Energy-saving and environment-friendly red brick manufacturing equipment and red brick manufacturing method

A technology for manufacturing equipment, energy saving and environmental protection, applied in the direction of manufacturing tools, lighting and heating equipment, furnace types, etc., can solve the problems that bricks cannot be watered immediately, rapid cooling cannot be achieved, and brick making efficiency is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0035]As in the context of the present invention, in order to solve the above technical problems, this application proposes an energy-saving and environmentally friendly red brick manufacturing equipment.

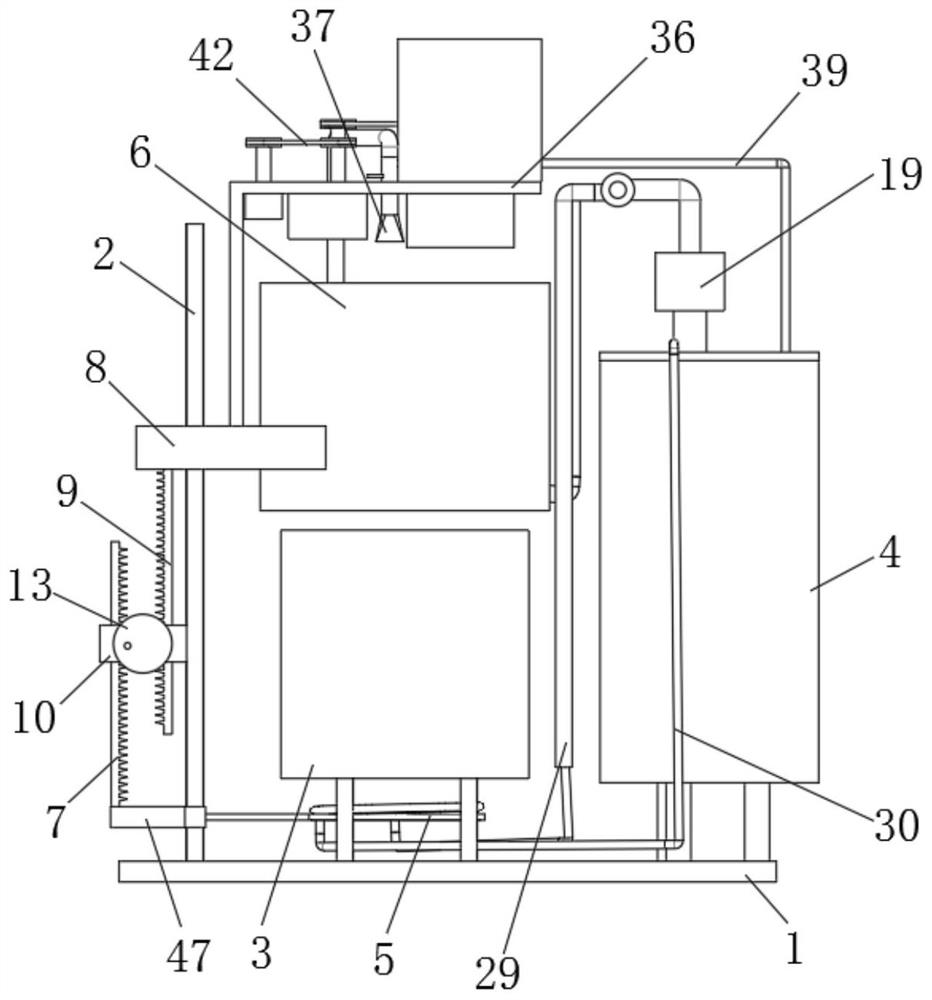

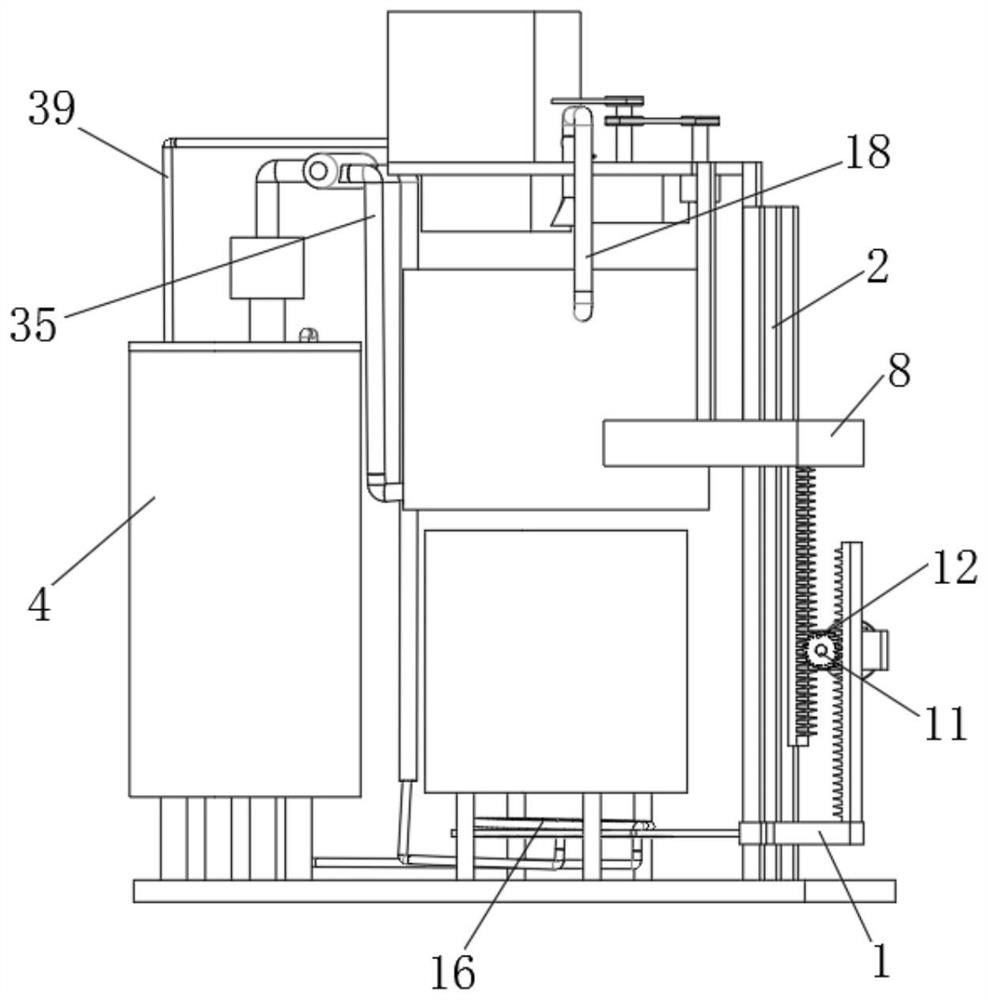

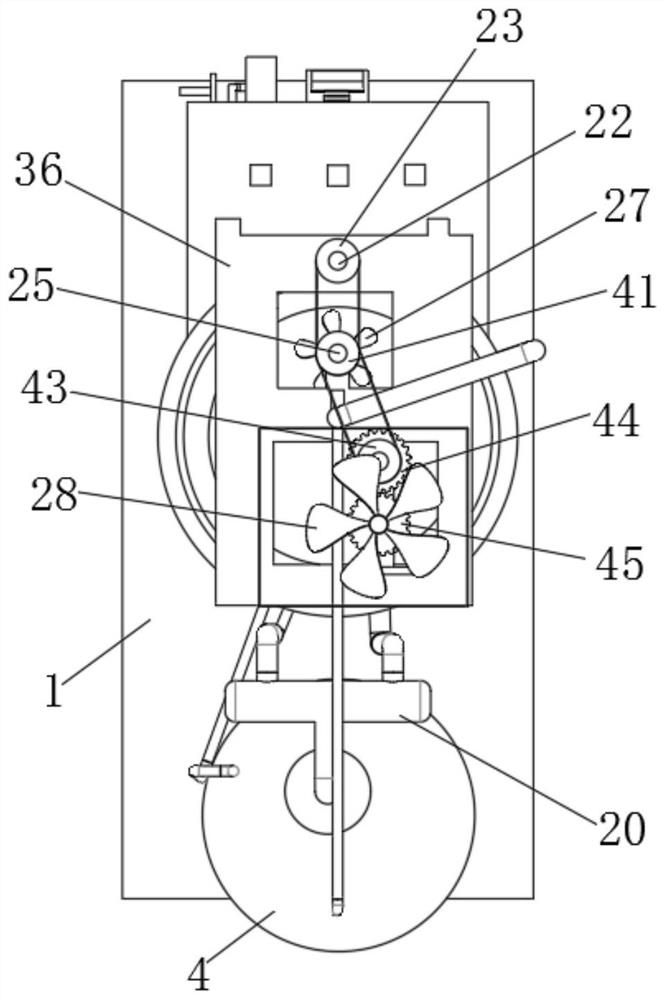

[0036]In a typical embodiment of this application, such asFigure 1-8As shown, an energy-saving environmentally friendly red brick manufacturing apparatus includes a base 1, and the base 1 is fixed to the upper surface of the support column 2, the baked brick furnace 3, and the water tank 4, the support column 2 active connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com