Patents

Literature

95results about How to "Achieve repeated use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

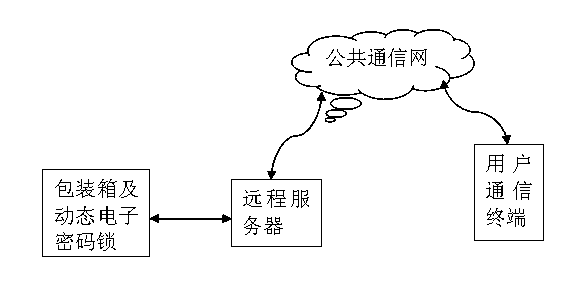

Logistics distribution system and distribution method thereof

InactiveCN103632243AImprove securityPrevent writing downIndividual entry/exit registersLogisticsLogistics managementPassword

The invention provides a logistics distribution system and a distribution method thereof. The distribution system comprises a packing case which is provided with a dynamic electronic password lock, a remote server which records information of the packing case, and a user communication terminal which is connected with the remote server via a network. The distribution method comprises the following steps: a distribution object is put into the packing case which is then locked; then the information of the packing case is bound with a user communication terminal number at the remote server terminal; and finally after the object is delivered to a destination, the user communication terminal is connected with the remote server, and the remote server sends a dynamic password, which is bound with the user communication terminal number and effective within a current certain period of time of the dynamic electronic password lock on the packing case, to the user communication terminal so that a user can open the packing case and extract the object. Safety of the logistics distribution object can be effectively enhanced by the logistics distribution system and the distribution method thereof.

Owner:上海达距物联网科技发展有限公司

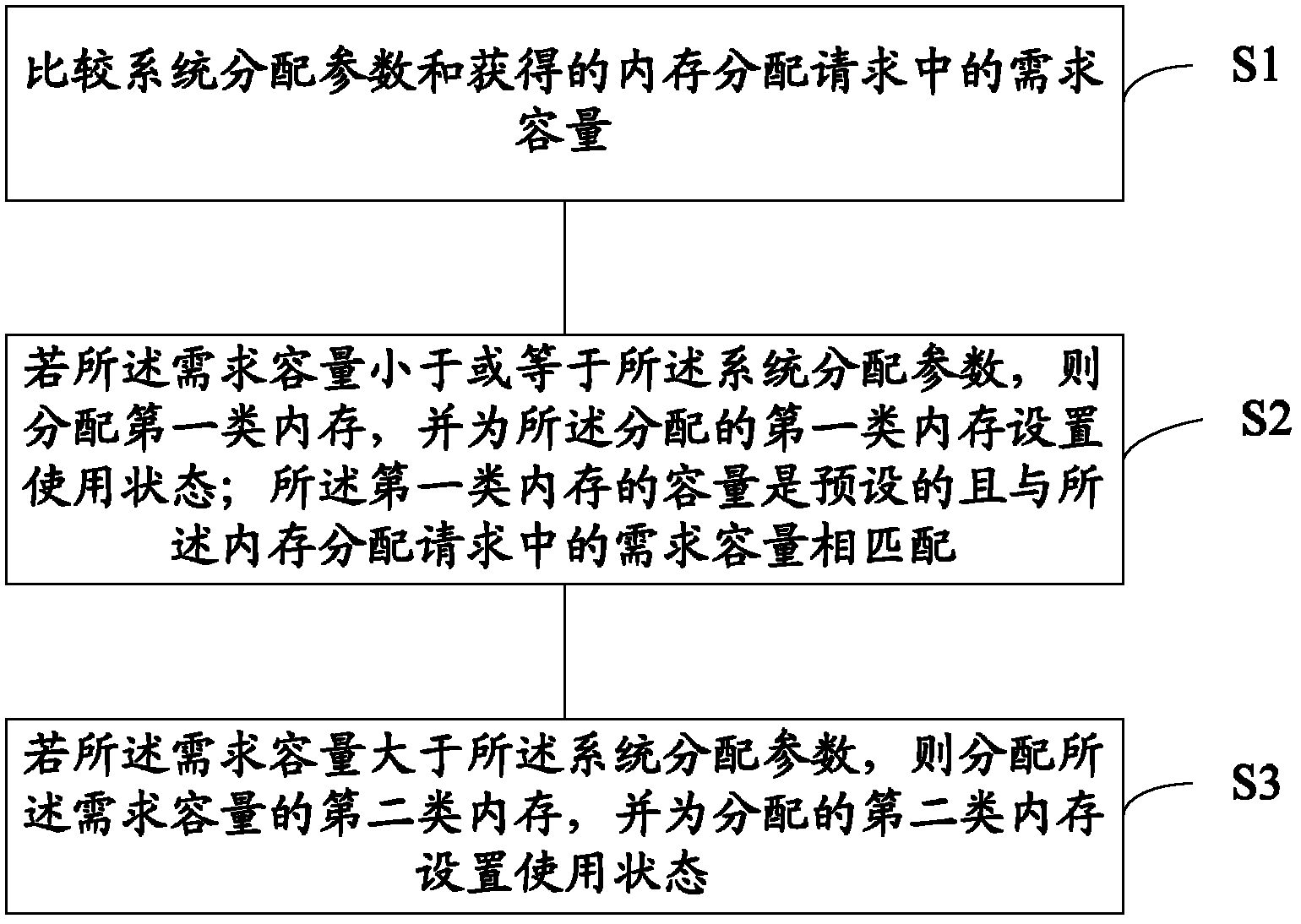

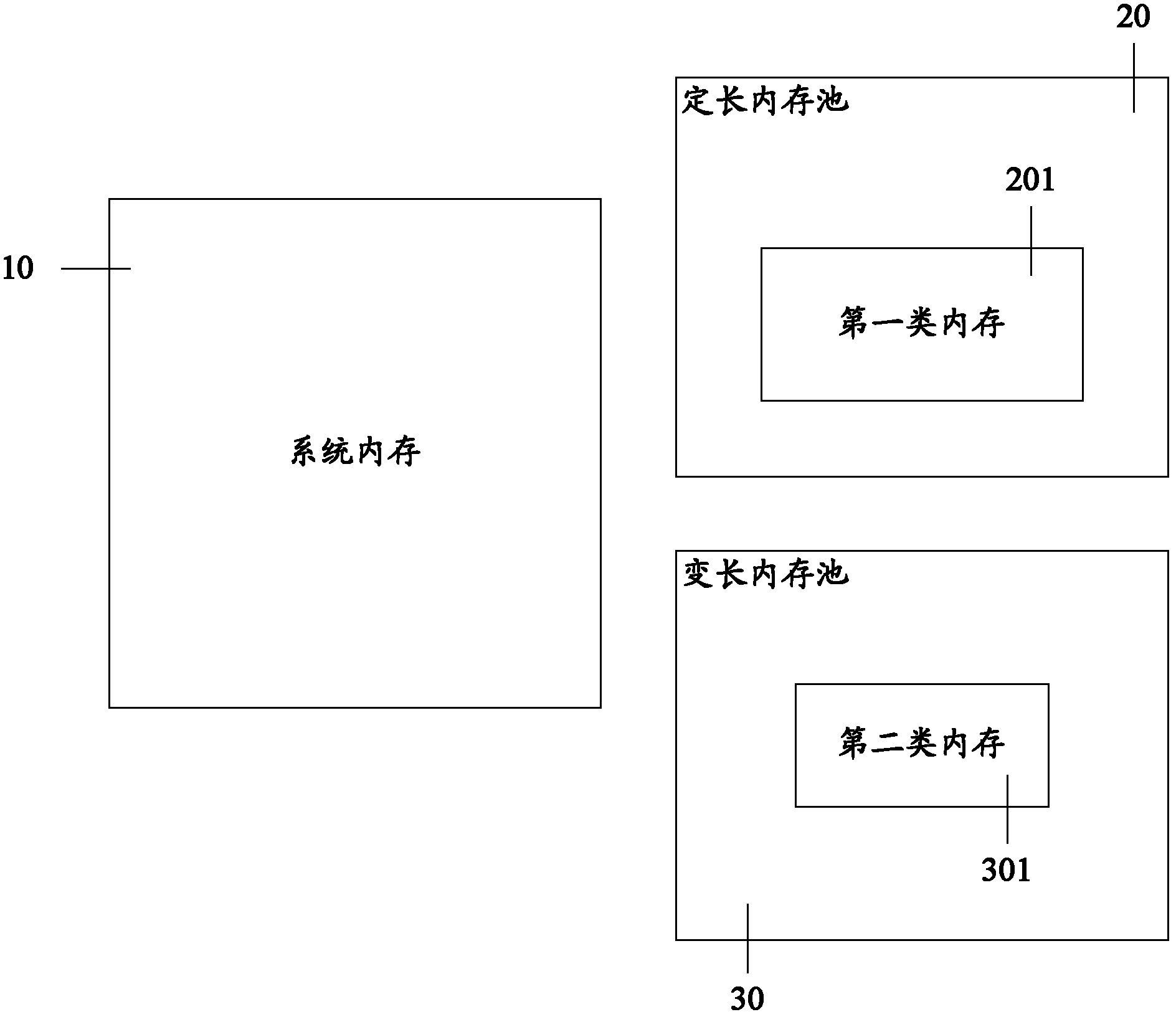

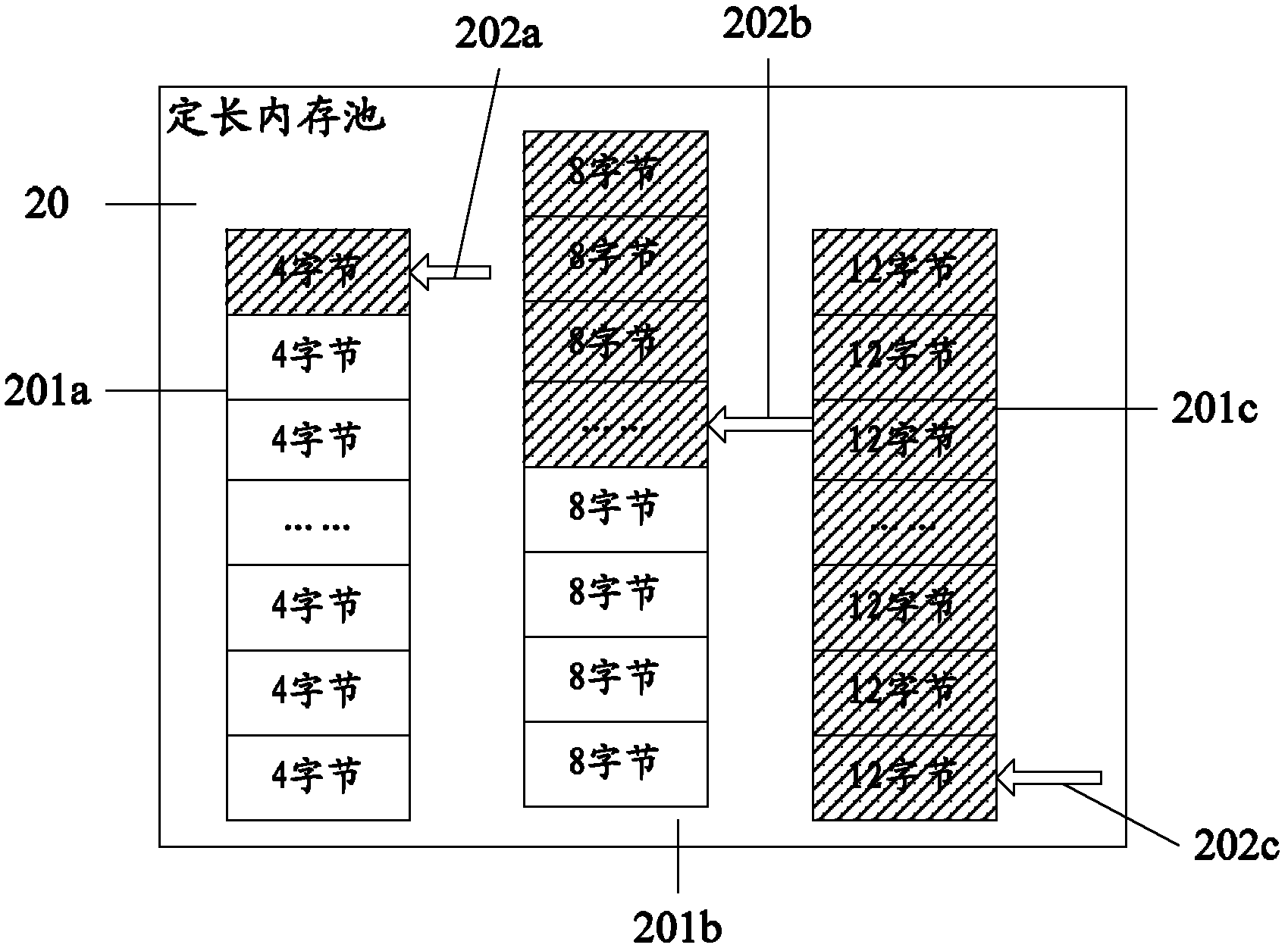

Memory allocation method and device, and memory recovery method

InactiveCN103186469AMeet needsImprove performanceMemory adressing/allocation/relocationRecovery methodParallel computing

The invention discloses a memory allocation method, a memory allocation device and a memory recovery method. The memory allocation method comprises the following steps: comparing a system allocation parameter with required capacity in an obtained memory allocation request; if the required capacity is less than or equal to the system allocation parameter, allocating a first type of memory, and setting a using state for the first type of memory which is allocated, wherein the capacity of the first type of memory is preset, and is matched with the required capacity in the memory allocation request; and if the required capacity is greater than the system allocation parameter, allocating a second type of memory with the required capacity, and setting a using state for the second type of memory which is allocated. According to the technical scheme, memory fragments are reduced, and the working efficiency of a system and the performance of the memory are improved.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

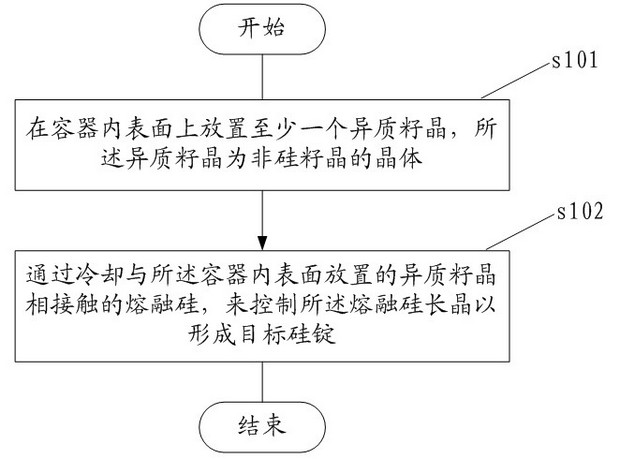

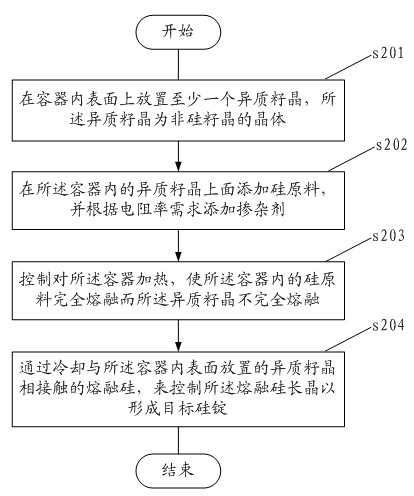

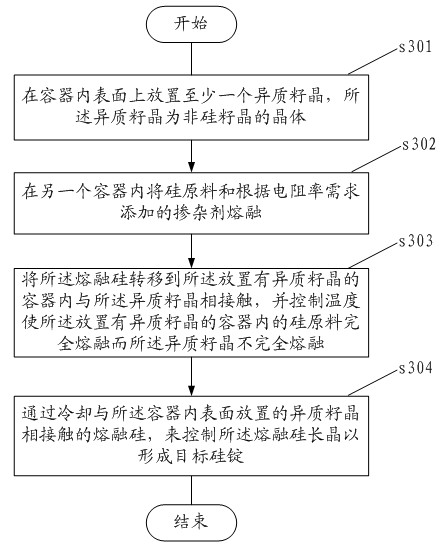

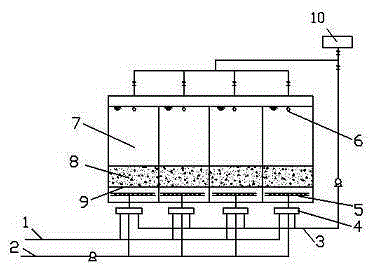

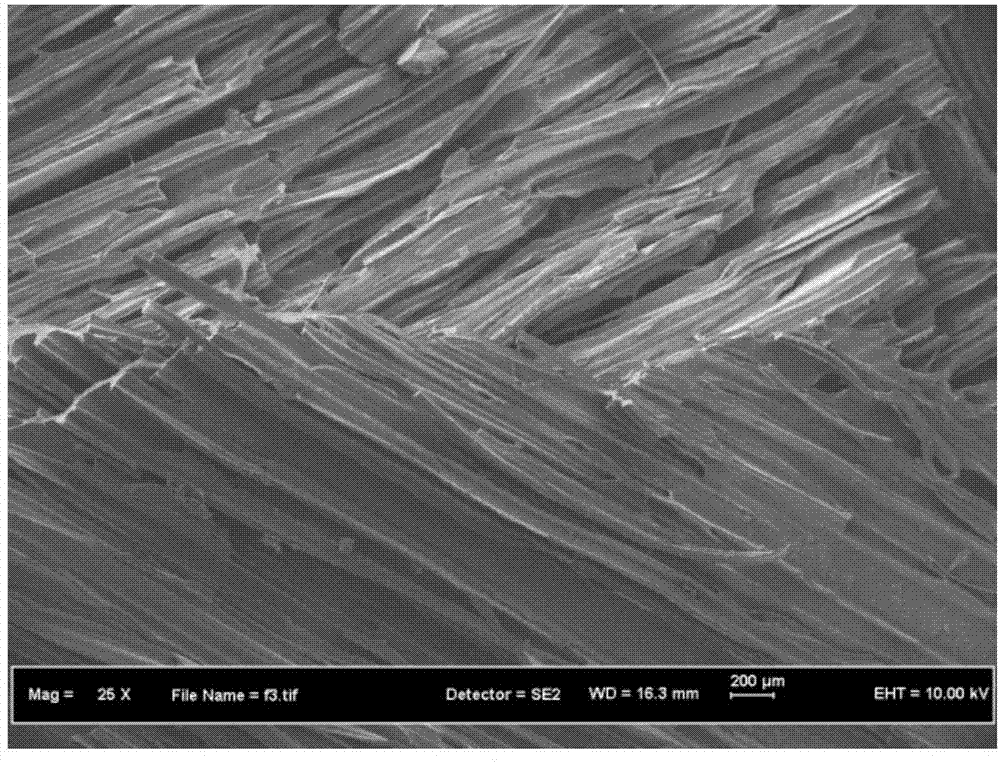

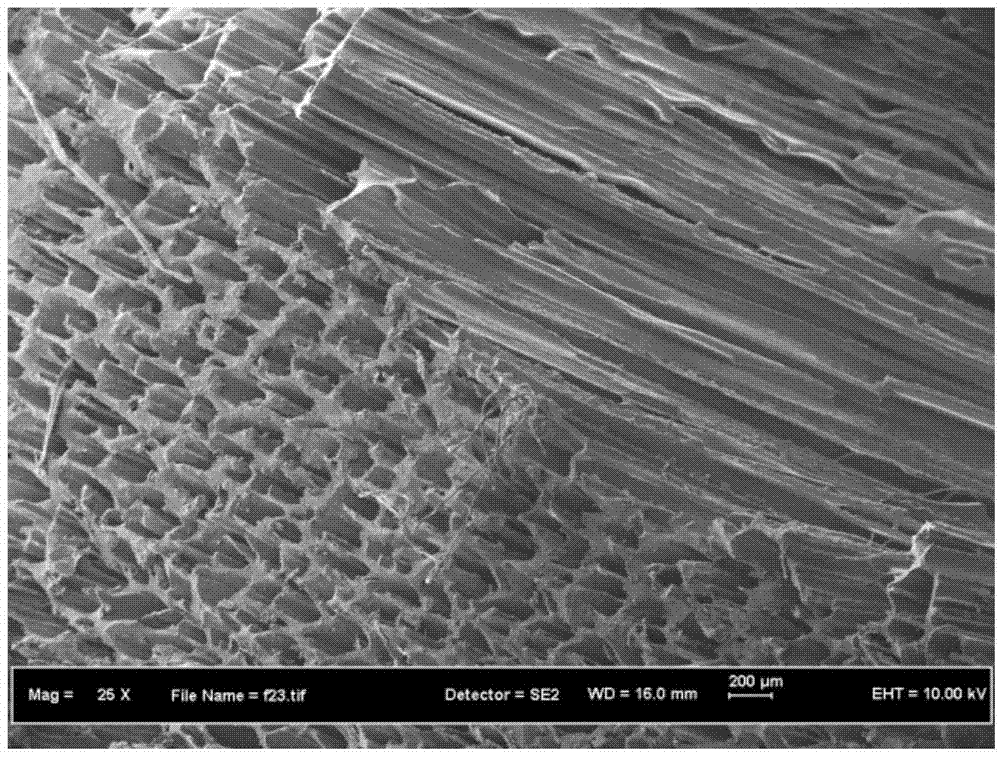

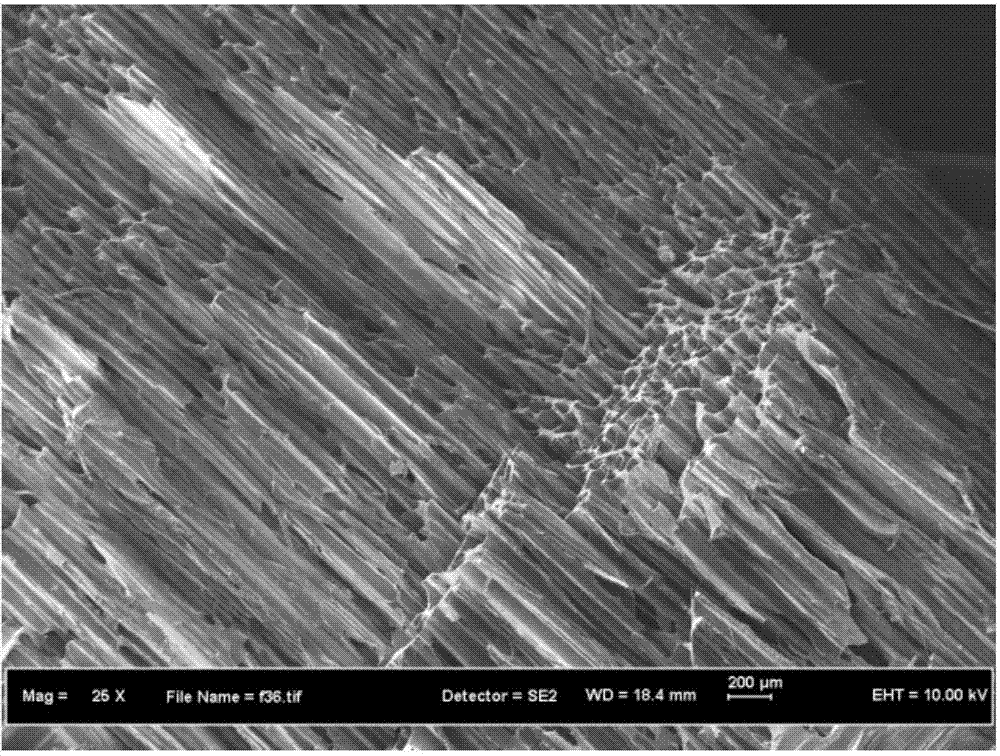

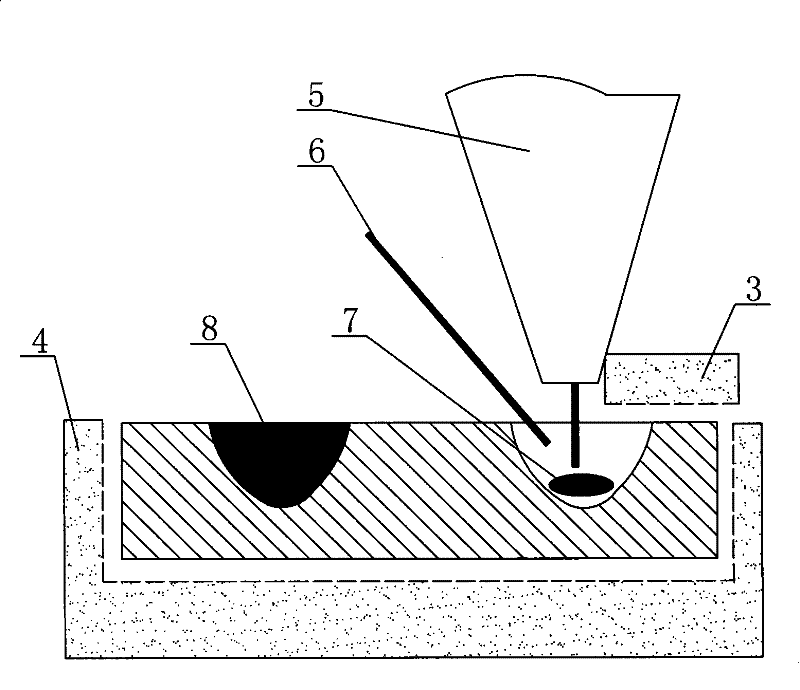

Crystalline silicon ingot casting method and silicon ingot

InactiveCN102154686AAchieve repeated useEasy temperature controlPolycrystalline material growthFrom frozen solutionsIngot castingCrystalline silicon

The invention discloses a crystalline silicon ingot casting method. The method comprises the following steps of: placing at least one heterogeneous seed crystal on the inner surface of a vessel, wherein the at least one heterogeneous seed crystal is a crystal of a non-silicon seed crystal; and controlling fused silica to grow crystals so as to form a target silicon ingot by cooling the fused silica which is contacted with the at least one heterogeneous seed crystal placed on the inner surface of the vessel. The invention also discloses the silicon ingot, and single crystals or large-grain polycrystalline silicon grow by using non-silicon crystals as the seed crystals in the vessel. The at least one heterogeneous seed crystal and the silicon crystals are substances with different physical and chemical properties, so that the temperature during ingot casting is easy to control to make the at least one heterogeneous seed crystal not completely fused. The aims that the at least one heterogeneous seed crystal is repeatedly used and the production process is simplified are fulfilled by the property that different substances are easy to separate.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Ozone catalytic oxidation method and device

PendingCN105417678AIncrease profitImprove solubilityWater contaminantsWater/sewage treatment by oxidationPipe waterCatalytic oxidation

The invention discloses an ozone catalytic oxidation method and device. The device comprises a contact oxidation tank, a water input pipe, a booster pump, a high-efficiency dissolved-air ejector, a perforated pipe water distributor, a catalyst filling material separation plate, a catalyst filling material, an ozone air inlet pipe, an ozone tail gas air inlet pipe and an ozone tail gas destroying device. The contact oxidation tank has a multi-section shunting type, sewage flows into the contact oxidation tank from the bottom and flows out from the top, and an up-flow contact oxidation reaction route is formed. Ozone is fully mixed with sewage and dissolved through the high-efficiency dissolved-air ejector, and is distributed at the bottom of the reaction tank through the perforated pipe water distributor. The catalyst filling material separation plate is arranged at the bottom of the reaction tank, and a catalyst layer is arranged on the separation plate. The catalyst is a high-efficiency load-type catalyst with metal and metal oxide loaded on a porous carrier. Sewage and ozone are subjected to a heterogeneous catalysis reaction in the contact oxidation tank under catalysis of the load catalyst, the ozone utilization efficiency and the oxidation efficiency are raised greatly, the ozone addition amount is reduced, and the operation cost is lowered.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

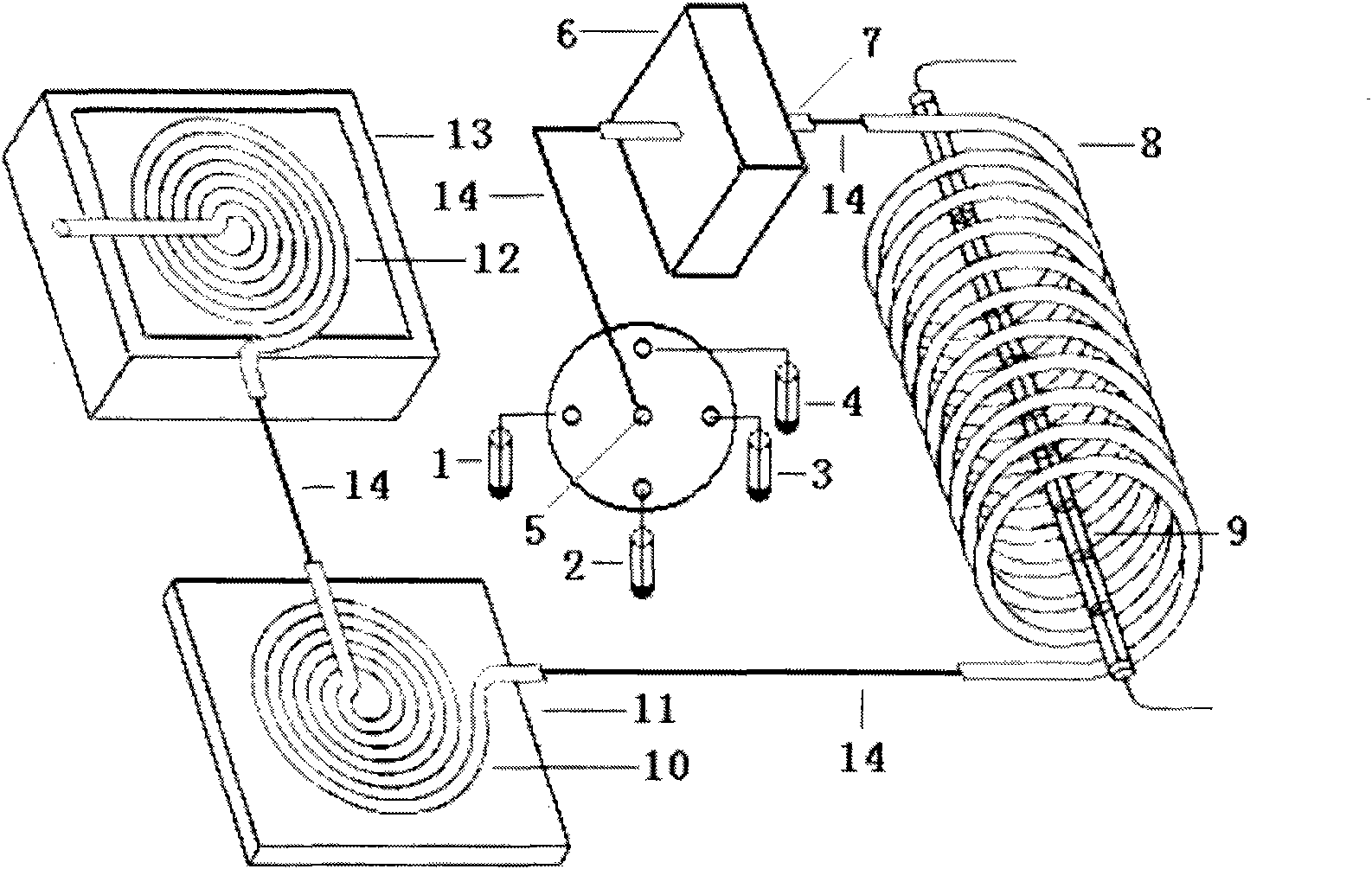

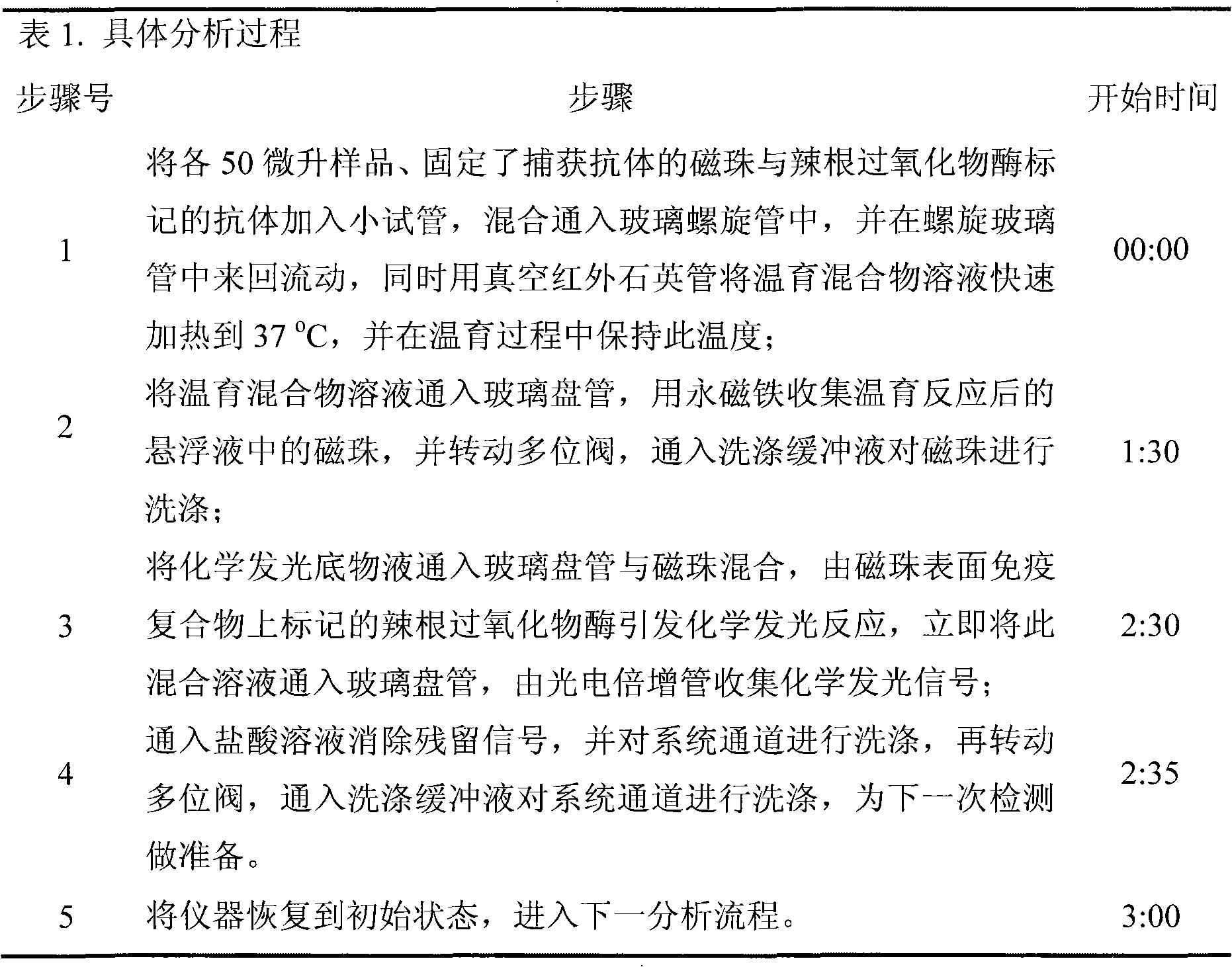

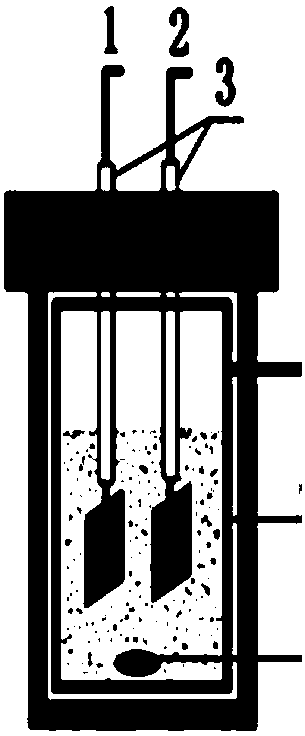

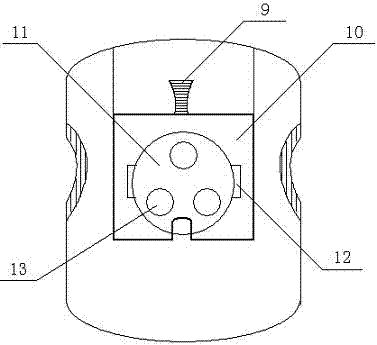

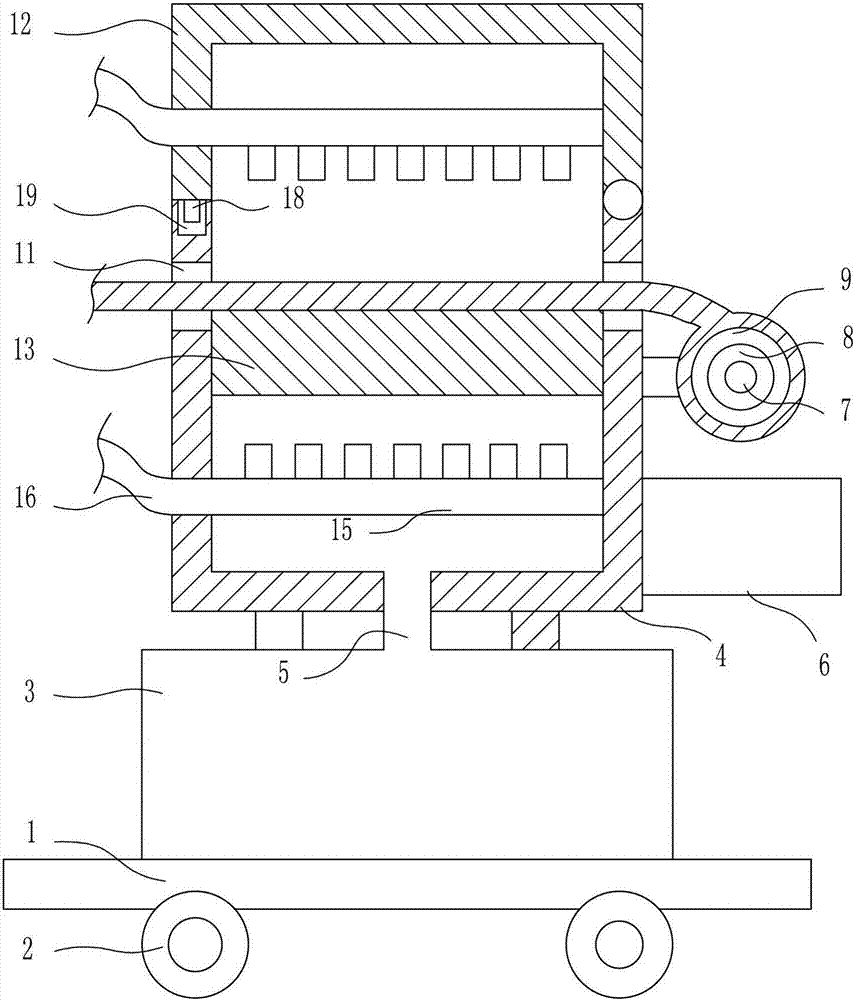

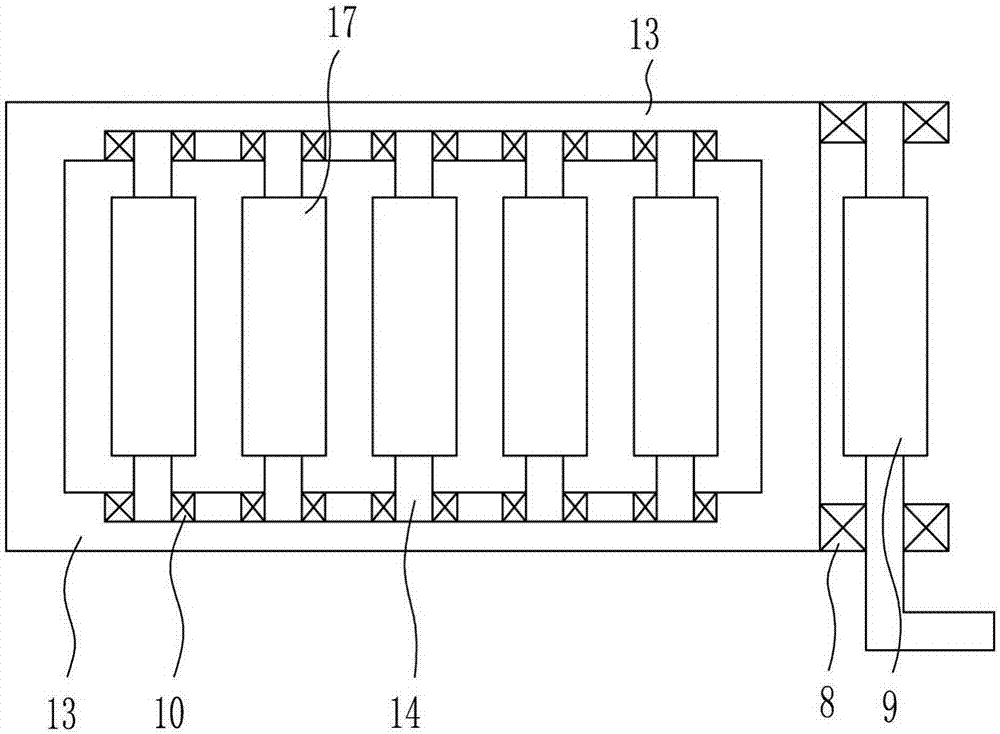

Fast chemiluminescence immune detection system and analysis method

InactiveCN101865912AEasy to operateReduce manual operationsChemiluminescene/bioluminescenceBiological testingPeristaltic pumpMagnetic bead

The invention relates to a fast chemiluminescence immune detection system and an analysis method. The solution transmission system of the detection system consists of cuvettes (1-4), a multi-position valve (5), a peristaltic pump (6) and a silicone rubber tube (7); an incubation system consists of a glass helix tube (8) and a vacuum infrared heating tube (9); a magnetic separation system consists of a glass coiled tube (10) and a permanent magnet (11); and a signal collection system consists of a glass coiled tube (12) and a photomultiplier (13). All the systems are connected by polytetrafluoroethylene tubes. Based on the sandwich method immune analysis and the flow injection system of magnetic bead surfaces, the invention carries out the infrared heating for the incubation process of the immune analysis, i.e. a turbulent mixing double acceleration method, so that the whole analysis process is reduced to 3 minutes and the inspection process can be controlled automatically. The method has the characteristics of fastness, simplicity, convenience, good reproducibility, high sensitivity, low cost and the like, can be applied to fields such as clinical diagnosis, environment monitoring, food safety and the like.

Owner:NANJING UNIV +1

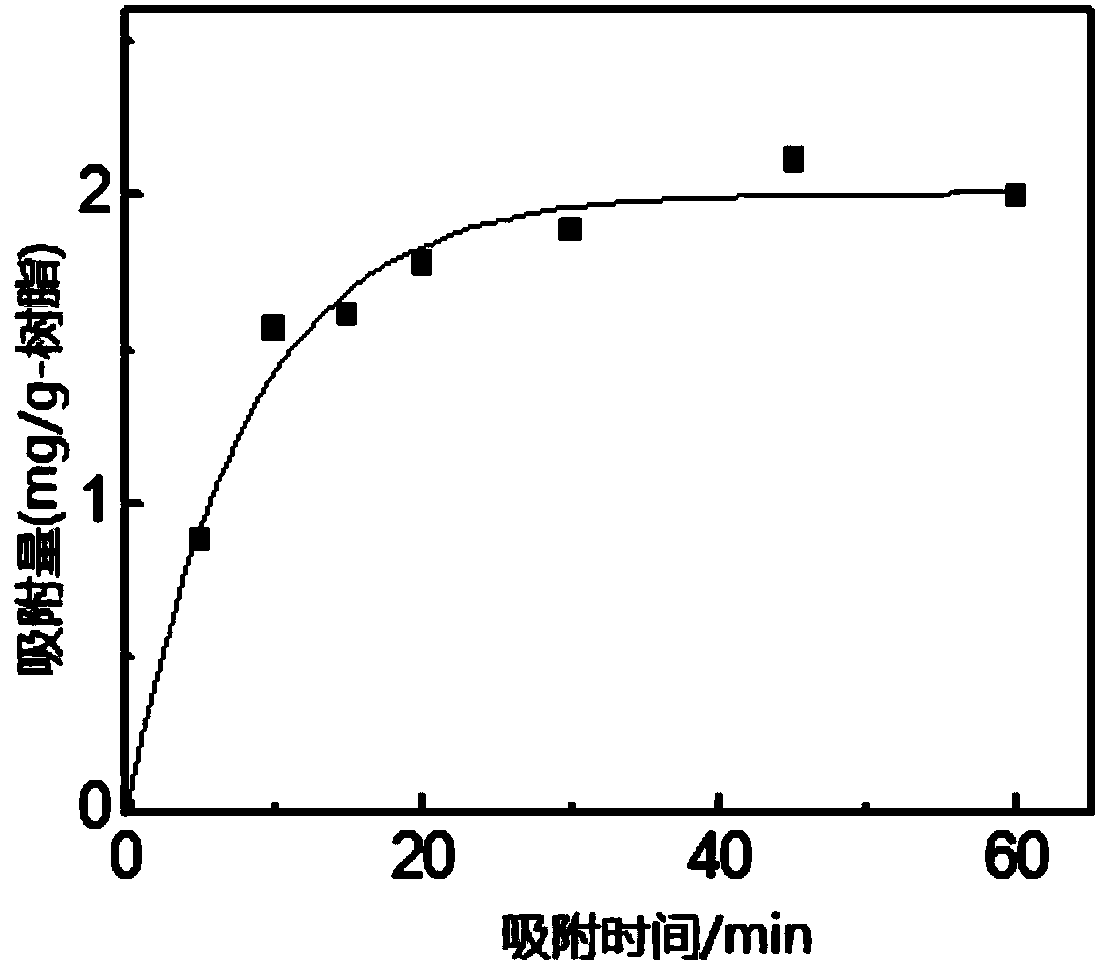

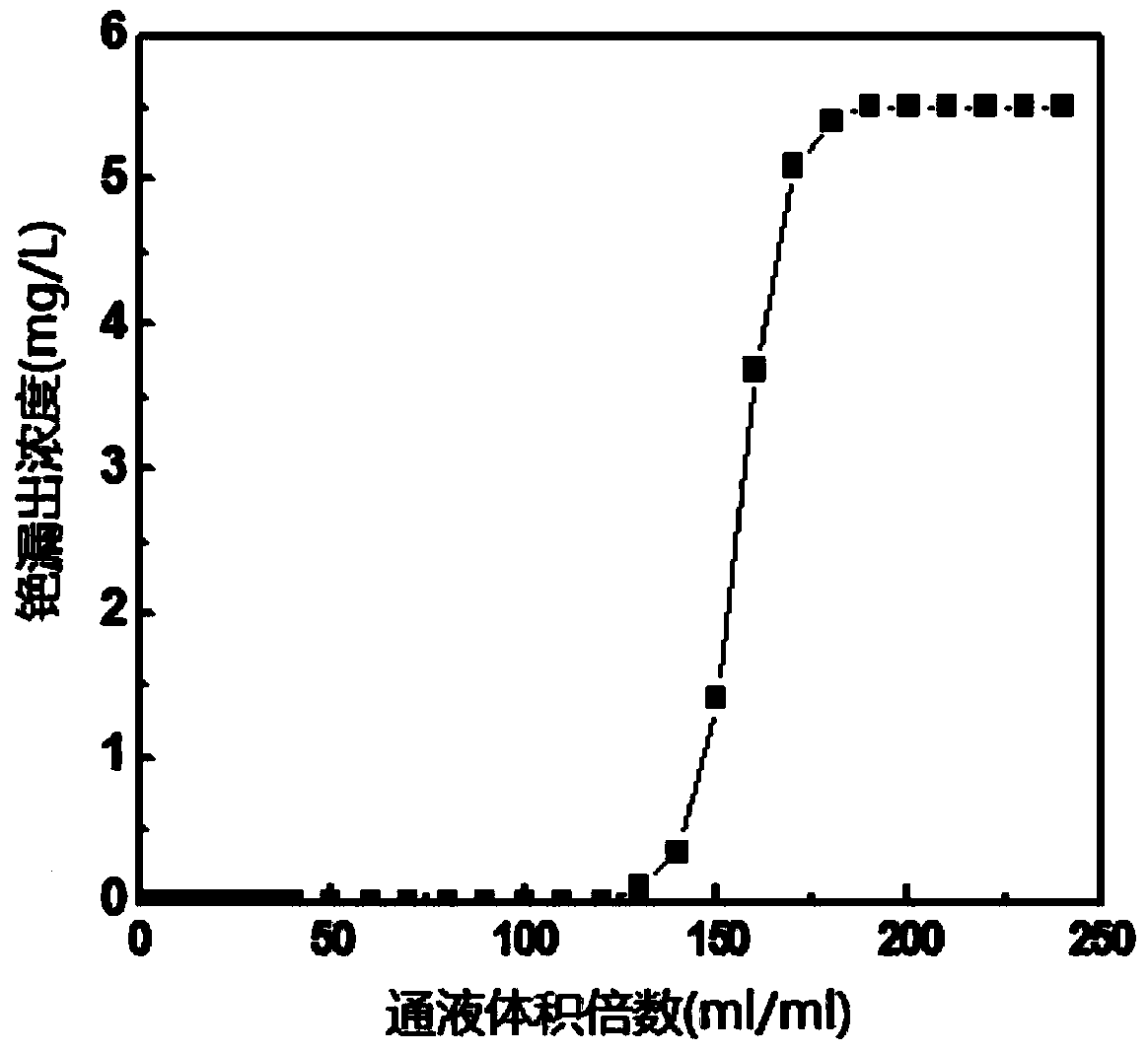

High-speed selective cesium adsorption resin material, method for preparing same and application thereof

InactiveCN103480345AImprove reaction efficiencyImprove controllabilityOther chemical processesRadioactive decontaminationCesium adsorptionAbsorption column

The invention relates to a cesium adsorption material. The cesium adsorption material is an organic-inorganic composite resin material formed by reaction of a high-molecular material containing an epoxy group and a phosphorus heteropoly acid salt-containing inorganic material. A surface layer of the composite resin material is mainly inorganic constituents. According to the cesium adsorption material, an ion adsorbent is led into the surface of a high-molecular base material, and accordingly the grain size of the cesium adsorption material can reach 400 microns and requirements for industrial absorption column filling are satisfied; the cesium adsorption material has the advantages of being high in absorption speed, Cs attached to resin can be completely desorbed easily through eluent, the treated absorption resin can absorb the Cs again and can be reused, and the cesium adsorption material has good economical benefits.

Owner:SHANGHAI JIAO TONG UNIV

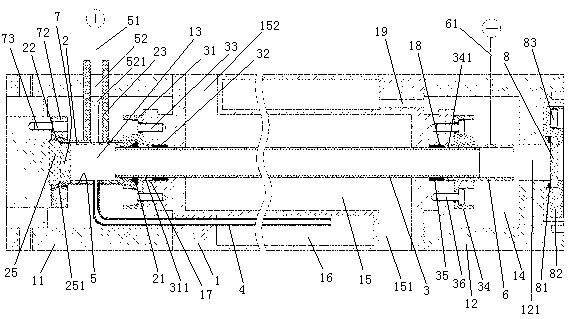

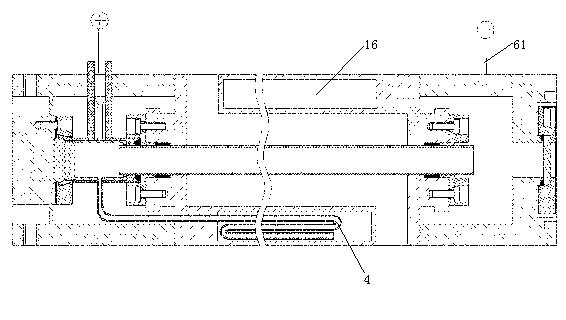

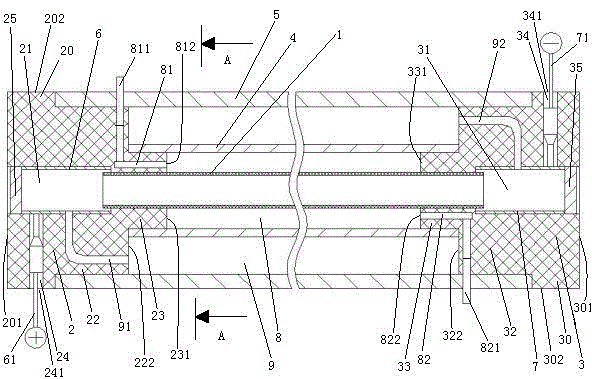

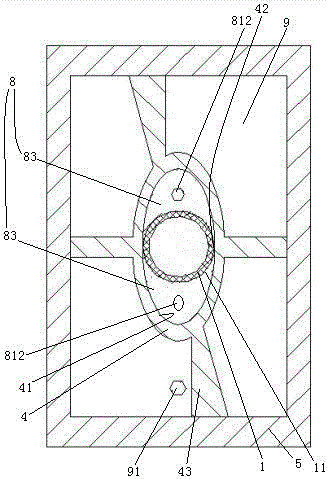

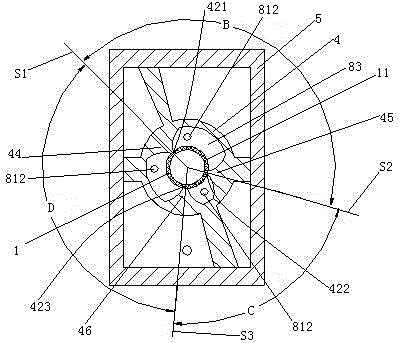

Water-cooled gas laser tube

InactiveCN103259157AEasy to replaceStable structureGas laser constructional detailsCooling chamberOptoelectronics

The invention relates to a gas laser tube. A water-cooled gas laser tube comprises a discharge tube, a cathode electrode, an anode electrode, a reflecting mirror, an output mirror, a metal supporting frame, an insulated anode electrode chamber and a cathode electrode chamber. The anode electrode chamber is connected at one end of the metal supporting frame, and the cathode electrode chamber is connected at the other end of the metal supporting frame. The metal supporting frame is provided with a cooling chamber and a gas storage chamber. The cooling chamber extends in the extension direction of the discharge tube, and the gas storage chamber is communicated with both the anode electrode chamber and the cathode electrode chamber. The discharge tube penetrates through the cooling chamber and communicates the anode electrode chamber with the cathode electrode chamber together , the two ends of the discharge tube are connected with the cooling chamber in a sealing mode, a water inlet is formed at one end of the cooling chamber, a water outlet is formed at the other end of the cooling chamber, the reflecting mirror and the anode electrode are located in the anode electrode chamber, the output mirror and the cathode electrode are located in the cathode electrode chamber. The water-cooled gas laser tube can be conveniently recycled and reused and solves the problems that an existing laser tube of a glass structure can be easily broken to caused losses to clients, is inconveniently to recycle and reuse and a large amount of harmful gas can be generated in the process of production.

Owner:HANGZHOU XINTOU TECH

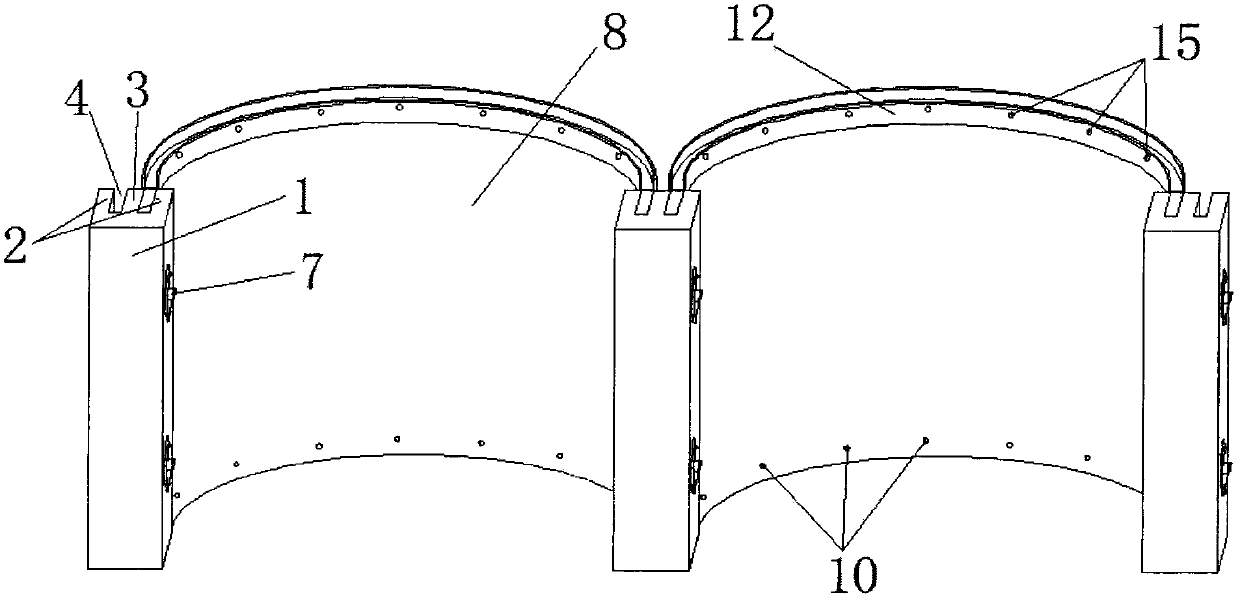

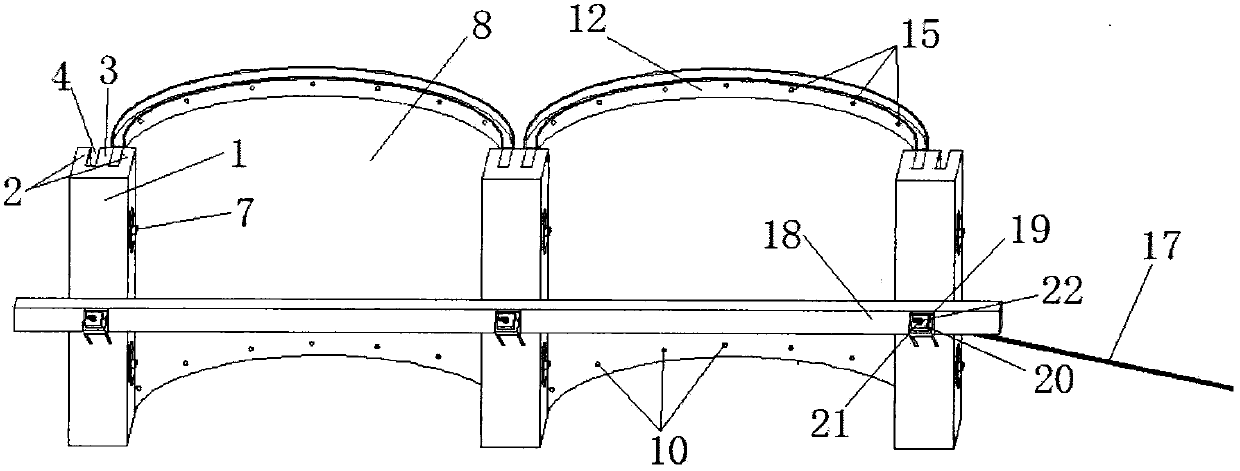

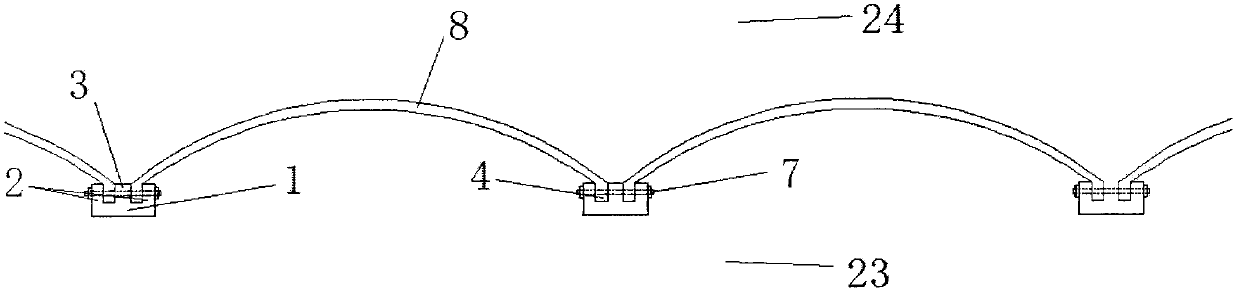

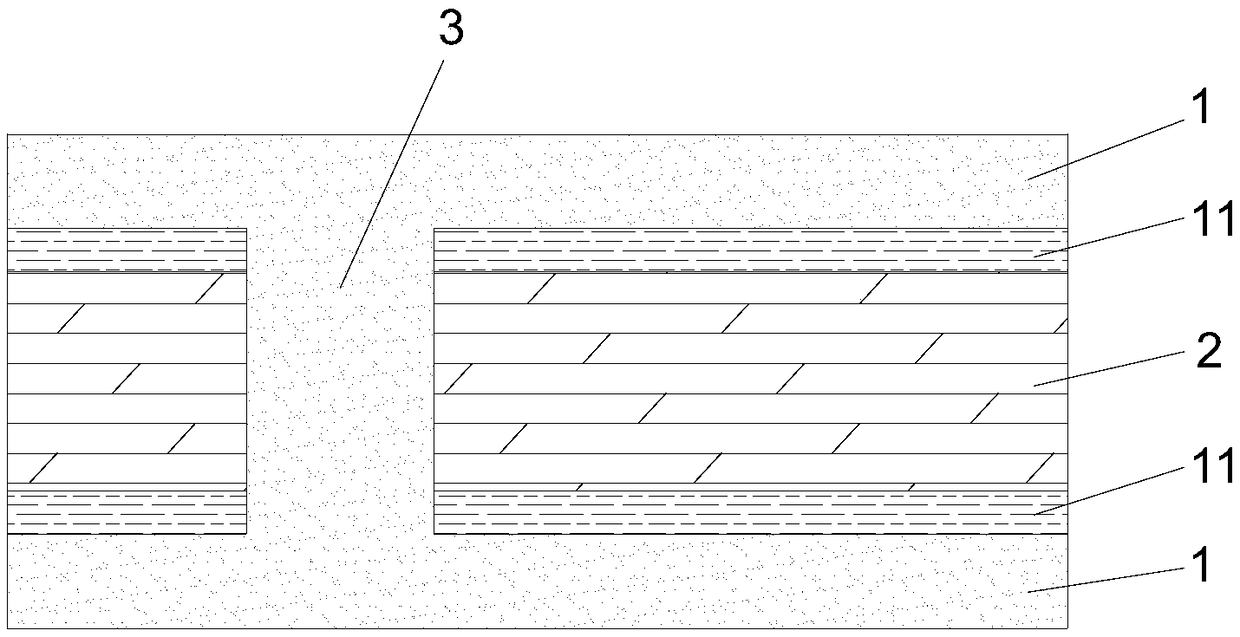

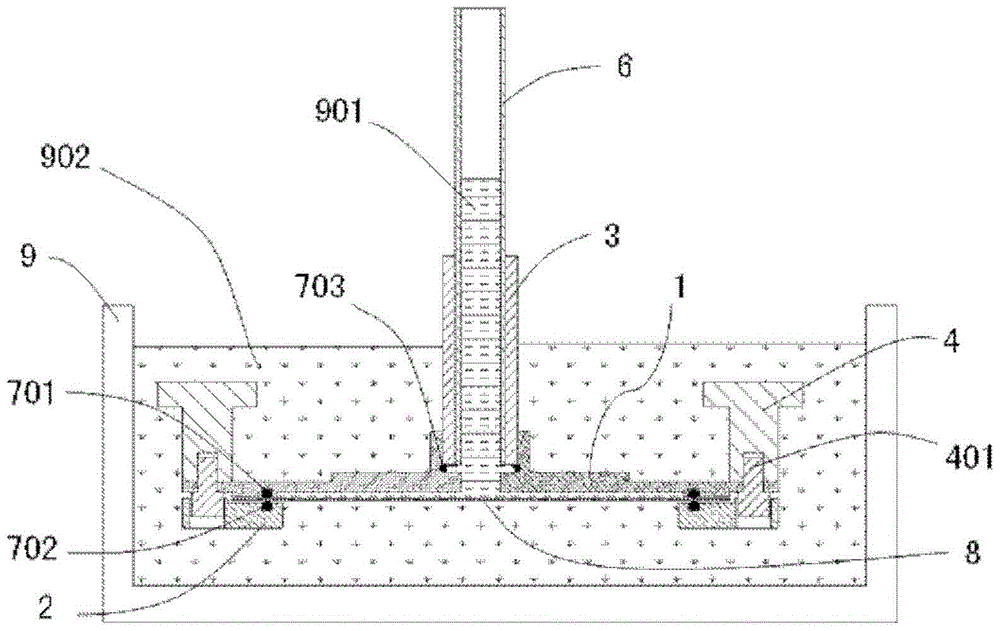

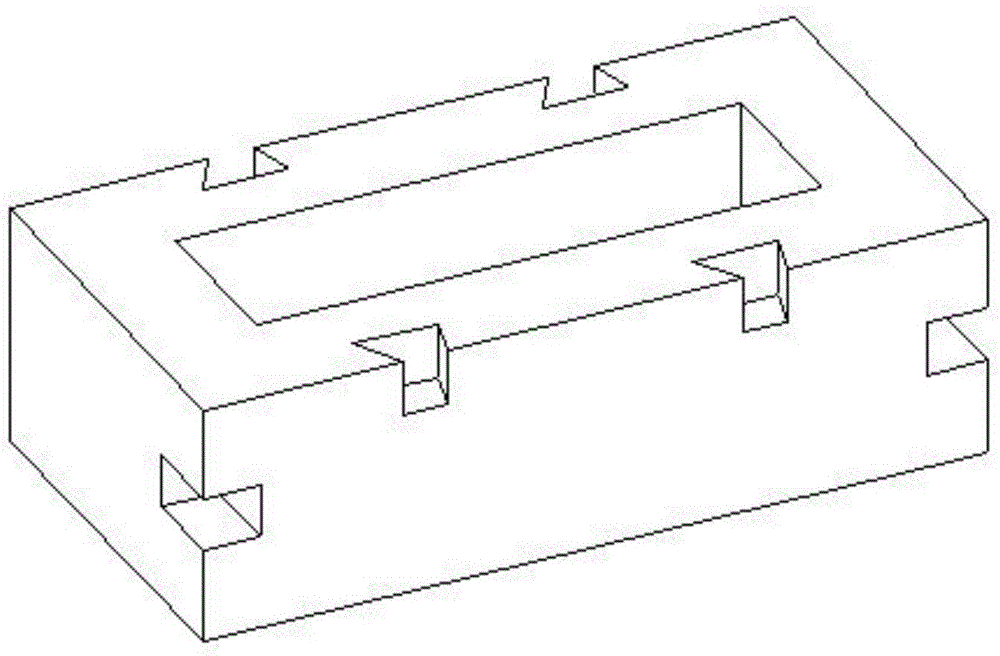

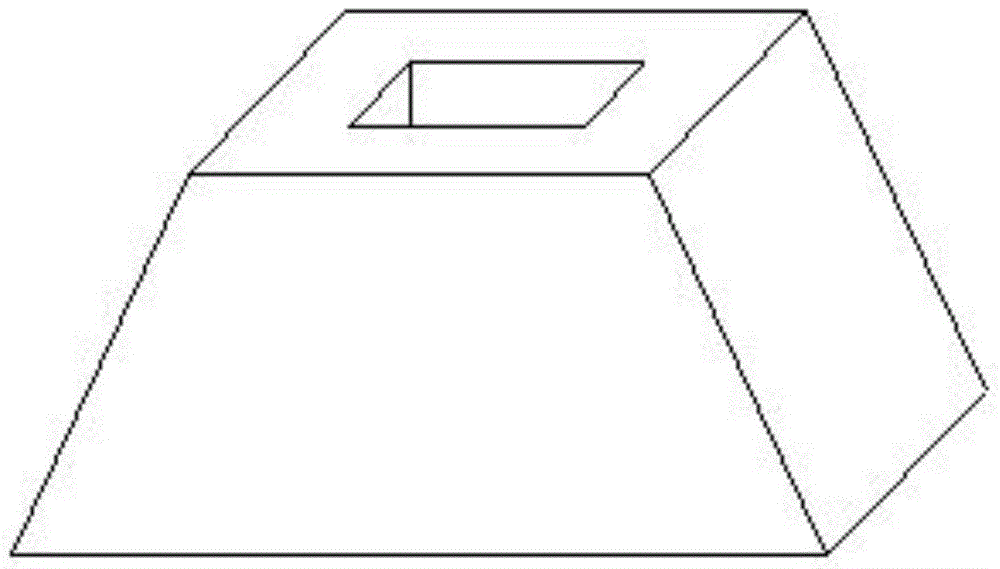

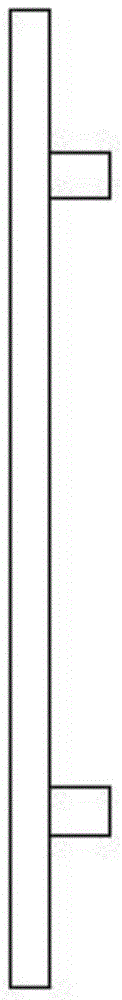

Fabricated multi-arch wall foundation pit supporting structure and construction technology

InactiveCN107740426AReasonable forceImproved force transmissionArtificial islandsProtective foundationSupporting systemReinforced concrete

The invention discloses a fabricated multi-arch wall foundation pit supporting structure and a construction technology, and belongs to the field of geotechnical engineering. The fabricated multi-archwall foundation pit supporting structure comprises precast concrete arch pieces and steel piles in the special shape like the Chinese character 'shan'. Arc-shaped steel with the H-shaped cross section, and each precast concrete arch piece are vertically combined together through casting, and the two arc pieces can be in butt joint at grooves of the arc-shaped steel in the vertical direction and connected at reserved holes through bolts. The cross section of each special-shaped pile shaped like the Chinese character 'shan', oblong reserved holes are formed in the flange of each steel pile at intervals and communicate with reserved holes in a corresponding arc piece connection rib, the oblong reserved holes in the steel piles can be connected with the reserved holes in the arc piece connection ribs through bolts, and reserved anchor rod holes can be formed in special-shaped pile webs. If a foundation pit is shallow, the special-shaped piles and the reinforced concrete precast arc piecesare subjected to combination construction, thus, a complete and closed cantilever pile foundation pit supporting system can be formed, no support or cat anchor need to be arranged, and if the foundation pit is deep, a cat anchor or an inner support can be additionally arranged.

Owner:NANJING UNIV OF TECH

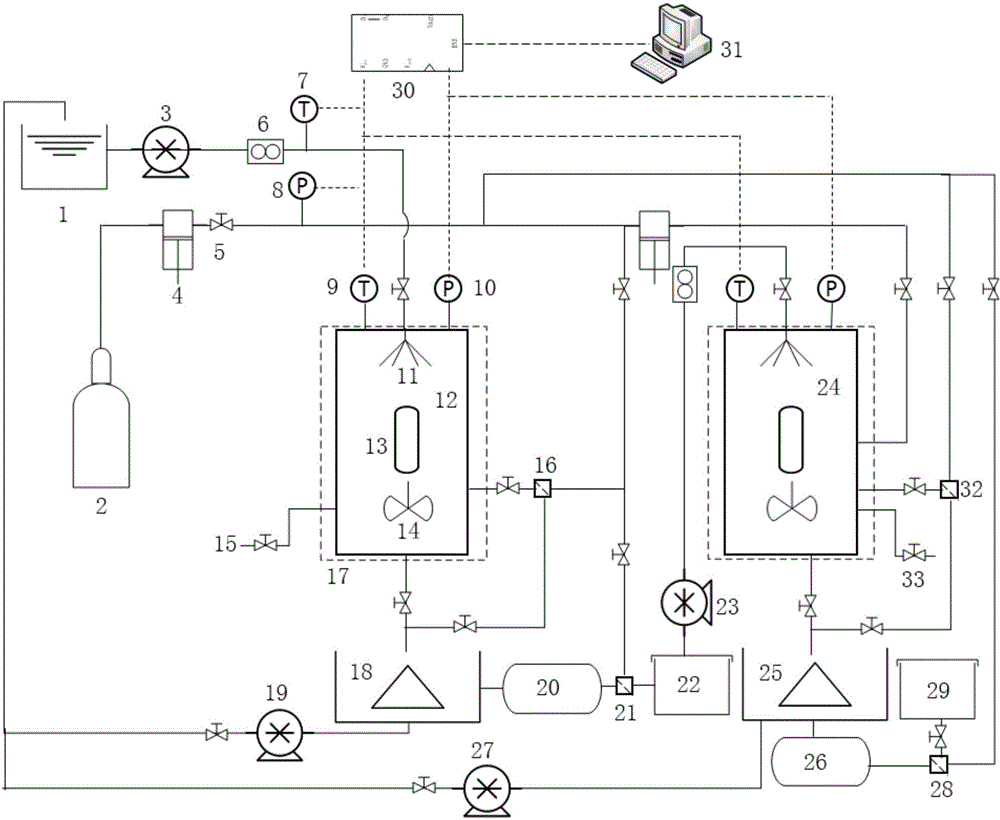

Gas hydrate method sewage treatment system

InactiveCN104591436AAchieve mutual circulationImprove the degree of purificationMultistage water/sewage treatmentIndustrial waste waterTreatments water

The invention relates to a gas hydrate method sewage treatment system belonging to the field of environmental science and engineering. The gas hydrate method sewage treatment system comprises two levels of treatment facilities and comprises a first-level treatment water mixture-sewage transportation unit, a first-level treatment hydrate generation decomposing unit, a secondary-level treatment water mixture-sewage transportation unit and a secondary-level hydrate generation decomposing unit. Hydrate decomposition water after first-level treatment is used as a raw material of secondary-level treatment, and pollutant removal efficiency is improved through two-level treatment. The gas hydrate method sewage treatment system is suitable for large-scale treatment of domestic wastewater and industrial wastewater, inorganic pollutant and organic pollutant can be effectively removed simultaneously, operating cost is reduced due to cyclic utilization of water mixture, heat and mass transfer of hydrate generation process is strengthened due to arrangement of a spray device and a stirrer, and the hydrate growth velocity is increased. The system and the method are reasonable and compact in structure, industrial production requirement is met, operation process is stable and reliable, cost is low, energy is saved and environment is protected.

Owner:DALIAN UNIV OF TECH

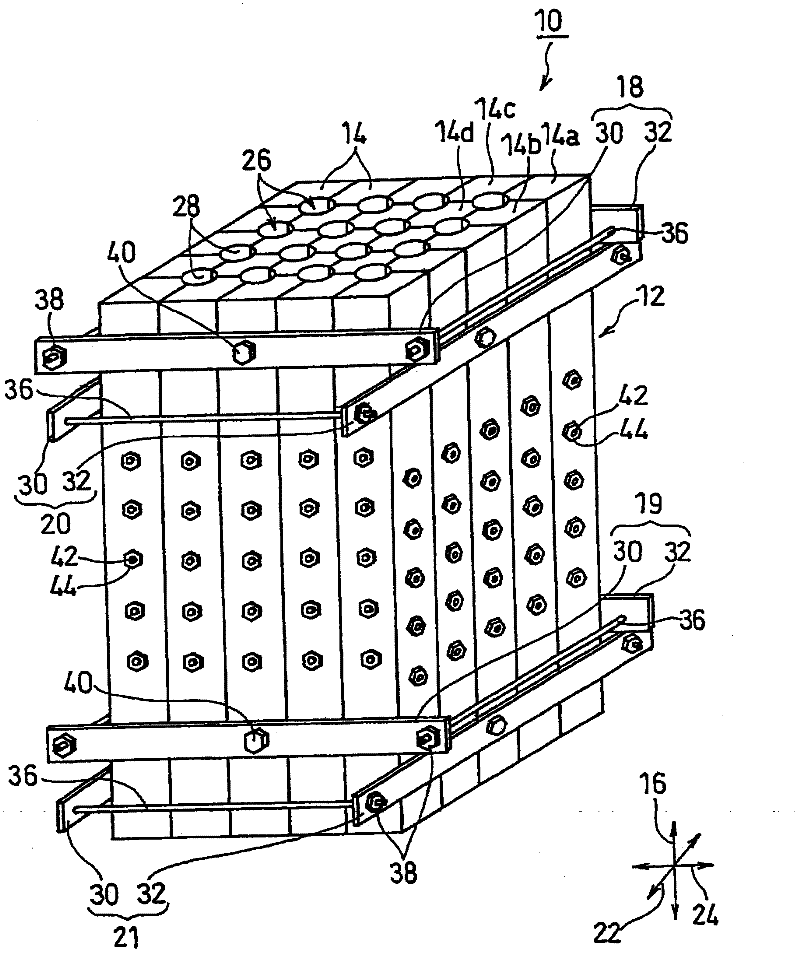

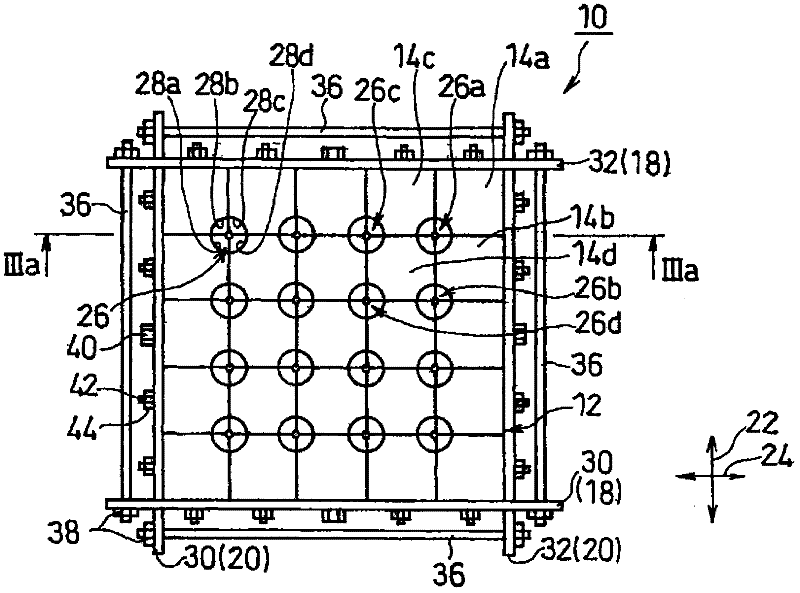

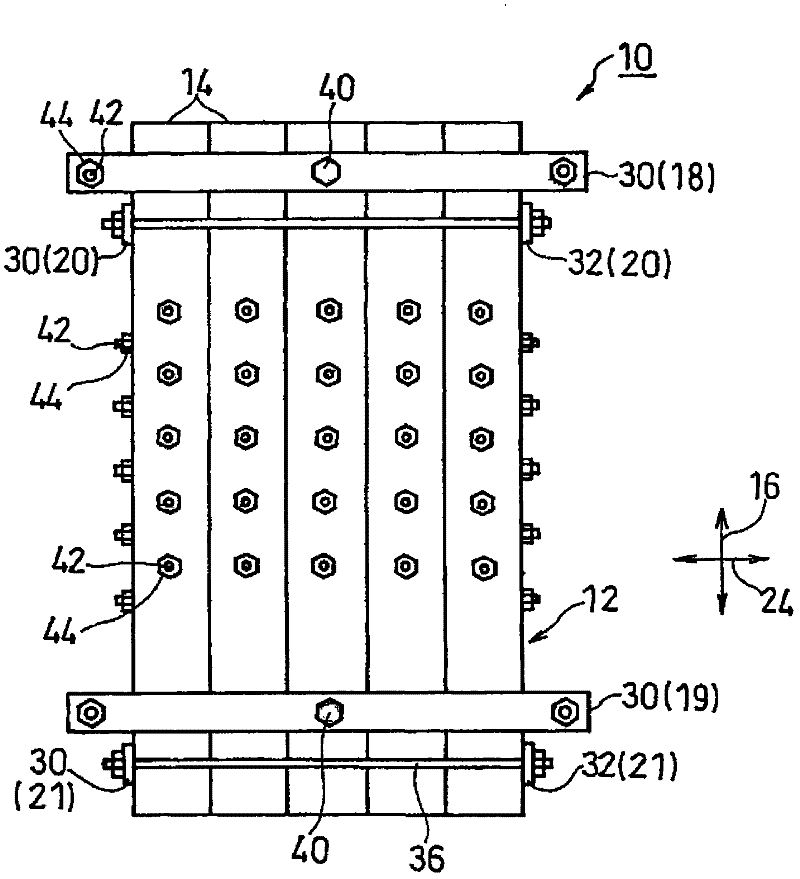

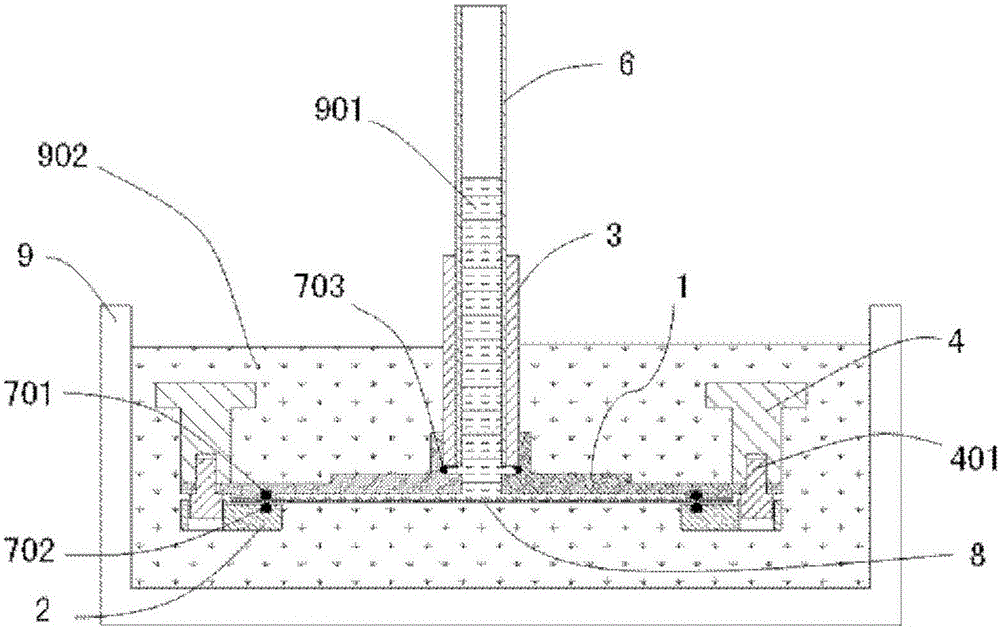

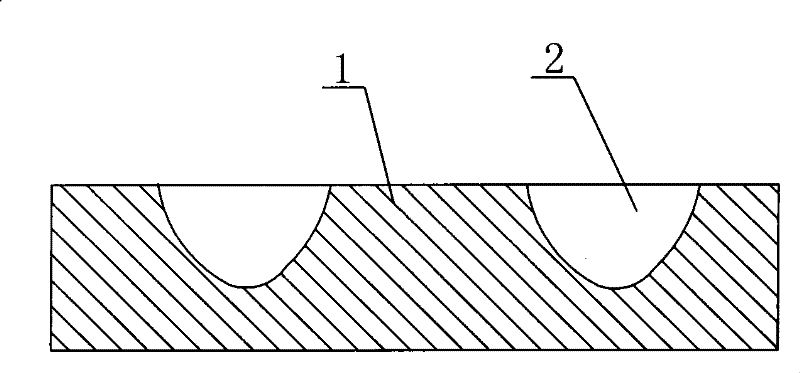

Mold used for forming casting bar, casting device, and method for producing casting bar

InactiveCN102131599AImprove production efficiencyImprove manufacturing yieldSiliconFoundry mouldsMaterials science

Owner:PANASONIC CORP

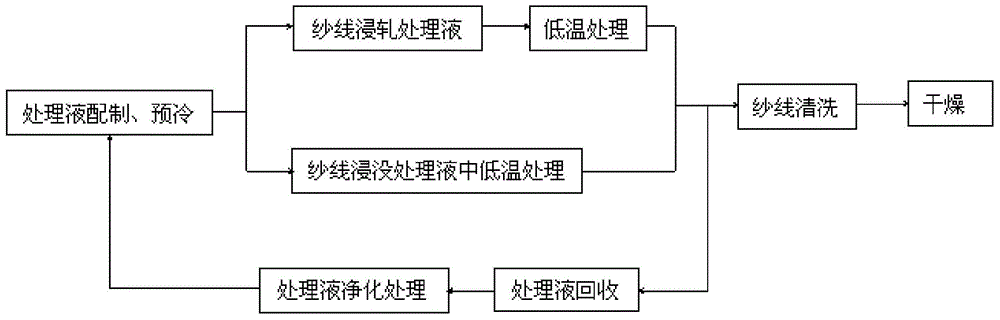

Non-slurry self-sizing method for cellulosic fiber containing yarns

ActiveCN104480722AAchieve repeated useRealize environmentally friendly processingVegetal fibresYarnHydrogen

The invention relates to a non-slurry self-sizing method for cellulosic fiber containing yarns. The non-slurry self-sizing method for the cellulosic fiber containing yarns comprises the following steps: mixing alkali, components effectively breaking hydrogen bonds among polysaccharide molecules and water to obtain a dissolved solution, and pre-cooling the solution to be 5 DEG C to 15 DEG C below zero; at 5 DEG C to 80 DEG C below zero, processing cellulosic fiber containing yarns in the dissolving solution or a padding solution for 10 seconds to 15 minutes, washing, and processing the yarns for once to ten times, drying and obtaining self-sized yarns. According to the non-slurry self-sizing method for the cellulosic fiber containing yarns, no slurry is consumed, the utilized various solutions and washing liquids can be recycled, the production cost is low, the energy and water consumption is reduced, the dependency of the textile industry on non-degradable or high-cost traditional slurry is reduced, and the transformation of the textile industry is beneficial of transforming to the low-carbon environment protection industry.

Owner:DONGHUA UNIV

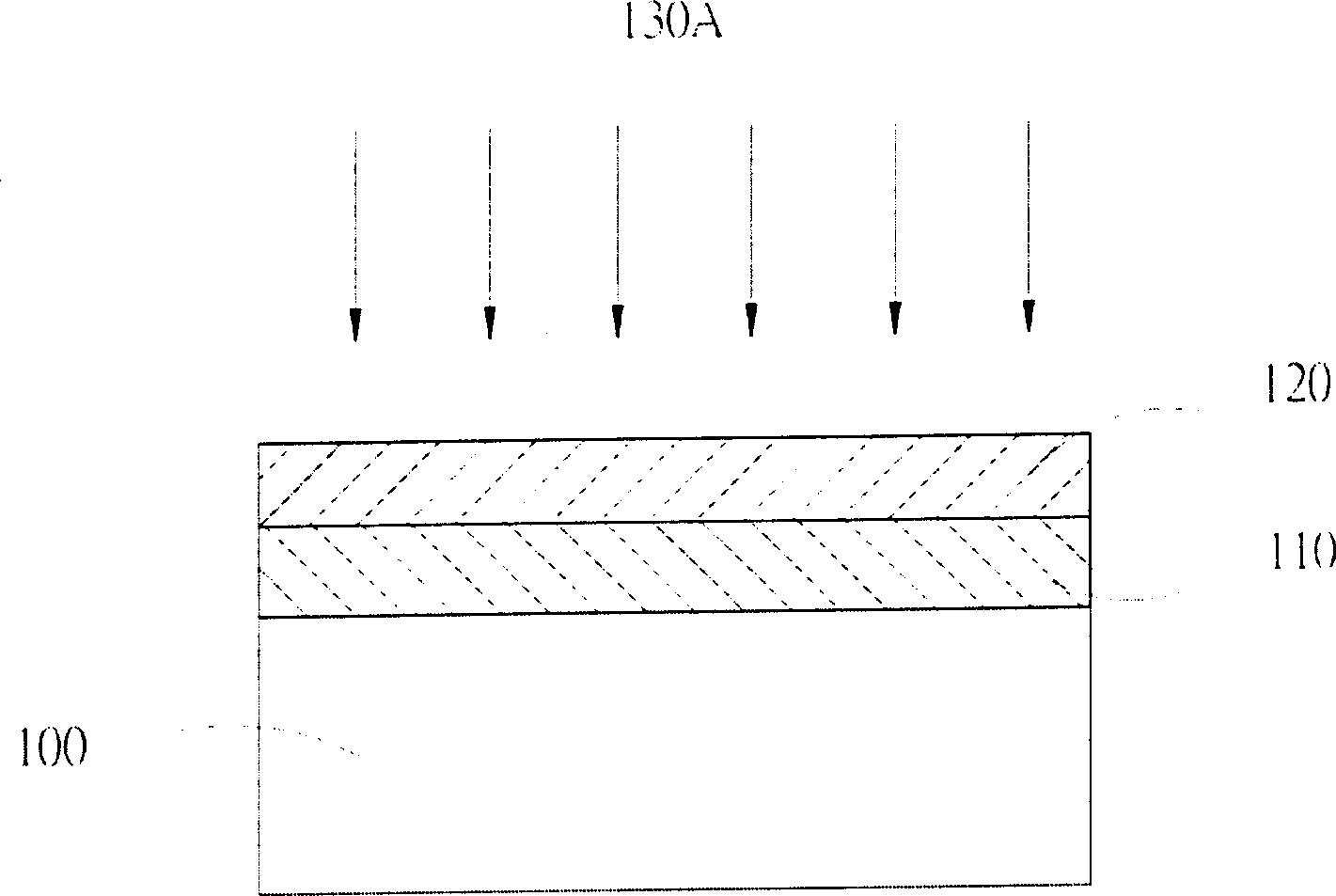

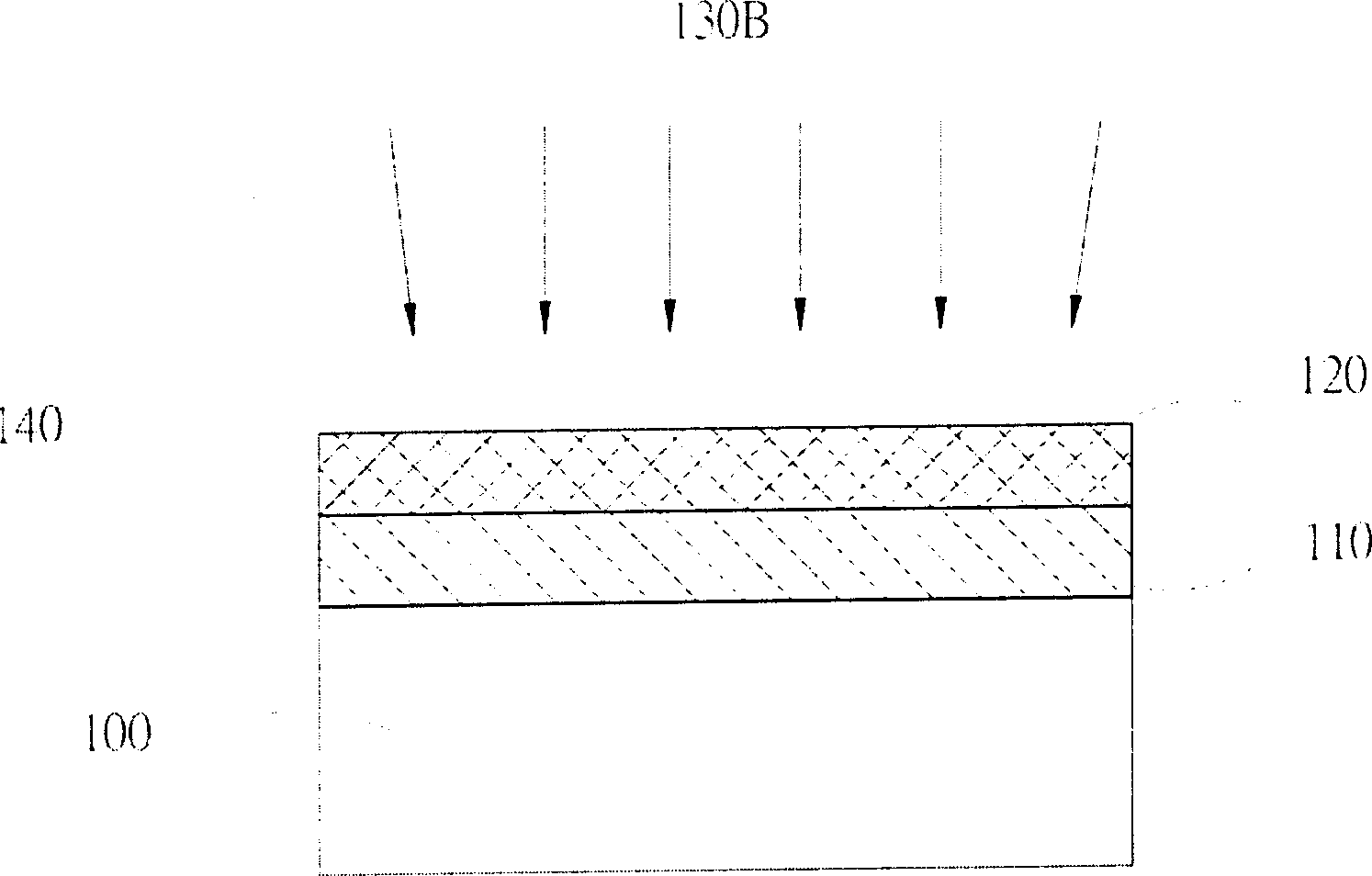

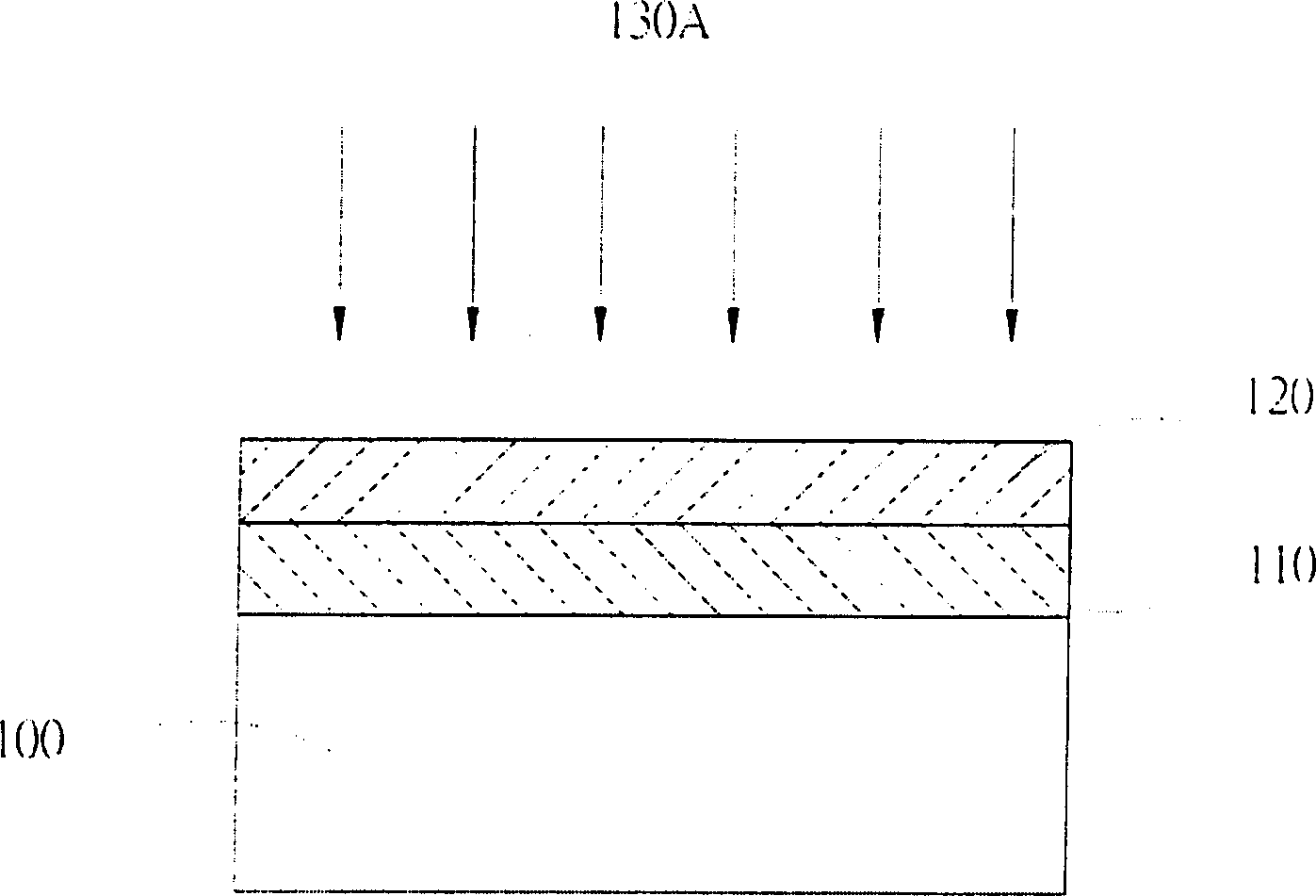

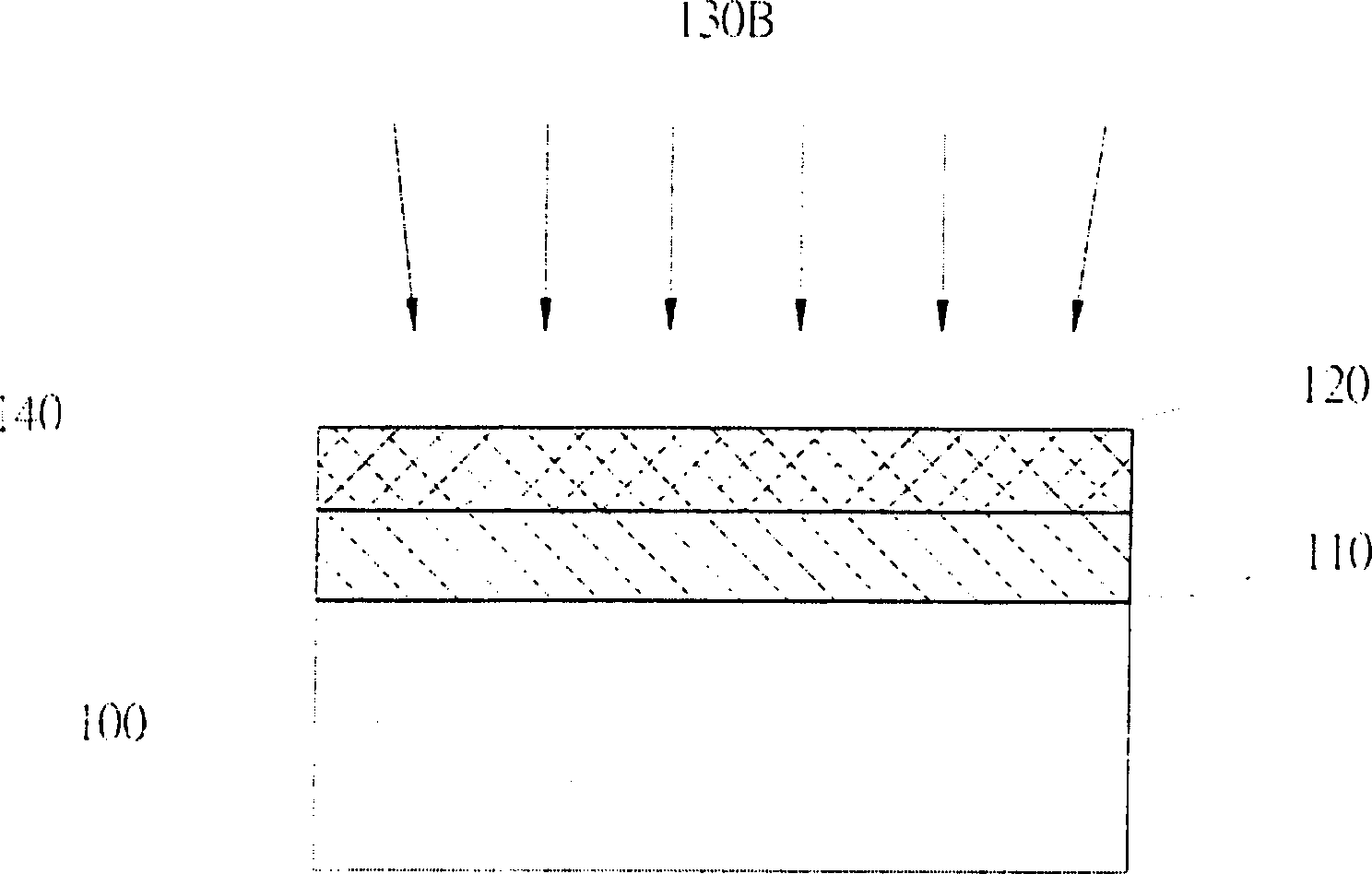

Repeatedly usable unpatterned wafer and forming method thereof

InactiveCN1466170AAchieve repeated useSemiconductor/solid-state device manufacturingEngineeringMoisture

This invention discloses a forming method for a unpatterned water of a semiconductor process. A basic material is provided first, then an oxidation layer is formed on it and a non-crystallosilicon layer is formed, after that an ion implantation process is carried out for doping the non-crystallosilicon layer and oxidation layer. Secondly, a temper process is taken to form a unpatterned wafer and Rs is tested after that and schedule monitor is done, the non-crystallosilicon layer and oxidation layer on the moisture control plate basic material and the unpatterned wafer can be used repeatedly to reduce schedule monitor cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

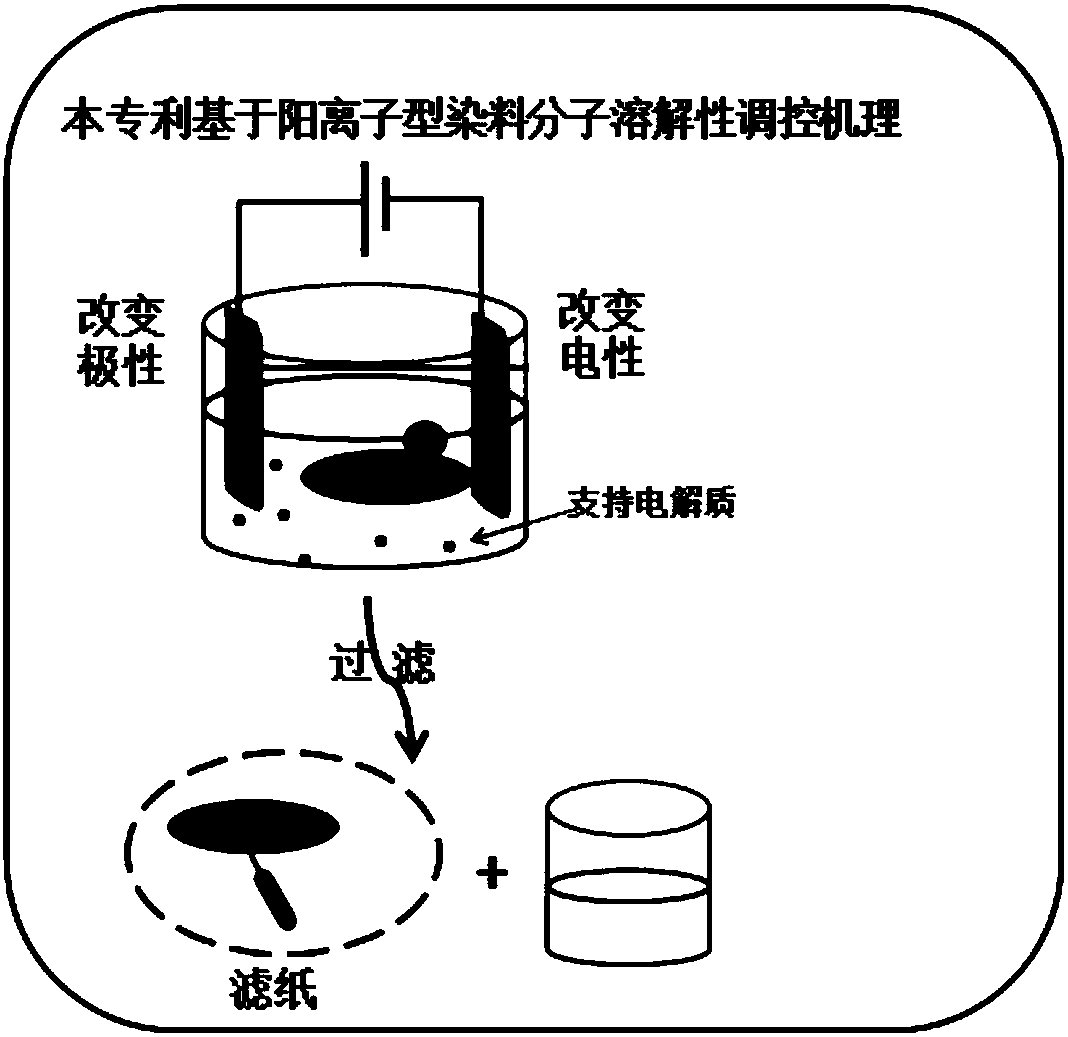

Method for treating cationic dye wastewater based electrochemical modification technology

ActiveCN108017118AShort processing timeImprove efficiencyWater contaminantsWater/sewage treatmentChemistryPollution

The invention relates to a high-efficiency method for treating cationic dye wastewater through an electrochemical technology, and belongs to the technical field of wastewater treatment. The method ischaracterized in that cationic dye molecules are modified through the electrochemical technology to make the molecules become an insoluble substance, and simple filtration is performed to separate themodified dye molecules from the wastewater in order to achieve the wastewater treatment purpose. The new method has the characteristics of high removal efficiency, simple operation process, no secondary pollution, low operating cost, friendliness to the environment and operators, and very high practical application values.

Owner:WUHAN UNIV OF SCI & TECH

Heavy rare earth metal target material repairing method

ActiveCN110373642ALower diffusion temperatureHigh densityVacuum evaporation coatingSputtering coatingRare earthHigh pressure

The invention provides a heavy rare earth metal target material repairing method and belongs to the technical field of magnetron sputtering surface treatment. The heavy rare earth metal target material repairing method comprises the following steps: filling the loss area of a to-be-repaired target material with alloy powder, and performing the repairing operation by adopting a vacuum sintering method or a high-pressure cold spraying method, wherein the alloy powder comprises a dysprosium-terbium alloy or one or two of dysprosium and terbium and one or two of metalloids. The heavy rare earth metal target material repairing method provided by the invention has the beneficial effects that the alloy powder is adopted as a repairing material; the repairing operation is performed by adopting thevacuum sintering method or the high-pressure cold spraying method; the alloy powder plays a role in brazing, and thus the sintering temperature during the follow-up target material repairing operation is reduced; furthermore, the diffusion temperature after the film coating operation on a magnetic sheet is reduced, and the repairing difficulty and cost are reduced; according to the structure of the target material repaired through the heavy rare earth metal target material repairing method, the problem that the existing target surface cannot be reused after being defective is effectively solved; and the process is simple, the cycle is short, the use effect is close to a new target material, and the application value is good.

Owner:BAOTOU JINSHAN MAGNETIC MATERIAL

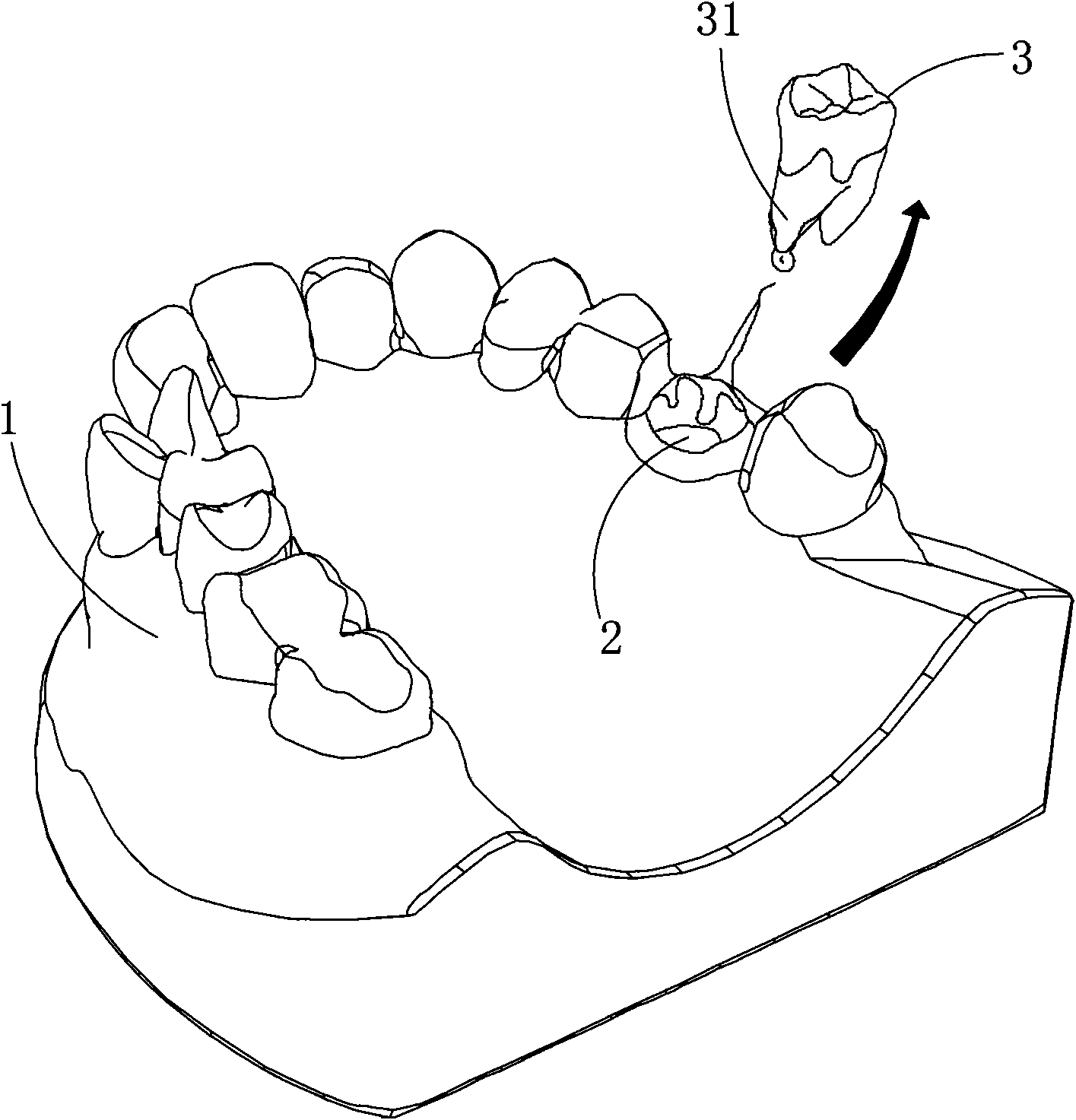

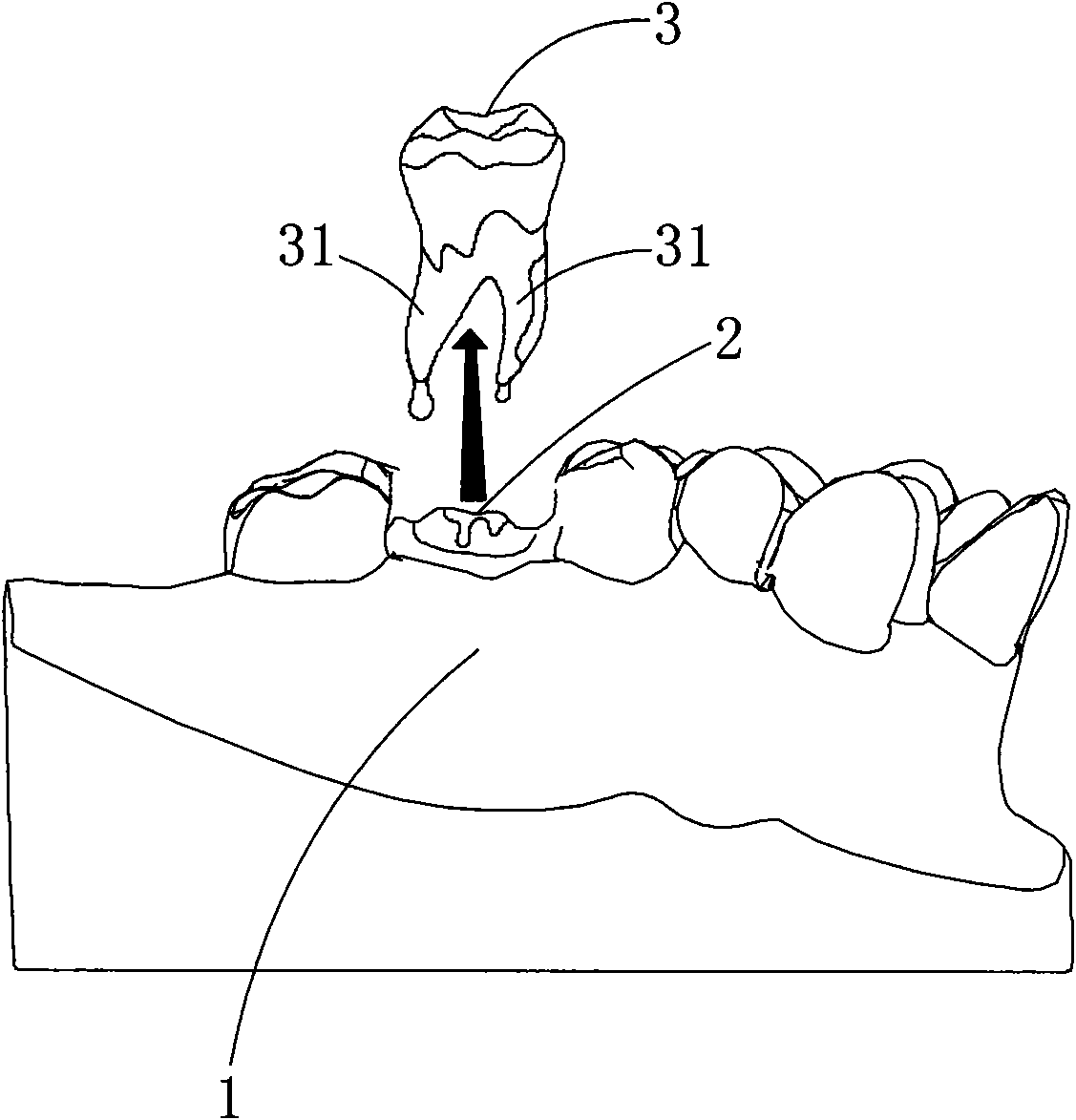

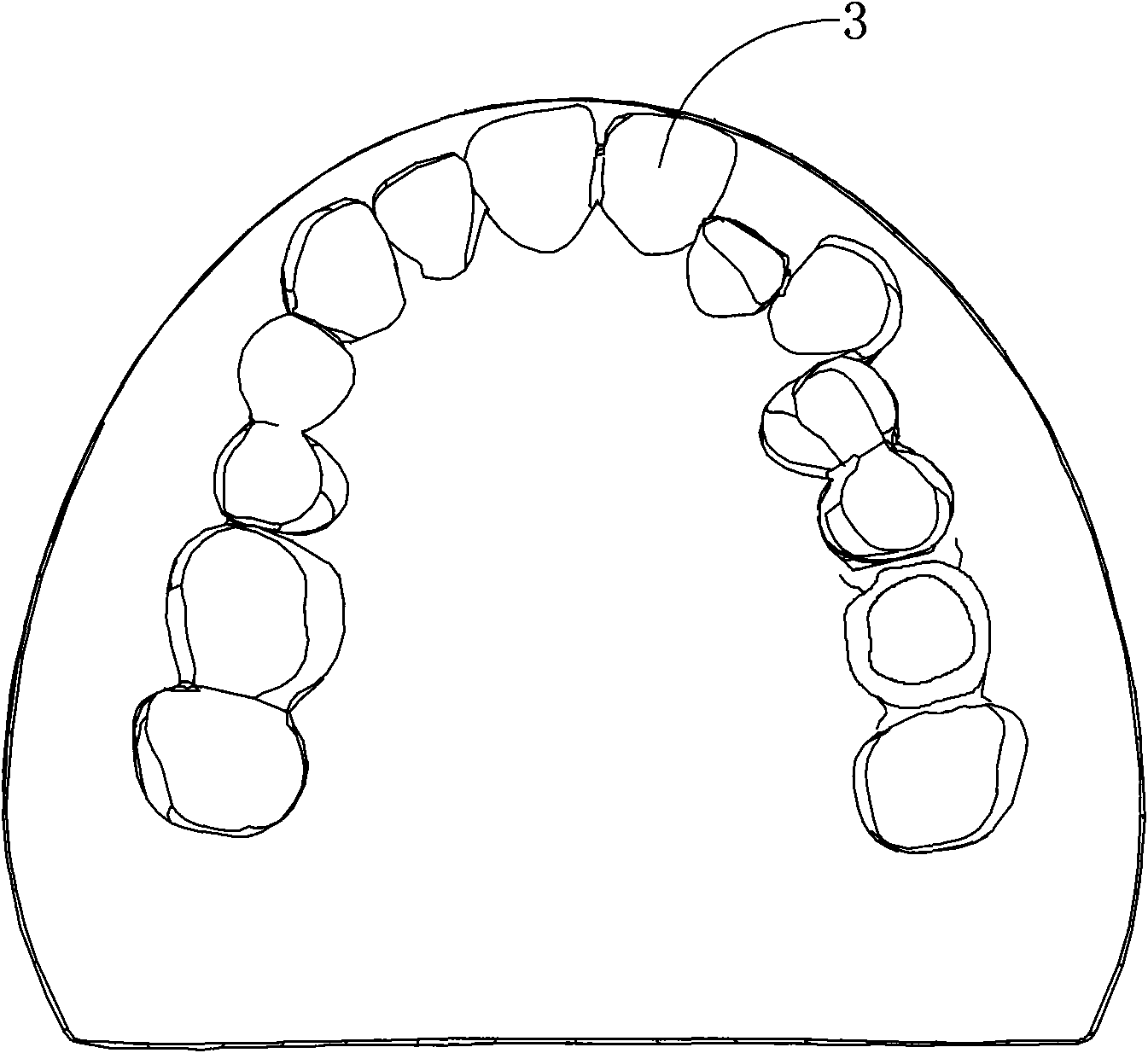

Tooth extracting model

InactiveCN101866573AEasy connectionGood simulationEducational modelsTOOTH EXTRACTIONSIrregular teeth

The invention discloses a tooth extracting model which comprises a simulation alveolar bone, wherein the simulation alveolar bone is provided with a plurality of alveolar grooves used for fixing teeth, and at least one of artificial teeth, which can be extracted, is glued in the corresponding alveolar groove. The tooth extracting model realizes the repeated use of extractable artificial teeth and the whole tooth extracting model, and meets the requirement on oral cavity teaching for a great quantity of operation training. An irregular tooth arrangement mode is adopted and is closer to the state of the oral cavity before treatment, and is convenient for linking with the real treatment environment. A design of the extractable artificial teeth with tooth roots has better simulation, an operator can effectively control the force and the angle of the teeth extraction according to different quantities and parts of the tooth parts, thereby lightening pain of patients in the real operation. A binding agent can form a layer of film similar to the parodontium at the tooth root of the extractable artificial tooth, and can further simulate the real oral cavity tissue.

Owner:日进齿科材料(昆山)有限公司

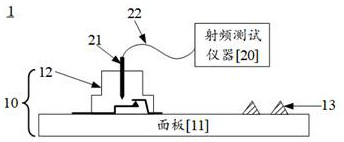

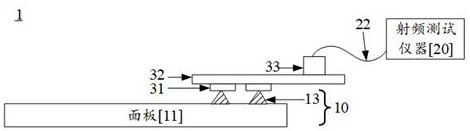

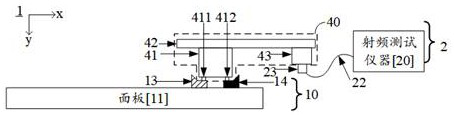

Antenna test system, to-be-tested single board and related equipment thereof

InactiveCN113640612AReduce layout areaLow costElectrical testingMeasurement instrument housingRadio frequency signalMonoboard

The invention provides an antenna test system, a to-be-tested single board and related equipment thereof, and relates to the technical field of radio frequency. The antenna test system comprises: a switching circuit board; a coaxial module which is arranged on the switching circuit board, wherein the coaxial module is used for elastically abutting against an antenna elastic sheet on the to-be-tested single board; and an adapter which is arranged on the adapter circuit board and connected with the coaxial module, wherein the adapter is used for being in butt joint with a test connector connected with a radio frequency test instrument. According to the antenna test system, the switching circuit board provided with the coaxial module is used for connecting the radio frequency test instrument and the to-be-tested single board, the radio frequency signal on the single board to be tested is externally guided to the radio frequency test instrument for detection, a radio frequency switch test seat does not need to be additionally arranged on the to-be-tested single board, the layout area of the single board is saved, and meanwhile, the device cost is also reduced.

Owner:深圳荣耀智能机器有限公司

Method of preparing chiral dichloro chrysanthemic acid using immobilized ester

A process for preparing chiral dichlorochrysanthemic acid from fixed esterase includes such steps as covalence-binding esterase to activated dual-functional group carrier, adding the recemic dichlorochrysanthemate, non-ionic surfactant and fixed esterase in a buffering solution, catalytic hydrolysis, separating the fixed esterase from reaction liquid, flushing the fixed esterase with buffering liquid, acidifying the reaction liquid, extracting in organic solvent, saponifying the organic phase to make dichlorochrysanthemic acid in water phase, acidifying and crystallizing. Its advantages are high speed, and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

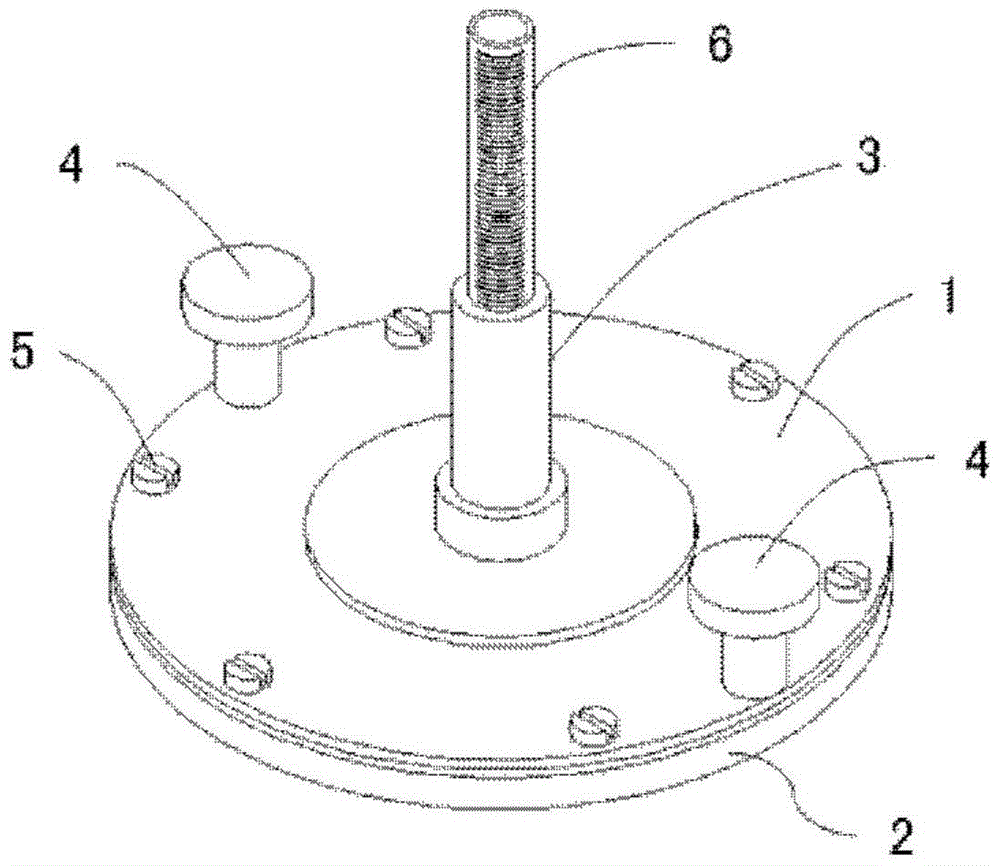

Acid and alkali corrosion resistant protection cover and application method thereof

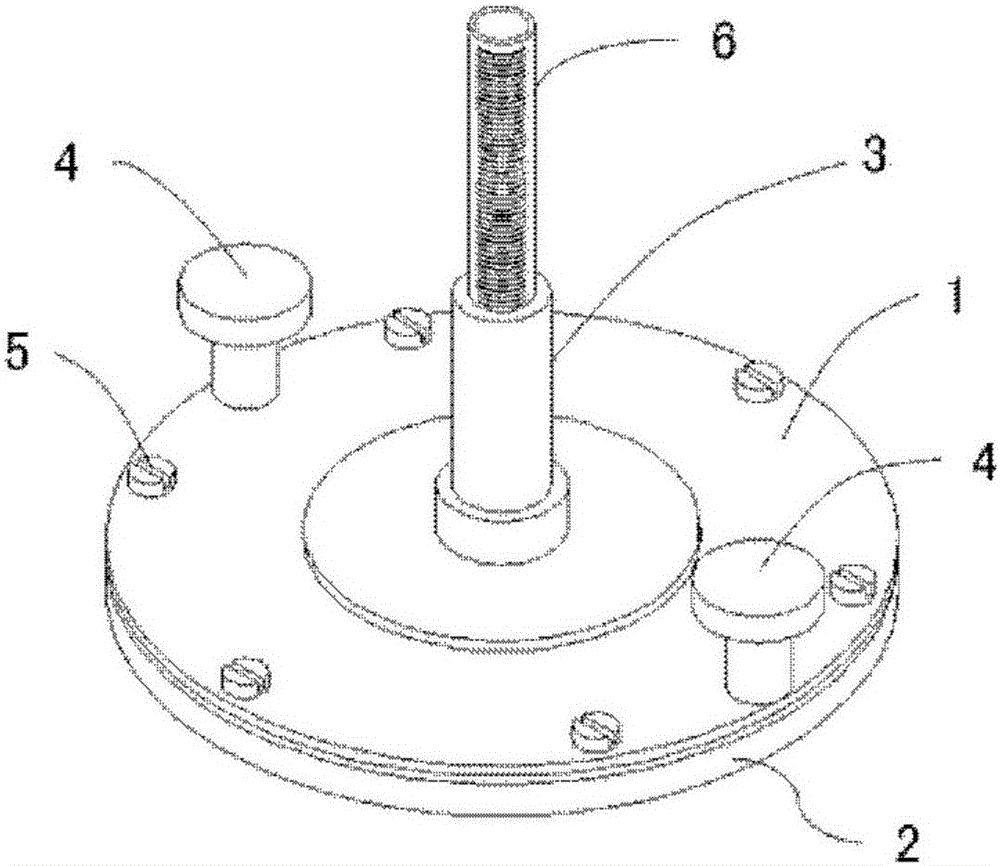

InactiveCN104986721ASimple structureEasy to useDecorative surface effectsSemiconductor/solid-state device manufacturingCorrosion resistantEtching

The invention discloses a protection cover capable of protecting a single-face pattern of a silicon wafer from being influenced by wet etching and an application method thereof. The protection cover adopts a top plate and a bottom plate to clamp a chip which needs pattern protection in the middle, and the top plate is in sealed connection with the bottom plate through a fastening screw; rubber rings are respectively placed between the top plate and the chip and between the bottom plate and the chip, and sealing is achieved through compressive deformation of the rubber rings; a round through hole is arranged in the center of the bottom plate, and corrosive liquid corrodes the back of the chip through the through hole; a round groove is arranged in the center of a sealed upper cover board, and water is injected into the groove to prevent the corrosive liquid from seeping into the inner sides of the rubber rings to directly corrode the silicon wafer. One face of the chip, which needs protection, is soaked into other liquid by the protection cover, so that damage from wet etching is avoided. The whole structure is easy to assemble and disassemble, simple and convenient to use, and through replacing the sealing rings, the protection cover can be repeatedly used.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of polyacrylate macroporous cross-linked polymer and product

The invention discloses a preparation method of a polyacrylate macroporous cross-linked polymer. The preparation method comprises the steps: (1) dissolving an acrylic monomer and an oil-soluble crosslinking agent in an oil-soluble solvent to form a precursor solution, wherein the weight percentage of the monomer in the precursor solution is 5wt%-20wt%, and the weight percentage of an initiating agent in the precursor solution is 0.1wt%-1wt%; (2) adding the initiating agent, putting the precursor solution at the temperature below the melting point of the solvent, and carrying out polymerization reaction to obtain an intermediate product; and (3) putting the intermediate product obtained in the step (2) at the temperature below the melting point of the solvent, and after fusing the solvent, compressing, washing, soaking and drying so as to remove the solvent, thus obtaining the macroporous cross-linked polymer. The preparation method disclosed by the invention has the advantages that selectable raw materials are sufficient and low in cost, the preparation method is suitable for industrial enlargement and application, and the prepared macroporous cross-linked polymer is small in relative density and high in specific strength, porosity and shape recovery percentage.

Owner:ZHEJIANG UNIV

Repeatedly usable unpatterned wafer and forming method thereof

InactiveCN1270366CAchieve repeated useSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringMoisture

This invention discloses a forming method for a unpatterned water of a semiconductor process. A basic material is provided first, then an oxidation layer is formed on it and a non-crystallosilicon layer is formed, after that an ion implantation process is carried out for doping the non-crystallosilicon layer and oxidation layer. Secondly, a temper process is taken to form a unpatterned wafer and Rs is tested after that and schedule monitor is done, the non-crystallosilicon layer and oxidation layer on the moisture control plate basic material and the unpatterned wafer can be used repeatedly to reduce schedule monitor cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

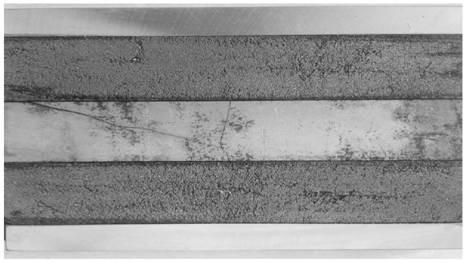

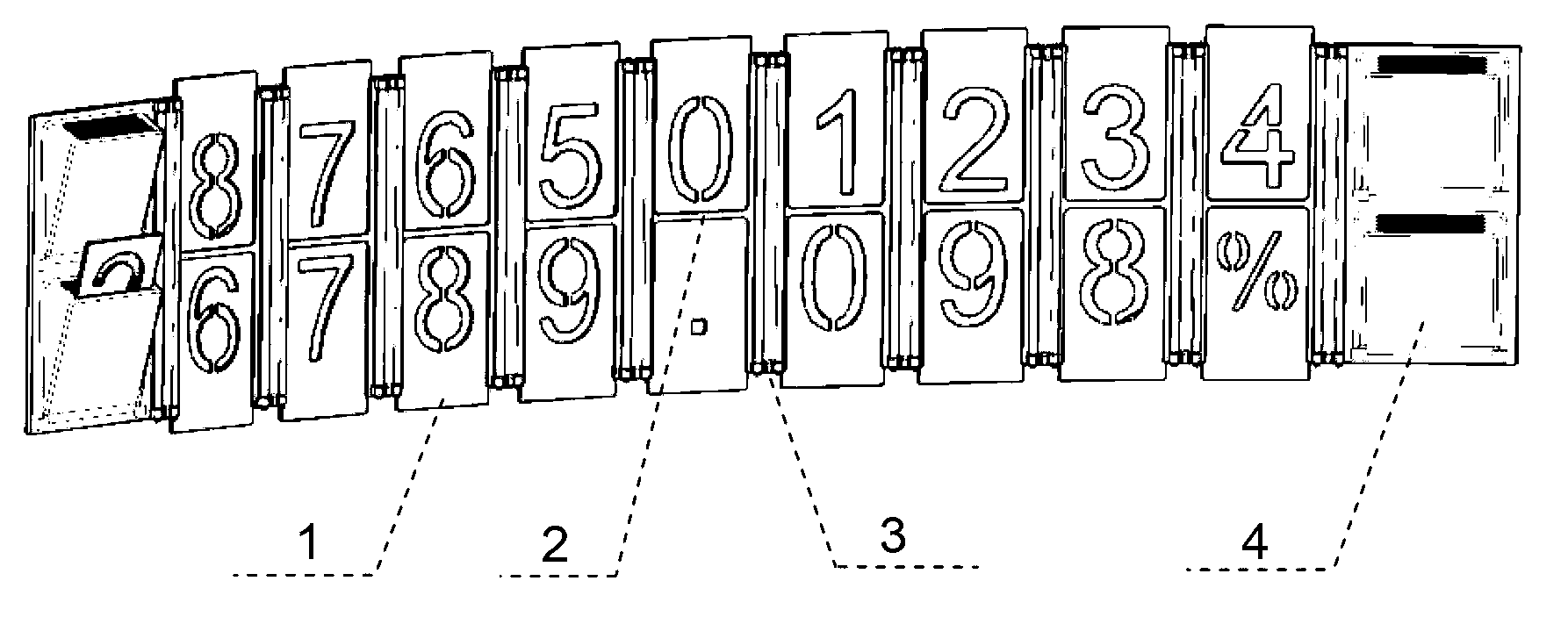

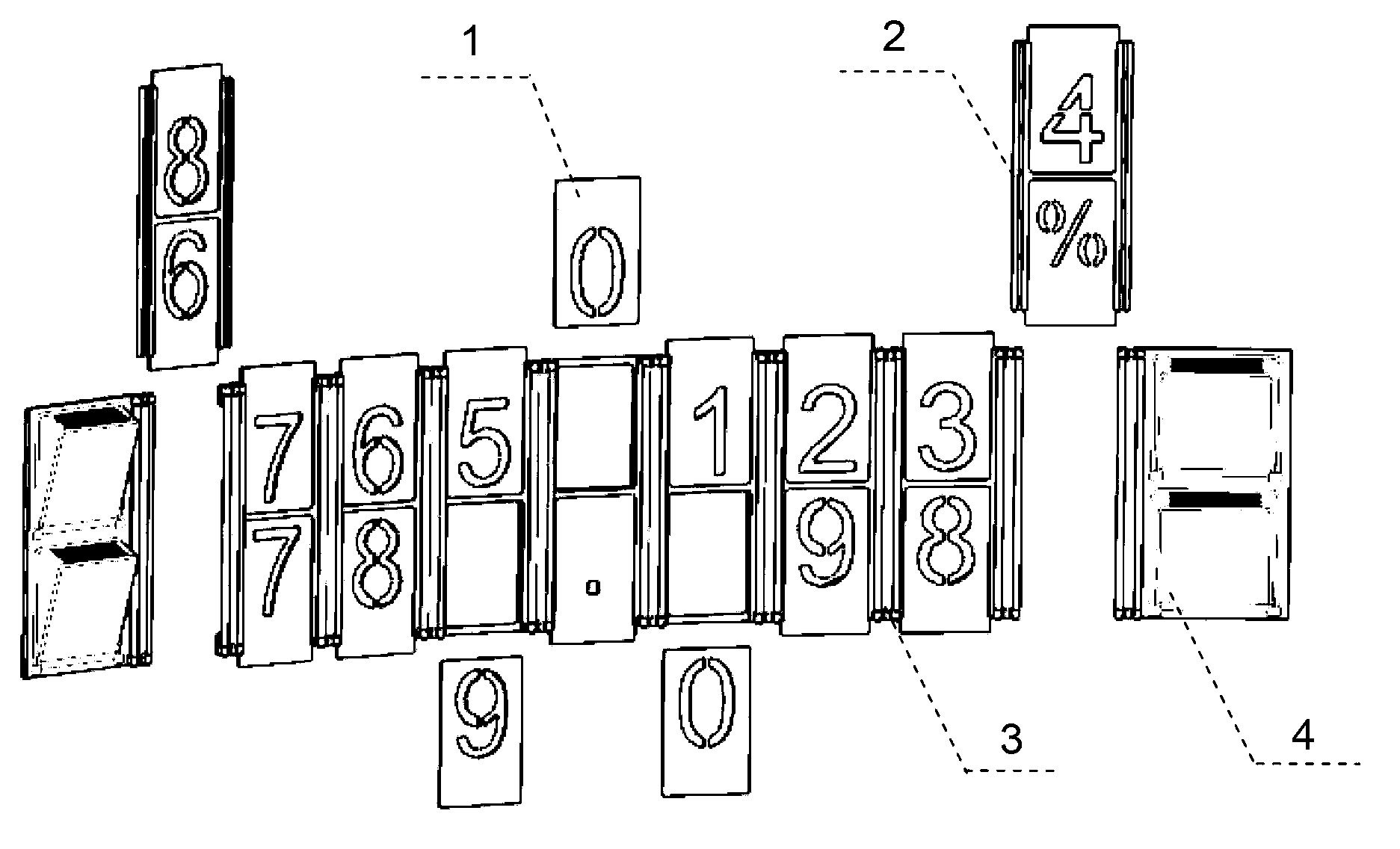

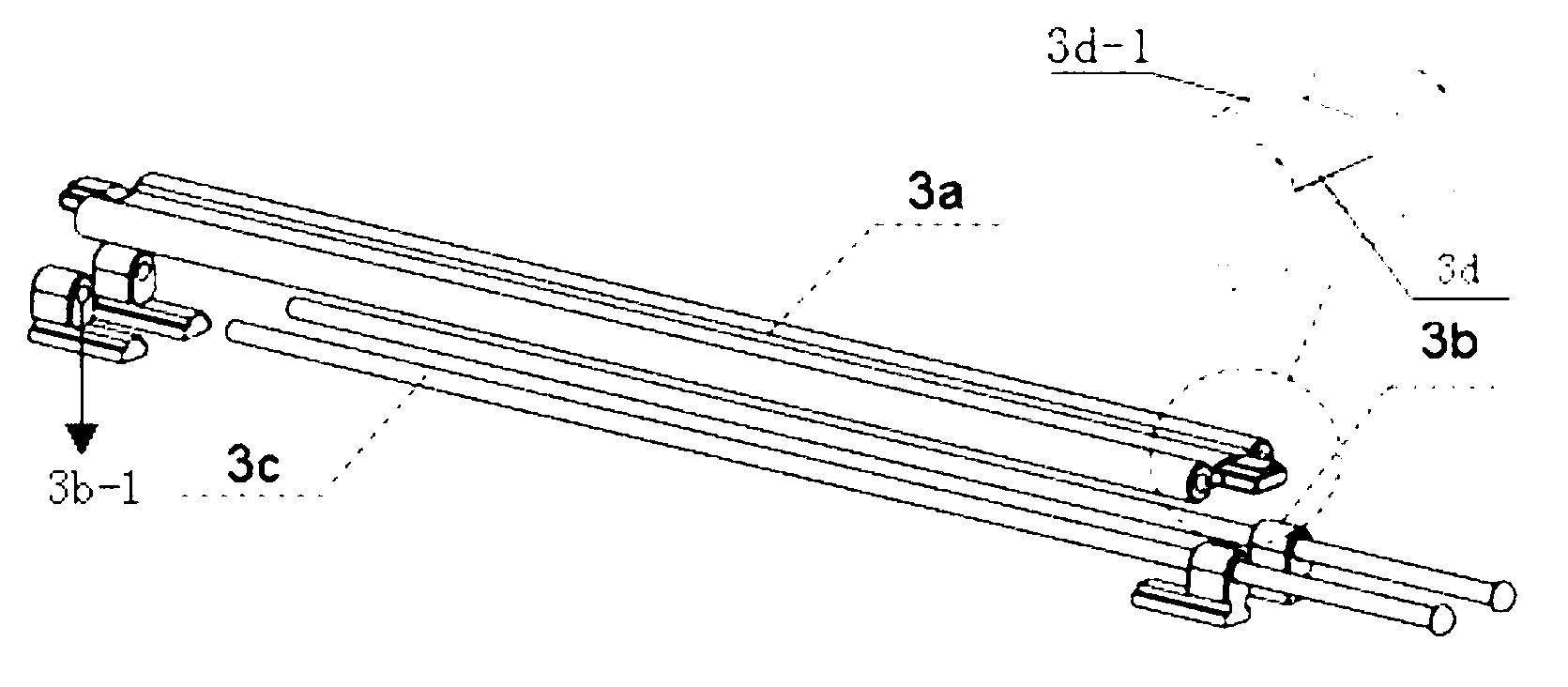

Metal spray marking plate special for cold and hot rolling

InactiveCN102974511AAchieve repeated useHigh reuse rateLiquid surface applicatorsCoatingsChinese charactersMetal

The invention relates to a metal spray marking plate special for cold and hot rolling. The metal spray marking plate special for the cold and hot rolling comprises a number plate engraved with numbers, base plates and chain shaft components used for connecting adjacent base plates. Each base plate is a frame shaped like a Chinese character 'ri'. Reverse T-shaped through grooves and inner grooves oppositely formed inwards are formed in the two sides of each frame. Two sides of the number plate is inserted in two groove openings of the base plate. The chain shaft components comprise a double-row connecting shaft, groove seats and a mandril. The double-row connecting shaft is provided with a connecting portion. The middle segment of the mandril penetrates through the double-row connecting shaft. Two ends of the mandril are respectively penetrate through circular holes of the groove seats. An end head of the mandril is riveted on one groove seat. The groove seats are arranged in the reverse T-shaped through grooves of the base plate. The shape of the lower portion of each groove seat is matched with that of each through groove. The groove seats are capable of rotating around the mandril. The metal spray marking plate special for the cold and hot rolling can be cleaned by organic solution so as to be reused after using and therefore cost is effectively saved. Due to the fact that the metal spray marking plate spares a number imprinting process, spraying and coating work efficiency is improved and optimized.

Owner:BAOSTEEL DEV CO LTD

Metal laser tube

InactiveCN104638499AAchieve repeated useImprove convenienceGas laser constructional detailsCooling chamberOptoelectronics

The invention relates to a laser tube, in particular to a metal laser tube which is not prone to breaking and convenient to manufacture and which is capable of forming a cooling chamber and a gas storage chamber without sintering. The metal laser tube comprises an anode supporting seat provided with an anode channel, a cathode supporting seat provided with a cathode channel, a metal inner tube, a metal outer tube and a glass discharging tube with the anode communicated with the anode channel and cathode channel; two ends of the discharging tube, inner tube and outer tube are connected to the anode and cathode supporting seats respectively in a sealed manner; the inner tube sleeves the discharging tube; the discharging tube, the anode and cathode supporting seats and the inner tube form a cooling chamber provided with two coolant channels; the outer tube sleeves the inner sleeve, the outer tube, the anode and cathode supporting seats and the inner tube form a gas storage chamber, and the anode channel and the cathode channel are communicated with the gas storage chamber. By the aid of the metal laser tube, the problems that a glass-structure laser tube is prone to breaking to cause the loss of a user and is inconvenient to recover and reuse, and large amount of harmful gas is produced during production are solved.

Owner:陈海榕

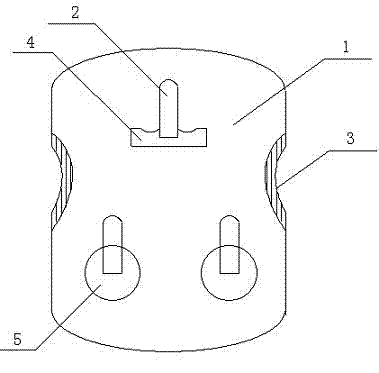

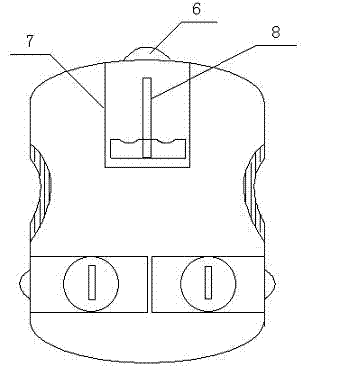

Power supply plug

InactiveCN102509978AWith repeated useAchieve repeated useCoupling device detailsClamped/spring connectionsPower cord

The invention discloses a power supply plug, which comprises a shell, a plugging sheet and a wire connection device, wherein the plugging sheet is positioned on the bottom surface of the shell, and is provided with a live wire plugging sheet, a null wire plugging sheet and an earth wire plugging sheet; the wire connection device is positioned on the front surface of the shell and is concealed in the shell; the bottom surface of the shell is provided with an embedded groove, a strip-shaped plugging sheet base and a round plugging sheet base; the front surface of the shell is provided with a sliding cover plate; and the side surface of the shell is provided with a plugging sheet distance-adjusting handle. The power supply plug disclosed by the invention is provided with movable plugging sheets, thus the rotation and shifting of the plugging sheets can be realized, requirements of different sockets are met, and the using range is wide; and the power supply plug is provided with the flexible wire connection device, thus the power supply plug is connected with a power supply wire conveniently, the recycling of the power supply plug can be realized, the using efficiency is improved greatly, and the economic burden is relieved.

Owner:常熟市董浜镇华进电器厂

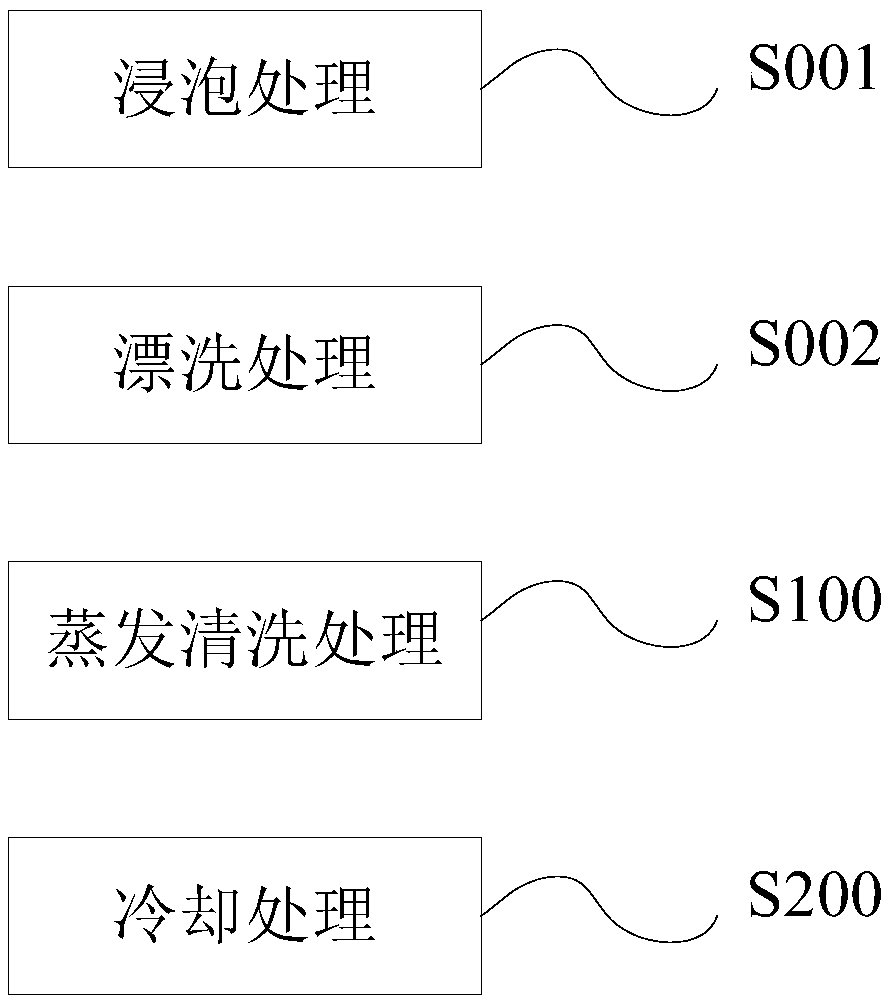

Semiconductor device cleaning process and device

InactiveCN109332252AAchieve repeated useLow costCleaning using liquidsSteam condensationCleansing Agents

The invention provides a semiconductor device cleaning process. The process comprises the following steps that S100, evaporating and cleaning are carried out, the semiconductor device to be treated iswashed by using a normal-bromine propane steam; S200, condensing is carried out, a condensation device is adopted for condensation treatment, so that the normal-bromine propane steam can be condensedinto liquid drops on a semiconductor device body; and the invention further provides a semiconductor cleaning device, specifically comprises an evaporative-condensation washing device, wherein the steam-condensation washing device comprises a closed shell body, a heating groove, a first heating device, a supporting frame and a condensing device. According to the process and the device, an evaporation-condensation process is adopted to realize repeated use of a cleaning agent, so that the cost is reduced, and the pollution is reduced.

Owner:YANGZHOU HY TECH DEV

Method for repairing noble metal target material

ActiveCN101413107BNo crackAchieve repeated useVacuum evaporation coatingSputtering coatingSputteringAlcohol

The invention discloses a method for rehabilitating a noble metal target material. The method comprises the following steps: the noble metal target material with a sputtering loss region formed by the implementation of sputtering is subjected to alkali cleaning, oil removal, washing through clean water and dehydration through absolute ethyl alcohol; an upper protective hood and a lower protectivehood carry out the argon gas protection of inert gas on the noble metal target material; a wire material with the same texture with the target material and the local target material are melted through a tungsten electrode of an argon arc welding gun and are accumulated in the loss region; therefore, repeated accumulation is carried out so that the loss region is gradually piled flatly to finally become an accumulation state. The method has easy operation, simple process, no pollution and low cost; in the rehabilitating process, the noble metal material is hardly lost so as to realize the repeated use of the target material and substantially improve the utilization rate of the target material; the rehabilitated target material has no crack and no air hole; and the interface between the filled noble metal material and the original sputtering target is in metallurgical bonding of a welding state and have no delamination and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

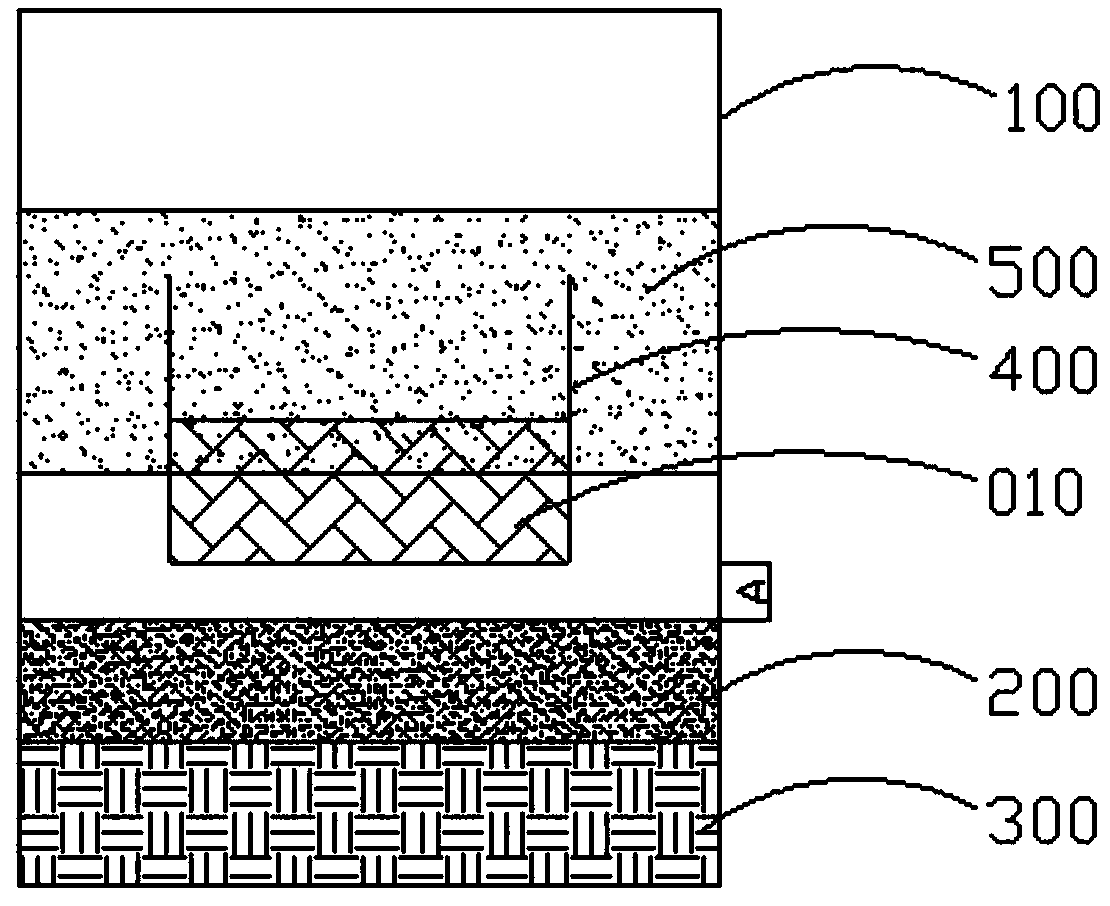

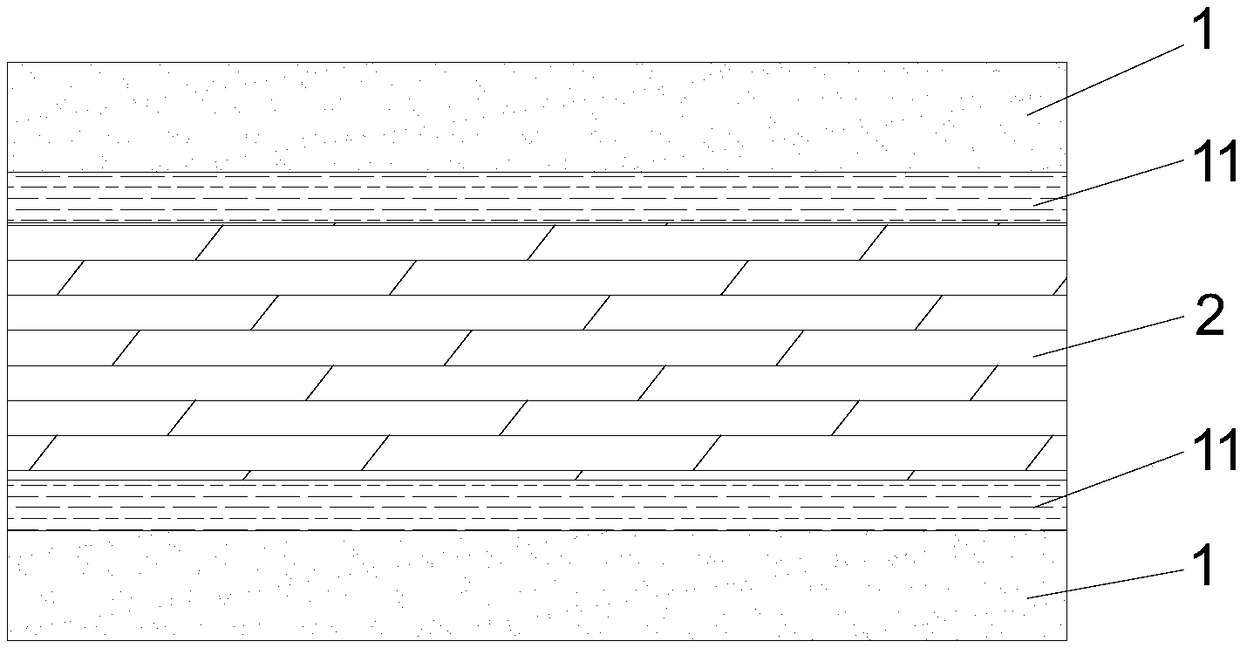

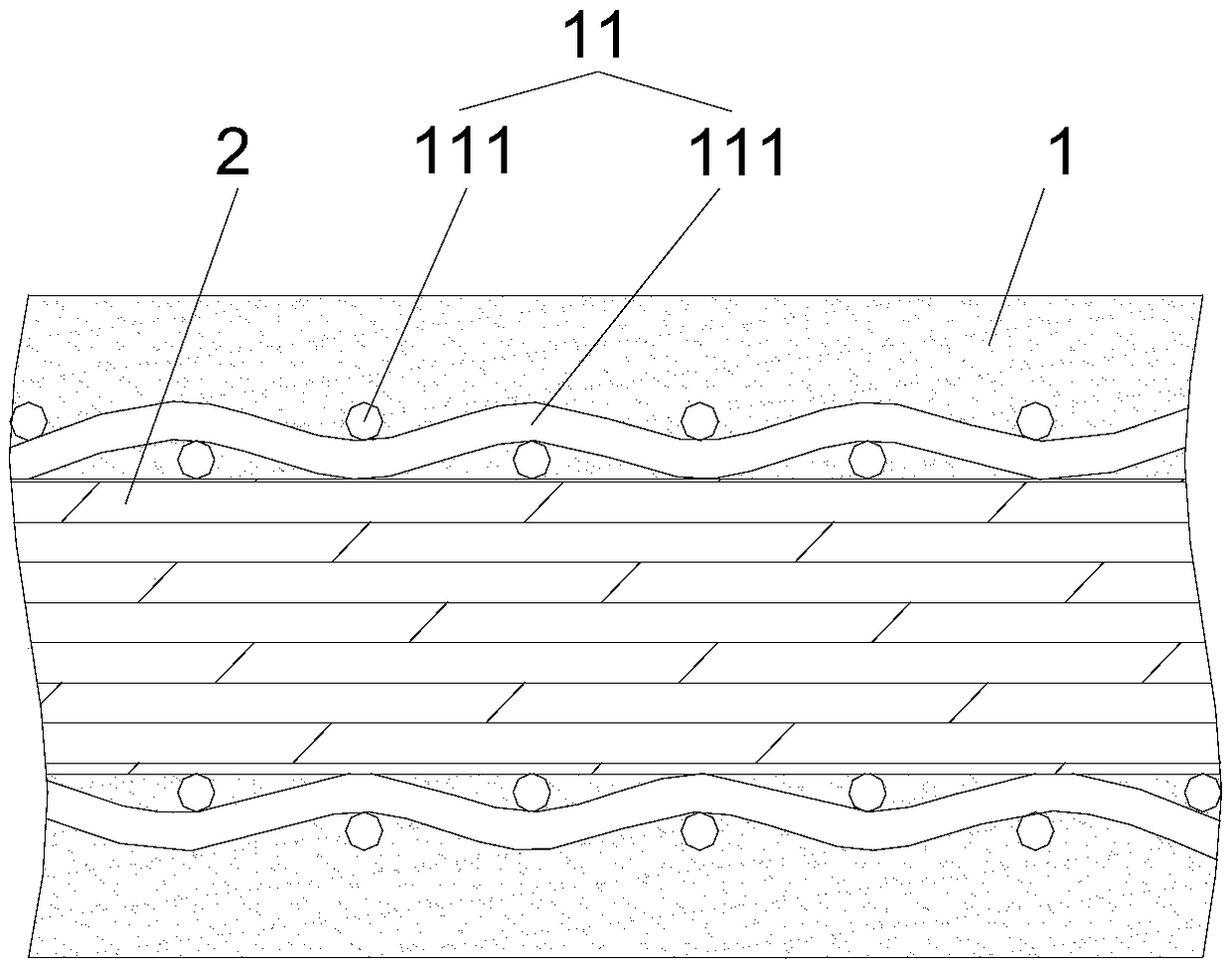

Building formwork

PendingCN109372252AImprove fire resistanceExtended service lifeForming/stuttering elementsWear resistantFire resistance

The invention provides a building formwork, relates to the technical field of building materials, and mainly solves the technical problem that in the prior art, a building formwork is poor in wear resistance and poor in fireproof performance. The building formwork comprises wear-resistant layers and a base layer, wherein the wear-resistant layers are positioned on the upper surface and the lower surface of the base layer; each wear-resistant layer comprises a wear-resistant surface and a reinforcing surface; each reinforcing surface comprises a channel and collateral layer; each channel and collateral layer is positioned on the surface, which is close to the base layer, of the corresponding wear-resistant layer; and each wear-resistant surface is positioned on the surface, which is away from the base layer, of the corresponding wear-resistant layer. The base layer is positioned between the wear-resistant layers, friction and / or scratching between the outside and the base layer can be prevented effectively, furthermore, the base layer can be isolated from a heat source of the outside by the wear-resistant layers, the base layer is prevented from being in direct contact with a fire source, and the fire resistance of the building formwork is improved. Each channel and collateral layer is close to the surface, which is close to the base layer, of the corresponding wear-resistant layer, the wearing capacity of the wear-resistant layers can be improved, and thus, the service life of the building formwork is prolonged.

Owner:卢志宣

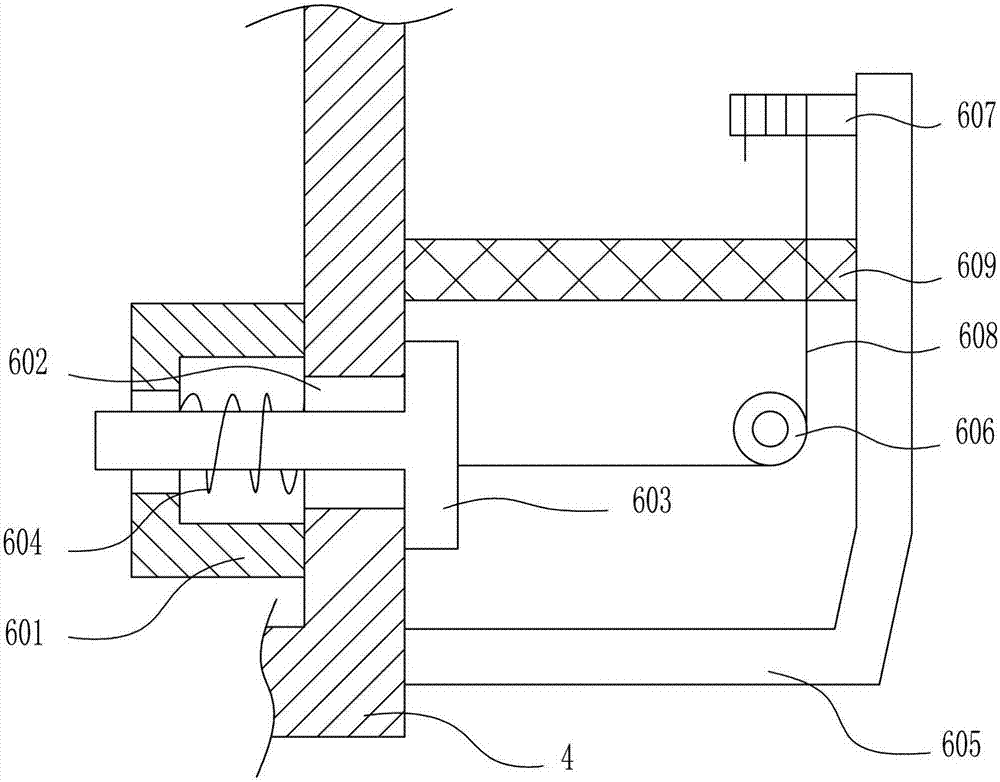

Acid pickling device for steel wire rope production technology

InactiveCN106868523AAvoid churnTo prevent the effect of affecting the collectionEngineeringWire rope

The invention relates to pickling equipment, in particular to pickling equipment for steel wire rope production technology. The technical problem to be solved by the present invention is to provide a device capable of recycling pickling liquid. In order to solve the above technical problems, the present invention provides such a pickling equipment for steel wire rope production process, which includes a bottom plate, a universal wheel, a purification mechanism, a first pickling tank, a liquid outlet pipe, a collection mechanism, a first rotating rod, The first bearing seat, the first roller, the second bearing seat, etc.; the bottom of the bottom plate is connected with universal wheels in a symmetrical rotation on the front, rear, left, and right sides; the top of the bottom plate is connected with a purification mechanism, and the top of the purification mechanism is connected with the first pickling tank . The present invention is first provided with a collection mechanism to realize the purpose of recovering and purifying the residual pickling liquid through the collection mechanism, achieving the effect of repeatedly using the pickling liquid and saving the cost of pickling.

Owner:陈云蕾

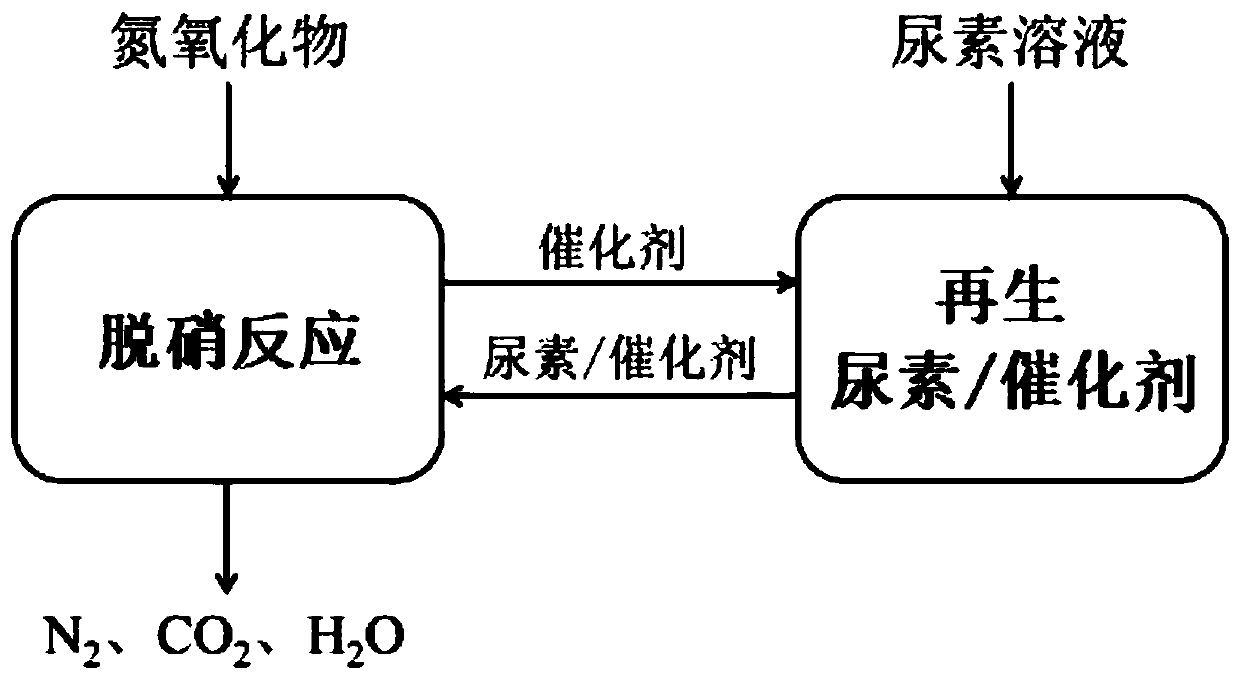

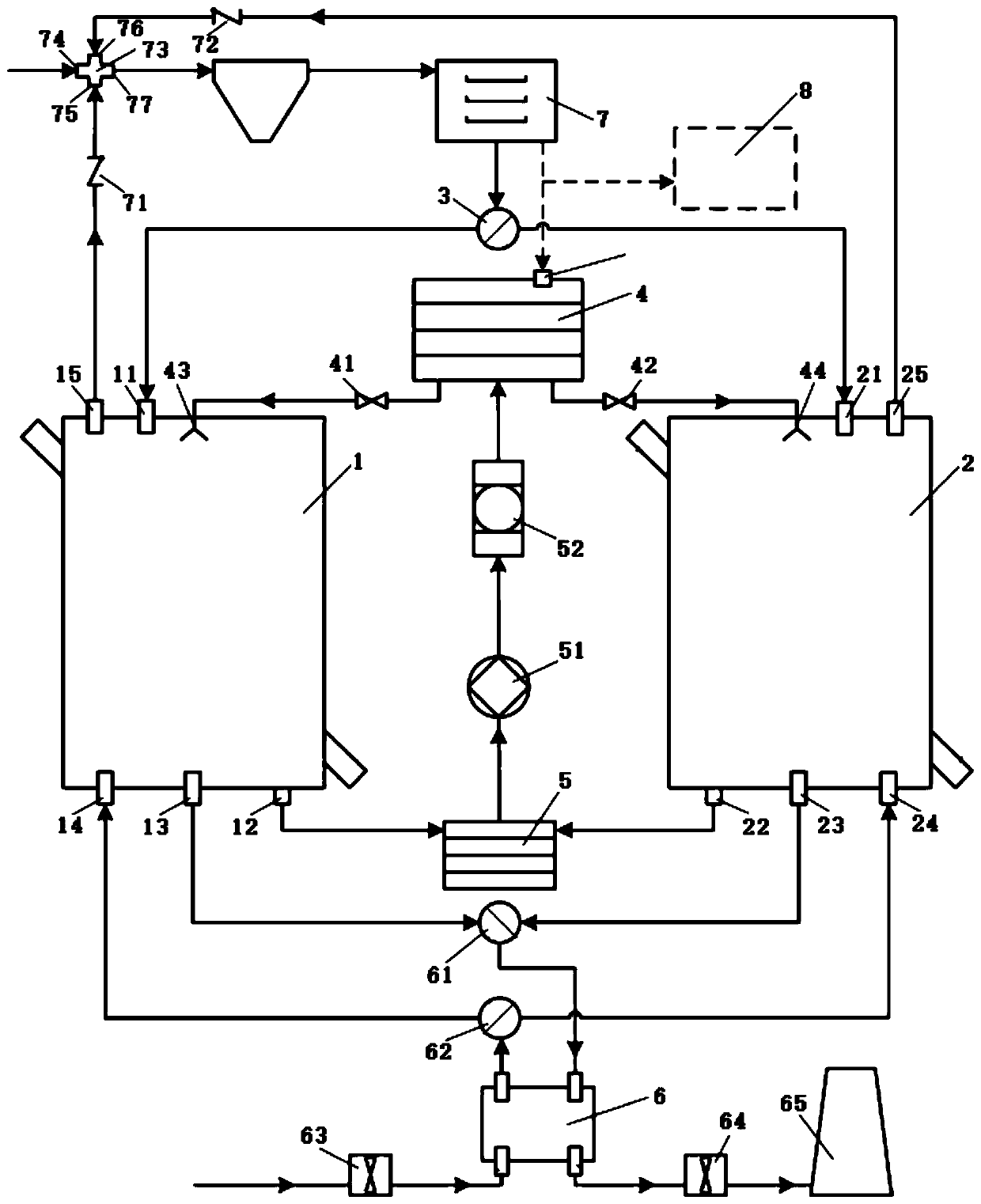

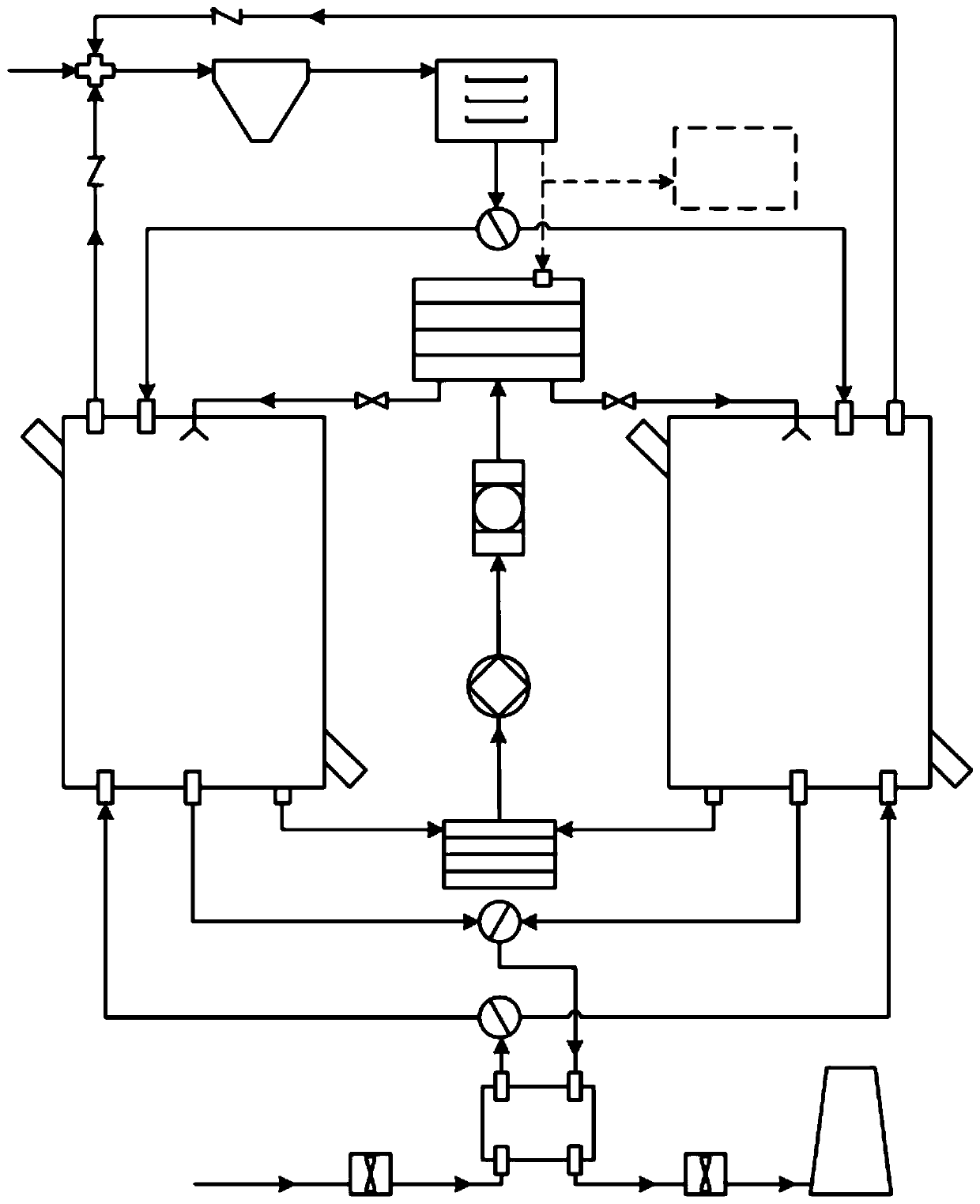

Method and system for removing nitrogen oxides from low-temperature flue gas

PendingCN109821416AAvoid ammonia slipReduce system power consumptionDispersed particle separationUreaNH3 compound

The invention relates to a method for removing nitrogen oxides from low-temperature flue gas, which comprises the following steps of: S1, preparing at least two reactors containing a catalyst and urealoaded on the catalyst, and dividing the reactors into a reaction group and a to-be-reacted group.S2, introducing low-temperature flue gas into the reaction group for denitration reaction; introducing the low-temperature flue gas into the reaction group for denitration reactionwhen urea in the reaction group is consumed to a preset value, and supplementing the urea in the reaction group.S3, introducing the low-temperature flue gas into the to-be-reacted group for denitration reactionwhen urea in the to-be-reacted group is consumed to a preset value, and supplementing the urea in the to-be-reacted group; and S4, alternately introducing the low-temperature flue gas into the reaction group and the to-be-reacted group according to the mode so as to achieve the continuous denitration of the low-temperature flue gas.The invention also provides a system for removing nitrogen oxides from low-temperature flue gas according to the method.The removal of nitrogen oxides in low-temperature flue gas is achieved, the problem of ammonia escape is avoided, and meanwhile, the continuous denitration of low-temperature flue gas and the repeated use of the catalyst are ensured.

Owner:NORTHEASTERN UNIV

Protective cover against acid and alkali corrosion and using method thereof

InactiveCN104986721BFree from destructionSimple structureDecorative surface effectsSemiconductor/solid-state device manufacturingRubber ringEtching

The invention discloses a protection cover capable of protecting a single-face pattern of a silicon wafer from being influenced by wet etching and an application method thereof. The protection cover adopts a top plate and a bottom plate to clamp a chip which needs pattern protection in the middle, and the top plate is in sealed connection with the bottom plate through a fastening screw; rubber rings are respectively placed between the top plate and the chip and between the bottom plate and the chip, and sealing is achieved through compressive deformation of the rubber rings; a round through hole is arranged in the center of the bottom plate, and corrosive liquid corrodes the back of the chip through the through hole; a round groove is arranged in the center of a sealed upper cover board, and water is injected into the groove to prevent the corrosive liquid from seeping into the inner sides of the rubber rings to directly corrode the silicon wafer. One face of the chip, which needs protection, is soaked into other liquid by the protection cover, so that damage from wet etching is avoided. The whole structure is easy to assemble and disassemble, simple and convenient to use, and through replacing the sealing rings, the protection cover can be repeatedly used.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A method to facilitate disassembly and assembly of molds in the production of concrete prefabricated parts

ActiveCN104002368BEasy to assemble and disassembleEasy to manufactureMouldsMould auxillary partsEngineeringSilica gel

The invention discloses a precast concrete element, and particularly discloses a method for making molds convenient to disassemble and assemble in the precast concrete element production process. The method is used for construction engineering, railways, bridges and hydraulic engineering. According to the method for making the molds convenient to disassemble and assemble in the precast concrete element production process, the molds are easy to manufacture, low in energy consumption and cost, high in working efficiency, convenient to disassemble and assemble and capable of being reused. Each mold is made of metal materials and composed of a bottom plate and four side plates, wherein the four side plates are movably connected with the bottom plate, and every two adjacent side plates are connected through a detachable clamping buckle or lock catch. According to the method for making the molds convenient to disassemble and assemble in the precast concrete element production process, not only are the molds easy and convenient to manufacture, but also the molds are convenient to disassemble and assemble, production cost is reduced, and silica gel elements can be reused.

Owner:杨炎林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com