Photovoltaic carrying structure of fabricated building body and management and control system

A management and control system and assembled technology, applied to the support structure of photovoltaic modules, building components, building structures, etc., can solve the problems that do not meet the comprehensive effects of energy saving and comfort, and achieve the effect of high-efficiency photovoltaic power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

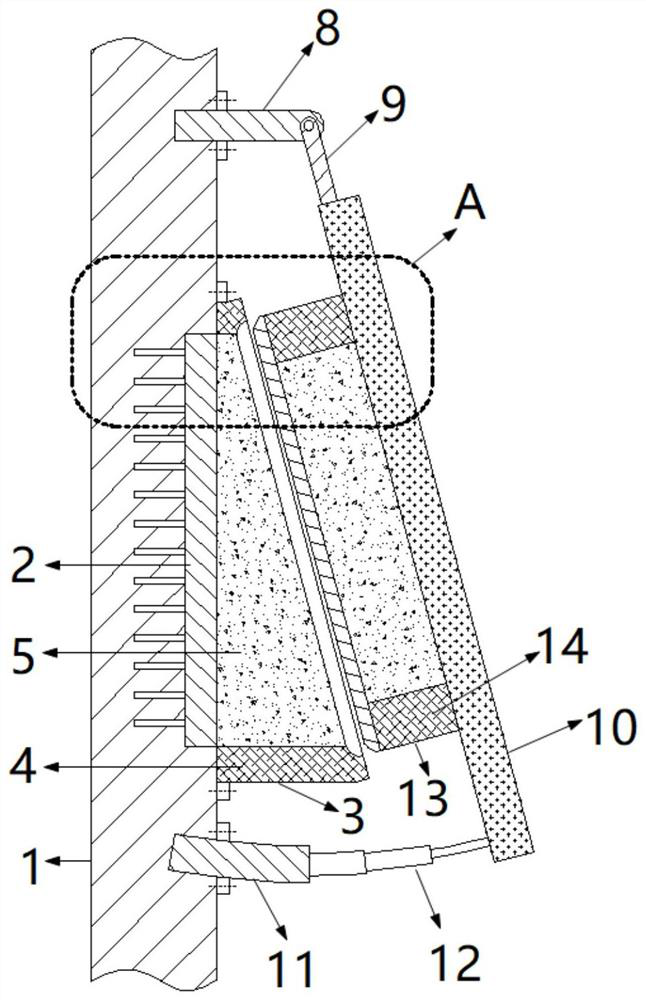

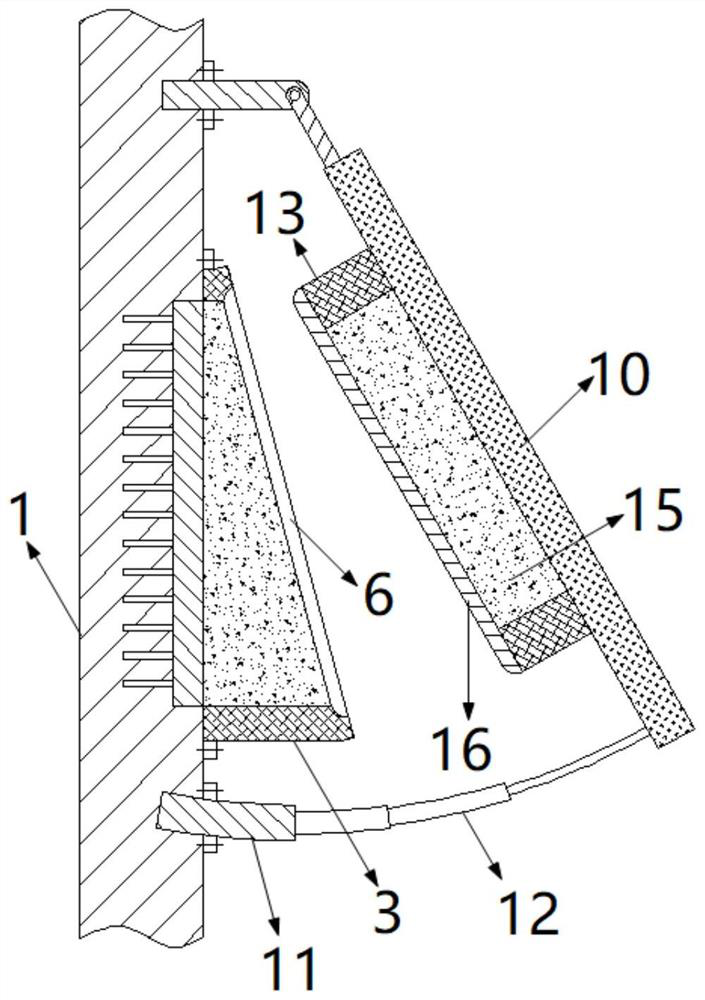

[0028] see figure 1 , image 3 As shown, the prefabricated wall 1 has a prefabricated installation groove for installing the arc hydraulic pipe 11, the rear section of the arc hydraulic pipe 11 is installed in the installation groove, and the ring side of the arc hydraulic pipe 11 is provided with a belt For the plate with installation holes, the arc hydraulic pipe 11 is installed on the assembled wall 1 by installing expansion screws, and the upper horizontal rod 8 on the upper part of the assembled wall 1 is also installed in this way, and will not be repeated here.

[0029] The upper side rotating rod 9 on the upper side of the photovoltaic panel 10 is rotatably installed on the upper horizontal rod 8, and two upper rotating rods 9 are arranged on the upper side of each photovoltaic panel 10 for stable rotation. Only one arc-shaped hydraulic pipe 11 is provided on the lower side of each photovoltaic panel 10 [saving money and meeting the requirements for stable support]. ...

Embodiment 2

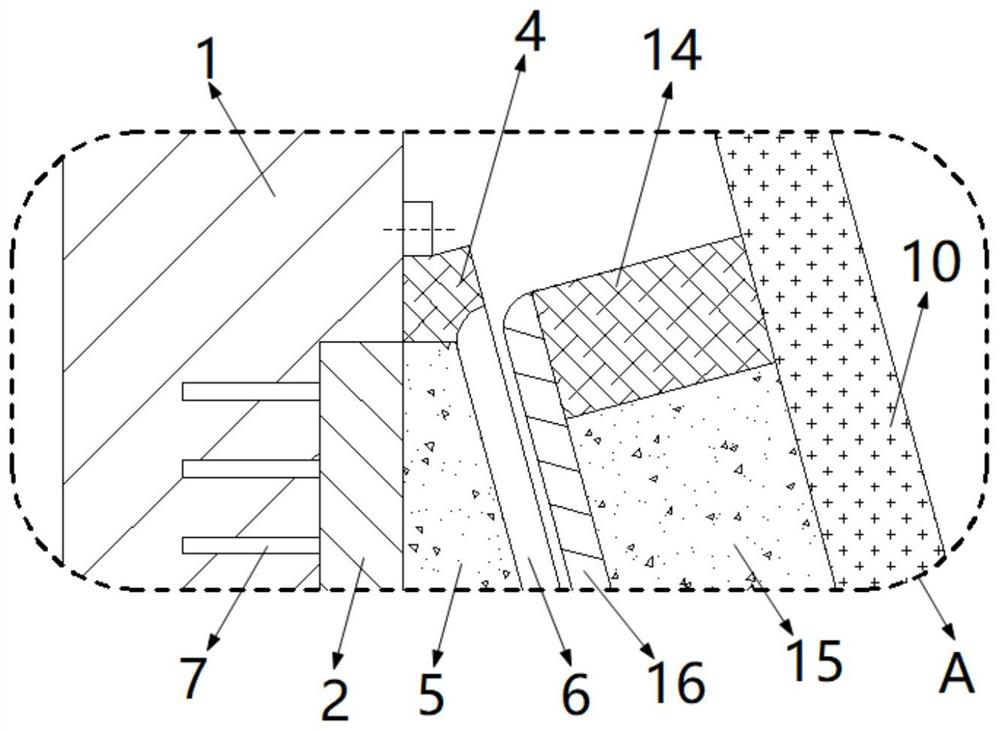

[0031] see figure 1 , figure 2 As shown, the heat-conducting material plate 2 and multiple heat-conducting rods 7 are integrally structured and can be prefabricated in the prefabricated wall 1. The multiple heat-conducting rods 7 are inserted into the interior of the prefabricated wall 1, and the heat can penetrate into the prefabricated wall 1. And dissipate to the inside of the prefabricated wall 1 to further improve the heat supply effect inside the prefabricated wall 1 .

[0032] The first heat-conducting filling layer 5 is filled with heat-conducting silica gel and heat-conducting silica gel sheets located on both sides of the heat-conducting silica gel for sealing the heat-conducting silica gel. The heat-conducting silica gel sheet on one side is thermally connected to the heat-conducting material plate 2, and the contact surface of the two is coated with Thermal Grease. A plastic partition plate is also provided between the first thermal insulation sponge layer 4 and...

Embodiment 3

[0034] see figure 1 , figure 2 , image 3, in winter or when the temperature is low, the arc-shaped hydraulic pipe 11 retracts the arc-shaped telescopic shaft 12, driving the photovoltaic panel 10 to return to the low position. The contact outer groove 6 of the frame body 3 . And in winter, when the angle of the direct sunlight is low, the photovoltaic panel 10 itself also needs to be rotated downward to ensure better sunlight exposure. After the photovoltaic panel 10 is irradiated by the sun, it receives more heat. The heat is transferred from the photovoltaic panel 10 to the second heat-conducting filling layer 15 and the heat-conducting alloy sheet 16 of the inner frame 13. The heat-conducting alloy sheet 16 transfers heat to the Fill the first thermally conductive filling layer 5 of the frame body 3, and the first thermally conductive filling layer 5 transfers heat to the thermally conductive material plate 2, so that the building assembly can also obtain the black abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com