A low-temperature multi-component nano-composite penetrating agent and surface treatment process to improve the wear resistance of burs

A nano-composite and nano-technology, used in metal material coating process, dental tools, dental drilling and other directions, can solve the problems of poor concentricity of welding bur processing, low flexural strength of welding, and large difference in expansion coefficient. , to save doctors and patients time, reduce labor intensity, and reduce needle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

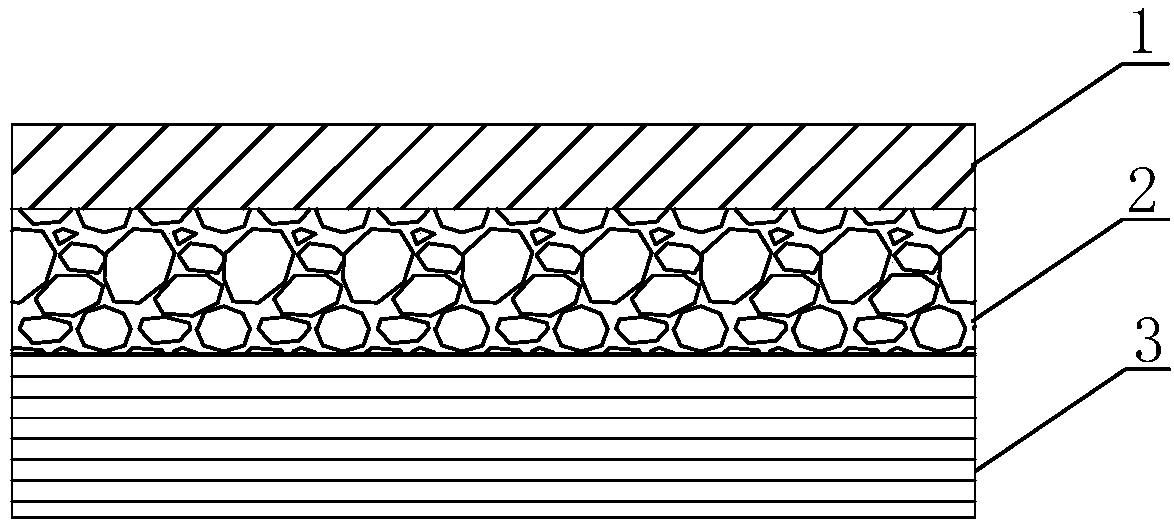

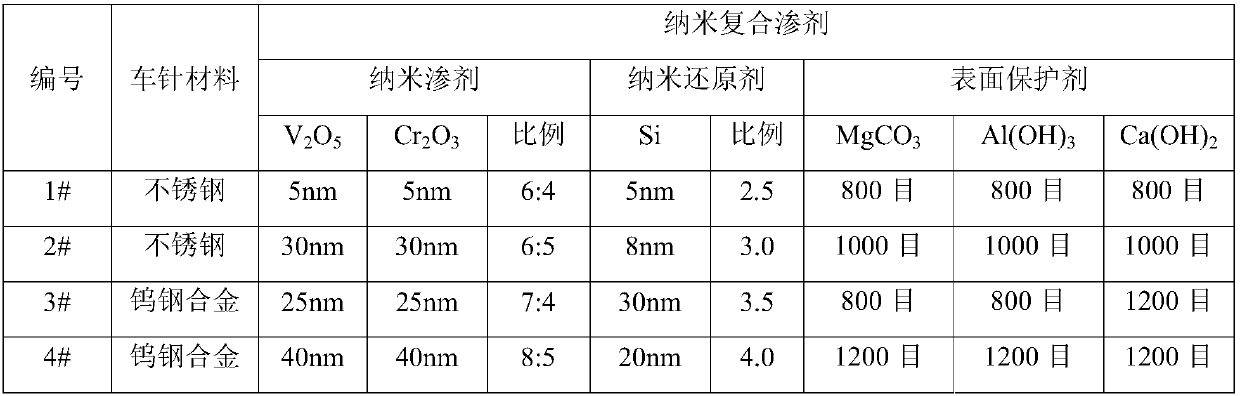

[0027] A low-temperature multi-component nanocomposite penetrating agent for improving the wear resistance of burs is composed of a nano penetrating agent, a nano reducing agent and a surface protecting agent. The nano-osmosis agent consists of V with a particle size of 5nm 2 o 5 Nanoparticles and Cr with a particle size of 5nm 2 o 3 Nanoparticle composition, V 2 o 5 Nanoparticles and Cr 2 o 3 The weight ratio of nanoparticles is 6:4. The nano-reducing agent is selected from Si nanoparticles with a particle diameter of 5 nm, and the added weight of the nano-reducing agent is 2.5 times the amount of the nano-osmotic agent. The surface protection agent is composed of magnesium carbonate, aluminum hydroxide and calcium hydroxide with a particle diameter of 800 mesh, and the weight ratio of magnesium carbonate, aluminum hydroxide and calcium hydroxide is 1.0:1.0:1.0.

[0028] Using the above-mentioned low-temperature multi-component nano-composite penetrating agent to carr...

Embodiment 2

[0035] A low-temperature multi-component nanocomposite penetrating agent for improving the wear resistance of burs is composed of a nano penetrating agent, a nano reducing agent and a surface protecting agent. The nano-osmotic agent consists of V with a particle size of 30nm 2 o 5 Nanoparticles and Cr with a particle size of 30nm 2 o 3 Nanoparticle composition, V 2 o 5 Nanoparticles and Cr 2 o 3 The weight ratio of nanoparticles is 6:5. The nano-reducing agent is Si nanoparticles with a particle diameter of 8nm, and the added weight of the nano-reducing agent is 3.0 times the amount of the nano-osmotic agent. The surface protection agent is composed of magnesium carbonate, aluminum hydroxide and calcium hydroxide with a particle diameter of 1000 mesh, and the weight ratio of magnesium carbonate, aluminum hydroxide and calcium hydroxide is 1.0:1.0:1.0.

[0036] Using the above-mentioned low-temperature multi-component nano-composite penetrating agent to carry out the pr...

Embodiment 3

[0043] A low-temperature multi-component nanocomposite penetrating agent for improving the wear resistance of burs is composed of a nano penetrating agent, a nano reducing agent and a surface protecting agent. The nano-osmosis agent consists of V with a particle size of 25nm 2 o 5 Nanoparticles and Cr with a particle size of 25nm 2 o 3 Nanoparticle composition, V 2 o 5 Nanoparticles and Cr 2 o 3 The weight ratio of nanoparticles is 7:4. The nano-reducing agent is Si nanoparticles with a particle diameter of 30nm, and the added weight of the nano-reducing agent is 3.5 times of the amount of the nano-osmotic agent. The surface protective agent is composed of magnesium carbonate, aluminum hydroxide and calcium hydroxide, the particle diameters of magnesium carbonate, aluminum hydroxide and calcium hydroxide are respectively 800 mesh, 800 mesh and 1200 mesh, magnesium carbonate, aluminum hydroxide and The weight proportion of calcium hydroxide is 1.0:1.0:1.0, and the added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com