Heavy rare earth metal target material repairing method

A repair method and metal target technology, which are applied in metal material coating process, ion implantation coating, pressure inorganic powder coating and other directions, can solve problems such as unreusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Pretreat the target to be repaired: that is, use 4wt% sodium hydroxide solution to remove oil, rinse with deionized water, and dehydrate with absolute ethanol;

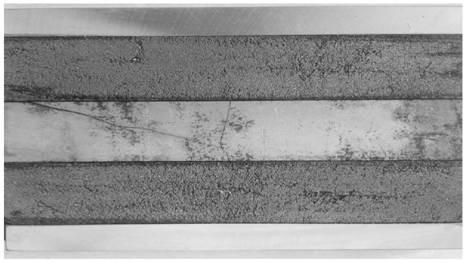

[0037] Among them, the target to be repaired is a dysprosium-terbium alloy target (the mass ratio of dysprosium to terbium is 1:1, and the sum of dysprosium and terbium content is >99wt%); the surface of the target to be repaired has a "racetrack" type loss area; the target to be repaired The size of the material is 350*125*10mm;

[0038] 2) Dysprosium, terbium, aluminum and gallium with a mass ratio of 4:4:1:1 were melted into alloy ingots in a medium-frequency induction melting furnace, and placed in a hydrogen crushing furnace for hydrogenation at 650°C to obtain alloy powder ;

[0039] 3) Put the pretreated target to be repaired in a rubber mold with a size of 352*127*11mm, add alloy powder to make the alloy powder cover the surface of the heavy rare earth metal target to be repaired, and use vacuum sin...

Embodiment 2

[0043] 1) Pretreat the target to be repaired: that is, use 4wt% sodium hydroxide solution to remove oil, rinse with deionized water, and dehydrate with absolute ethanol;

[0044] Among them, the target to be repaired is a dysprosium-terbium alloy target (the mass ratio of dysprosium to terbium is 1:1, and the sum of dysprosium and terbium content is >99wt%); the surface of the target to be repaired has a "racetrack" type loss area; the target to be repaired The specification of the material is 350*125*10mm;

[0045] 2) Dysprosium, terbium, aluminum and gallium with a mass ratio of 4:4:1:1 were melted into alloy ingots in a medium-frequency induction melting furnace, and placed in a hydrogen crushing furnace for hydrogenation at 650°C to obtain alloy powder ;

[0046] 3) The pretreated target to be repaired is inert to the heavy rare earth metal target with an upper protective cover located on the heavy rare earth metal target and a bottom protective cover located at the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com