Gas hydrate method sewage treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

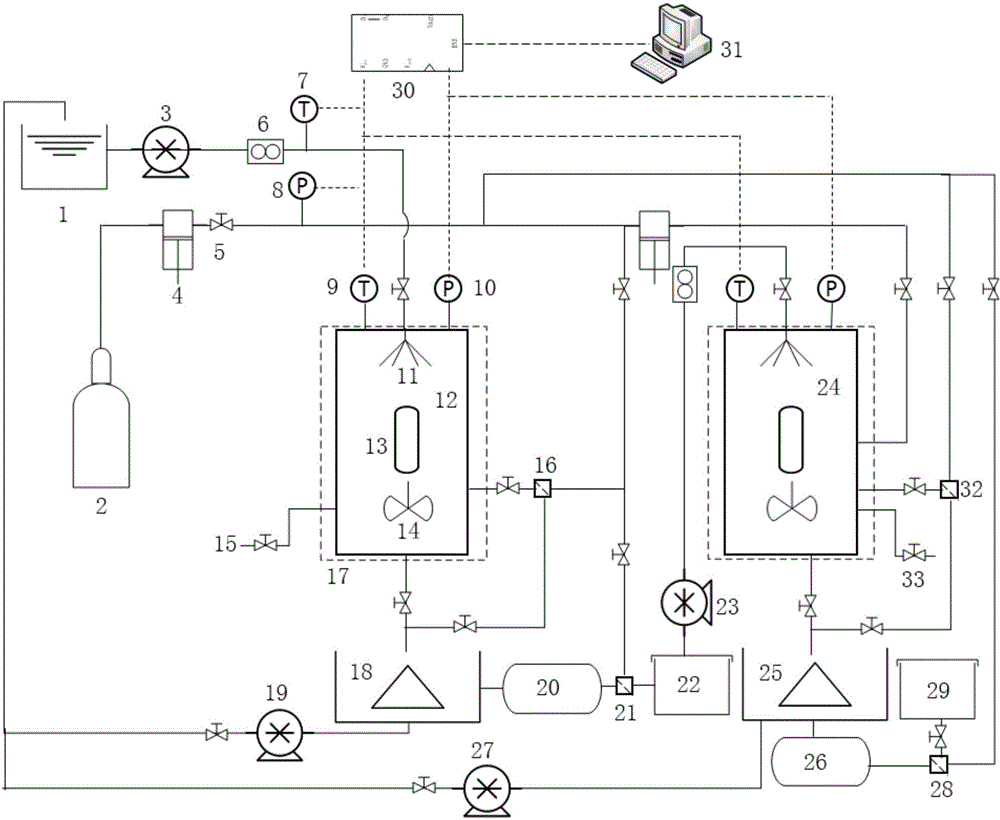

[0012] As shown in the attached figure, the system employs a two-stage treatment facility using gas hydrants for sewage treatment. Connect according to the device structure described above, and use the system for gas hydrate sewage treatment, the steps are as follows:

[0013] In the first step, the sewage in the sewage tank 1 and the gas in the gas cylinder 2 are injected into the primary reactor 12 according to a certain ratio, and a certain amount of hydrate accelerator is added at the same time, and the temperature sensor 7 and the pressure sensor 8 detect that the gas enters the primary reactor. 12 of the sewage temperature and gas pressure.

[0014] In the second step, open the high and low temperature thermostat box 17, set the reaction temperature and stirring rate, keep the pressure in the kettle constant through the booster pump 4, judge the amount and rate of hydrate formation through the temperature sensor 9 and the pressure sensor 10, and pass through the sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com