Building formwork

A construction template and one-sided technology, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of poor wear resistance and fire resistance, and achieve the goals of protecting the base layer, good heat resistance, and improving flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

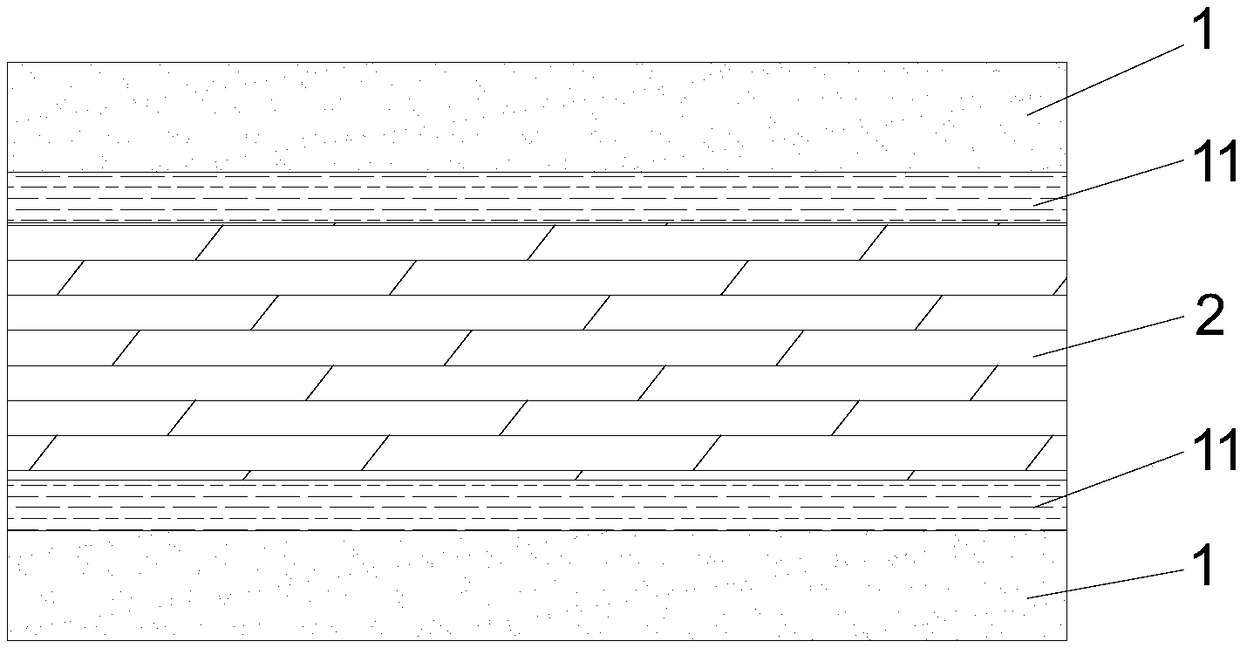

[0040] refer to figure 1 , a building template, comprising a wear-resistant layer 1 and a base layer 2, wherein the wear-resistant layer 1 is located on the upper and lower surfaces of the base layer 2, the wear-resistant layer 1 includes a wear-resistant surface and a reinforced surface, and the reinforced surface includes a meridian layer 11, and, The meridian layer 11 is located on the side of the wear-resistant layer 1 close to the base layer 2 , and the wear-resistant surface is located on the side of the wear-resistant layer 1 away from the base layer 2 .

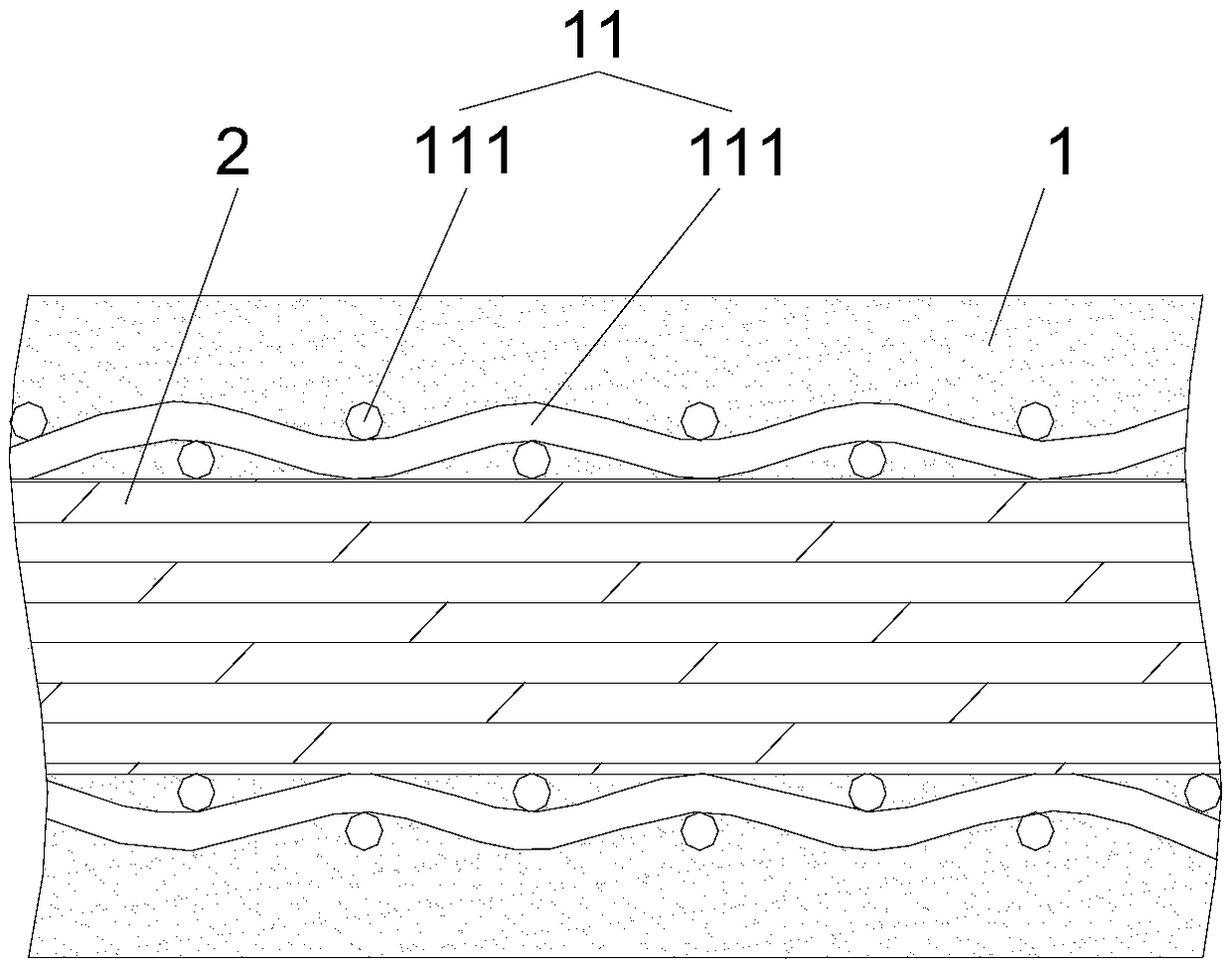

[0041] refer to figure 1 or figure 2 , the meridian layer 11 is pasted and / or embedded in the wear-resistant layer 1 on the side close to the base layer 2 .

[0042] Preferably, the meridian layer 11 is embedded in the wear-resistant layer 1 on the side close to the base layer 2 . refer to figure 2 , the meridian layer 11 is embedded in the wear-resistant layer 1. On the one hand, the meridian layer 11 can be co...

Embodiment 2

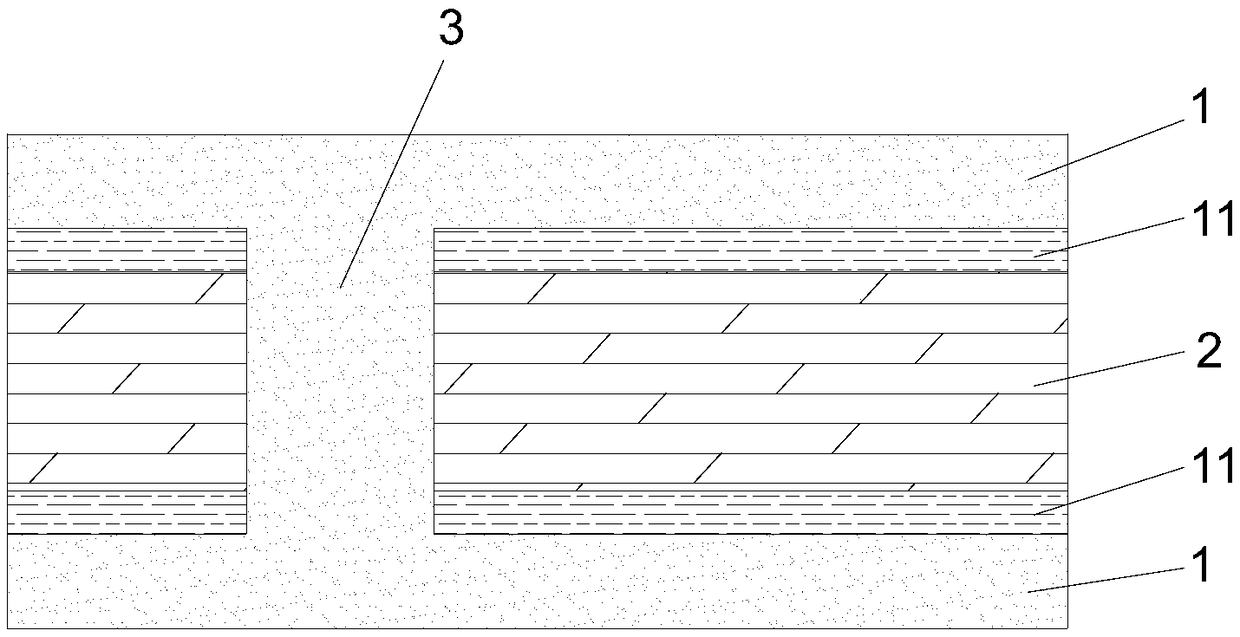

[0074] This embodiment is a further improvement on Embodiment 1, and only the improved part will be described in detail below.

[0075] As a preferred embodiment of the present invention, the base layer 2 is provided with through holes and / or counterbore holes, and the wear-resistant layer 1 contains reinforcements 3 that match the through holes, and the reinforcements 3 are embedded in the base layer 2. through hole. On the one hand, the setting of the reinforcing member 3 can effectively improve the shear stress transfer efficiency between the base layer 2 and the wear-resistant layer 1 in the building formwork, and prevent delamination between the base layer and the wear-resistant layer 1; on the other hand, the reinforcing member 3 can effectively Improve the compressive capacity of building formwork.

[0076] As a preferred embodiment of the present invention, the reinforcing member 3 is fixedly connected to the friction-resistant 1 . Preferably, the wear-resistant laye...

Embodiment 3

[0081] This embodiment is a further improvement on Embodiment 1 and Embodiment 2, and only the improved part will be described in detail below.

[0082] refer to Figure 5 or Image 6 as well as Figure 7 , the building formwork also includes a fixing part 4 for convenient connection and fixing with the outside world.

[0083] Specifically, the building formwork includes a through hole and a fixing piece 4 matching the through hole, and the fixing piece 4 is embedded in the through hole, so that the through hole in the building formwork is completely filled. Preferably, the fixing member 4 is made of plastic material, so that nails and / or bolts used for fixing building formwork can pass through the fixing member 4 .

[0084] The setting of the fixing part 4 can not only effectively reduce the difficulty of punching holes in the building formwork during the fixing process, but also improve the stability of the joint used for fixing with the outside world, preventing the buil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com