Constant-temperature controller for compost fermentation

A constant temperature controller and composting technology, which is applied in the preparation and application of organic fertilizers, organic fertilizers, etc., can solve the problems of increasing energy consumption and wasting waste heat, and achieve the effect of realizing thermal energy storage and enhancing thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

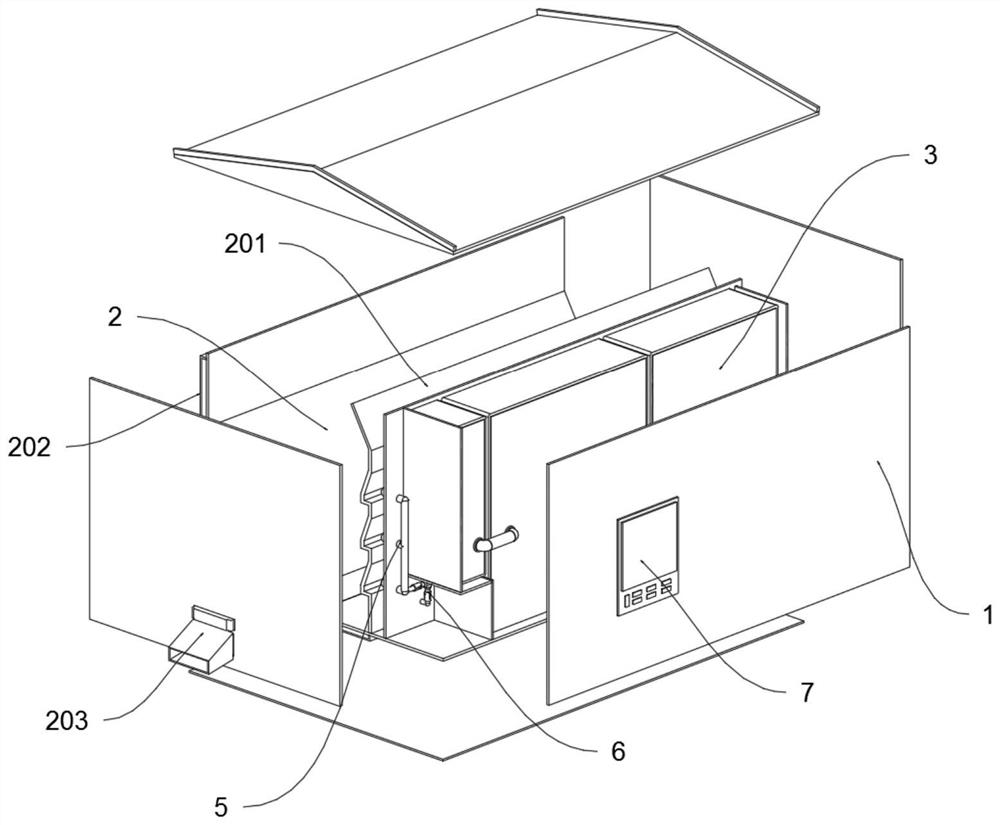

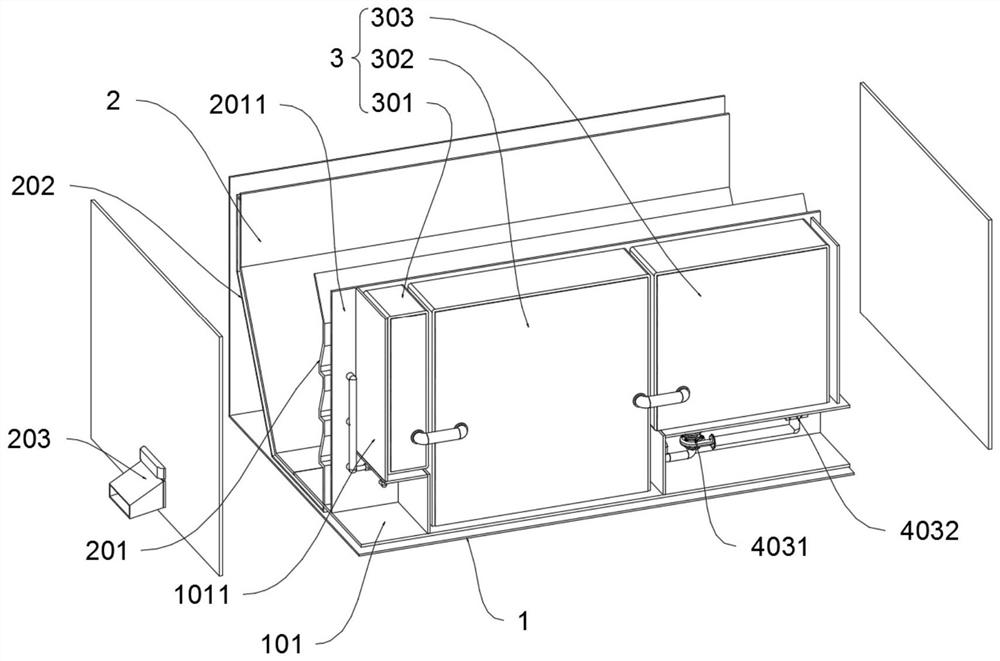

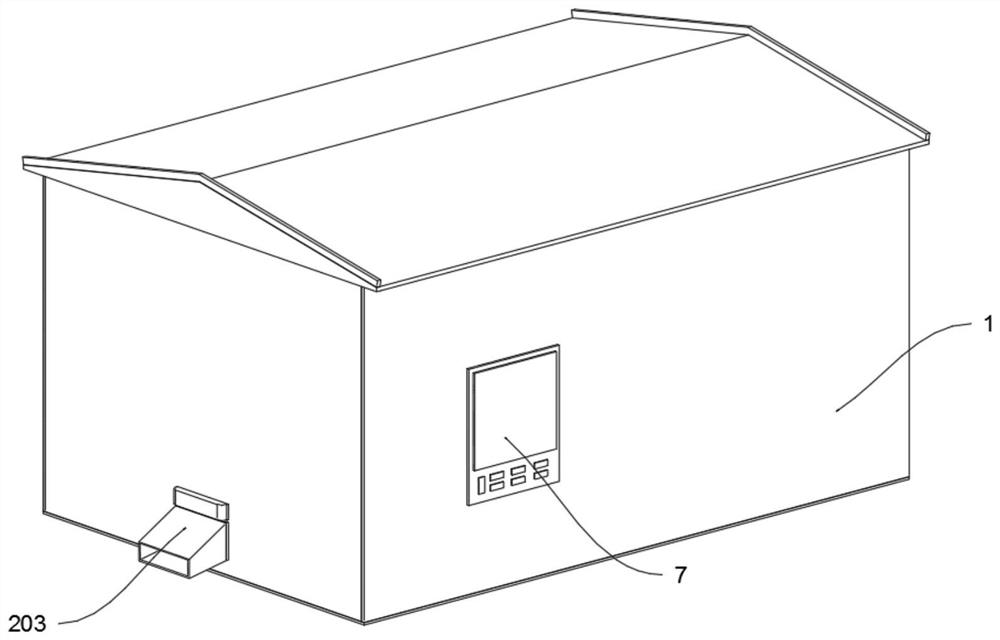

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031]The present invention provides a constant temperature controller for compost fermentation, comprising an outer box wall 1; a constant temperature fermentation tank 2 is fixedly connected to the inside of the outer box wall 1; The energy storage group 3 includes an imported constant temperature box 301, and an asbestos insulation layer is arranged on the front surface of the imported constant temperature box 301; The room is connected through a connecting pipe, and an asbestos insulation layer is provided on the front surface of the middle thermostat 302; the outlet thermostat 303 is located on the right side of the middle thermostat 302, and the outlet thermostat 303 is connected to the middle thermostat 302 through a connecting pipe, and The outer surface of the outlet constant temperature box 303 is fixedly connected with an asbestos insulation layer, and the heat source energy storage group 3 of this structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com