Fabricated multi-arch wall foundation pit supporting structure and construction technology

A foundation pit support and assembly technology, which is applied in the direction of foundation structure engineering, underwater structures, artificial islands, etc., can solve the problem of affecting the mechanical performance and anti-seepage function of the support system, and cannot be used independently as a cantilever support , easy to fall off the water-stop effect of the support structure and other issues, to achieve the effect of reasonable force, convenient construction, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

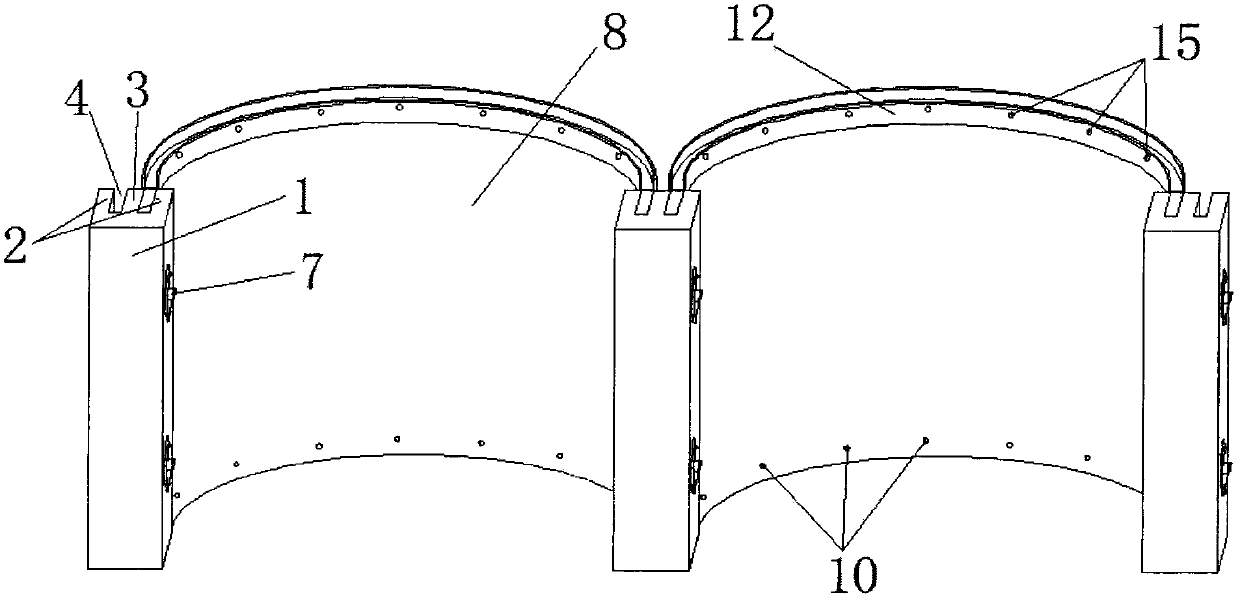

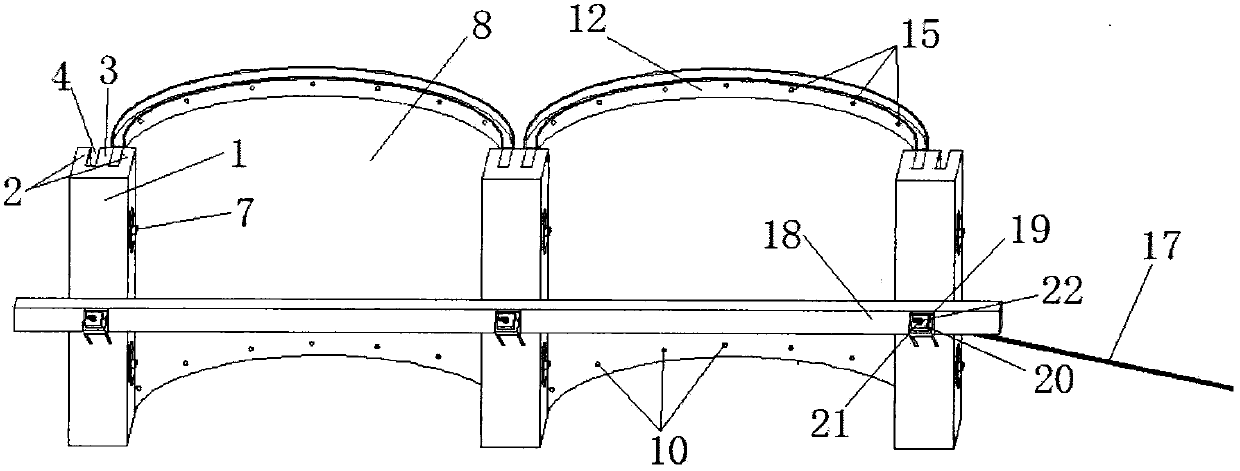

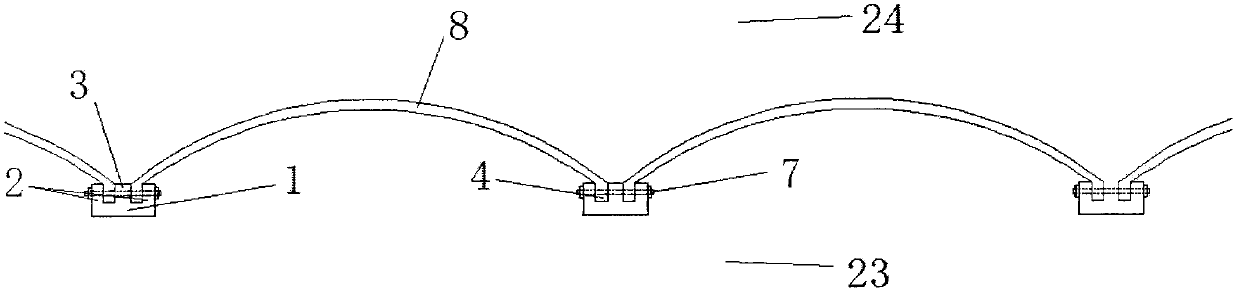

[0025] see Figure 1-6 As shown, a prefabricated double-arch wall foundation pit support structure. The special-shaped "mountain" piles 1 are arranged at intervals along the support positioning line of the foundation pit 23, and there are long oval-shaped reserved holes 5 arranged at intervals in the vertical direction on the left, middle and right three flanges, which can be connected with the concrete arch piece on the rib 9 The reserved holes 11 communicate with each other, and are connected with bolts 7 to fix the arch piece 8 . The H-shaped cross-section arc steel 12 and the prefabricated reinforced concrete arch 8 are poured together up and down. When the two arches are butted up and down, the bottom of the upper arch is placed in the groove 14 at the curved steel web on the top of the lower arch. After the arch pieces are butted, the bolt holes 10 reserved at the lower edge of the concrete arch pieces communicate with the bolt holes 15 reserved at the upper flange 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com