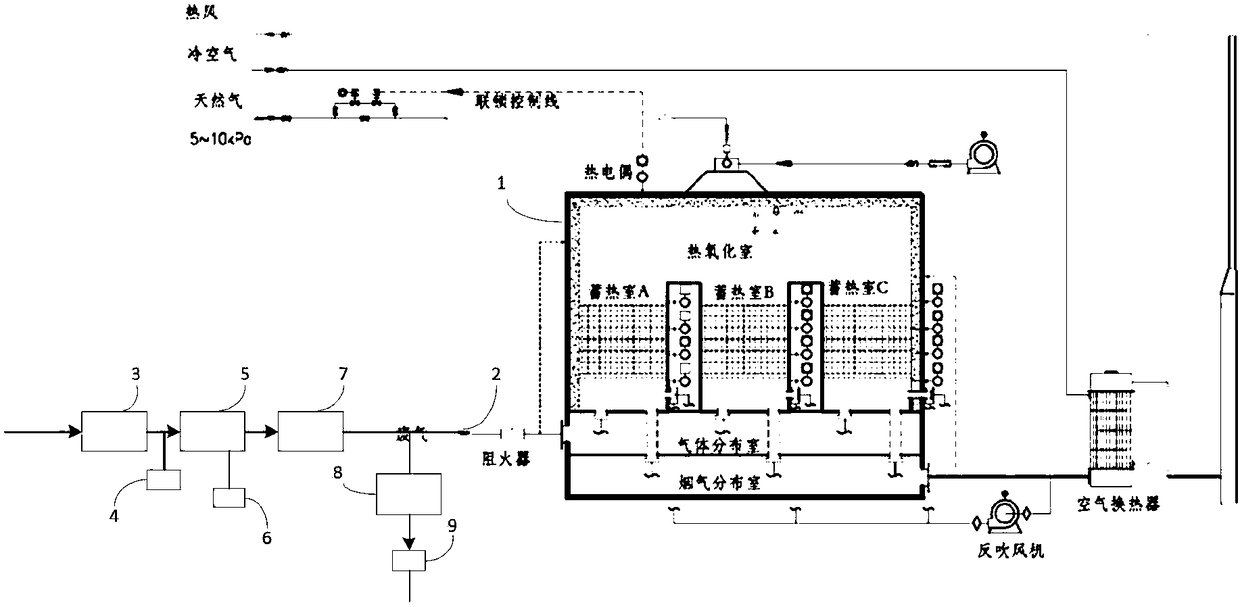

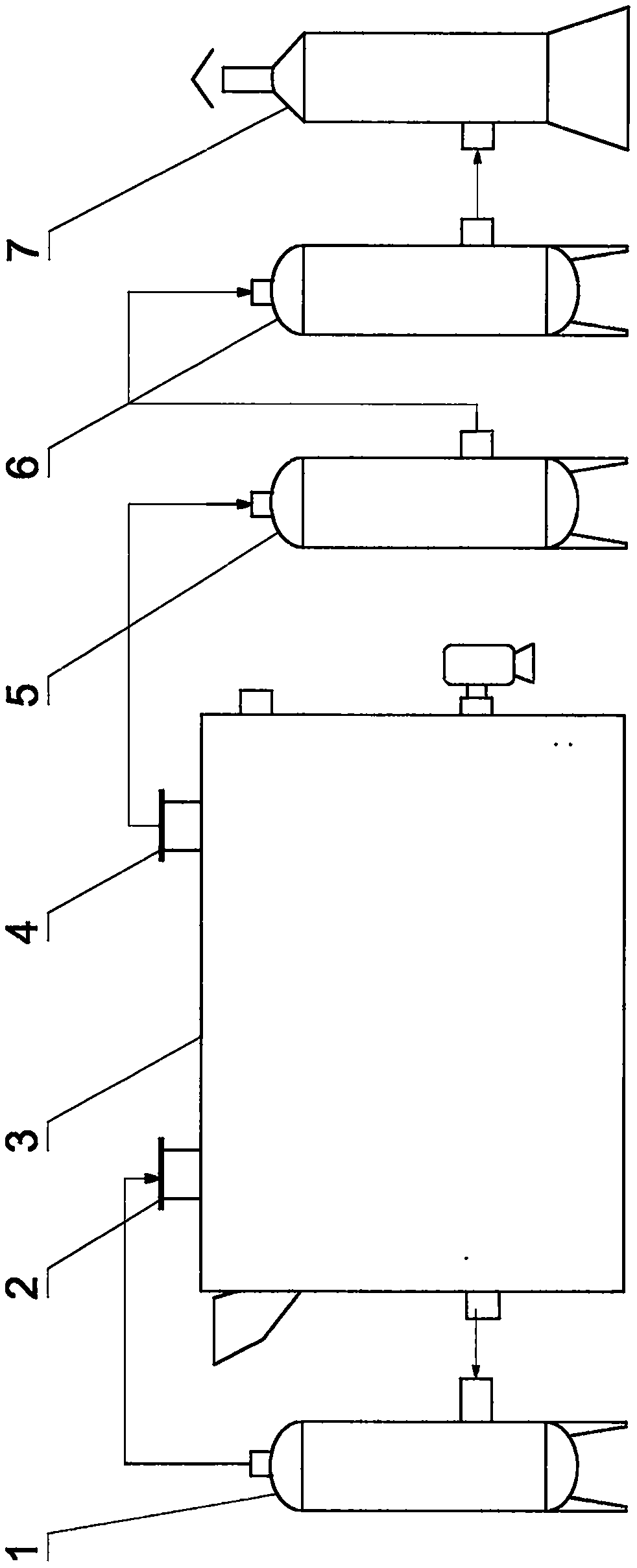

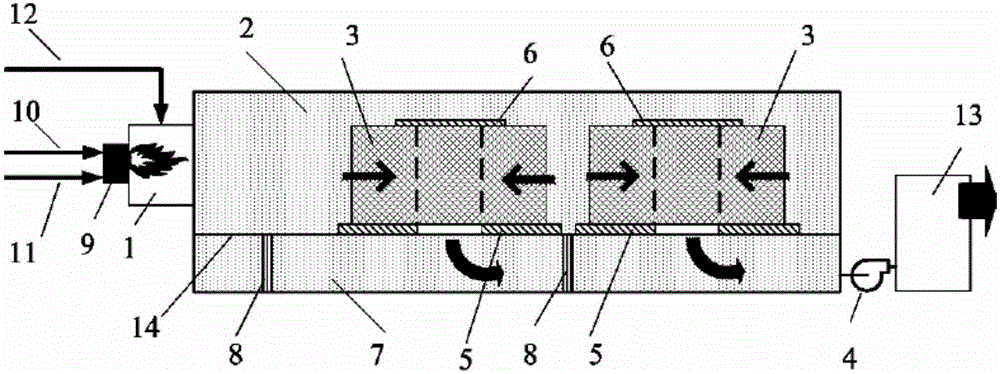

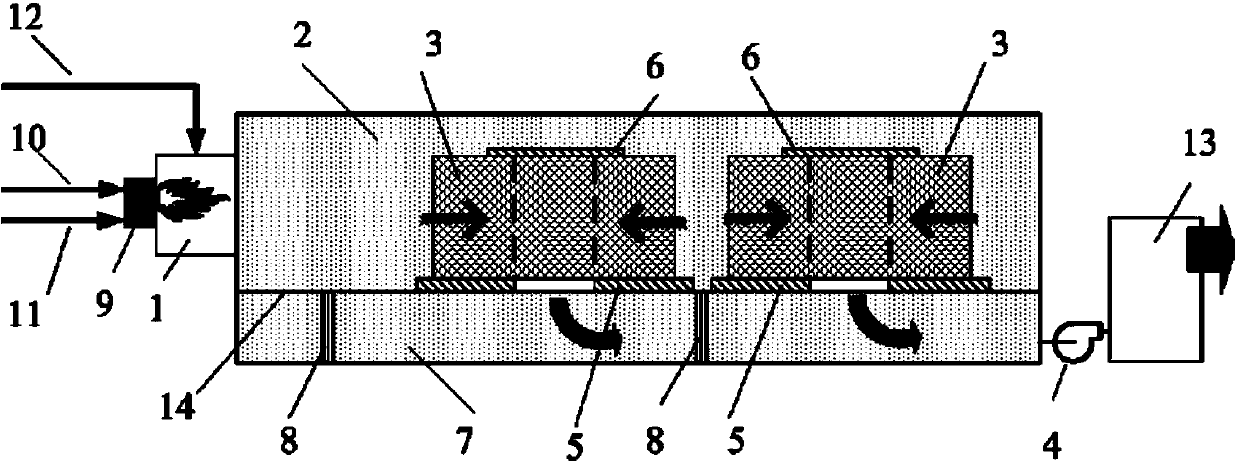

Industrial waste gas incineration treatment system

PendingCN108426257AProcess safetyRealize environmentally friendly processingIncinerator apparatusAir volumeAutomatic control

The invention discloses an industrial waste gas incineration treatment system. The system comprises a heat storage type thermal incinerator, an acid-alkaline adsorption mechanism, a buffering tank mechanism and an explosion-proof fan; a gas inlet of the acid-alkaline adsorption mechanism is connected with a waste gas source to be treated; a gas inlet of the buffering tank mechanism is connected with a gas outlet of the acid-alkaline adsorption mechanism. According to the system provided by the application, necessary countermeasures are taken against hazard factors in a using process of the heat storage type thermal incinerator, so that the overall treatment process is safe and reliable. The industrial waste gas incineration treatment system has the characteristics that the investment is low; the occupied area is small; the mounting period is short; the requirements on working conditions are low; waste gas can contain a plurality or organic components; the treatment air volume range islarge; the purifying rate is high; full-automatic control is realized; the operation is simple; the operating cost is low. The industrial waste gas incineration treatment system has good structural design and high-quality equipment configuration; the purposes of environment-friendly treatment of VOCs in industrial waste gas, energy conservation and emission reduction, and up-to-standard emission of exhaust are achieved.

Owner:BEIJING ENJI ENERGY SAVER TECH

Recovery device for anode and cathode materials of lithium ion battery

ActiveCN110336091AReduced pollutionImprove recycling rateSolid waste disposalWaste accumulators reclaimingEngineeringLithium-ion battery

The invention discloses a recovery device for cathode and anode materials of a lithium ion battery. The structure of the recovery device comprises a motor bottom case groove, a polar plate winding drum, a grinding roller, a clamping shaft frame, a beam plate, a side ring slot vertical plate, a drawer plate cut-off cabinet and a heat exchange bottom groove. The recovery device achieves that the polar plate winding drum and the drawer plate cut-off cabinet are matched to pull out the cathode and anode material rolled plates of the lithium ion battery, the stretched surface enters the polar platewinding drum and the upper and lower sliding surfaces of the grinding roller to press and rotate a surface-grinding cleaning block layer, the effects of eliminating and cleaning the thickness of an upper additive and a lower additive and sweeping powder particles on the surface of an iron-copper incineration plate are formed, a cathode and anode material plate recycling and outputting effect is formed, and after the cathode and anode material plates of the battery are pulled out, the splitting hydrolysis operation of the lithium battery is supported, the free state of organic matters with chemical properties can be decomposed and ionized, the cathode and anode plates of the lithium ion battery taken out from a terminal can be forged, remelted and deformed, the recycling utilization rate is high, the pollution degree of the battery is low, and the environment-friendly treatment is achieved.

Owner:YANGTZE NORMAL UNIVERSITY

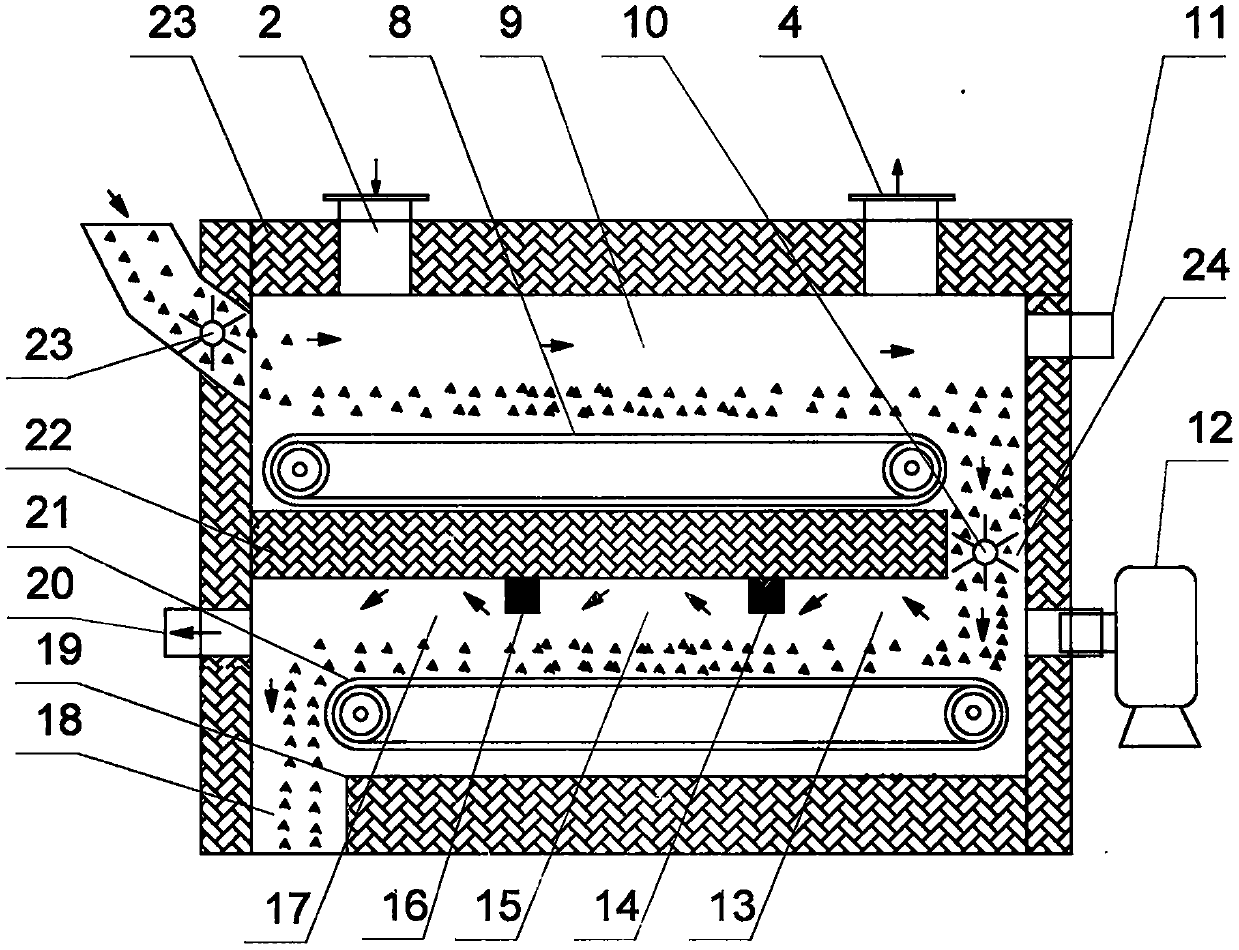

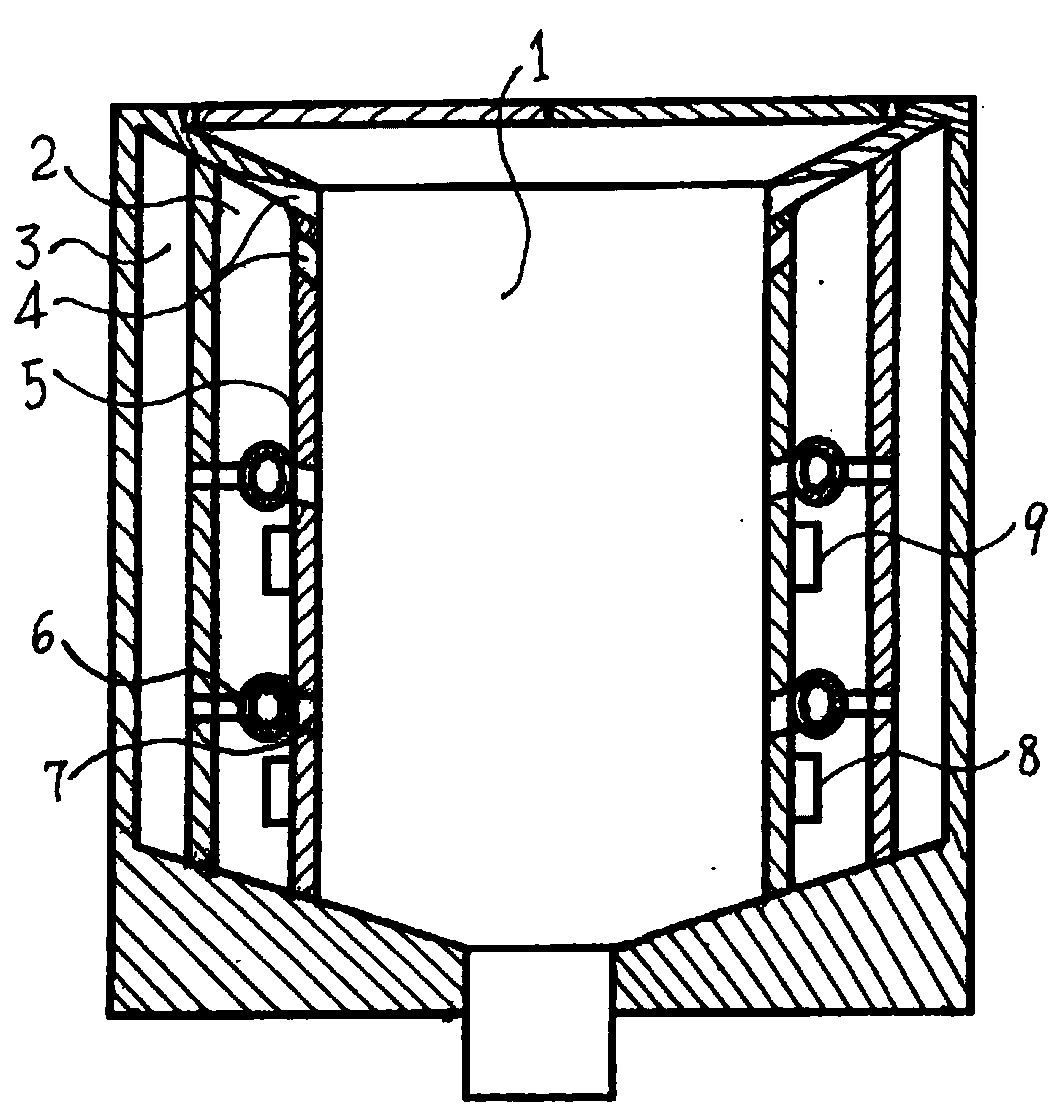

Waste gas collecting and processing device, and workpiece cleaning system

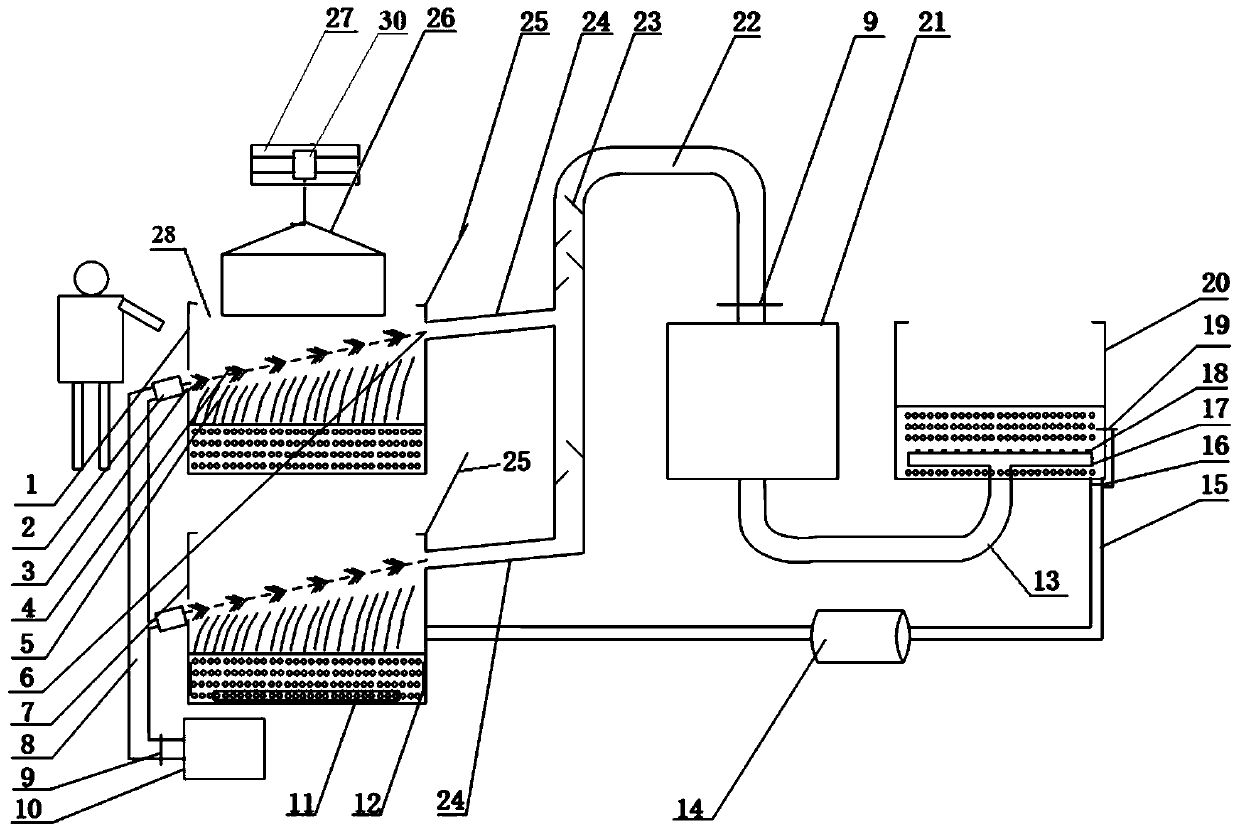

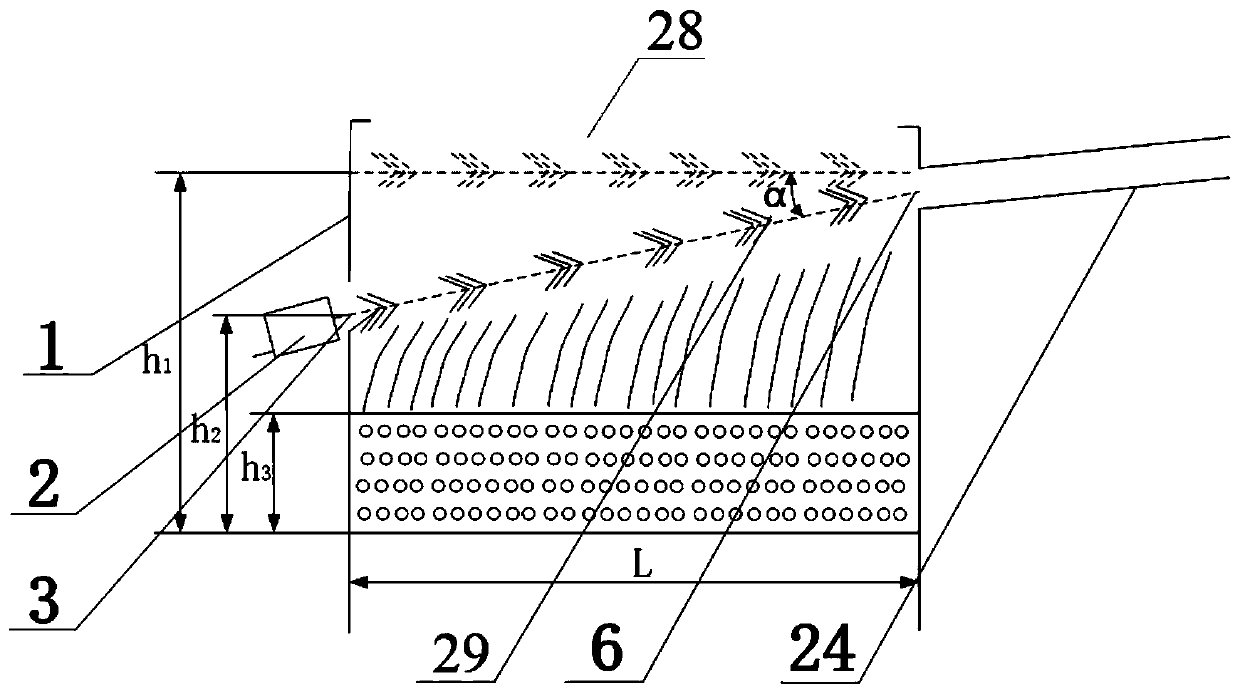

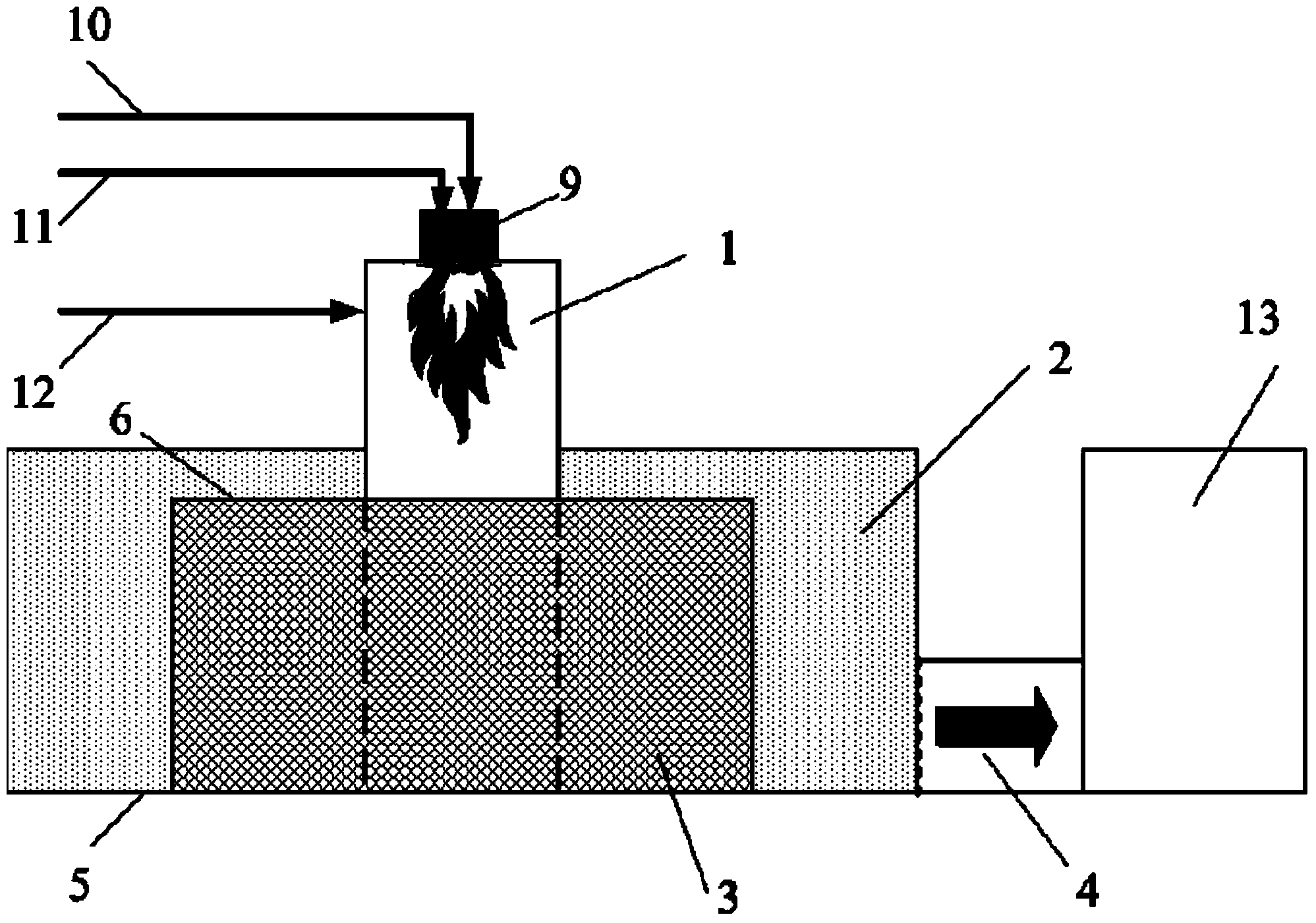

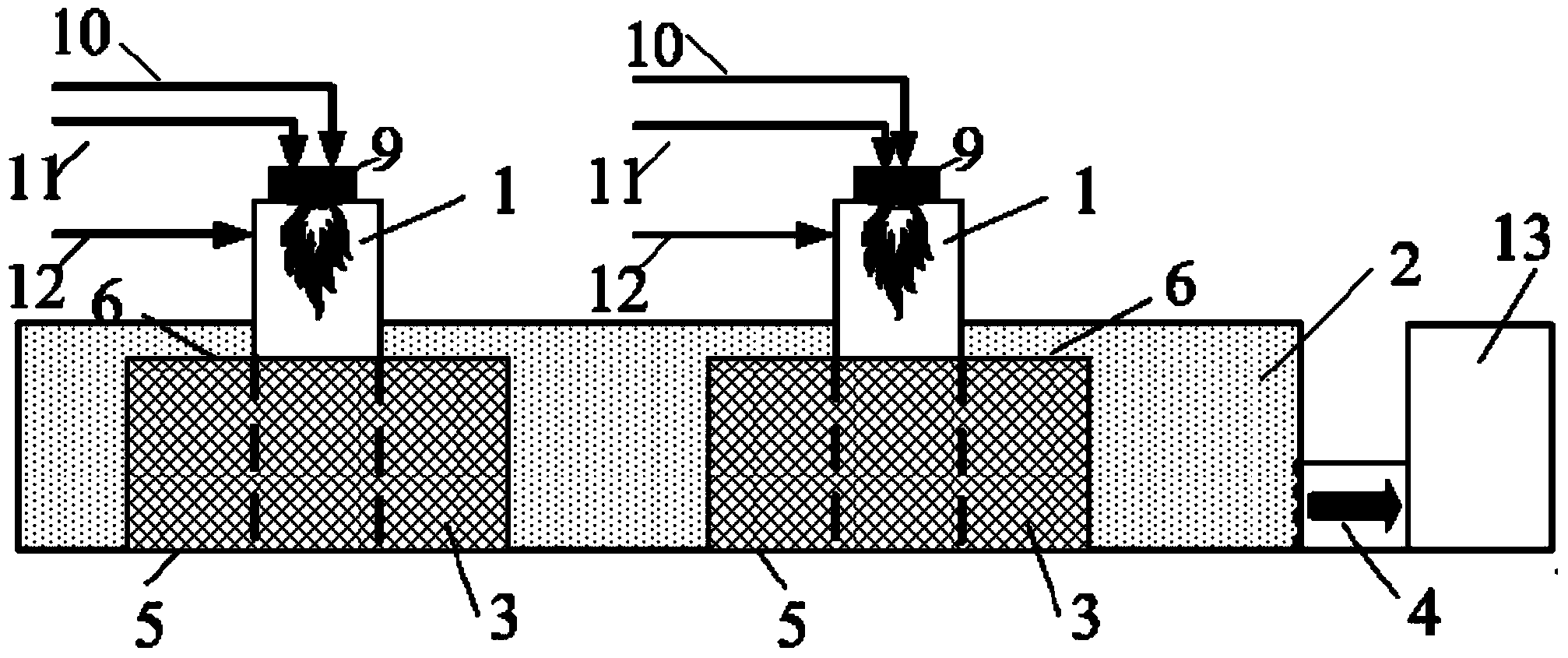

PendingCN110721560APrevent escapeRealize environmentally friendly processingDispersed particle separationDirt cleaningExhaust fumesEnvironmental engineering

The invention provides a waste gas collecting and processing device, and a workpiece cleaning system. The waste gas collecting and processing device comprises an accommodating groove (1; 7) configuredto contain a cleaning fluid; an air blowing opening (3) is formed in a first side wall of the accommodating groove (1, 7), an air suction opening (6) is formed in a second side wall of the cleaning tank (1, 7), the first side wall and the second side wall are oppositely arranged, and the air blowing opening (3) and the air suction opening (6) are higher than cleaning liquid; an air blowing component (10) and an air suction component (21) are respectively communicated with the air blowing port (3) and the air suction port (6); and an air curtain layer (4) is formed in an area between the air blowing port (3) and the air suction port (6) in the accommodating grooves (1; 7) in a state that the air blowing component (10) and the air suction component (21) are turned on. According to the wastegas collecting and processing device, waste gas in a tank body can be prevented from escaping, environment-friendly treatment of the waste gas can be achieved, and the automatic cleaning efficiency is improved; and moreover, a pollution-free and safe operation environment is provided for operators.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Circularly ecological planting and breeding method

InactiveCN108076960ARealize environmentally friendly processingEffective Ecological Circular EconomyClimate change adaptationPisciculture and aquariaRed mulletCompost

The invention provides a circularly ecological planting and breeding method which includes planting of edible fungi and breeding of fishes and ducks. The method includes the steps: S1 building more than two fungus culture sheds, digging fish ponds among the culture sheds, arranging fences on the peripheries of the fungus culture sheds and the fish ponds to form duck breeding sports grounds, planting trees in the duck breeding sports grounds, and forming mutually communicated channels which can be opened and closed in the fungus culture sheds, the fish ponds and the duck breeding sports grounds; S2 planting the edible fungi into the fungus culture sheds, taking fungus residues generated in the planting process of the edible fungi to feed the fishes and the ducks, and taking pond sludge, duck manure and pond water to compost to produce organic cultivation media. According to the method, planting of the edible fungi serves as a core, fish and duck breeding industries are developed, and rapid development of ecological breeding is facilitated.

Owner:GUANGXI LONGZHOU BEIBU GULF MODERN AGRI CO LTD

Low-temperature chlorination tail gas comprehensive utilization method

InactiveCN110606471AReduce processing costsRealize environmentally friendly processingChlorine/hydrogen-chloride purificationTitanium dioxidePhysical chemistrySolid particle

The invention relates to the field of tail gas treatment, and discloses a method for comprehensively utilizing low-temperature chlorination tail gas. The method comprises the following steps: (a) sequentially acid-pickling and filtering the low-temperature chlorination tail gas to obtain a waste hydrochloric acid solution with the concentration of 10-20 wt% and solid particles; (b) concentrating the waste hydrochloric acid obtained in the step (a) to obtain a concentrated hydrochloric acid solution with the concentration of 22-28 wt%; and (c) leaching the titanium-containing material and the concentrated hydrochloric acid obtained in the step (b), and roasting the solid material to obtain the artificial rutile of which the TiO2 content is greater than 88 wt%. According to the method, wasteacid obtained after low-temperature chlorination tail gas treatment is used for leaching titanium-containing materials after the purification concentration is increased; the titanium-containing component in the titanium dioxide is enriched, the titanium resource enrichment efficiency is improved, the obtained artificial rutile can be used as a high-quality titanium-containing raw material for producing high-temperature chlorinated titanium dioxide, comprehensive utilization of resources is achieved, the comprehensive cost of tail gas treatment is reduced, environment-friendly treatment of tail gas is achieved, operation is easy, and the comprehensive cost of low-temperature chlorination production is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Environment-friendly treatment method of medical garbage

InactiveCN105757687ARealize environmentally friendly processingRealize rationalityEmission preventionIncinerator apparatusCombustionProcess engineering

The invention belongs to the field of heavy metal pollutant treatment and particularly relates to an environment-friendly treatment method of medical garbage.By the adoption of coal powder, high-dielectric heavy metal in the medical garbage is reduced into non-toxic low-dielectric heavy metal under the high-temperature condition, the low-dielectric heavy metal is sealed up in a final product glass body object, exhausted smoke is separated, collected and treated again, and the medical garbage can be treated in a complete environment-friendly mode really.Meanwhile, heat generated by combustion of the coal powder and the medical garbage can serve as a heat source of a heating boiler, and energy sources can be distributed reasonably and applied in an environment-friendly mode.

Owner:河南景耀热电环保科技有限公司

High-temperature deoiling device under pressure

ActiveCN103447259AShorten degreasing cycleRealize combustion and oil removalCleaning processes and apparatusCombustionProcess engineering

The invention provides a high-temperature deoiling device under pressure. The high-temperature deoiling device under pressure comprises a waste gas chamber, a hot smoke gas inlet pipeline, a smoke gas generator and a combustion air pipeline, wherein a space for accommodating a porous oily component is formed in the waste gas chamber, the hot smoke gas inlet pipeline extends into the waste gas chamber, in addition, one end of the hot smoke gas inlet pipeline is communicated with the inside of the porous oily component, the hot smoke gas generator is arranged at the other end of the hot smoke gas inlet pipeline, the combustion air pipeline is communicated with the hot smoke gas generator, and the combustion air pipeline is provided with a pressurizing device. The hot smoke gas generated by the hot smoke gas generator forms a certain pressure under the effect of the pressurizing device, the hot smoke gas with the pressure is sent into the inside of the porous oily component through the hot smoke gas inlet pipeline, under the effect of pressure, the hot smoke gas penetrates through the porous oily component, and the combustion deoiling on grease inside the component is realized. A top sealing press sheet and a bottom sealing press sheet can prevent the short circuit phenomenon of high-pressure hot smoke gas in the work process, so good deoiling effects are obtained. The deoiling operation period of the porous oily component is shortened, and the production efficiency is improved.

Owner:DATANG ENVIRONMENT IND GRP

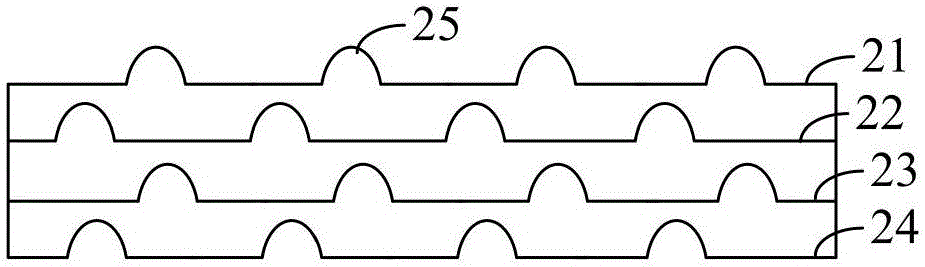

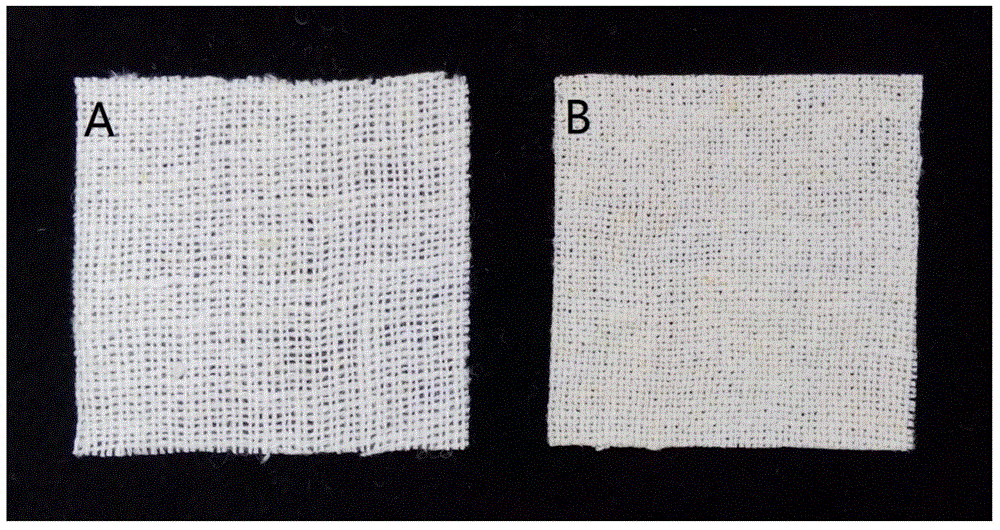

Method for manufacturing environment-friendly cellulosic-fiber-containing fabric lining cloth

The invention relates to a method for manufacturing environment-friendly cellulosic-fiber-containing fabric lining cloth. The method includes the steps that a multi-ratio aqueous solution prepared from alkali metal hydroxide and amide substances capable of being effectively combined with hydrogen bonds of hydroxide radicals between cellulose molecules serves as treating fluid; cellulosic-fiber-containing fabric is immersed or padded into the treating fluid; hairlines parts of cellulose in the fabric are dissolved to be cured at the low temperature to improve the compactness and the stiffness of the structure of the fabric; in addition, cellulose base materials can be dissolved into the treatment fluid according to the rigidity requirement to further improve the rigidity of the fabric after the curing process. According to the method, the treatment process does not involve any slurry consumption, and only the small quantity of cellulose base materials wide in source are consumed; in addition, the use treatment fluid and washing liquor can be recycled, and the production cost is low accordingly; in the production process, energy consumption and water consumption are reduced, toxic ingredients including adhesives are avoided, and production of healthy and environment-friendly safe clothes can be promoted.

Owner:DONGHUA UNIV

Plumbagin process wastewater treatment method

InactiveCN111499076ARealize environmentally friendly processingDissolve fastOrganic chemistryOrganic compound preparationPotassium cyanideDistillation

The invention belongs to the field of medicine, and relates to the field of environmental protection, in particular to a plumbagin process wastewater treatment method which comprises the following steps: step 1, filtering wastewater to remove solid impurity particles in the wastewater; 2, carrying out a constant temperature distillation reaction on the wastewater, and removing the solvent to obtain a precipitate; step 3, adding the precipitate into hydrogen peroxide for continuous reaction, and then performing reduced pressure distillation reaction to obtain potassium carbonate crystals; 4, dissolving potassium carbonate in dimethyl sulfoxide, and then adding calcium chloride for precipitation to obtain a potassium chloride-dimethyl sulfoxide solution; and step 5, distilling the potassiumchloride-dimethyl sulfoxide solution to obtain a dimethyl sulfoxide recovery solution and potassium chloride. The method solves the problem that the potassium cyanide wastewater is severe in toxicityand cannot be discharged, converts potassium cyanide into potassium carbonate and potassium chloride by utilizing hydrogen peroxide, and realizes environment-friendly treatment of the wastewater.

Owner:SHANGYU ZHONGXIAN BIOTECH

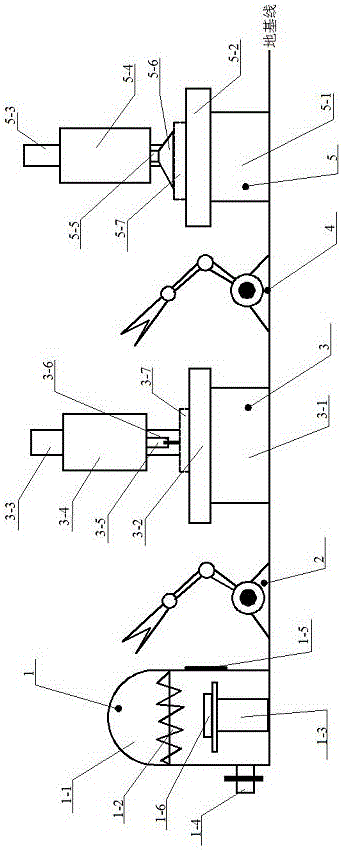

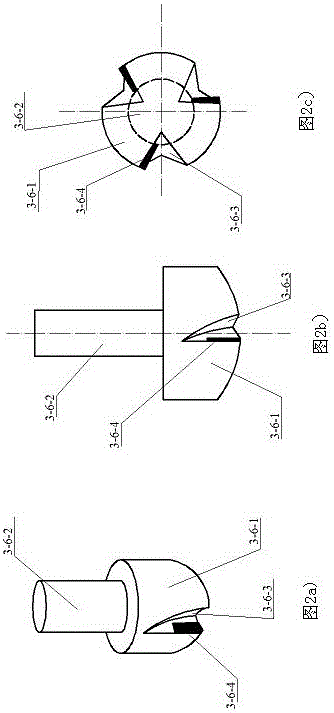

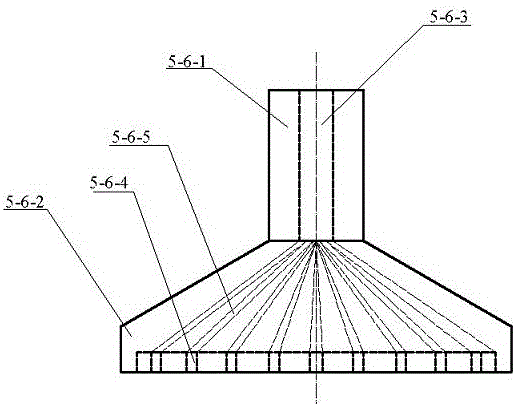

A bamboo product recycling device

ActiveCN111530889BRealize environmentally friendly processingQuality improvementTransportation and packagingSolid waste disposalProcess engineeringIndustrial engineering

The invention relates to the field of plant processing and recycling, in particular to a bamboo product recycling device. The technical problem to be solved by the present invention is to provide a bamboo product recycling device. A bamboo product recycling device, including a deoiling and softening mechanism, a material lifting conversion mechanism, an off-line mechanism, a control panel and a hooking mechanism; an off-line mechanism is arranged on the top right side of the outer surface of the deoiling and softening mechanism; the top left of the off-line mechanism is There is a material lifting conversion mechanism; a control panel is set in the middle right before the off-line mechanism. The invention realizes the deoiling of the mat, the grinding of the braided thread after heating and softening, and then recycling the bamboo chips one by one; the quality of the recycled bamboo chips is greatly improved, and at the same time, the bottom fabric and the hemming can also be recycled in a unified manner, realizing The environmental protection processing mat is provided, and the beneficial use place is provided for discarded mat simultaneously.

Owner:益阳和祥竹业有限公司

Fuel-free device for oil-sludge segmented drying, pyrolysis, incineration and secondary combustion of garbage sludge

InactiveCN109556118ACompact structureVersatileEmission preventionIncinerator apparatusExhaust gasElectrostatic precipitator

A fuel-free device for oil-sludge segmented drying, pyrolysis, incineration and secondary combustion of garbage sludge is composed of a quench cooler, a hot gas inlet, a multifunctional integrated furnace, a gas outlet, a denitrator, a desulfurizer and an electrostatic dust collector. The quench cooler is connected with and communicates with the hot gas inlet through a connecting pipe. The hot gasinlet is arranged on one side of the upper portion of the multifunctional integrated furnace and communicates with the multifunctional integrated furnace. The gas outlet is arranged on one side of the upper portion of the multifunctional integrated furnace and communicates with the multifunctional integrated furnace. The multifunctional integrated furnace is connected with and communicates with the denitrator through a connecting pipe. The denitrator is connected with and communicates with the desulfurizer through a connecting pipe. The desulfurizer is connected with and communicates with theelectrostatic dust collector through a connecting pipe. The multifunctional integrated furnace is connected with and communicates with the quench cooler through a connecting pipe. Multiple function areas are arranged in the multifunctional integrated furnace, drying, pyrolysis, incineration and secondary combustion are integrated, and environment protection treatment of garbage and the like is perfectly achieved by cooperating with the tail gas purification function.

Owner:李艺 +3

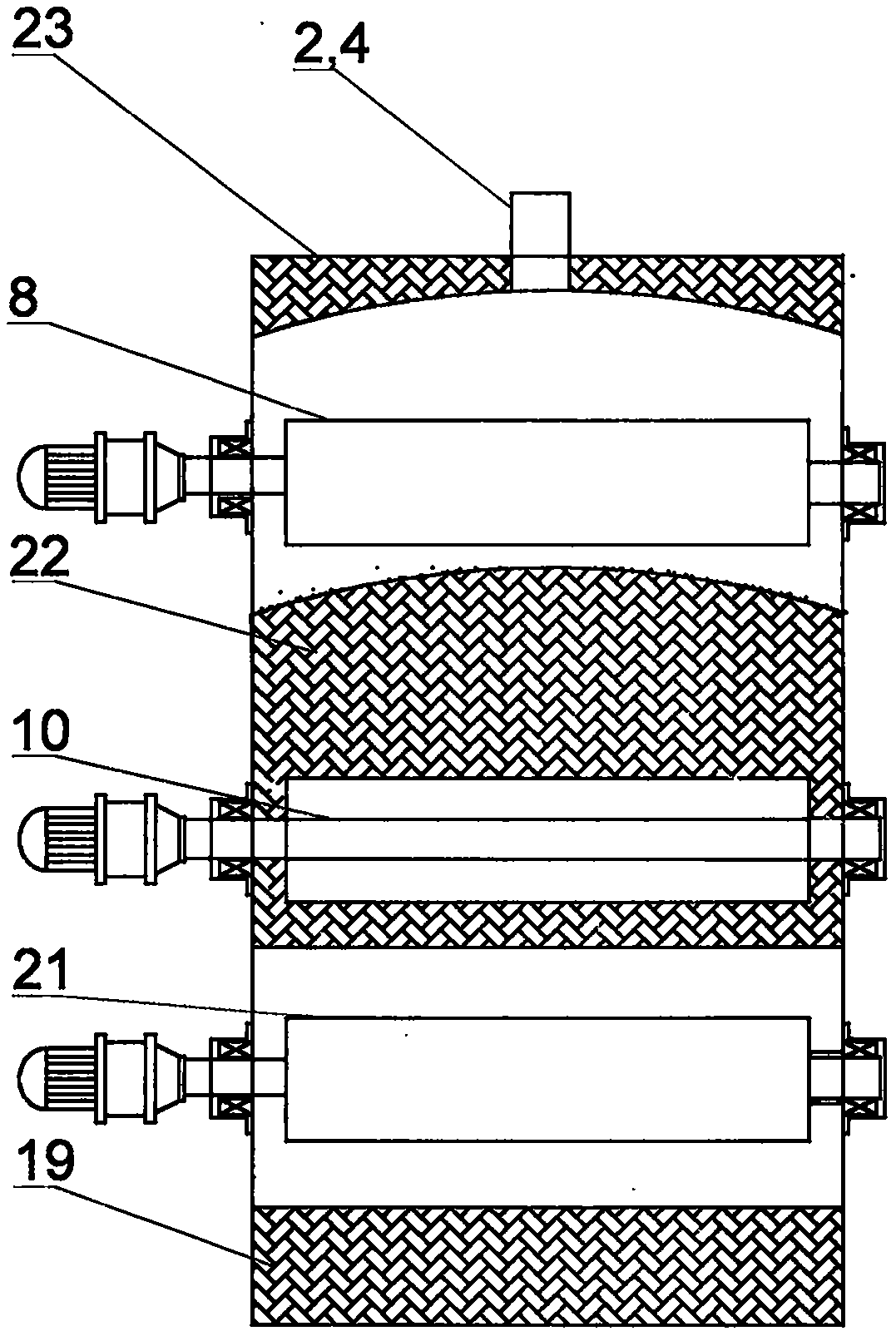

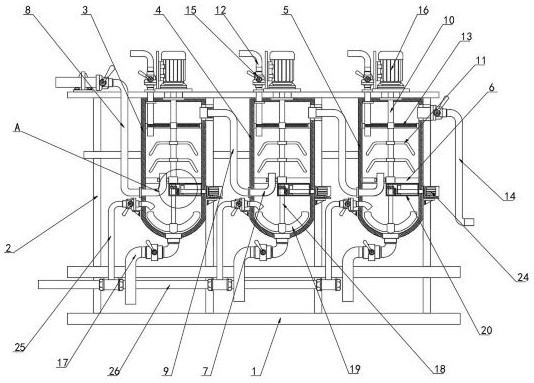

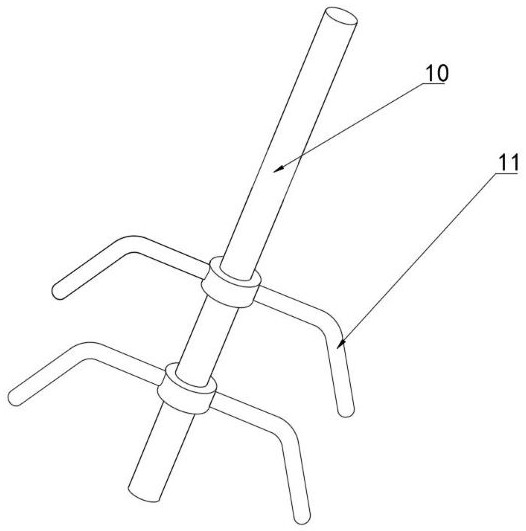

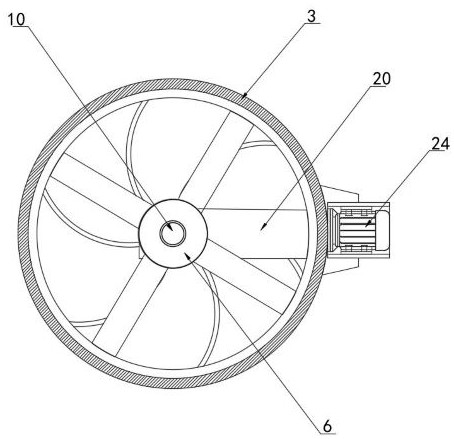

Wastewater treatment equipment capable of realizing sequential dosing and working method of wastewater treatment equipment

InactiveCN113479982ARealize dosing treatment operationConvenient and orderly processingSpecific water treatment objectivesMixer accessoriesWater treatment systemProcess engineering

The invention discloses wastewater treatment equipment capable of achieving sequential dosing and a working method of the wastewater treatment equipment, and particularly relates to the technical field of sewage treatment. The wastewater treatment equipment comprises an equipment base, wherein an equipment rack is fixedly arranged at the top of the equipment base, a first chemical dosing treatment tank, a second chemical dosing treatment tank and a third chemical dosing treatment tank are sequentially and fixedly arranged in the equipment rack from left to right, fixing frames are fixedly arranged on the inner walls of the middles of the first chemical dosing treatment tank, the second chemical dosing treatment tank and the third chemical dosing treatment tank, and wastewater inlet pipes are fixedly arranged at the bottom of the first dosing treatment tank, the second dosing treatment tank and the third dosing treatment tank. The first dosing treatment tank, the second dosing treatment tank and the third dosing treatment tank are matched with the wastewater inlet pipe and the connecting pipe to form a wastewater treatment system, dosing is implemented by using the dosing inlet pipe, three times of continuous wastewater dosing treatment operation on wastewater is realized, and a stirring rod on a rotating shaft stirs and mixes wastes and drugs, so that the drug reaction treatment quality is improved.

Owner:WEIFANG UNIV OF SCI & TECH

Bio-organic foliar fertilizer

InactiveCN109608261ARealize environmentally friendly processingIncrease productionExcrement fertilisersUrea compound fertilisersMicrobial agentBiology

The invention discloses a bio-organic foliar fertilizer, and relates to the technical field of foliar fertilizers. The bio-organic foliar fertilizer is prepared from, by weight, 0.2-0.4 part of carbonyl diamide, 25-40 parts of livestock urine, 30-50 parts of animal waste, 15-30 parts of straw powder, 0.3-1.2 parts of a biological microbial agent, 0.2-0.8 parts of trace elements and 0.2-0.6 parts of a traditional Chinese medicine extracting solution. The bio-organic foliar fertilizer does not contain hormones, pesticides, humic acid and the like, and has raw materials easy to obtain and a goodfertilizer effect; the foliar fertilizer also has the function of biological sterilization; nitrogen element, molybdenum element, copper element, manganese element, iron element and chlorine element are added in the foliar fertilizer; the fertilizer is conductive to the growth of the crops and increases the yield of the crops.

Owner:LOMON LAND AGRI

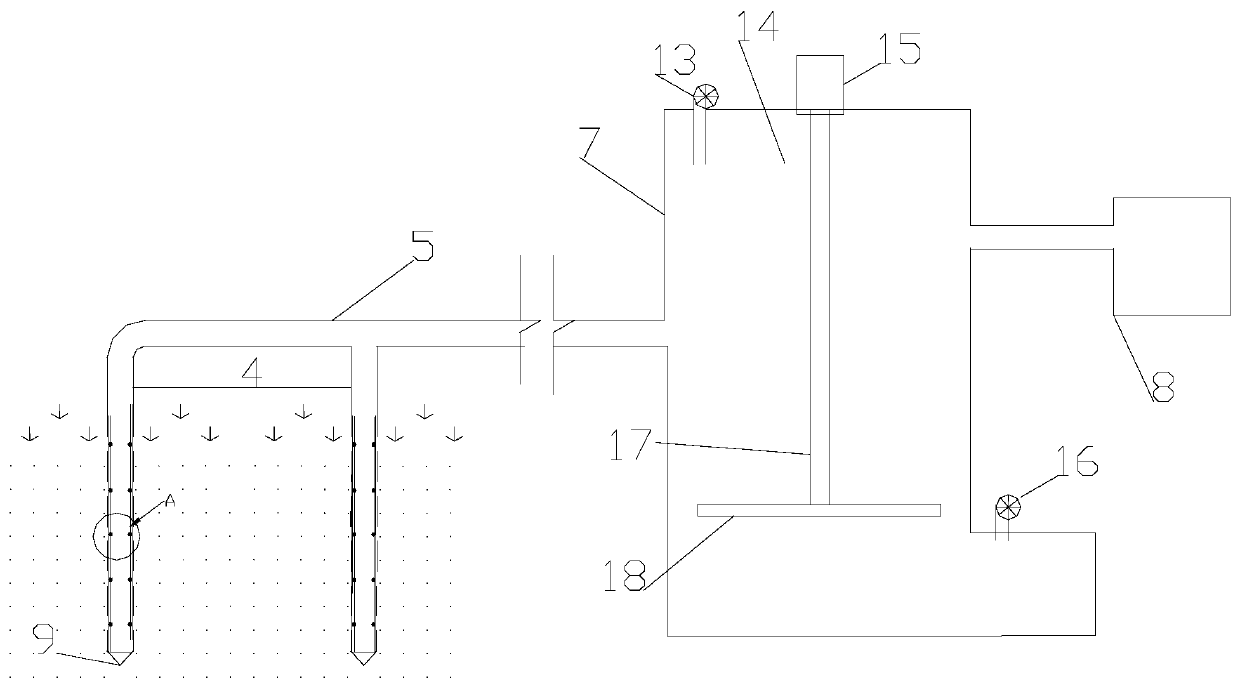

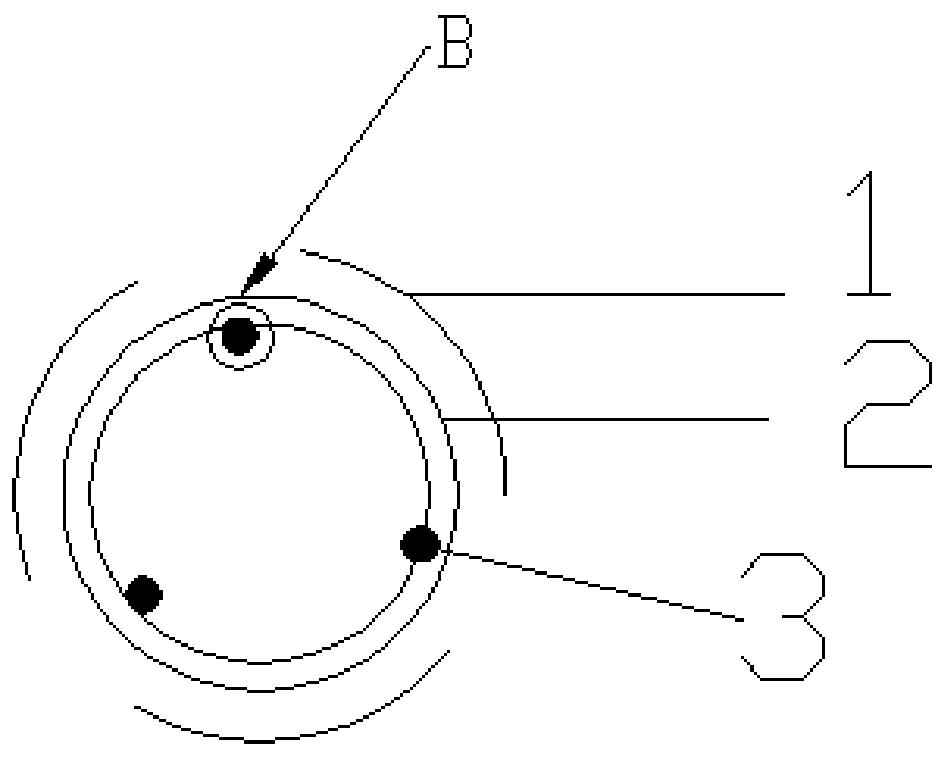

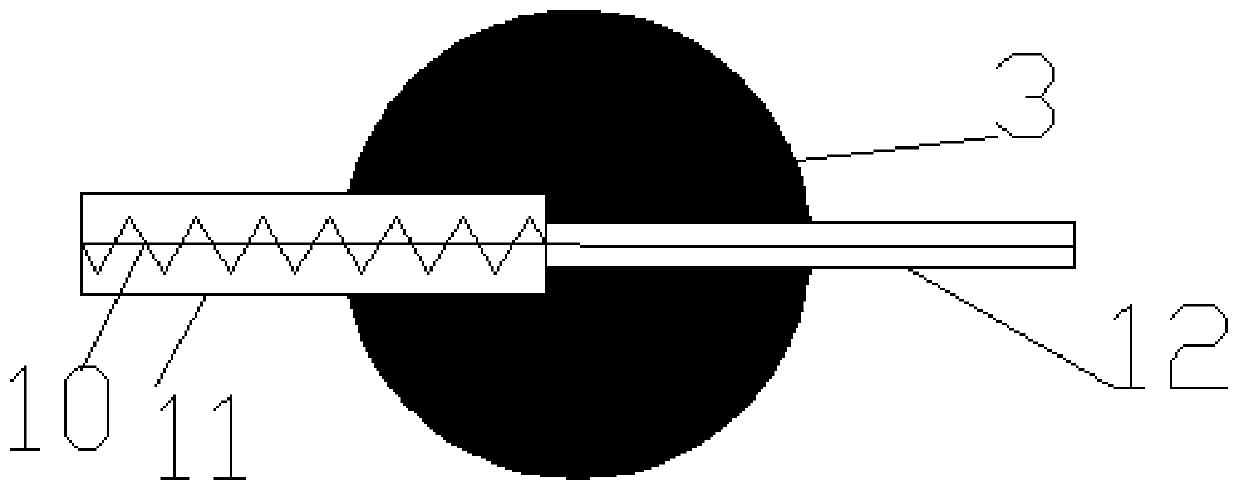

Soil heavy metal in-situ sensing monitoring, adsorption transfer and precipitation recovery system

PendingCN110883080ASimple and efficient operationLow running costContaminated soil reclamationPre treatmentEnvironmental chemistry

The invention provides a soil heavy metal in-situ sensing monitoring, adsorption transfer and precipitation recovery system. The system comprises a reaction chamber group, a treatment tank and a precipitation pump. The treatment tank is connected to the reaction chamber group through a pipeline, and the precipitation pump is respectively connected to the treatment tank and the reaction chamber group through pipelines; the reaction chamber group comprises a plurality of reaction cavities with the same structure, and the reaction cavities are connected through pipelines; the reaction cavities are internally equipped with filter membranes, on which a plurality of enzyme membrane biosensors are loaded, and the enzyme membrane biosensors are connected to a controller through circuits. The soilheavy metal in-situ sensing monitoring, adsorption transfer and precipitation recovery system provided by the invention can realize in-situ real-time monitoring, does not need pretreatment on a soil sample, is simple to operate and low in operation cost, can provide continuous analysis, and meets the actual requirements of rapid monitoring.

Owner:HEBEI UNIV OF TECH

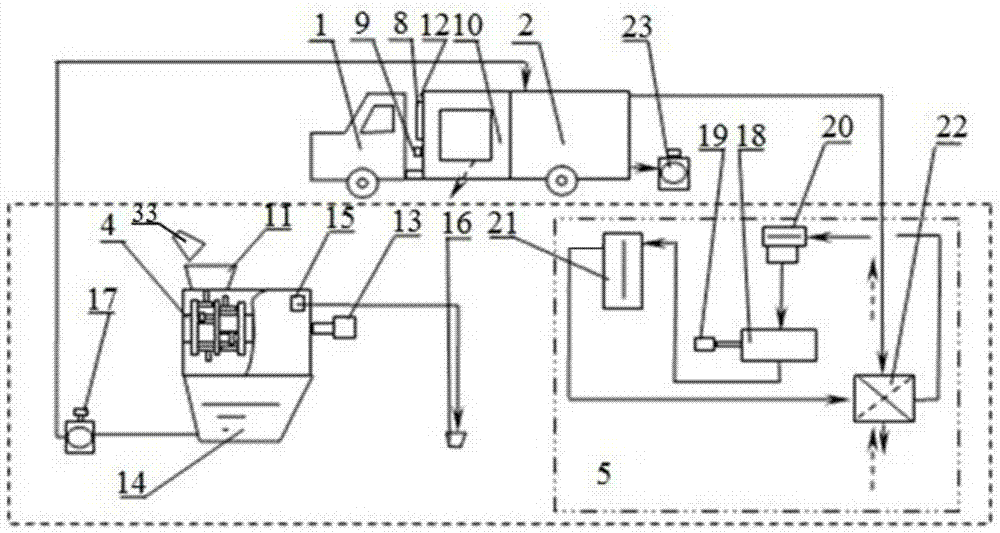

Vehicle-mounted movable household and medical waste treatment device with tail gas treatment system arranged horizontally

InactiveCN107355794AImplement collection-side processingRealize processingEmission preventionDispersed particle separationCombustion chamberMedical waste

A vehicle-mounted movable household and medical waste treatment device with a tail gas treatment system arranged horizontally is characterized by comprising a vehicle, an induced draft fan, a horizontal adsorber, a horizontal deduster, a first connecting pipe, a horizontal dehydrator, a horizontal quenching desulfuration and deacidification device, a second connecting pipe, a horizontal secondary combustion chamber, a pyrolyzing furnace, a water pump, a third connecting pipe, a fourth connecting pipe, a fifth connecting pipe and a liquid storage tank, wherein the liquid storage tank is arranged on the vehicle; the horizontal adsorber arranged on the liquid storage tank is connected with the induced draft fan through the corresponding connecting pipe; the horizontal adsorber is connected with the horizontal deduster through the fifth connecting pipe; the horizontal deduster is connected with the horizontal dehydrator through the first connecting pipe; the horizontal dehydrator is connected with the horizontal quenching desulfuration and deacidification device through the fourth connecting pipe; the horizontal quenching desulfuration and deacidification device is connected with the liquid storage tank through the third connecting pipe and connected with the secondary combustion chamber through the second connecting pipe; the secondary combustion chamber is arranged on the upper portion of the pyrolyzing furnace; and one end of the water pump is put in the liquid storage tank, and the other end of the water pump is connected with the horizontal quenching desulfuration and deacidification device. The vehicle-mounted movable household and medical waste treatment device is novel in structure, the tail gas treatment system is arranged horizontally, the overall height is decreased, and operation and vehicle transportation are facilitated.

Owner:李艺 +3

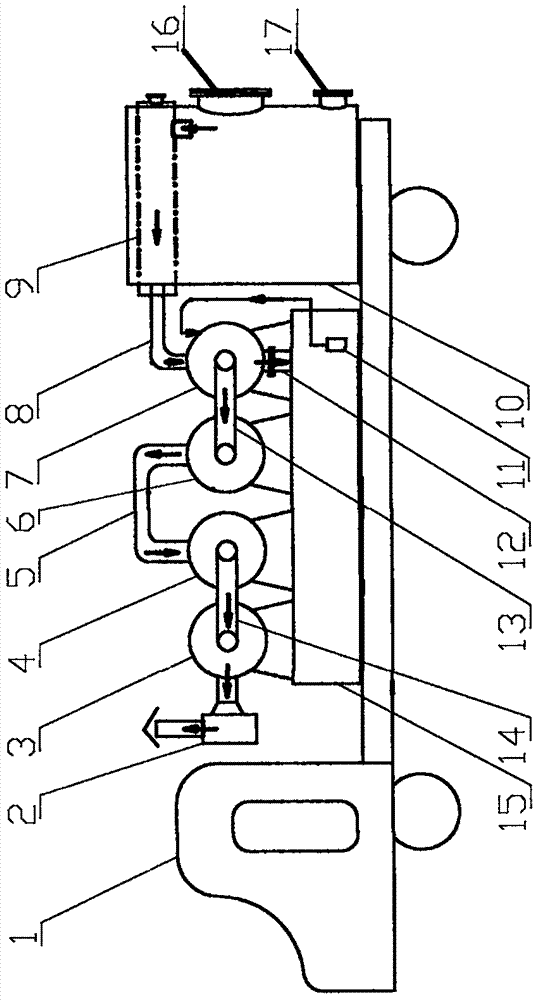

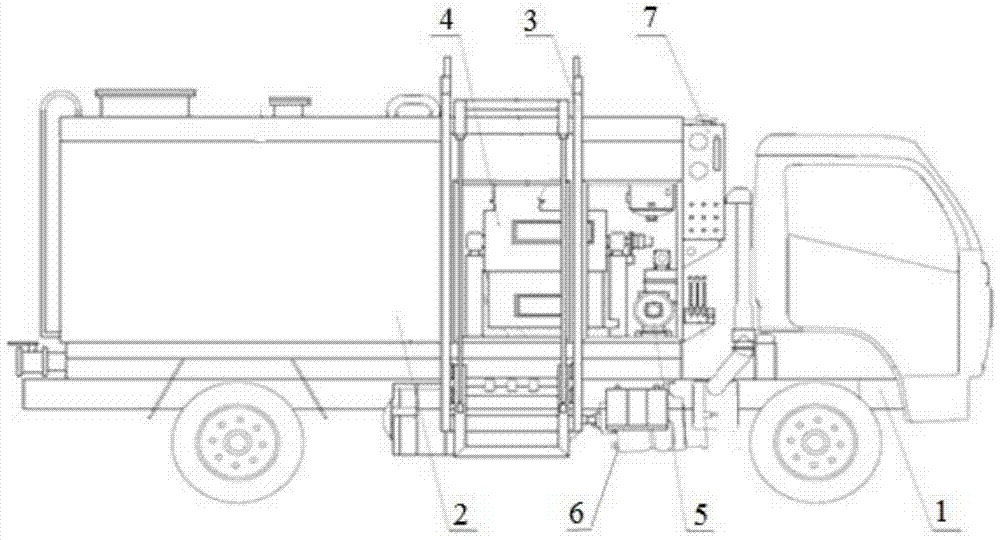

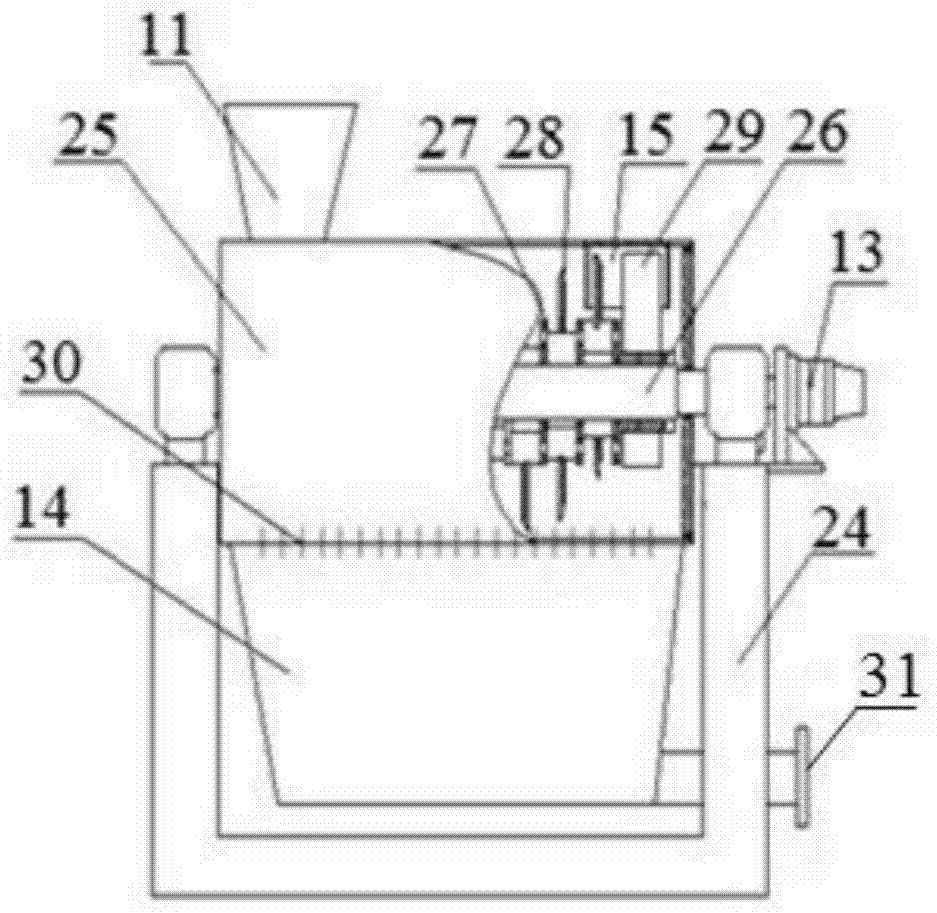

A kind of food waste pretreatment device and its collecting and transporting vehicle

The invention relates to a kitchen waste pretreatment device which comprises a sorting and pulping device, a waste storage container and a vacuumizing system, wherein a feeding and lifting mechanism used for transporting kitchen waste bins to the top of the sorting and pulping device is arranged at the side part of the sorting and pulping device; the sorting and pulping device comprises a support frame, a housing, a horizontal process turn-back type structure and a first hydraulic motor; mesh holes for allowing slurry to pass through and enter a lower liquid collection box are formed in the bottom of the sorting and pulping device; and the vacuumizing system provides a vacuum state for the waste storage container. The invention further relates to a collection and transportation vehicle which comprises the kitchen waste pretreatment device, an automobile chassis and a dynamic system. The kitchen waste pretreatment device has the benefits that the leakage during the kitchen waste transportation, loading and unloading processes is effectively avoided, the secondary pollution caused during secondary sorting and pulping after the fermentation of kitchen waste is avoided, the kitchen waste is treated in an environment-friendly manner, and the investment cost required by treatment of leakage and odor overflow is effectively reduced.

Owner:HUBEI GUOXIN TIANHUI ENERGY

Graded degradation treatment method for plastic bags

PendingCN113752418ARealize environmentally friendly processingAchieve recyclingPlastic recyclingMechanical material recoveryPlastic bagCement Material

The invention discloses a graded degradation treatment method for plastic bags. The graded degradation treatment method comprises the following steps: S1, collecting and bundling the plastic bags, and then carrying out preliminary chopping operation to obtain plastic fragments; S2, placing the plastic fragments in a stirrer, and conducting stirring and cleaning operation after a cleaning agent is added; S3, after the plastic fragments are sieved and water is filtered, placing the plastic fragments into a drying box for drying operation; S4, placing the dried plastic fragments into a high-temperature smelting furnace for smelting operation, and cooling to obtain plastic blocks; S5, crushing and then grinding the plastic blocks to obtain plastic powder; S6, adding degradation liquid into the plastic powder, and reacting in a sealed container for 7-10 days to obtain mixed degradation particles; S7, adding a coloring agent into the mixed degradation particles, and stirring for 3-5 minutes at the rotating speed of 100-200 r / min to obtain colored particles; and S8, mixing the colored particles with cement powder, and stirring for 20-30 minutes at the rotating speed of 200-300 r / min.

Owner:SHENZHEN JINLICHANG BLISTER PROD

Multi-energy environmental protection garbage pyrolysis device

ActiveCN107300181BAchieve pyrolysis environmental protection standardsConducive to pyrolysis environmental protection standardsIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberSludge

Owner:袁甫新 +1

A hot smoke negative pressure degreasing device

ActiveCN103433246BAvoid short circuitShorten degreasing cycleCleaning processes and apparatusEngineeringProcess engineering

Owner:DATANG ENVIRONMENT IND GRP

Method and device for improving surface properties of copper alloy

InactiveCN105014388BImprove surface propertiesImprove processing efficiencyOther manufacturing equipments/toolsMachined surfaceFriction stir processing

Owner:HUANGSHAN UNIV

Negative-pressure hot smoke de-oiling device

ActiveCN103433246AAvoid short circuitShorten degreasing cycleCleaning processes and apparatusProcess engineeringGas chamber

The invention provides a negative-pressure hot smoke de-oiling device. The negative-pressure hot smoke de-oiling device comprises a high-temperature gas chamber, a hot smoke gas inlet pipeline, a negative-pressure chamber and a hot smoke gas generation device, wherein the high-temperature gas chamber is provided with a space capable of containing a porous oiled part; one end of the hot smoke gas inlet pipeline is communicated with the high-temperature gas chamber; the negative-pressure chamber is separated from the high-temperature gas chamber; the hot smoke gas generation device is arranged at the other end of the hot smoke gas inlet pipeline; a position, at which the porous oiled part is placed, in the high-temperature gas chamber is communicated with the negative-pressure chamber; an air inducing device is communicated with the negative-pressure chamber so as to enable the negative-pressure chamber to be kept in a negative-pressure state. Under the action of forced flowing of high-temperature hot smoke gas of which the temperature and the oxygen content are adjustable in the porous oiled part, the porous oiled part with a complicated structure is subjected to high-temperature de-oiling treatment, so that the thorough cleaning is realized.

Owner:DATANG ENVIRONMENT IND GRP

A recovery device for positive and negative electrode materials of lithium-ion batteries

ActiveCN110336091BHigh quality and purityGuarantee the effect of sealed incinerationSolid waste disposalWaste accumulators reclaimingElectrical batteryLithium-ion battery

The invention discloses a recovery device for cathode and anode materials of a lithium ion battery. The structure of the recovery device comprises a motor bottom case groove, a polar plate winding drum, a grinding roller, a clamping shaft frame, a beam plate, a side ring slot vertical plate, a drawer plate cut-off cabinet and a heat exchange bottom groove. The recovery device achieves that the polar plate winding drum and the drawer plate cut-off cabinet are matched to pull out the cathode and anode material rolled plates of the lithium ion battery, the stretched surface enters the polar platewinding drum and the upper and lower sliding surfaces of the grinding roller to press and rotate a surface-grinding cleaning block layer, the effects of eliminating and cleaning the thickness of an upper additive and a lower additive and sweeping powder particles on the surface of an iron-copper incineration plate are formed, a cathode and anode material plate recycling and outputting effect is formed, and after the cathode and anode material plates of the battery are pulled out, the splitting hydrolysis operation of the lithium battery is supported, the free state of organic matters with chemical properties can be decomposed and ionized, the cathode and anode plates of the lithium ion battery taken out from a terminal can be forged, remelted and deformed, the recycling utilization rate is high, the pollution degree of the battery is low, and the environment-friendly treatment is achieved.

Owner:YANGTZE NORMAL UNIVERSITY

Method for preparing self-compacting concrete by using herbal pulp waste liquid

The invention discloses a method for preparing self-compacting concrete by utilizing a herbal paper pulp waste liquid. The method comprises the following steps: filtering suspended substances and sediments out of the herbal paper pulp waste liquid, subjecting the suspended substances and the sediments to co-sintering with titanium gypsum and the like so as to obtain a powder material, blending substances filtered out of a filtrate through a hollow fiber ultrafiltration film with a plurality of substances like sodium sulfite and polyaniline so as to obtain an additive, and mixing the additive with the powder material, fine aggregate, coarse aggregate, water and the like so as to prepare the self-compacting concrete. According to the invention, main pollution components are separated from the herbal paper pulp waste liquid and used as auxiliary components of the self-compacting concrete after simple treatment, so environmental protection treatment of a large amount of the herbal paper pulp waste liquid can be realized; and comprehensive performances of the self-compacting concrete can be greatly improved, e.g., a water-cement ratio can be greatly reduced; the strength, compactness, compressive strength, tensile strength, heat and frost resistance, salting resistance and permeability resistance of the self-compacting concrete are improved; the service life of the self-compacting concrete is long; and corrosion of reinforcing steel bars to the self-compacting concrete can be greatly retarded.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

Environmental protection treatment method of heavy metal sludge in sewage treatment plant

ActiveCN105964648BRealize environmentally friendly processingRealize rationalityTransportation and packagingSolid waste disposalCombustionFlue gas

The invention belongs to the field of heavy metal pollutant treatment, in particular to an environment-friendly treatment method for heavy metal-containing sludge in a sewage treatment plant. The present invention uses coal powder to reduce the high-priced heavy metals in the sludge to non-toxic low-priced heavy metals under high temperature conditions and seals them in the glass body of the final product, and separates and collects the exhausted flue gas for reprocessing, so as to truly realize the recovery of heavy metal sludge. It is 100% environmentally friendly, and the heat generated by pulverized coal combustion can be used as a heat source for heating boilers to achieve reasonable energy distribution and green applications.

Owner:河南景耀热电环保科技有限公司

A kind of chemical industry sewage environmental protection treatment device

ActiveCN114590931BRealize triple filtration and purification operationEffective filtering and blockingSpecific water treatment objectivesTreatment involving filtrationChemical industryActivated carbon filtration

The invention relates to the field of waste water treatment, and discloses an environmental protection treatment device for chemical industry sewage. Both sides are provided with a push mechanism, the push mechanism includes a side plate, a U-shaped plate, a fixing block, a threaded rod and a first drive motor, and symmetrical side plates are fixedly connected to both sides of the processing box, and the threaded rod passes through The first rotating rods installed at both ends are movably installed between the side plates. Through the filter mechanism provided in the present invention, when the waste water enters the treatment box and flows through the filter frame, the first filter screen, the second filter screen and the activated carbon filter screen installed in the three filter frames will sequentially filter the relatively small amount of waste water contained in the waste water. It can effectively filter and block the toxic particles of large waste residue, small waste residue and tiny waste residue, and effectively realize the triple filtration and purification operation of waste water.

Owner:青岛市团岛污水处理厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com