Method for manufacturing environment-friendly cellulosic-fiber-containing fabric lining cloth

A technology of cellulose fibers and production methods, which is applied in fiber treatment, plant fibers, textiles and papermaking, etc., can solve the problems that environmental protection benefits do not meet the corresponding standards, achieve the promotion of health, environmental protection and safe production, reduce energy consumption and water consumption, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

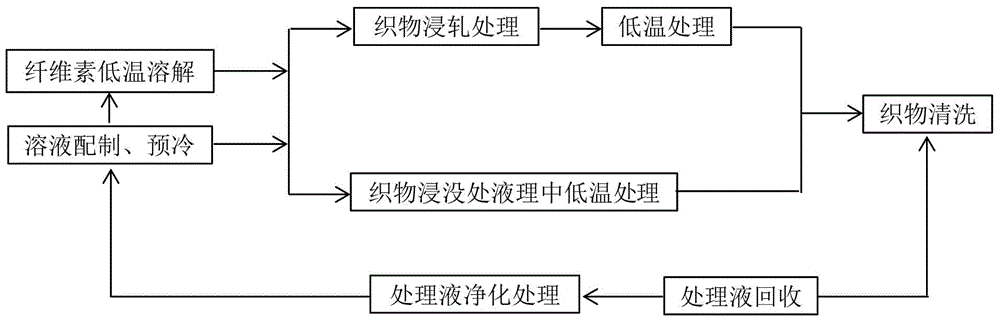

Method used

Image

Examples

Embodiment 1

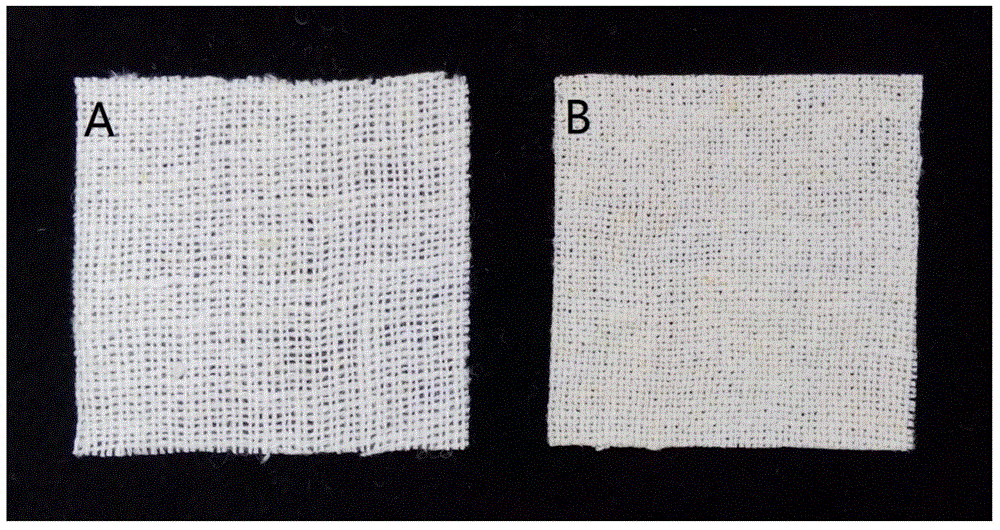

[0029] Preparation sodium hydroxide / urea / water mass ratio is the solution of 7% / 12% / 81%, adds the microcrystalline cellulose of 4wt.% under the condition of-10 ℃, shakes until it dissolves completely; The ramie fabric is immersed in Freeze at -15°C for 10 minutes, wash with water at room temperature, and dry at 40°C for 3 hours to obtain an interlining. Morphology of the fabric before and after treatment figure 2 shown.

Embodiment 2

[0031] Prepare a solution with a mass ratio of lithium hydroxide / thiourea / water of 7% / 12% / 81%, add 8wt.% cotton pulp at -7°C, shake until the cotton pulp is no longer dissolved; use a low temperature of -15°C The treated liquid soaked the ginned cotton fabric together, and placed it in the -15°C environment to freeze for 1 minute, washed it with water at room temperature, and dried it at 60°C for 2 hours to obtain the interlining cloth.

Embodiment 3

[0033] Prepare a solution with a mass ratio of potassium hydroxide / urea / water of 9% / 12% / 79%, add 6wt.% microcrystalline cellulose at -15°C, shake until it dissolves completely; immerse the cotton fabric in Freeze at -15°C for 1 minute, repeat the treatment for 3 times, wash with water at room temperature, and dry at 60°C for 3 hours to obtain an interlining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com