Mold used for forming casting bar, casting device, and method for producing casting bar

一种铸棒、铸模的技术,应用在铸棒形成用铸模、铸造装置和铸棒的制造领域,能够解决不适用等问题,达到制造效率和成品率提高、提高制造效率、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

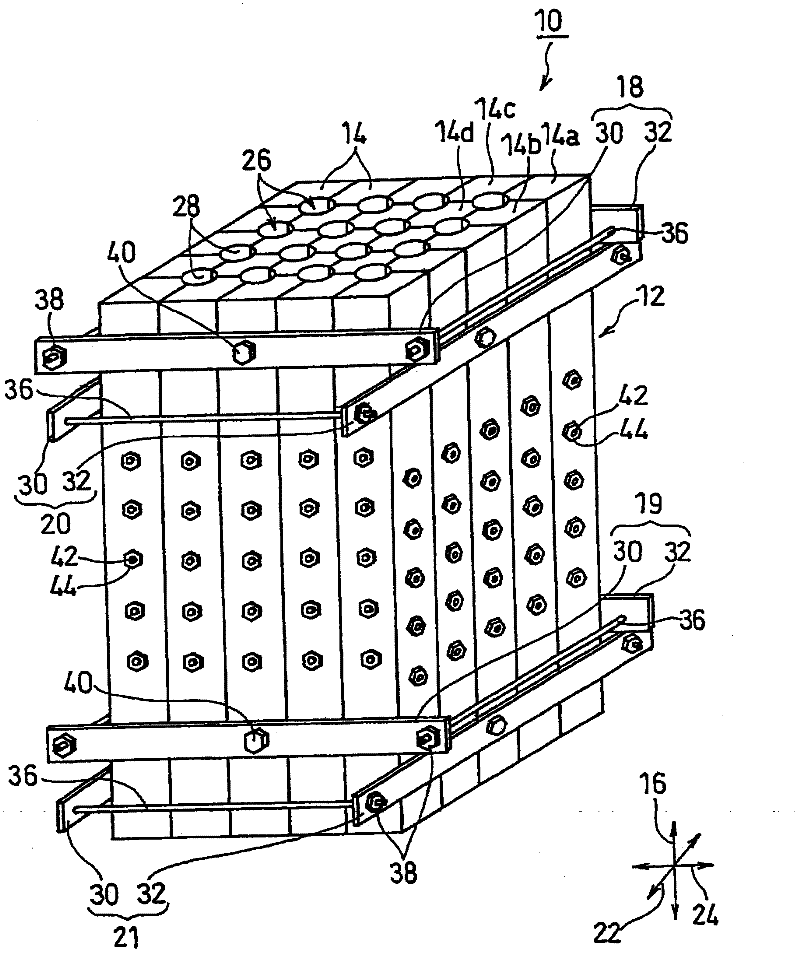

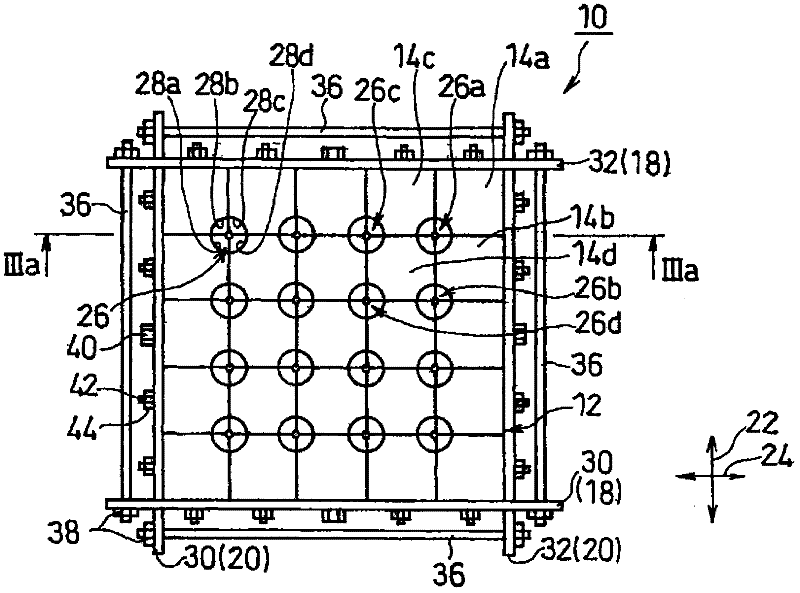

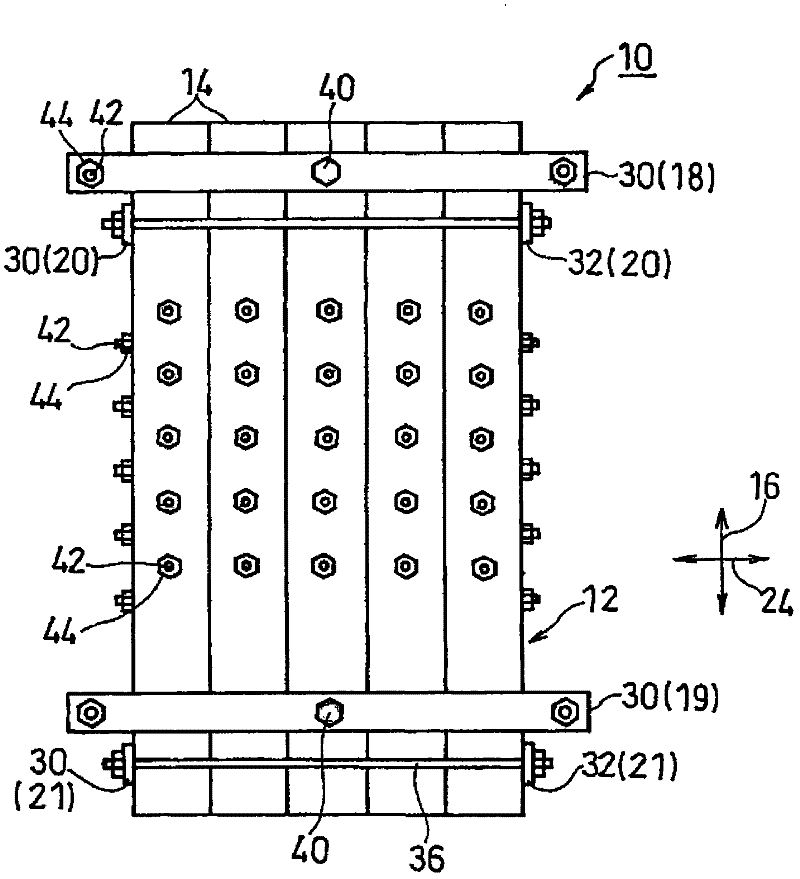

[0048] figure 1It is a perspective view which shows one Embodiment of the casting mold for casting rods of this invention. Figure 2A yes figure 1 top view of Figure 2B yes figure 1 main view of Figure 2C yes figure 1 right side view of the , Figure 2D yes figure 1 bottom view. Figure 3A yes Figure 2A and Figure 2C IIIa-IIIa arrow direction view, Figure 3B yes Figure 3A A partial enlargement of the . in addition, Figure 4 is the composition figure 1 A plan view of the modules of the shown module assembly separated from each other in a direction perpendicular to the longitudinal direction.

[0049] In addition, in the description of the following casting molds for casting rods and casting equipment, when referring to directions, they are based on the directions when they are placed in the horizontal direction. Specifically, the direction arrows shown in each figure are benchmark.

[0050] refer to figure 1 and Figure 2A ~ Figure 2D , the casting mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com