a micro-orifice plate

A technology of micropores and micropores, applied in the field of biochemical detection, can solve the problems of cost, dependence, and large volume, and achieve the effect of automatic biochemical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

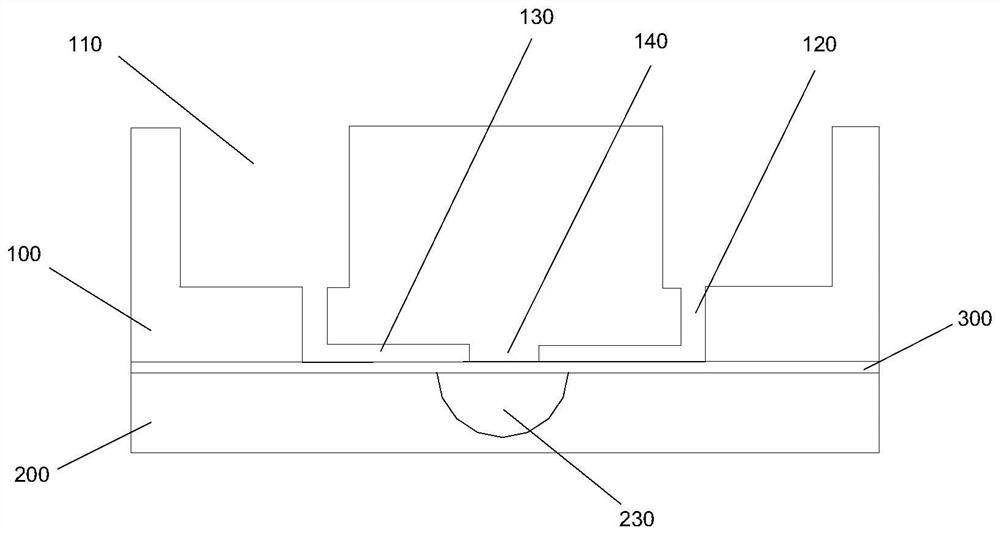

[0037] This embodiment provides a micro-orifice plate, including an upper substrate 100 , a lower substrate 200 and an intermediate film 300 .

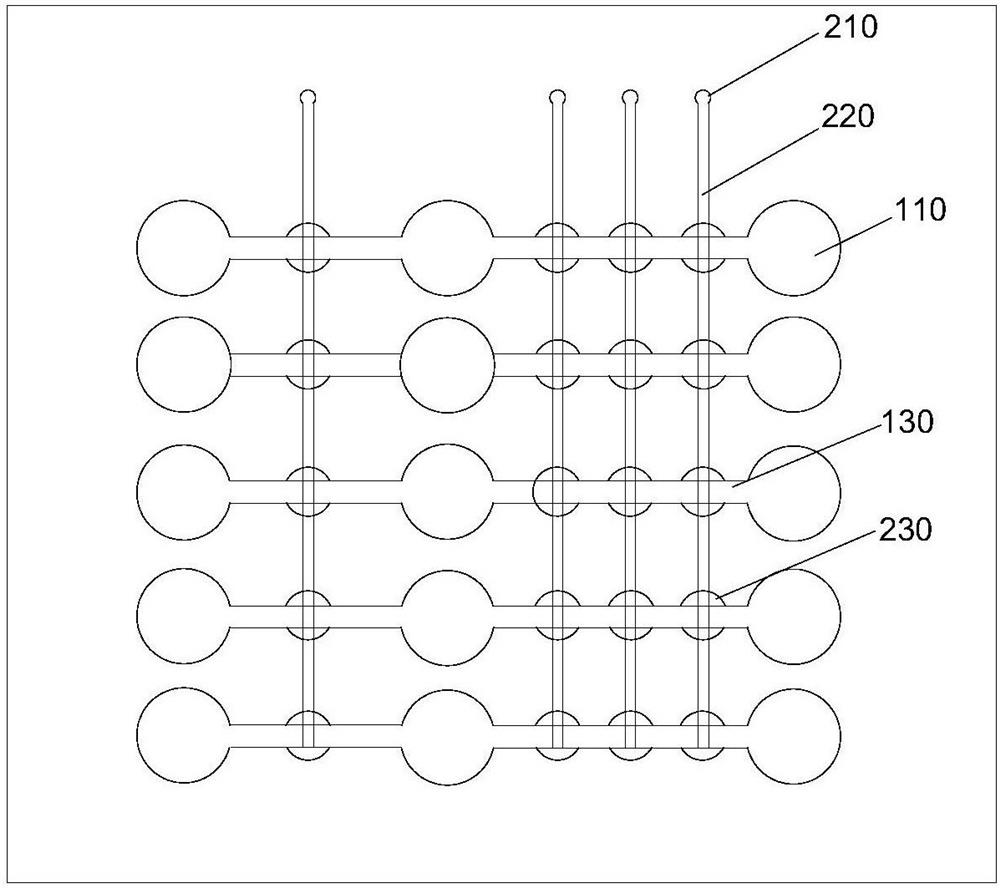

[0038] refer to figure 1 , as shown in 3-4, the upper substrate 100 is provided with a plurality of microholes 110 arranged in a matrix of 5×3, each microhole 110 is provided with a communicating hole 120 at the bottom of the hole, and the two transversely adjacent communicating holes 120 They are connected by a flow channel, and at least one break point 140 is set in the flow channel. In this embodiment, 1 and 3 breakpoints 140 are respectively provided in the two transverse channels. The break point 140 functions to block the flow of liquid.

[0039] The lower substrate 200 is provided with cavities 230 corresponding to the breakpoints 140 one by one, so that the cavities 230 form a 5×4 matrix arrangement. Among the four rows of cavities 230 arranged vertically, each row of cavities 230 is provided with a gas interface 210 , and ...

Embodiment 2

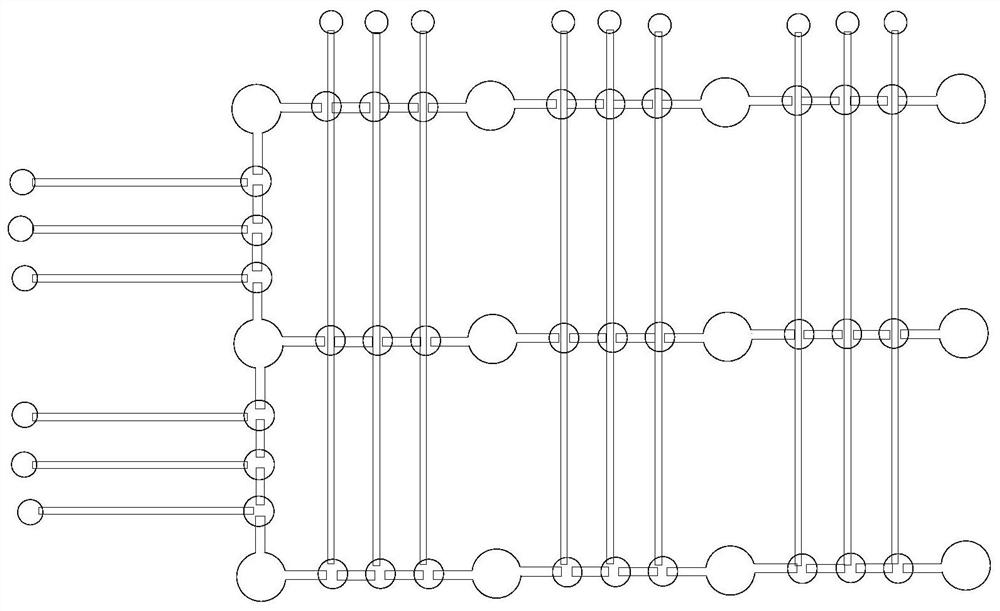

[0042] figure 2 Shows a schematic structural view of a microwell plate according to another embodiment of the present invention. In this embodiment, the upper substrate 100 is provided with a plurality of microwells 110 arranged in a 3×4 matrix, and the bottom of each microwell 110 Each of them is provided with a communication hole 120 , two horizontally adjacent communication holes 120 are connected by a flow channel, and the leftmost column of vertically adjacent two communication holes 120 is connected by a flow channel. There are three breakpoints in each runner.

[0043] The lower substrate 200 is provided with cavities 230 corresponding to the breakpoints 140 one-to-one. Among the nine columns of cavities 230 arranged vertically, each column of cavities 230 is provided with a gas interface 210, and the gas interface 210 is connected to the gas channel 220 through the gas channel 220. The outermost cavity 230 communicates with each other. In the leftmost row of cavitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com