Rapid repairing method for sunken ballastless track through grouting lifting

A ballastless track and repair method technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of unsuitable repair work, unfavorable repair work, high cost, etc., and achieve saving of repair material costs, significant technical and economic efficiency, and saving The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 of the present invention provides a rapid repair method for grouting and lifting of a single-line subsidence ballastless track in a straight line section. The method includes the following contents:

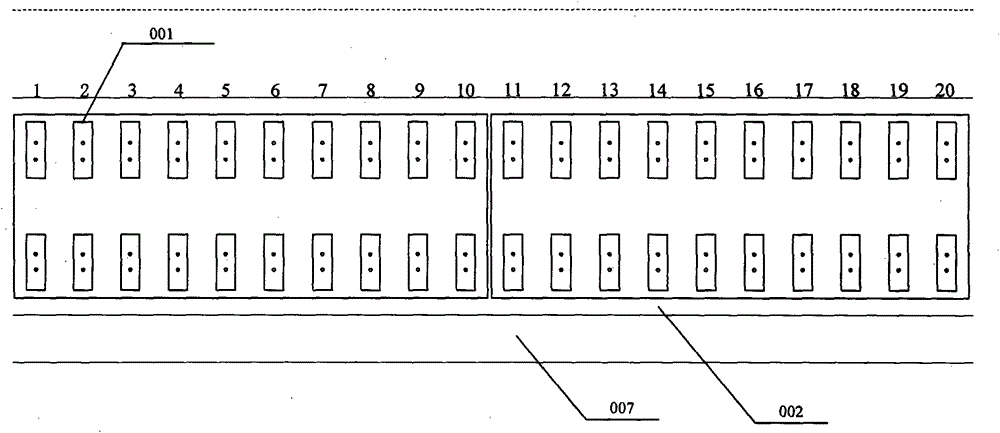

[0045] (1) Before lifting, use an electronic level (with an accuracy of at least 0.1mm) to measure the smoothness of the ballastless track structure in the subsidence area, and establish a monitoring network for lifting points; The design lifting height corresponding to the rail platform (001) is shown in Table 1. figure 1 shown.

[0046] Table 1 Design lifting height of 1# to 20# rail support platform

[0047] Rail platform number

Design Lifting Height (mm)

Rail platform number

Design Lifting Height (mm)

1#

17

11#

31

2#

17

12#

30

3#

20

13#

27

4#

21

14#

25

5#

22

15#

23

6#

24

16#

21

7#

25

17#

18

8#

...

Embodiment 2

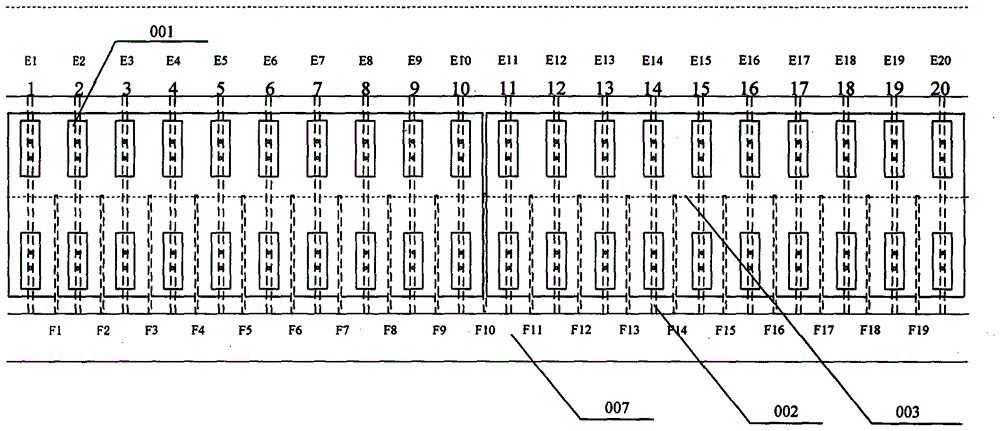

[0059] Embodiment 2 of the present invention provides a rapid repair method for grouting and lifting of a single-line settlement ballastless track in a curved section. The method includes the following contents:

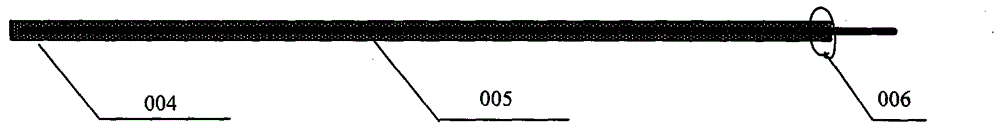

[0060] (1) The repair process and steps are basically the same as in Example 1, except that the drilling and layout of lifting and filling grouting holes are slightly different, and the schematic diagrams are as follows Figure 8 , 9 As shown, the interface of the grouting pipe (005) for lifting is set on the superelevation side of the line curve, and the grout flows from the low side to the superelevation side, while the interface of the grouting pipe (005) for filling is preferably set on the outside of the line, and the grout flows from the superelevation side. The high side flows to the low side to ensure a lifting effect.

[0061] (2) The material used for grouting the lifting grouting hole is polyurethane foam material, which can work for 10s and reach more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com