Patents

Literature

149results about How to "Reduce the difficulty of repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly converter bedding-face repairing material and preparation method thereof

The invention discloses an environment-friendly converter bedding-face repairing material and a preparation method thereof. The repairing material comprises the following ingredients by weight percent: 30 to 65 percent of sintering magnesium sand, 10 to 45 percent of waste magnesite-chrome bricks, 1 to 10 percent of asphalt powder, 5 to 15 percent of tar, 1 to 5 percent of ethanol, 1 to 5 percent of N-methyl-2-pyrrolidinone and 0 to 5 percent of o-xylene. The preparation method comprises the following steps: 1) pre-crushing the sorted sintering magnesium sand and recycled waste magnesite-chrome bricks; 2) uniformly mixing the pre-crushed sintering magnesium sand and waste magnesite-chrome bricks to obtain a mixed coarse material; 3) finely crushing the mixed coarse material to obtain a mixed fine material; 4) uniformly mixing the mixed fine material and asphalt powder in a stirring machine; 5) adding tar, ethernol, N-methyl-2-pyrrolidinone and o-xylene, and stirring the mixture for 10 to 25 minutes. The practices prove that the converter repairing material has good mobility, can be sintered easily, has long service life and generates little smoke when sintered.

Owner:武汉钢铁有限公司

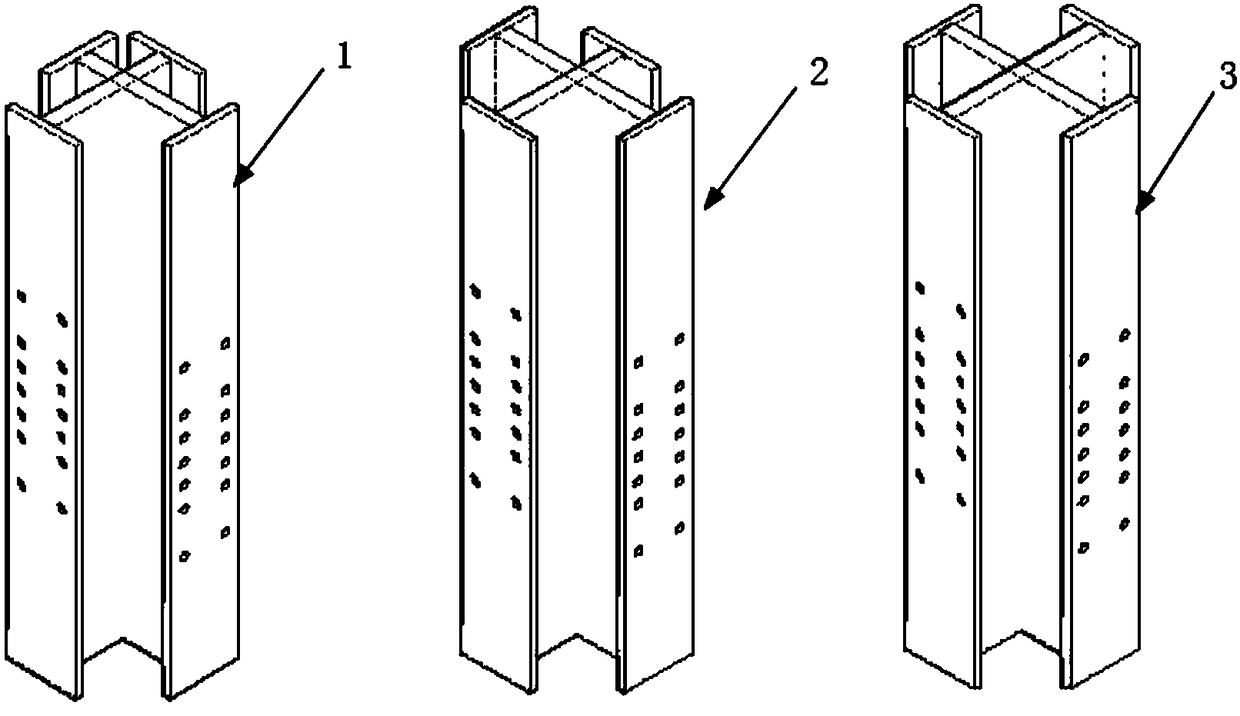

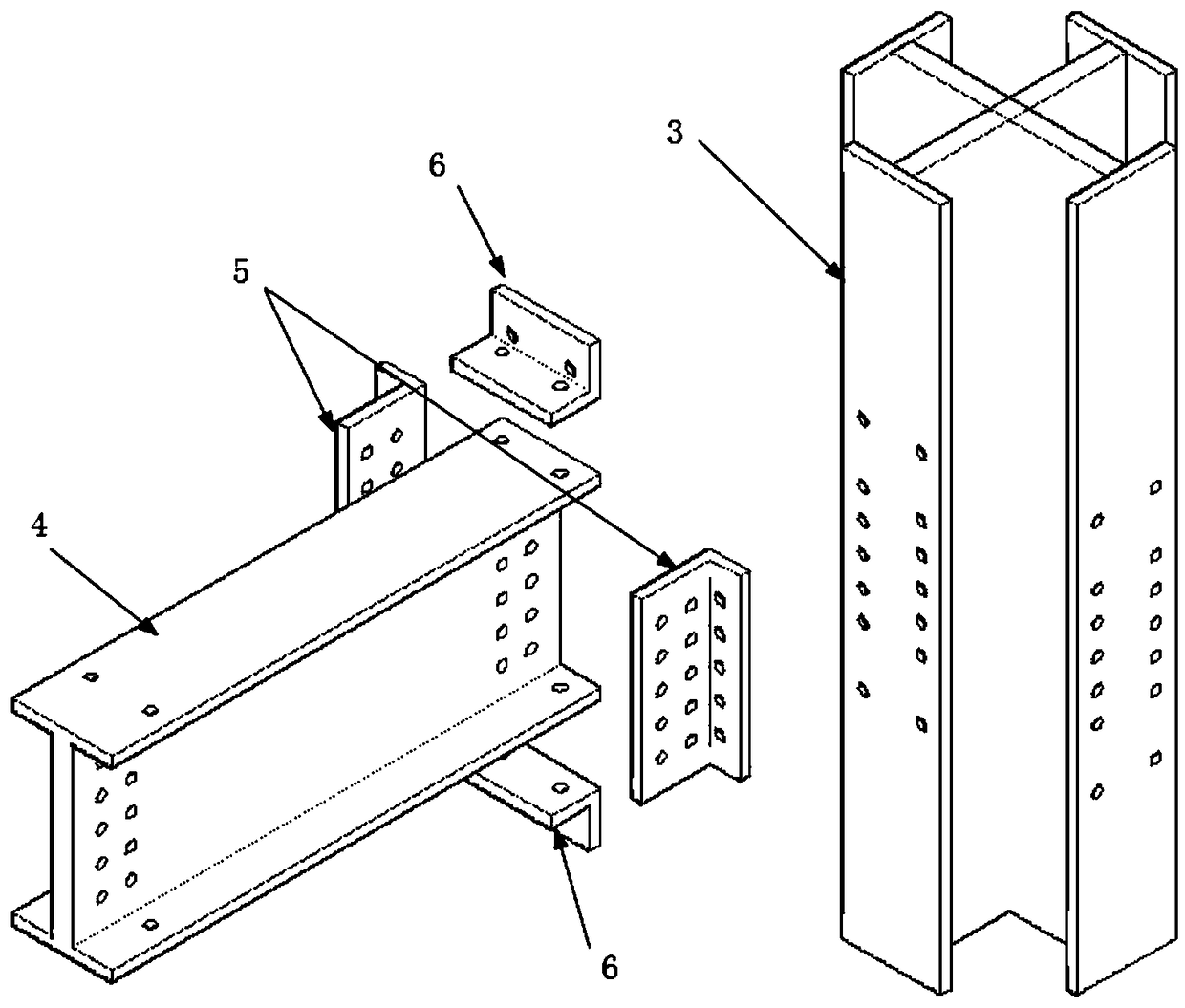

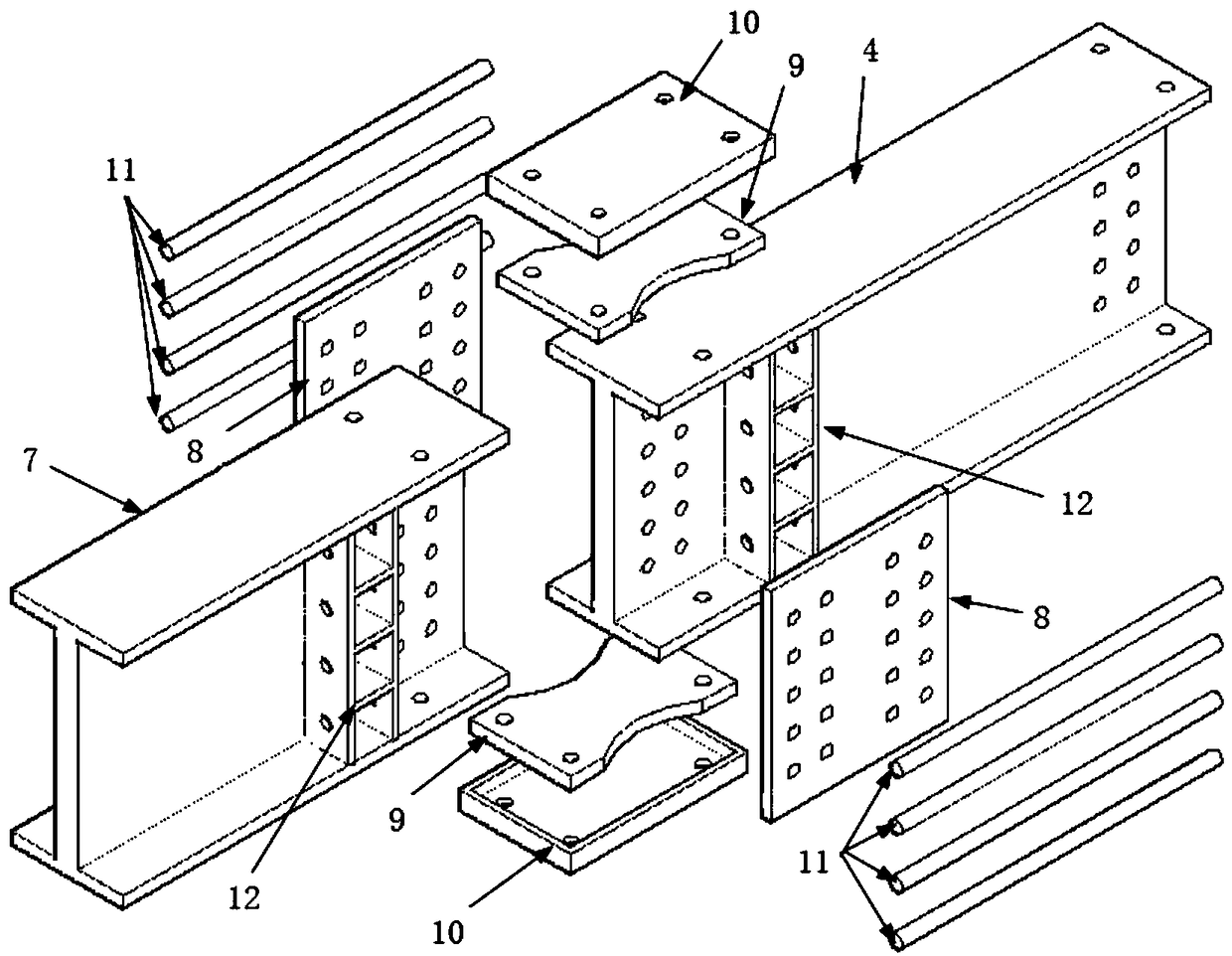

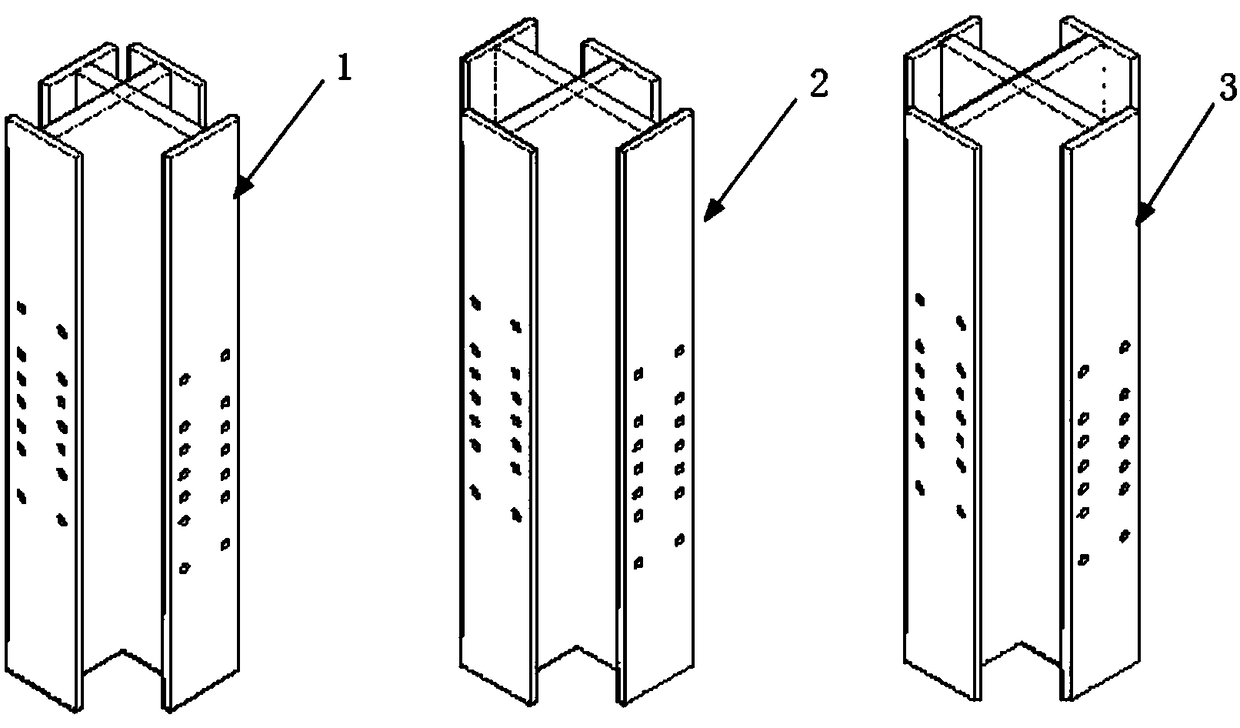

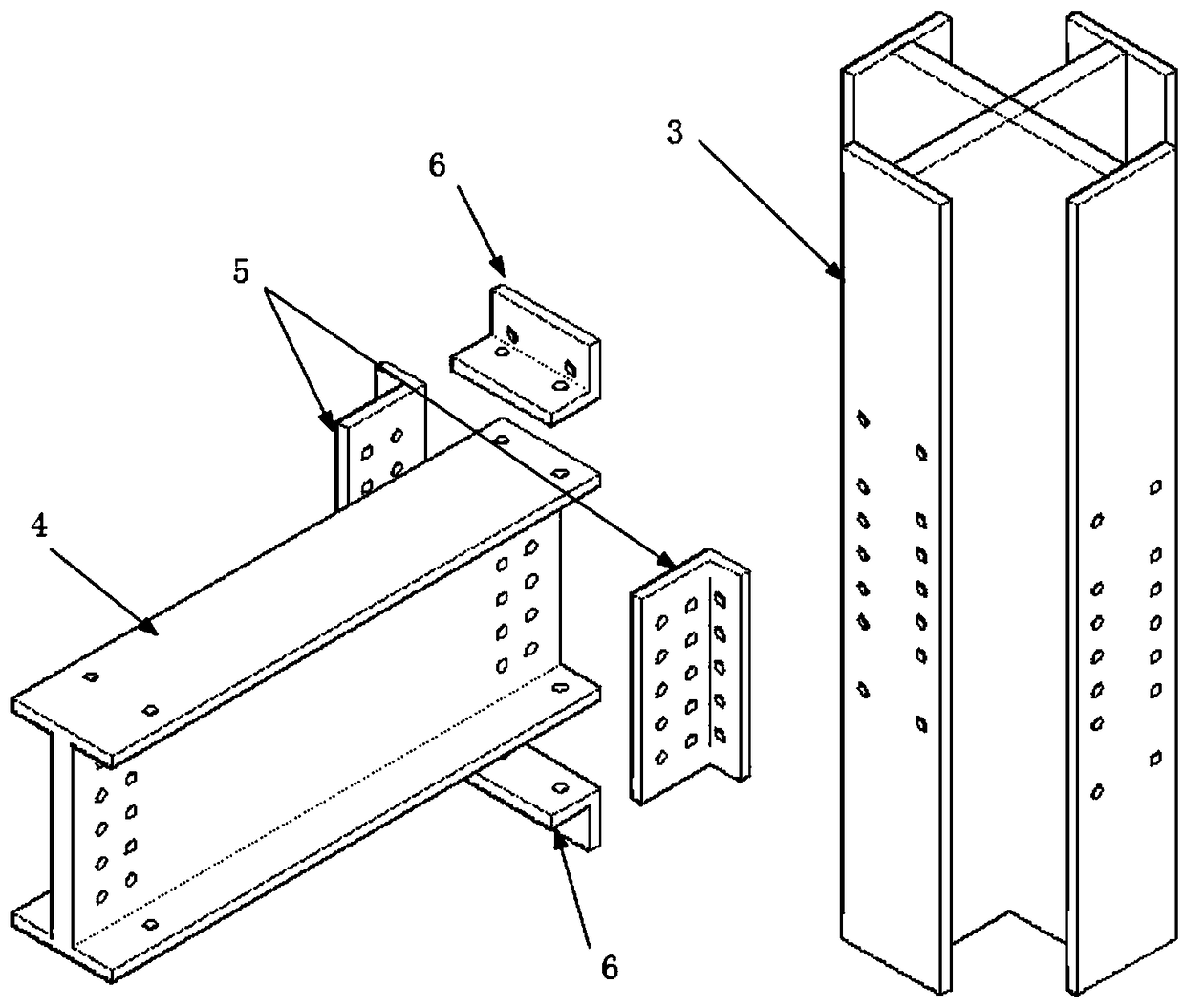

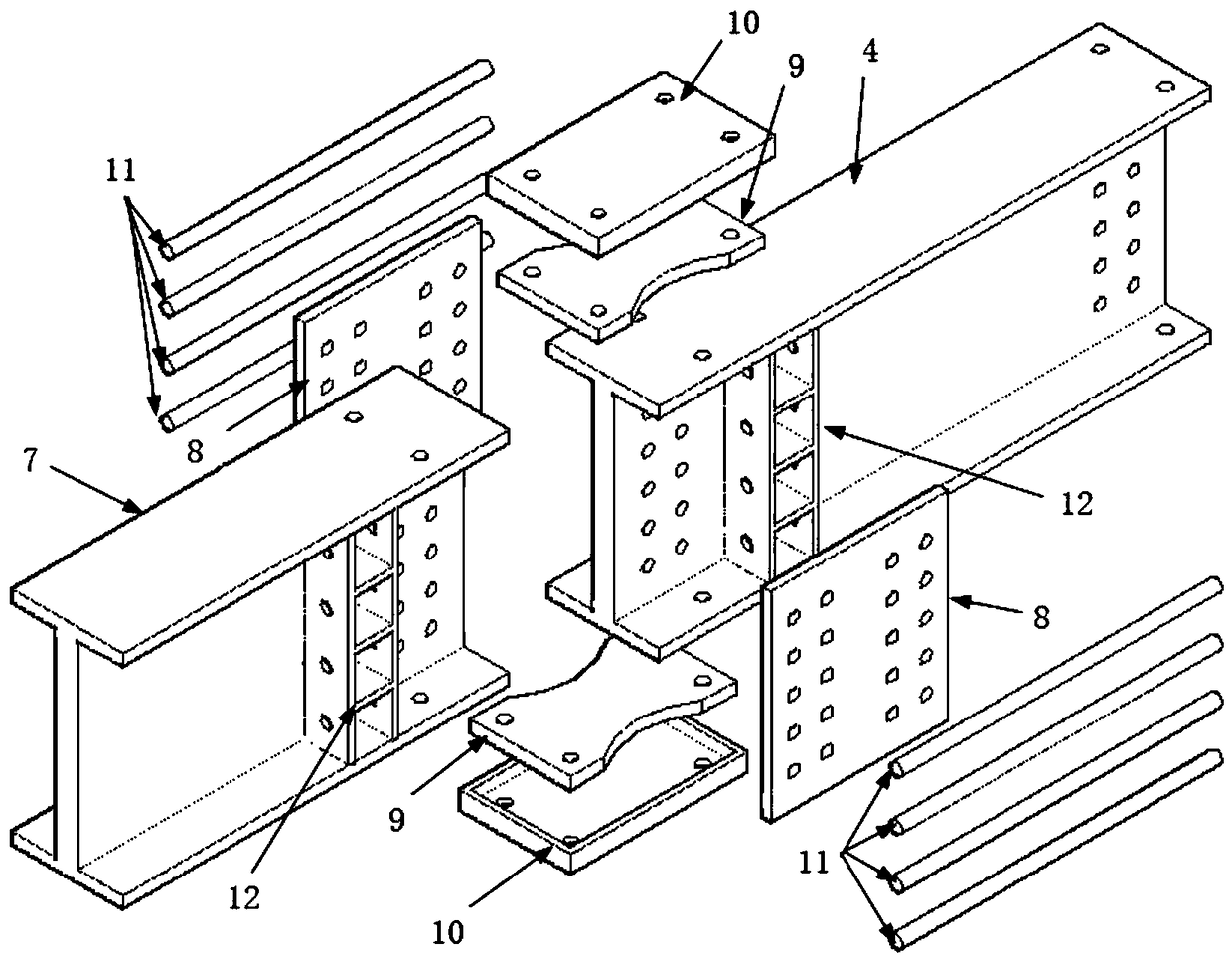

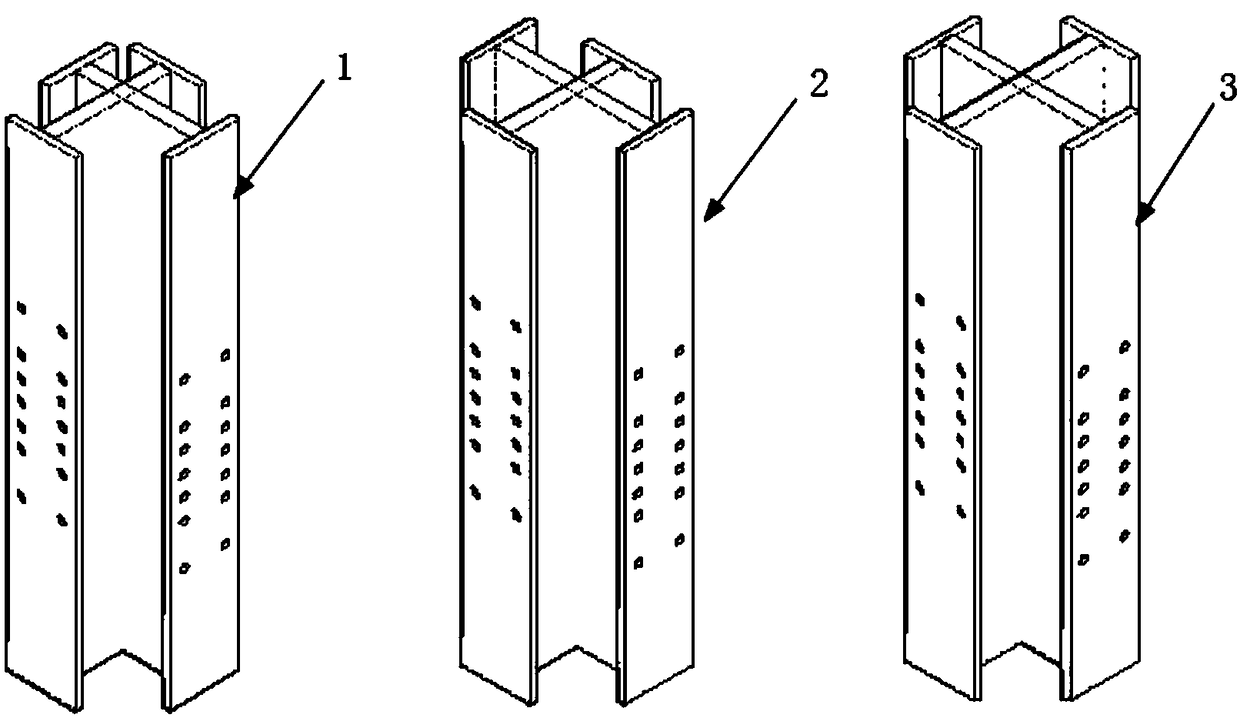

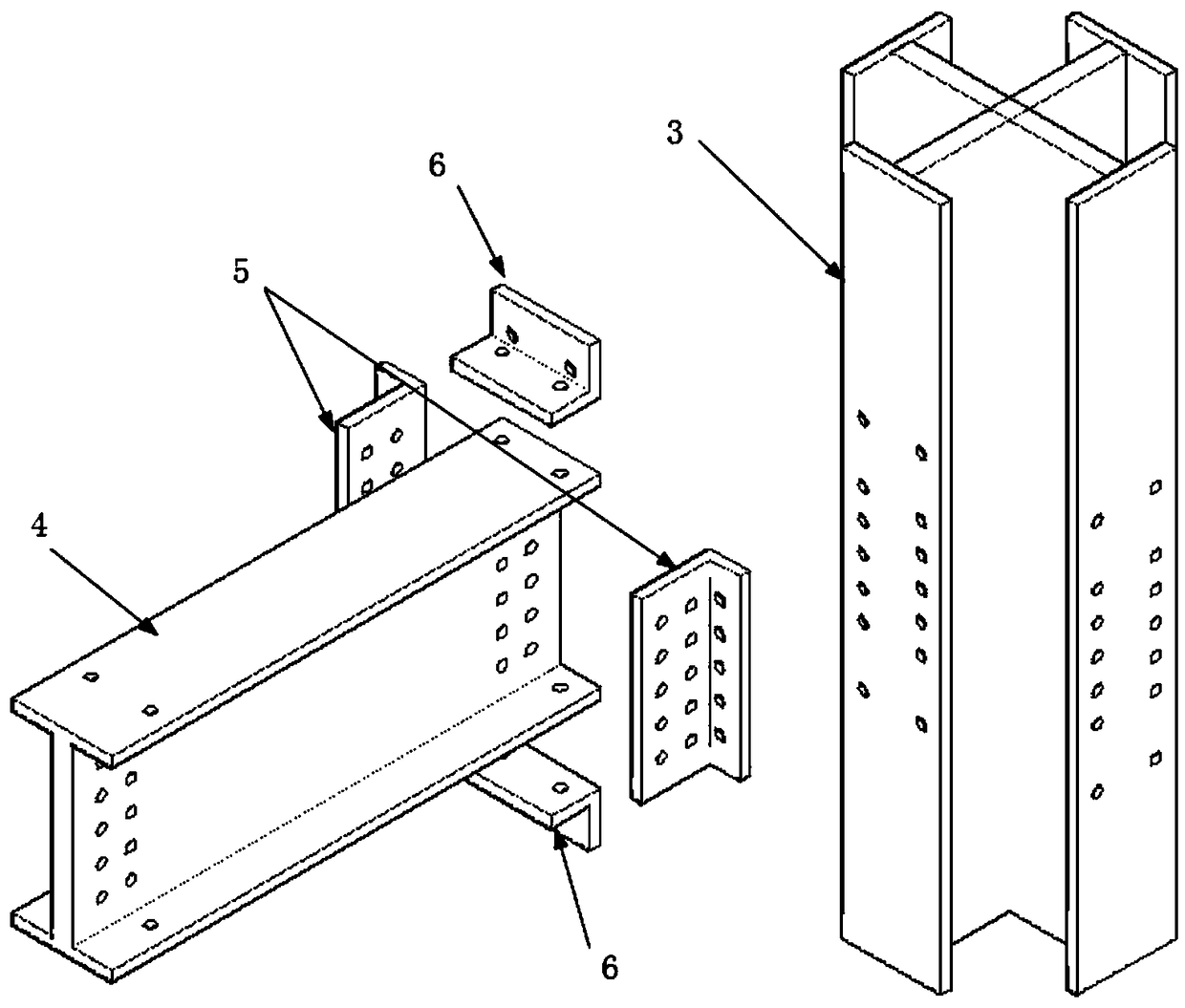

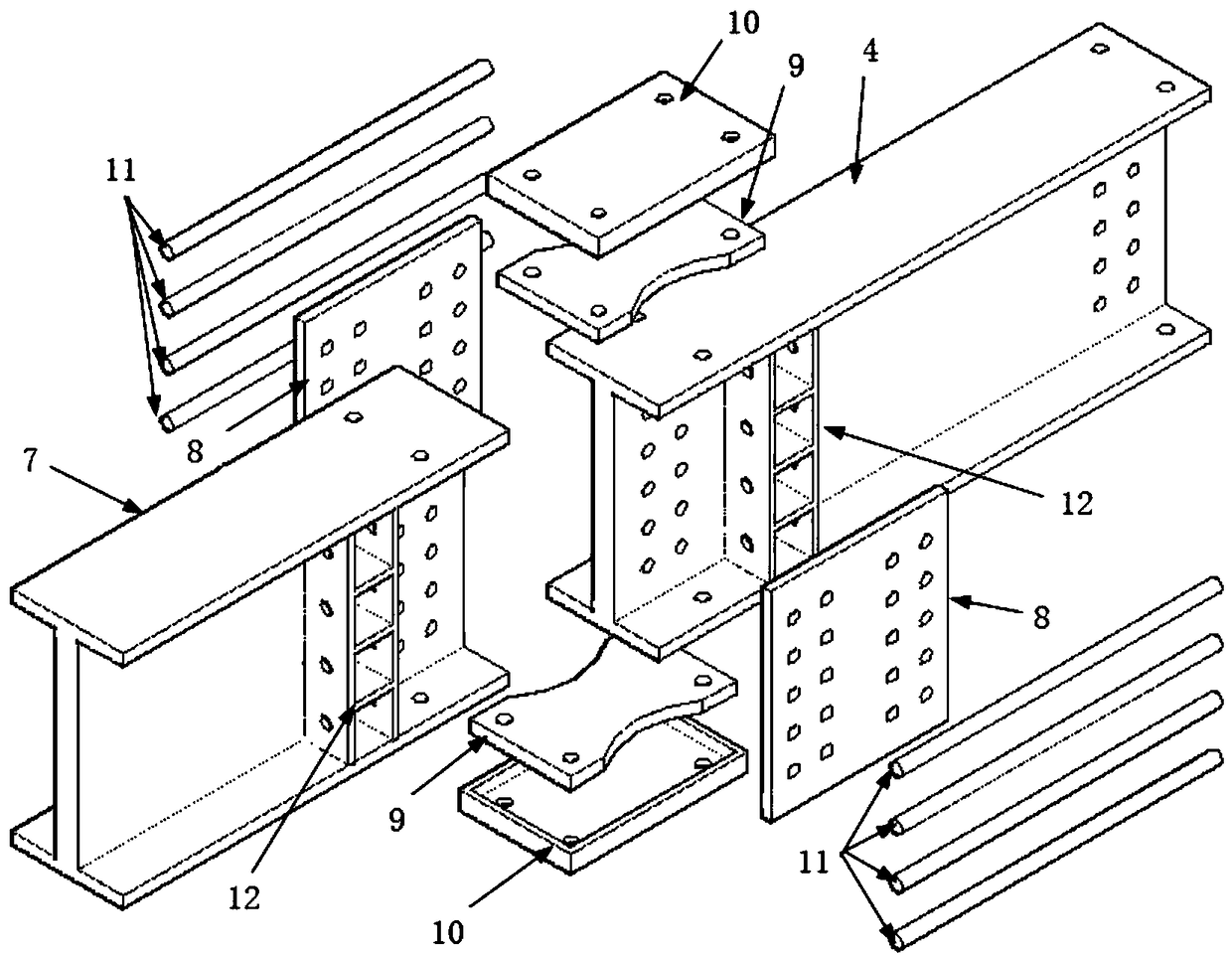

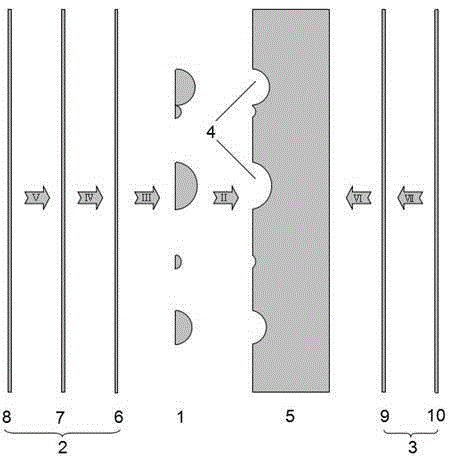

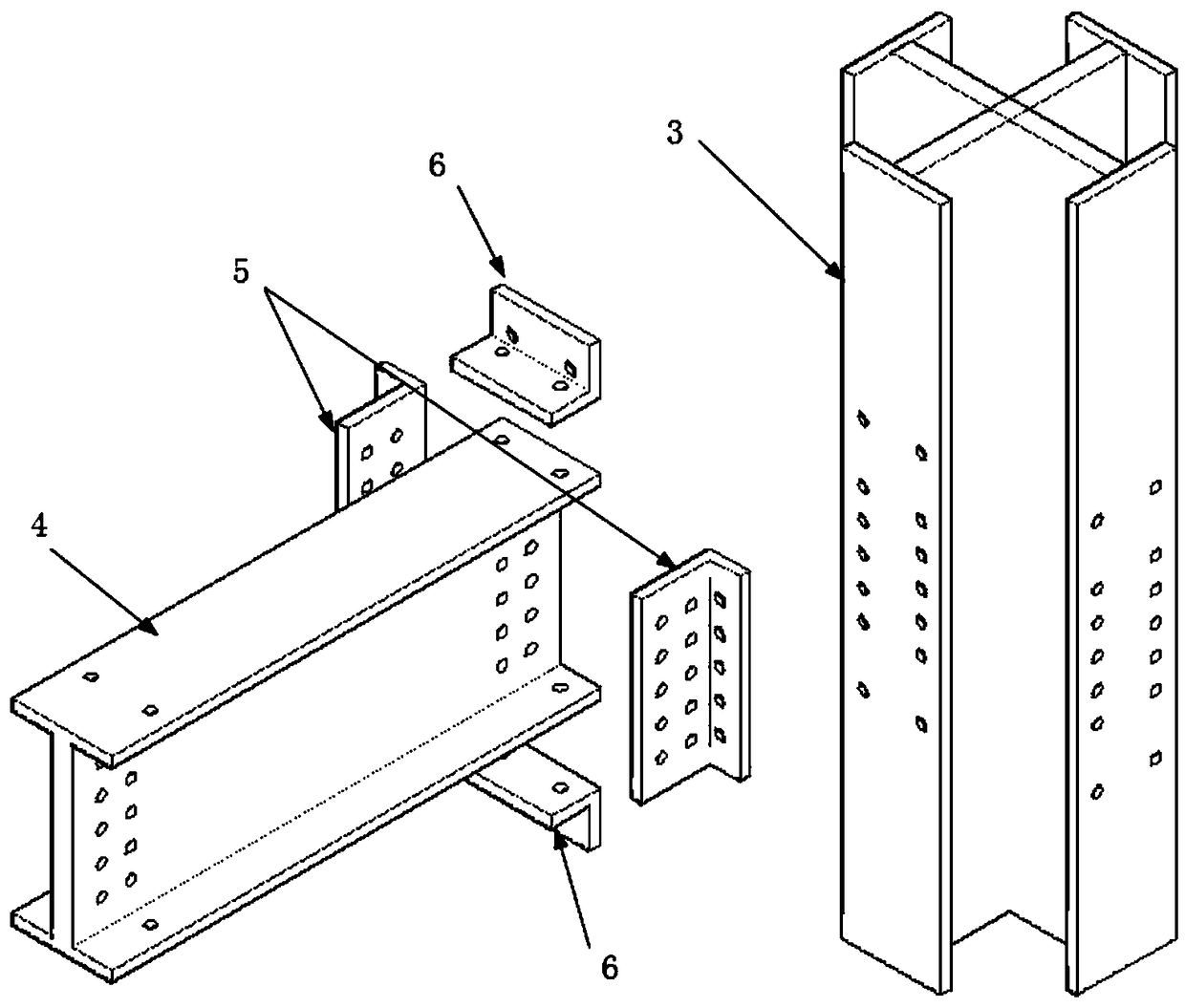

Assembling multi-section beam center support steel frame capable of self-centering after earthquake

The invention discloses an assembling multi-section beam center support steel frame capable of self-centering after earthquake. An I-beam is connected with special-shaped columns of different forms through a web angle steel and a flange angle steel to form a connecting form of full bolts without weld seams; a middle I-beam is connected with an end I-beam through a web connecting plate and a high-strength silicone rubber plate to form a connecting form of full bolts without weld seams with good ductility and high energy consumption; a prestressed steel cable is applied at the connecting part ofthe full bolts without the weld seams of the middle I-beam and the end I-beam to form self-centering nodes after the prestressed earthquake, and after the nodes are connected in sequence, a precast concrete-profiled steel plate composite slab or a poured concrete slab is assembled to form an assembling multi-section beam center support steel frame structure system capable of self-centering afterthe earthquake.

Owner:BEIJING UNIV OF TECH

Foliar fertilizer, preparation method and method for reducing cadmium pollution of crops

InactiveCN108046902AAchieve technical effectAvoid direct processingFertilising methodsHorticulture methodsCadmium CationSe element

The invention relates to the technical field of heavy metal remediation of farmland, in particular to a foliar fertilizer, a preparation method and a method for reducing cadmium pollution of crops andaims to reduce the content of heavy metal cadmium in edible parts of crops. The foliar fertilizer is prepared from the following raw materials: 5-10 parts of soluble selenium, 60-80 parts of solublesilicon, 5-10 parts of chitosan, 20-30 parts of ascorbic acid, 140-160 parts of deionized water and 2-5 parts of absolute ethanol. According to the foliar fertilizer, a new idea that the inhibitor issprayed to foliage of crops for inhibiting transfer of heavy metals from the crop section of a soil-plant system to edible parts so as to remedy heavy metal pollution of cultivated land is provided.

Owner:北京本农科技发展有限公司

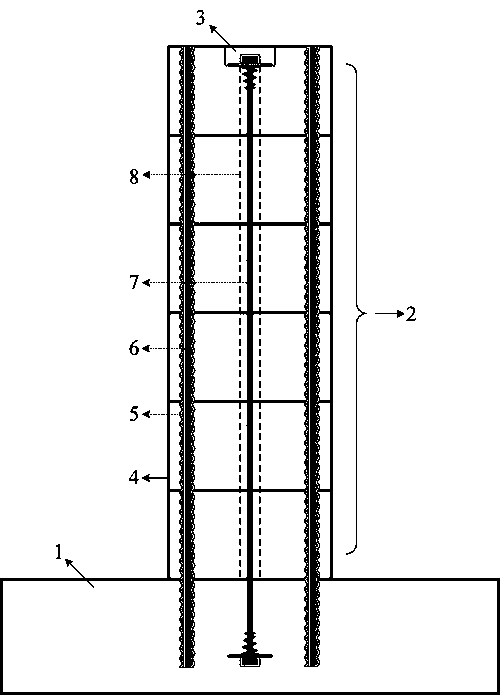

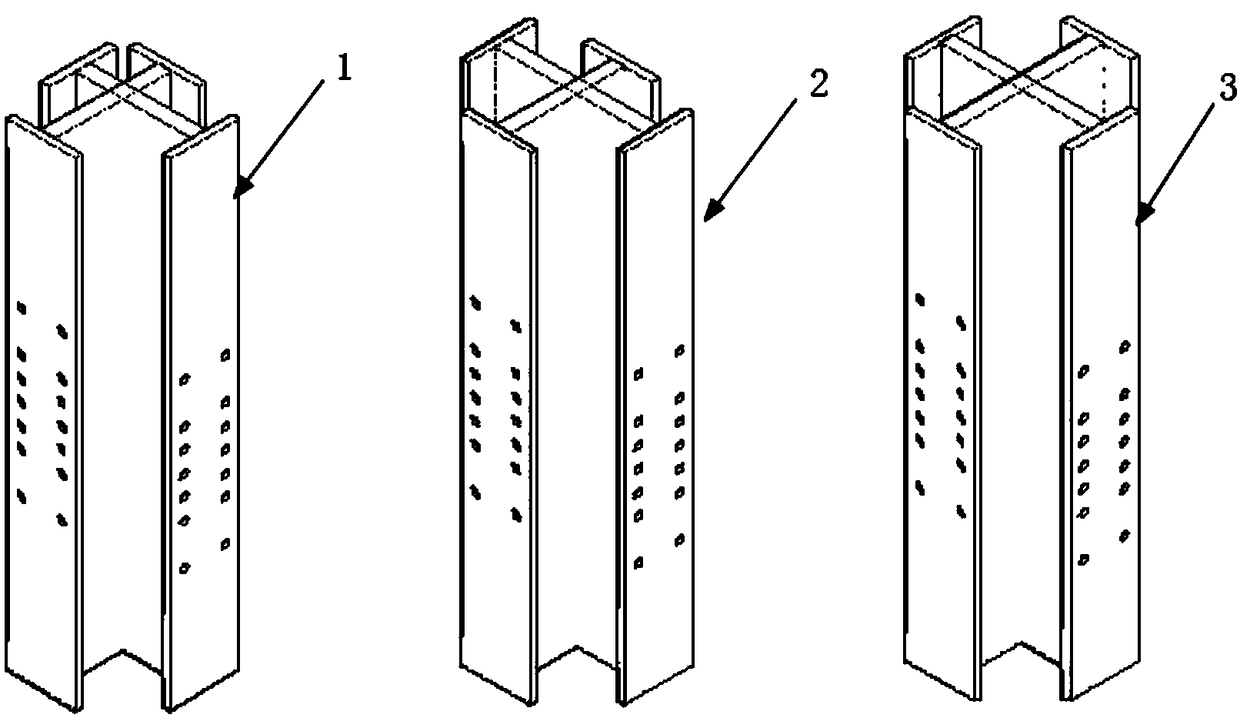

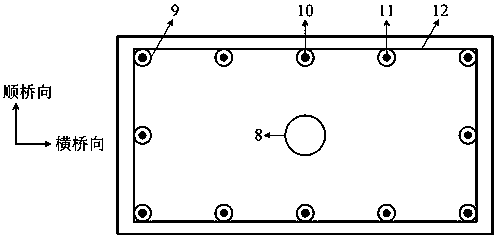

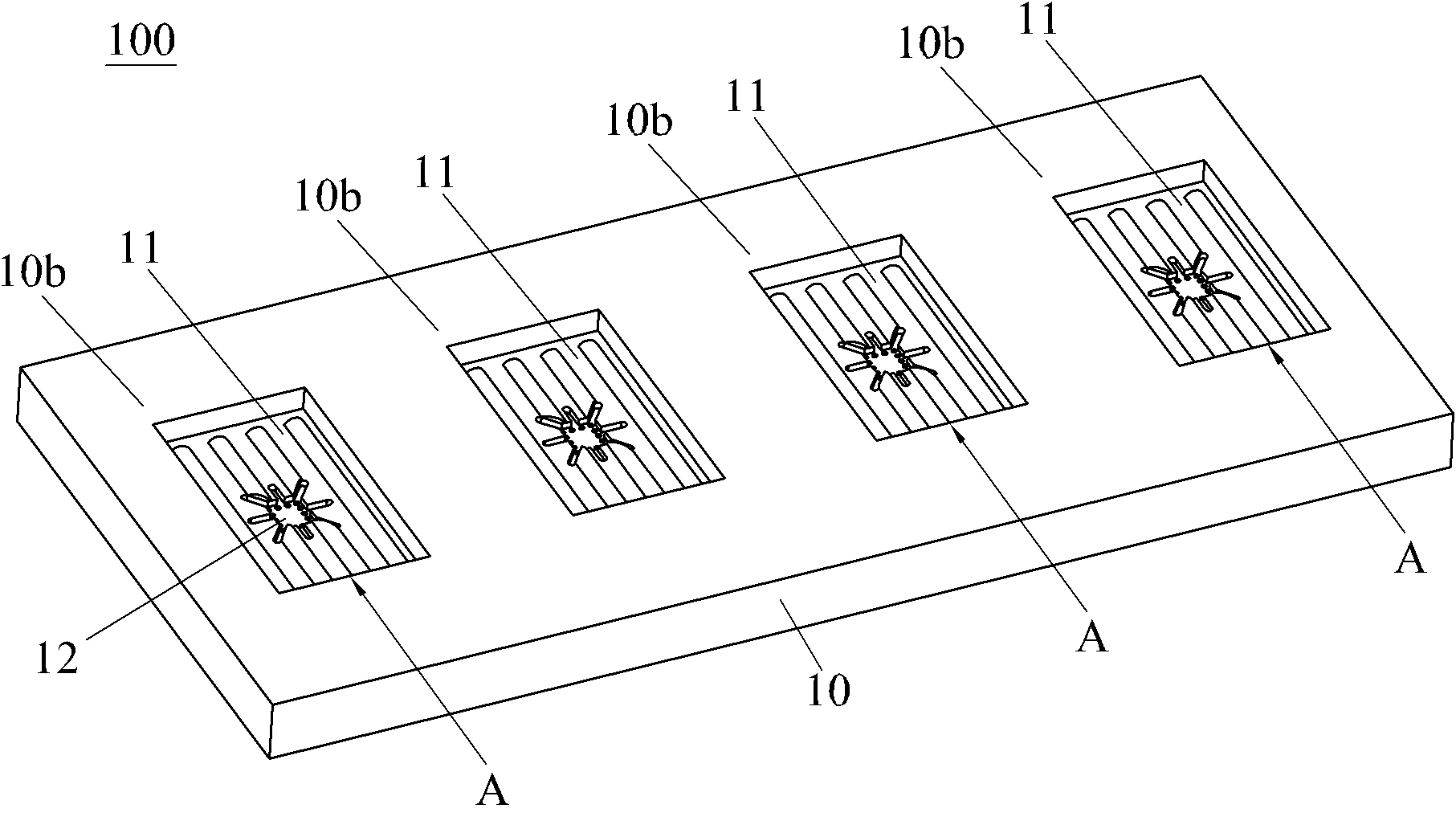

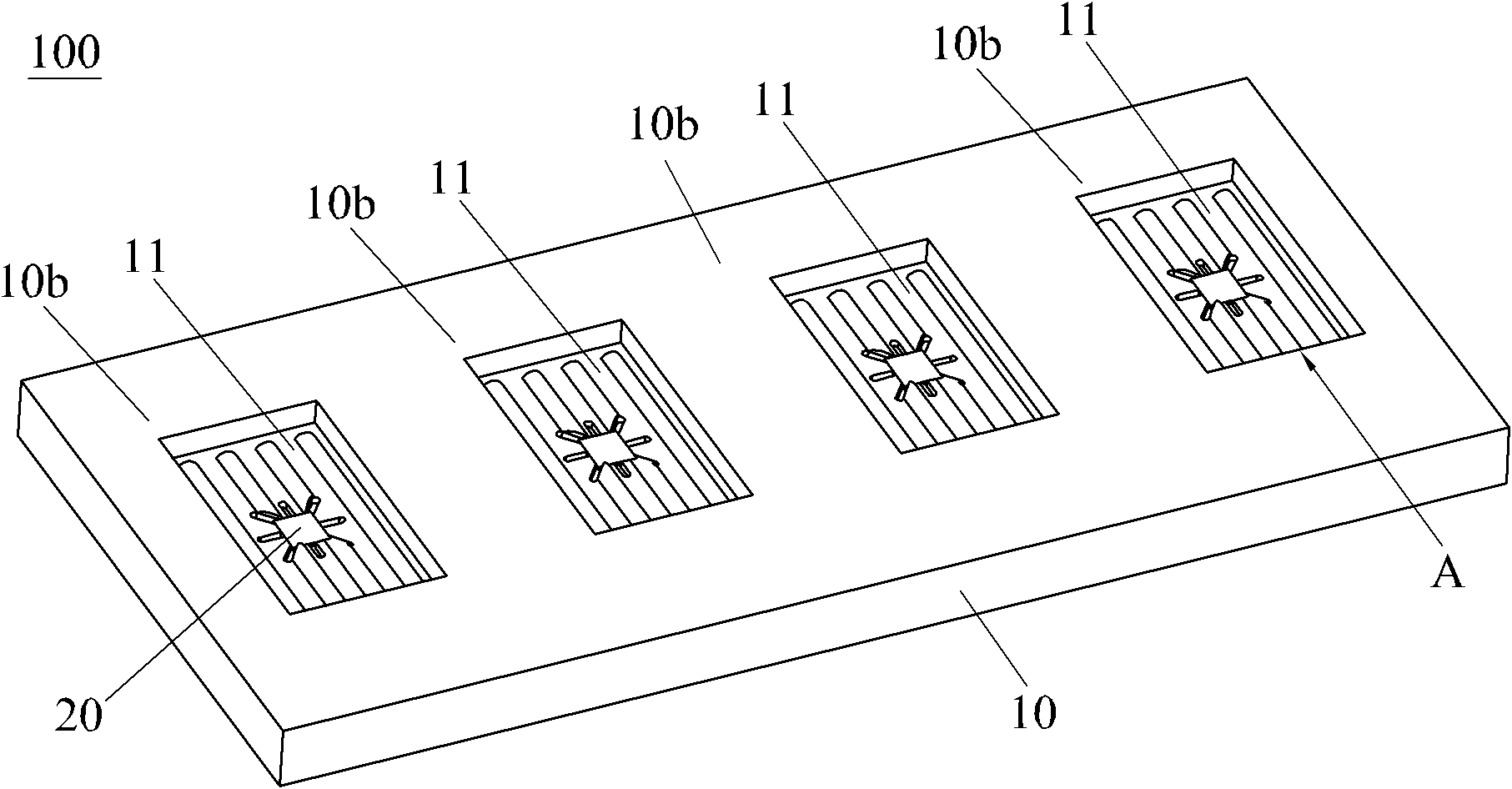

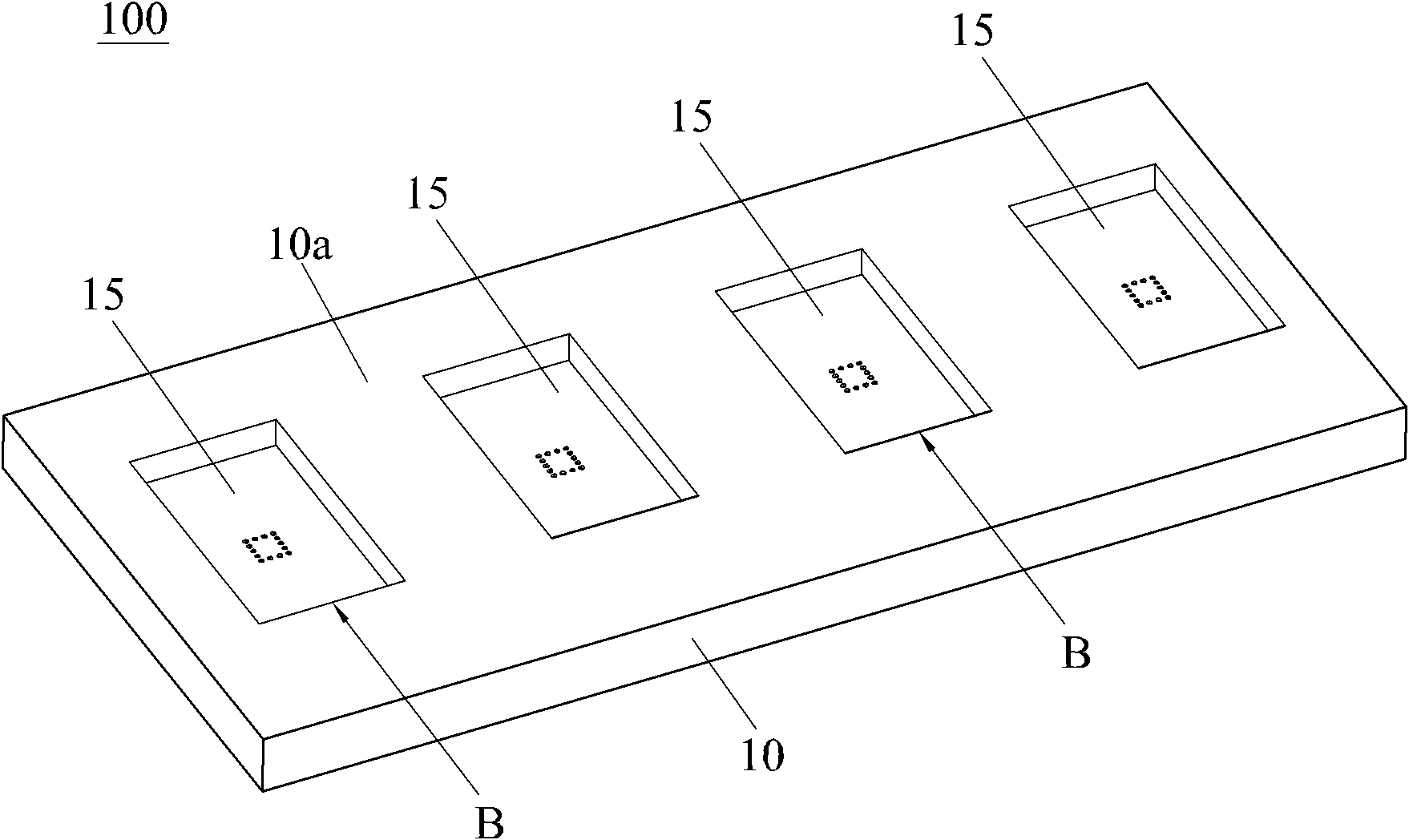

Construction method of ordinary steel bar and finished deformed bar mixed reinforcement assembled pier

ActiveCN108560423AGood self-resetting performanceImprove post-earthquake functionalityBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention discloses a construction method of an ordinary steel bar and finished deformed bar mixed reinforcement segmental assembled pier. The ordinary steel bar and finished deformed bar mixed reinforcement segmental assembled pier comprises a concrete bearing platform, a prefabricated segmental reinforced concrete pier body and two through longitudinal bars and an unbonded prestressed tendon, wherein the two through longitudinal bars and the unbonded prestressed tendon are used for connecting each prefabricated segment. Metal corrugated pipes are placed in the bearing platform and the prefabricated segmental pier body to reserve pore passages; during construction, firstly, each prefabricated segmental pier body is vertically overlapped first, the unbonded prestressed tendon is made to penetrate into the pore passages reserved on the section and is tensioned, each segmental pier body is integrally connected, and mortar does not need to be grouted into the pore passages to seal thepore passages; secondly, ordinary steel bars and finished deformed bars vertically penetrate into the pore passages and pressure grouting is carried out on the pore passages; and thirdly, the mixed reinforcement segmental assembled pier is formed.

Owner:HENGQIN GONGE TECH CO LTD

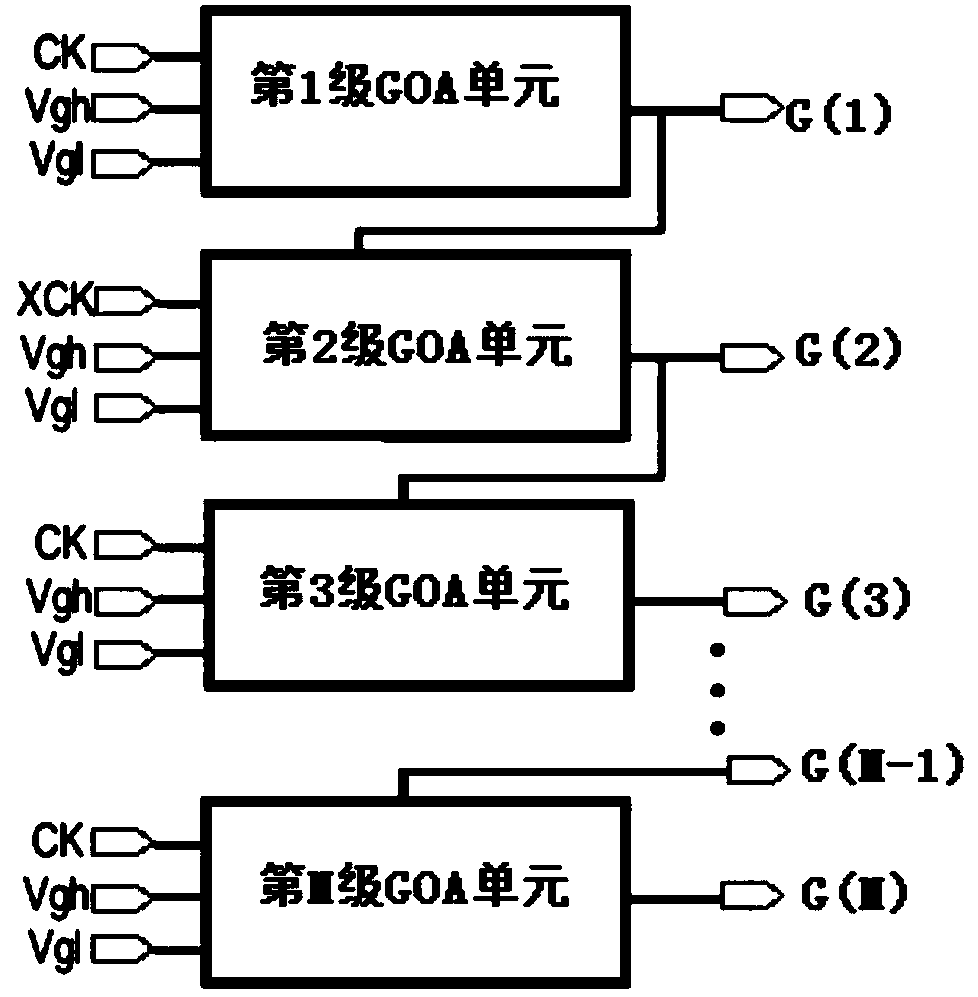

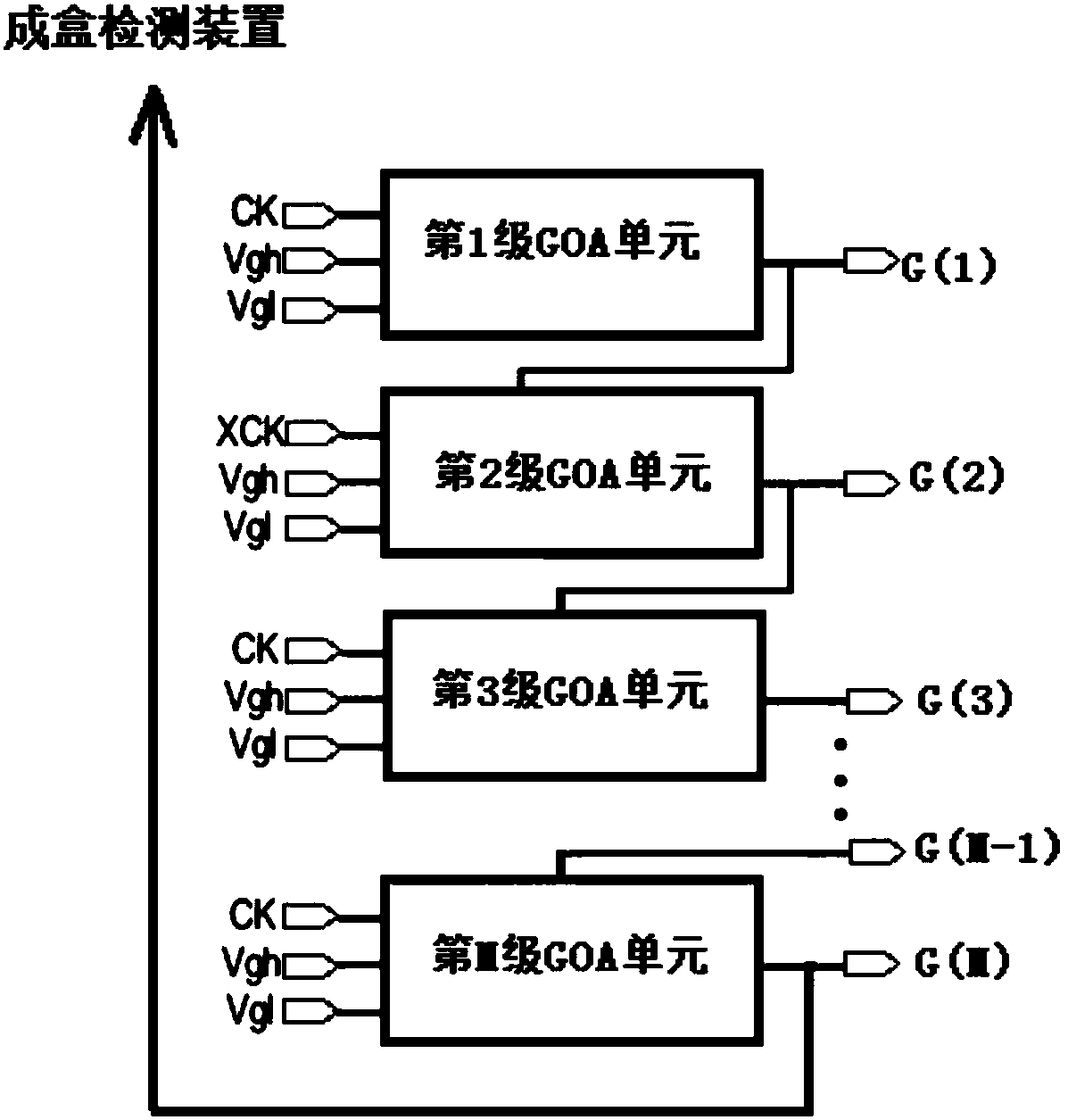

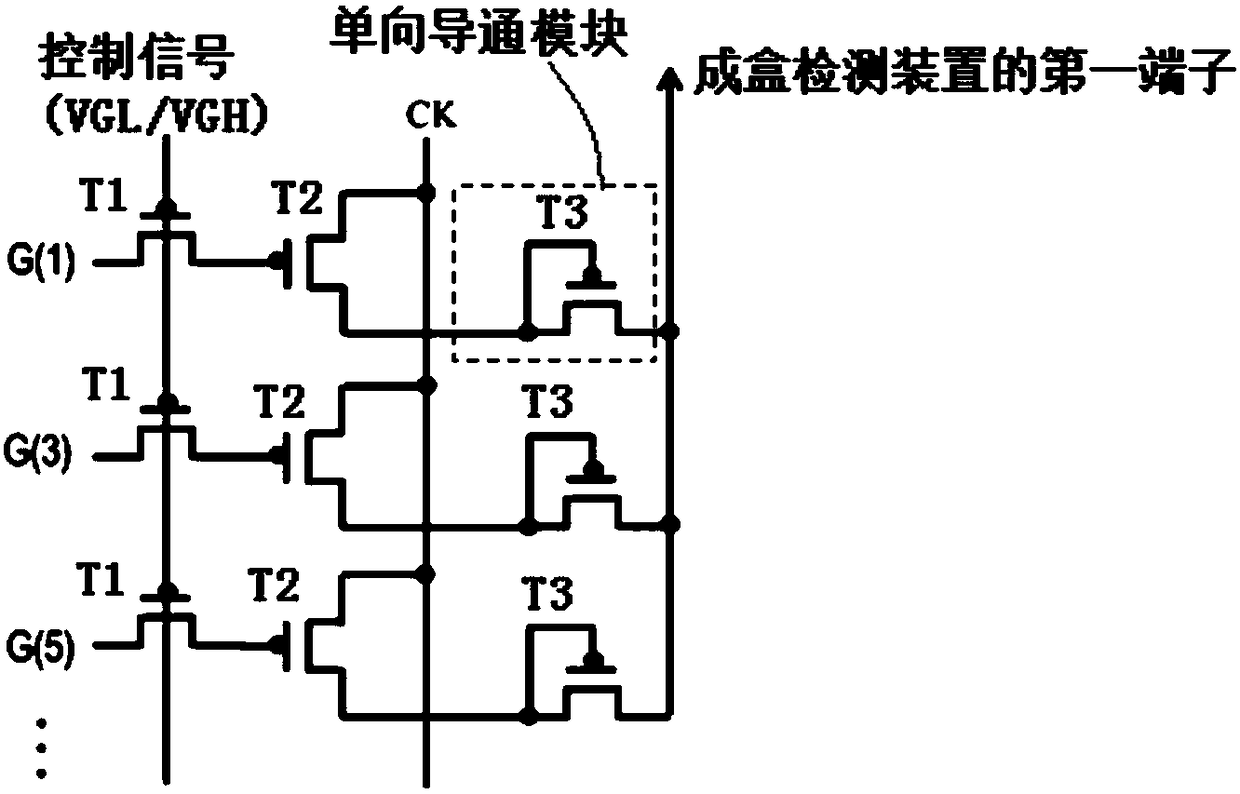

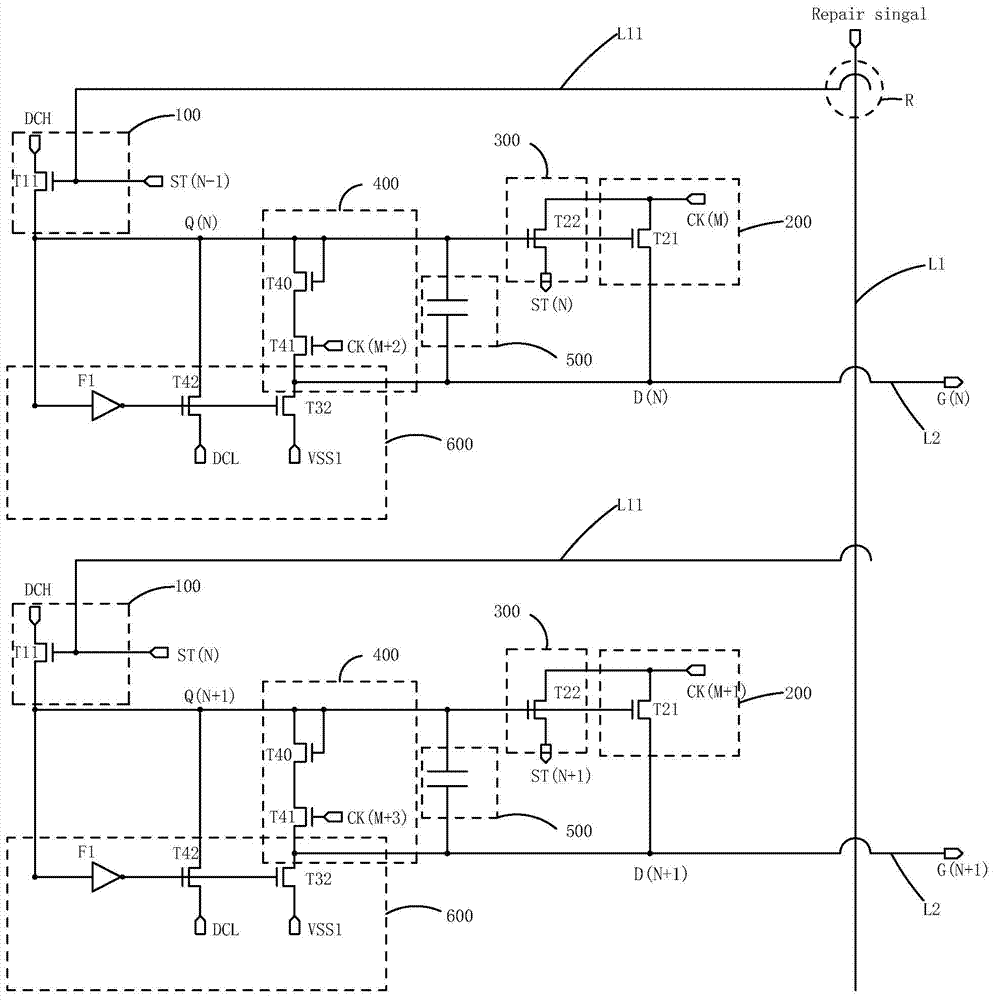

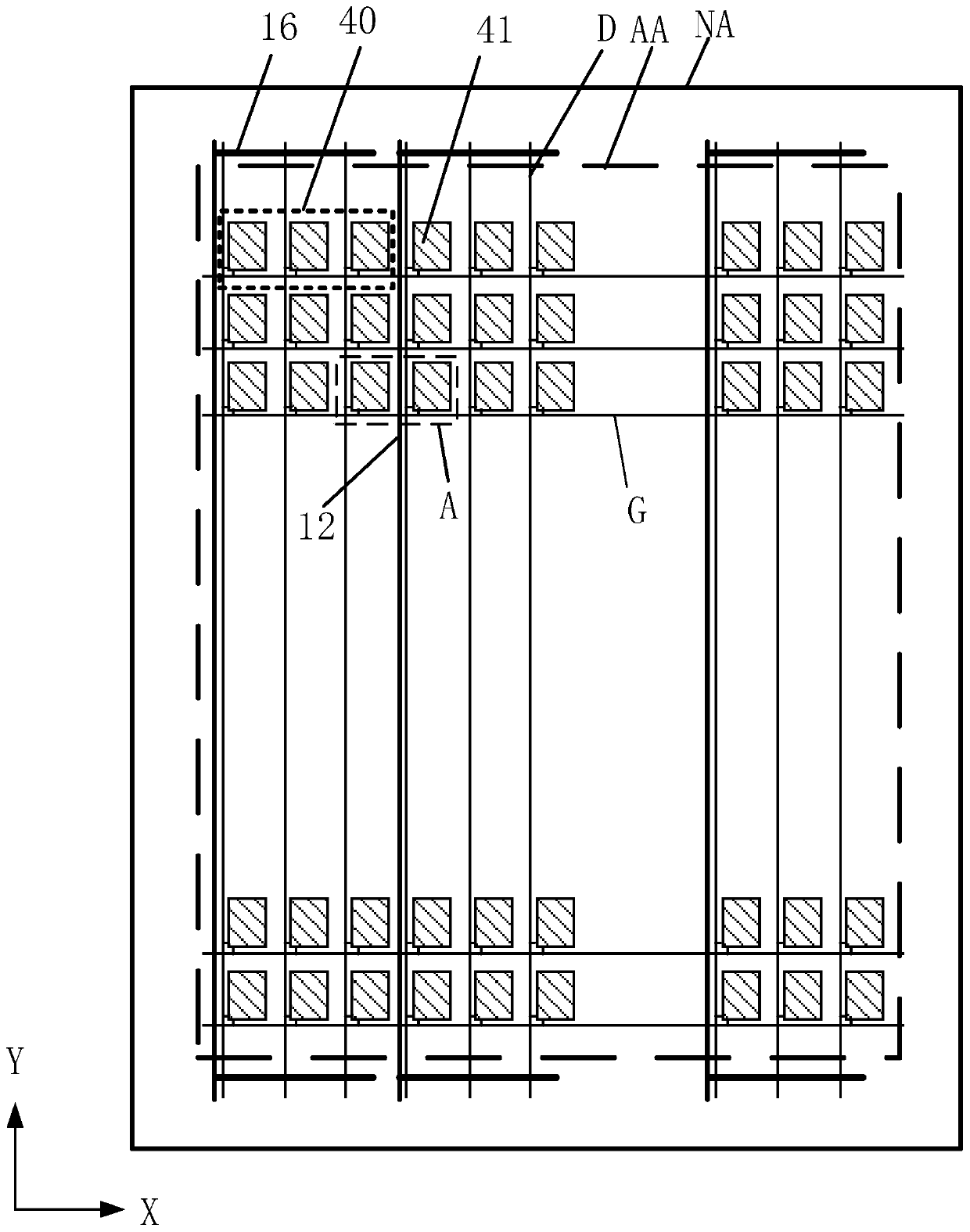

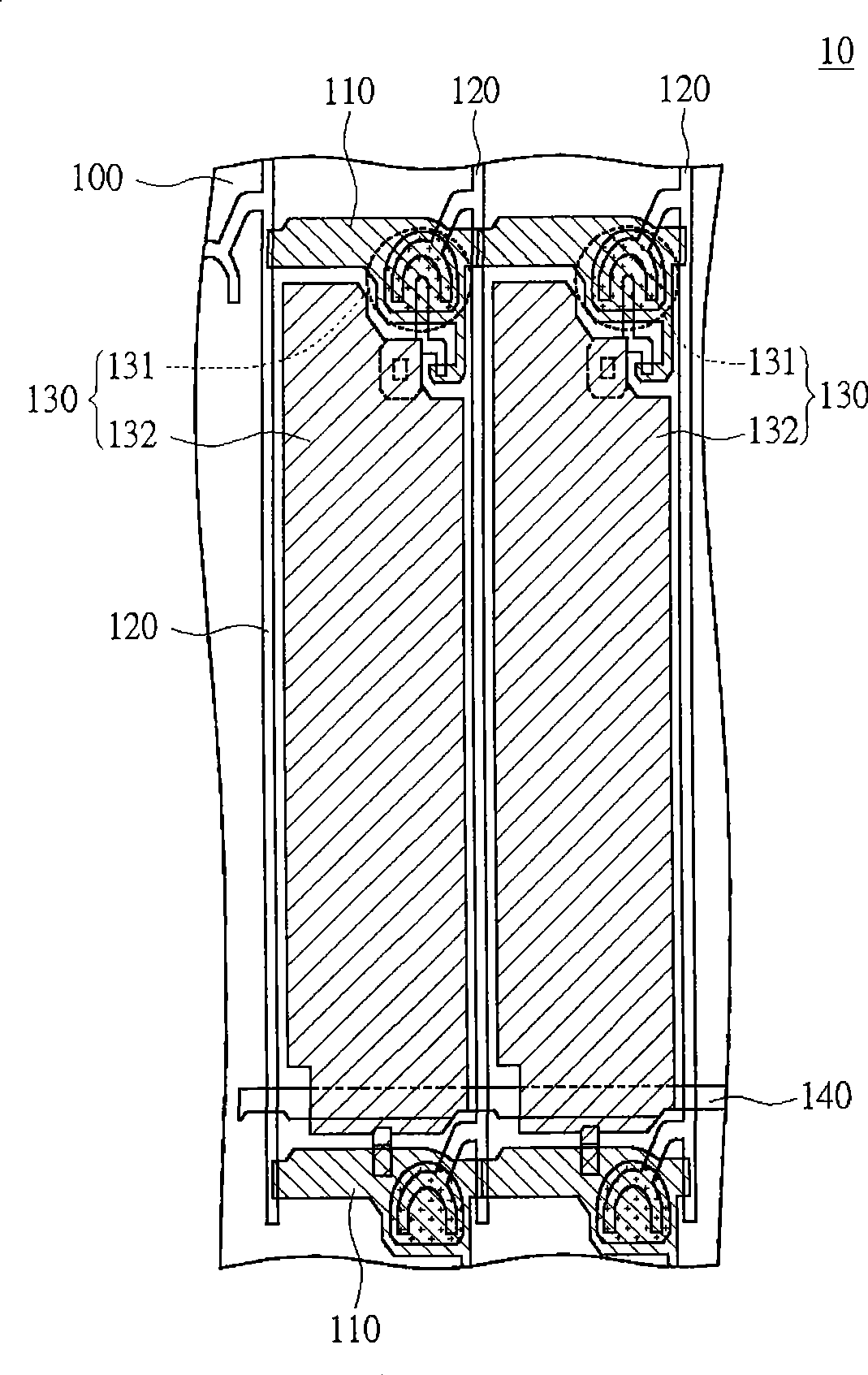

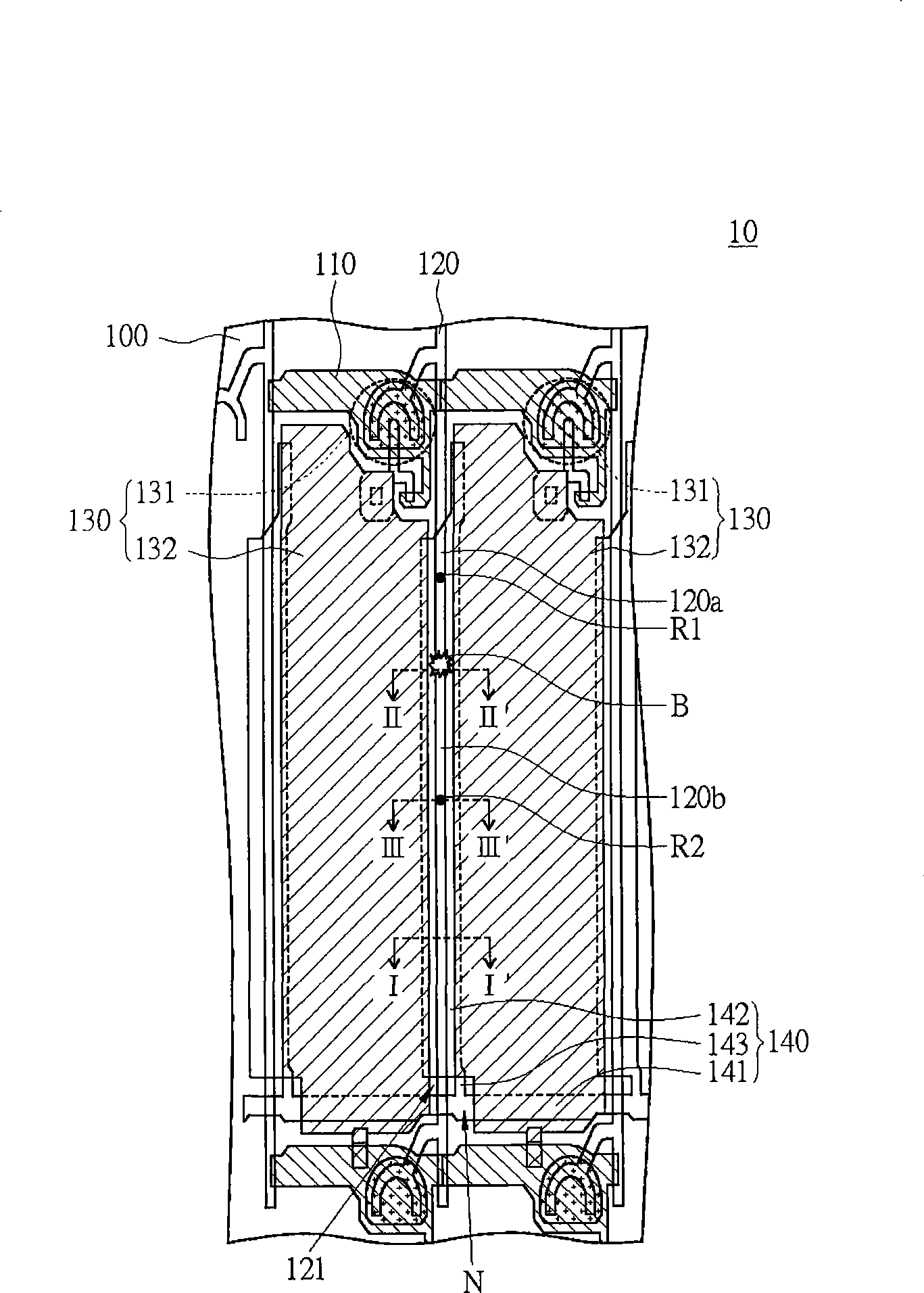

Circuit and method for detection of GOA circuit malfunction, and display panel

ActiveCN108269515AImprove anomaly detection rateReduce the difficulty of repairStatic indicating devicesAnomaly detectionControl signal

The present invention provides a circuit and a method for detection of GOA (Gate on Array) circuit malfunction, and a display panel. The circuit comprises: a plurality of first thin film transistors,a plurality of second thin film transistors and a plurality of unidirectional conduction modules allowing signals to perform unidirectional flowing; source electrodes and drain electrodes of the firstthin film transistors are respectively connected with an output end of a GOA circuit and gate electrodes of the second thin film transistors, and gate electrodes of the first thin film transistors are configured to access control signals configured to control on-off of the first thin film transistors; source electrodes of the second thin film transistors access clock signals or inverted clock signals, drain electrodes of the second thin film transistors are connected with a boxing detection device configured to perform signal detection; and drain electrodes of the first thin film transistorsare in one-to-one correspondence connection with gate electrodes of the second thin film transistors, and gate electrodes of the second thin film transistors are in one-to-one correspondence connection with the plurality of unidirectional conduction modules. The circuit and the method for detection of the GOA circuit malfunction, and the display panel can increase an anomaly detection rate of a GOA unit in the GOA circuit so as to reduce the repairing difficulty of the GOA circuit.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

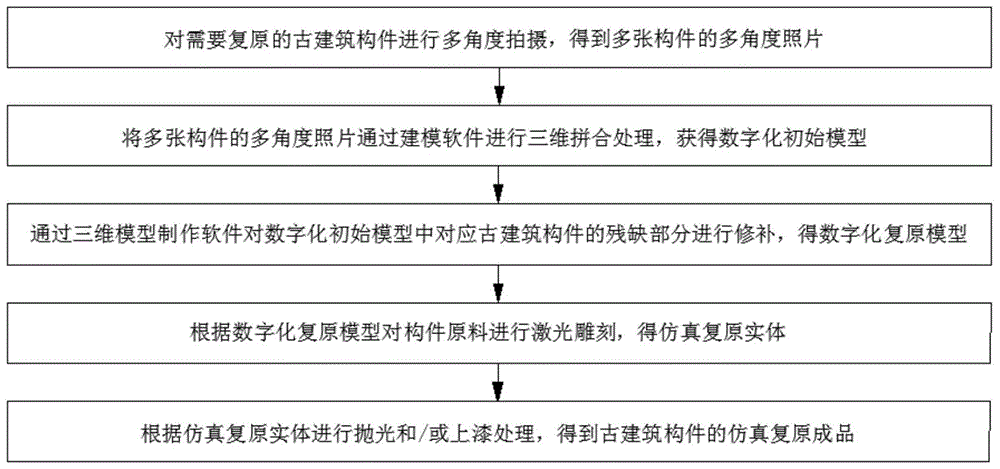

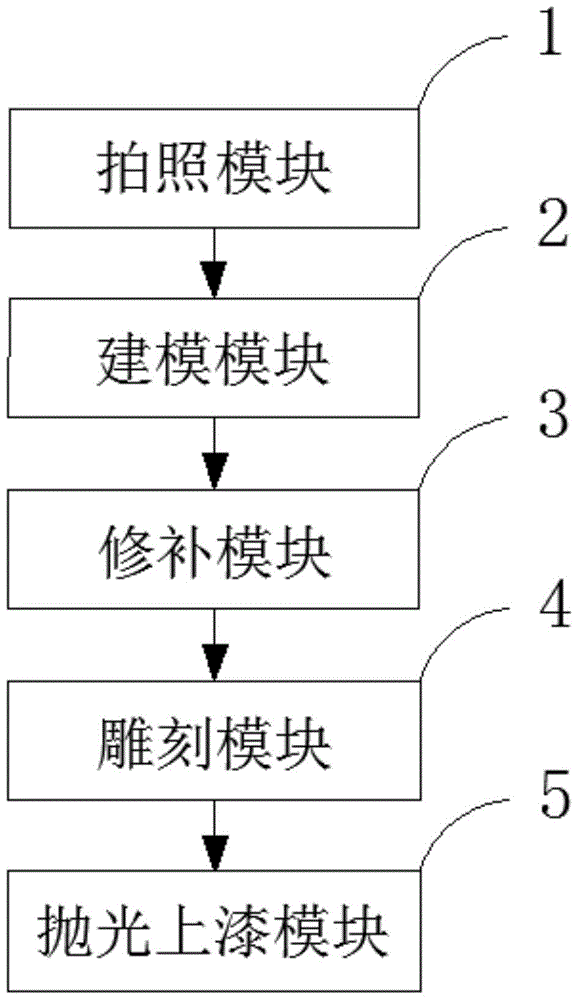

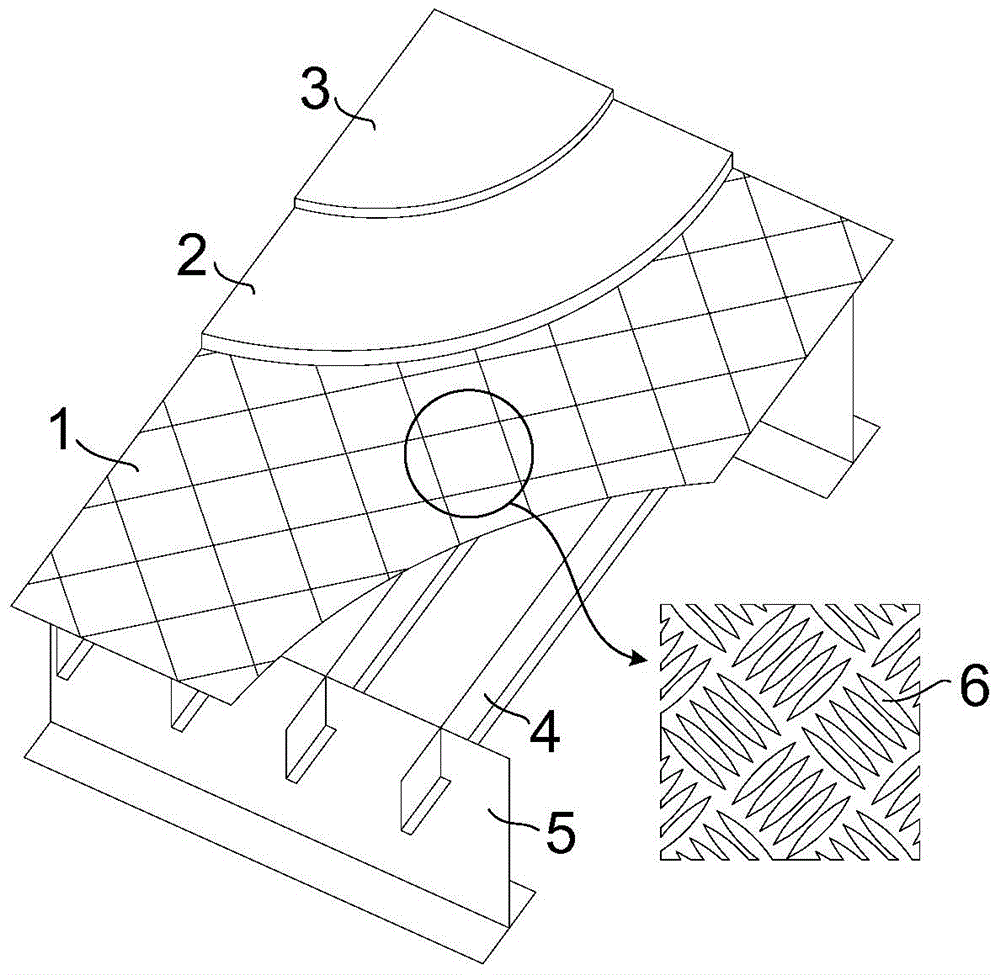

Simulation recovery system and method of historic building component

InactiveCN105741347AReduce manufacturing costImprove repair efficiency3D-image rendering3D modellingModeling softwareLaser engraving

The invention relates to a simulation recovery system and method of a historic building component. The method comprises the following steps: carrying out multi-angle shooting on the historic building component which needs to be recovered to obtain a plurality of multi-angle photos of the historic building component; carrying out three-dimensional split processing on the plurality of multi-angle photos of the historic building component through modeling software to obtain a digitized initial model; through three-dimensional model manufacture software, repairing the missing part of the corresponding historic building component in the digitized initial model to obtain a digitized recovery model; according to the digitized recovery model, carrying out laser engraving on the raw materials of the historic building component to obtain a simulation recovery entity; and according to the simulation recovery entity, carrying out polishing and / or painting processing to obtain a simulation recovery finished product of the historic building component. Compared with the prior art, the simulation recovery system and method can show texture characteristics and colors, is low in manufacture cost, is free from the restriction of height where the historic building component is positioned, and can meet bath quick surveying and mapping and simulation recovery requirements of the historic building.

Owner:GUILIN UNIV OF ELECTRONIC TECH

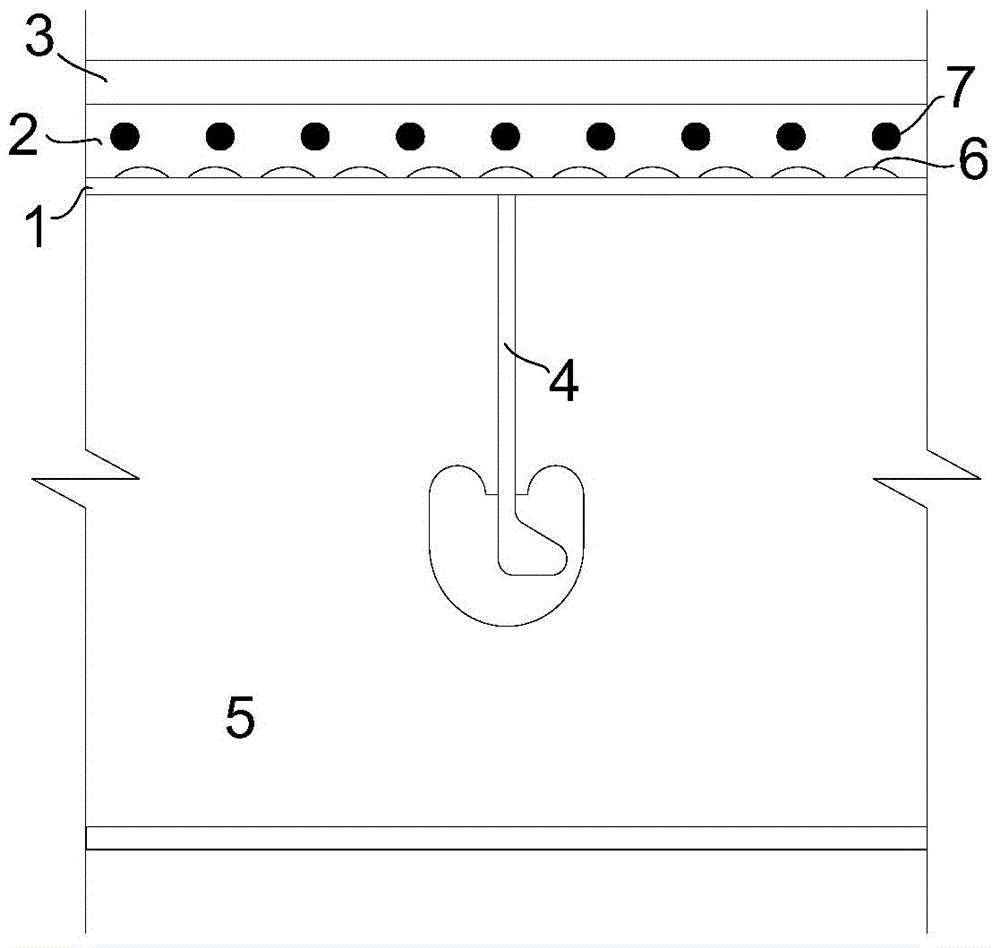

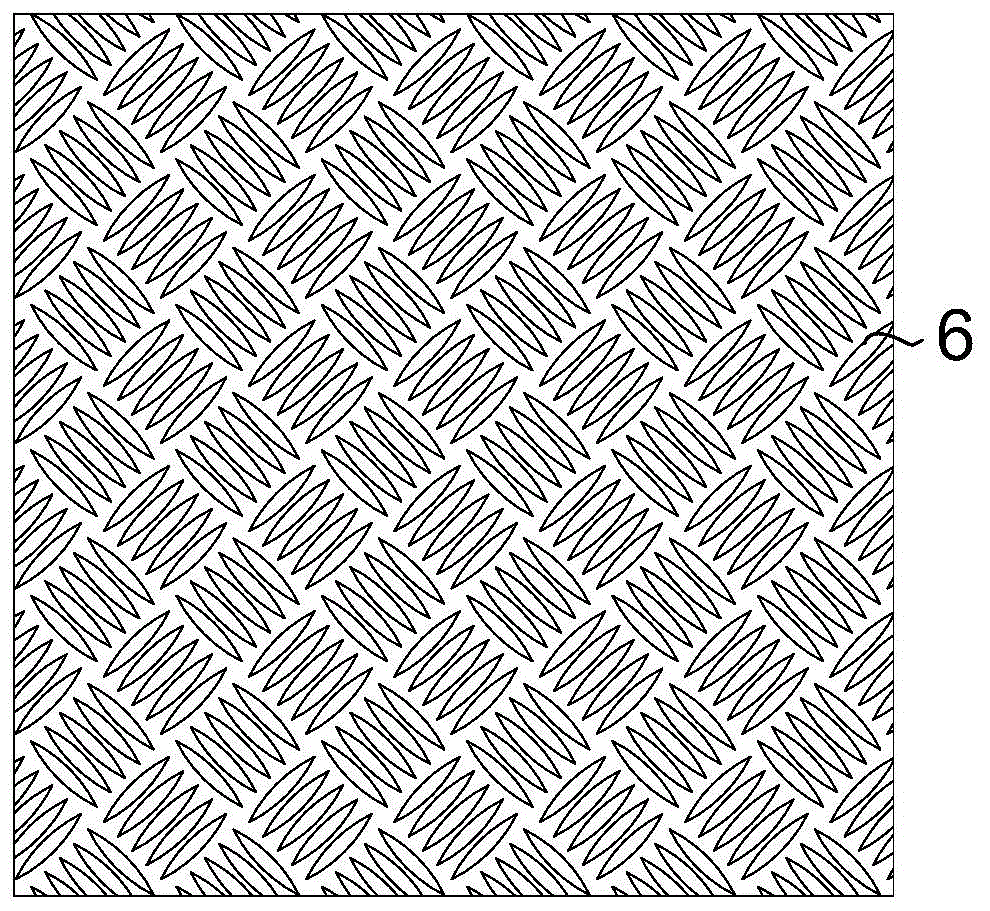

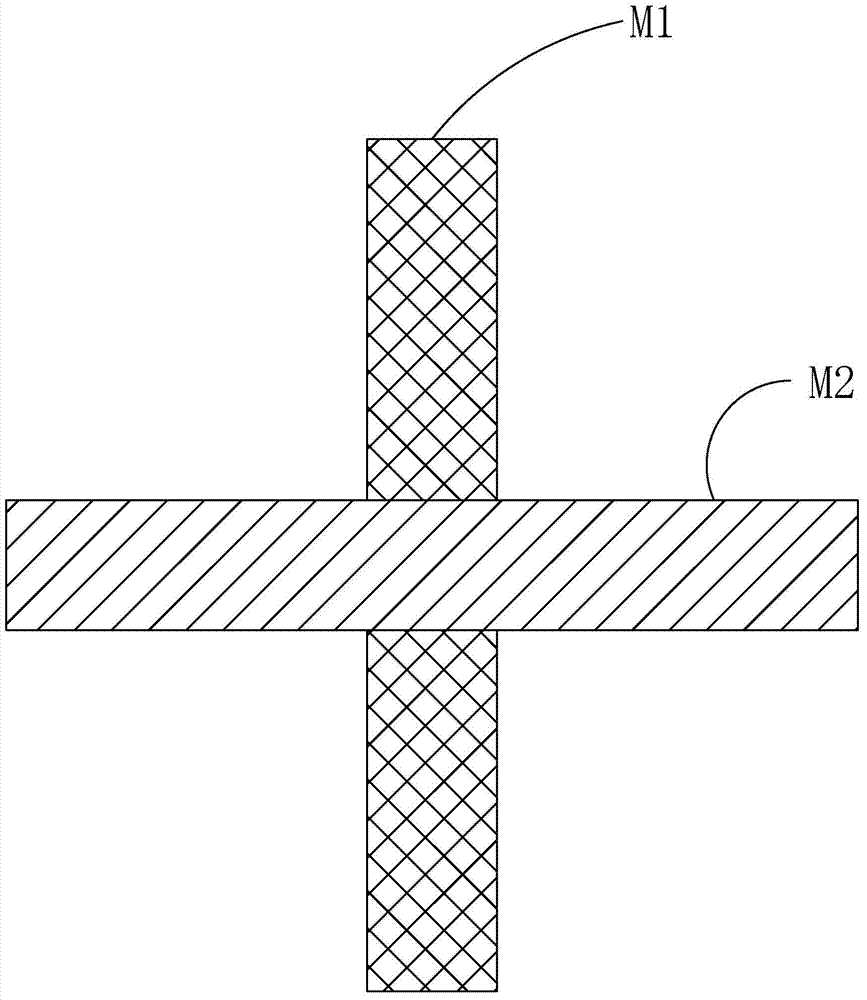

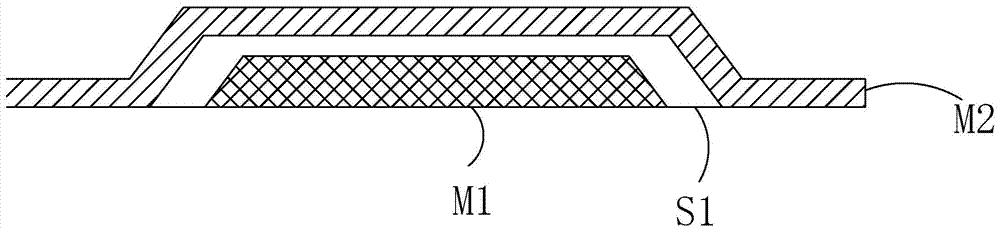

Connector-free steel and ultrahigh-performance concrete combined bridge deck structure and construction method thereof

InactiveCN104631319AAvoid connectionReduce the difficulty of repairBridge structural detailsBridge erection/assemblyBridge engineeringBridge deck

The invention belongs to the technical field of bridge engineering and relates to a connector-free steel and ultrahigh-performance concrete combined bridge deck structure and a construction method thereof. The bridge deck structure comprises a steel bridge deck slab, a bridge deck pavement layer is paved on an ultrahigh-performance concrete layer which is paved on the steel bridge deck slab; the upper surface of the steel bridge deck slab is provided with protruding lines, and the lower portion of the steel bridge slab is provided with longitudinal stiffening ribs and transverse stiffening ribs. Compared with a steel and ultrahigh-performance concrete combined bridge deck structure with welding stud connectors, the connector-free steel and ultrahigh-performance concrete combined bridge deck structure has the advantages that welding of a great quantity of shear connectors is avoided, and construction and repair difficulty of bridge decks can be lowered. Compared with a traditional orthotropic steel bridge deck structure, the connector-free steel and ultrahigh-performance concrete combined bridge deck structure has the advantage that technical problems of fatigue rupture of steel structures and proneness to damages of the pavement layers can be effectively solved according to the scheme. Moreover, the connector-free steel and ultrahigh-performance concrete combined bridge deck structure has the advantages of convenience in material acquisition, structural simplicity, quickness in construction, force reasonability and high technical and economical benefits.

Owner:TSINGHUA UNIV

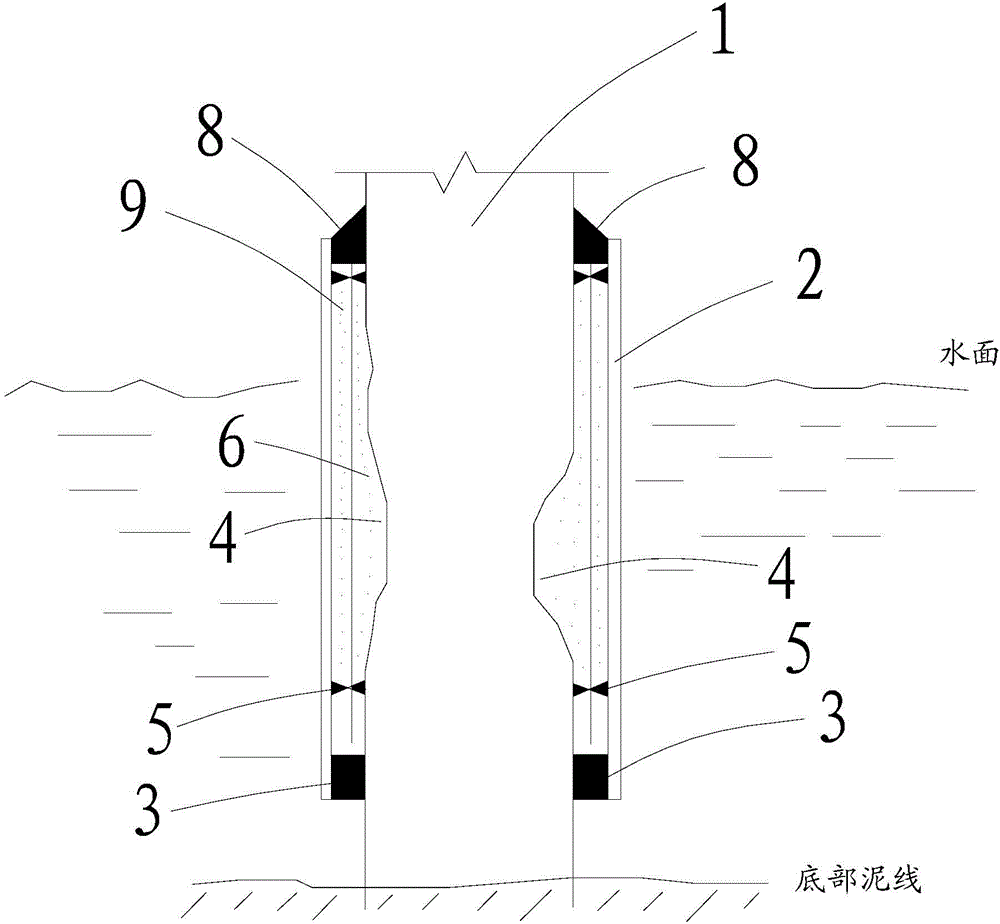

Reinforcing and protection system and repair method of hydraulic pile

InactiveCN104929165AReduce the difficulty of repairEasy constructionFoundation repairBridge erection/assemblyFiberSlurry

The invention relates to a reinforcing and protection system and a repair method of a hydraulic pile. The system comprises a sleeve which surrounds a damage area of the pile, a sealing strip attached to the pile is arranged at the bottom of the sleeve, the inside, surrounding the damage area of the pile, of the sleeve is wrapped with a fiber grid, a stopper is arranged between the inside of the sleeve and the pile, and the space between the sleeve and the pile is filled with a slurry. The method is realized by the aid of the system. The construction is simple, the repair difficulty is effectively reduced, and the construction period is shortened.

Owner:ZHANGJIAGANG YINGHUA MATERIAL TECH CO LTD

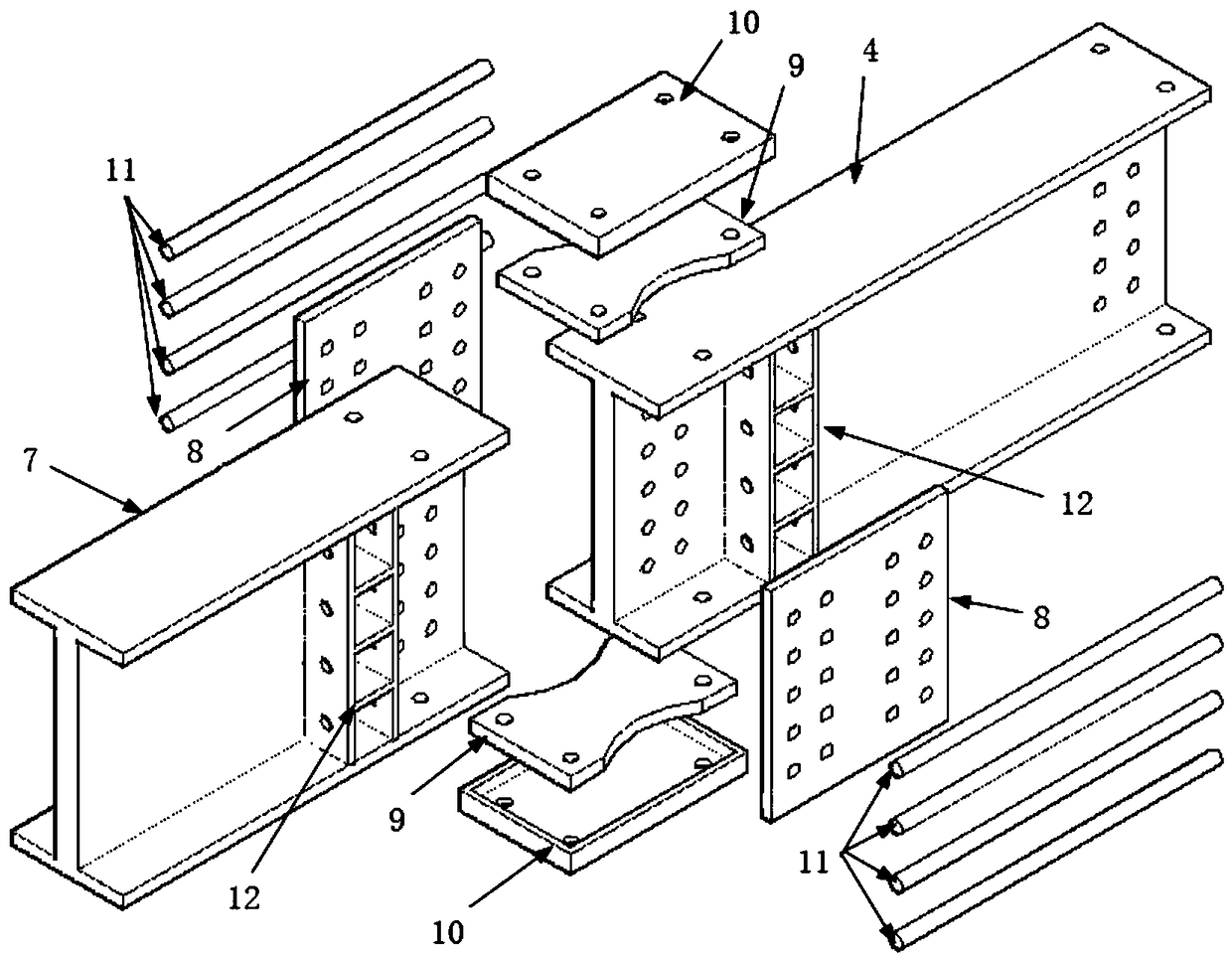

Assembly type joint based on austenite SMA-steel plate set and martensite SMA bars

ActiveCN109057026AImprove the problem of brittle failureGood self-resetting performanceProtective buildings/sheltersShock proofingSteel frameMartensite

The invention discloses an assembly type joint based on an austenite SMA-steel plate set and martensite SMA bars. The joint comprises I-shaped steel beams, friction type high-strength bolts, high-strength steel rectangular end plates, dog bone type connecting steel plates, austenite SMA dog bone type connecting plates, austenite SMA dish-shaped springs, the martensite SMA bars and anchoring blocks. The upper and lower flanges of the steel beams are connected with the friction type high-strength bolts through the steel-SMA dog bone type connecting plate set, and webs of the steel beams are connected with the high-strength rectangular end plates through the martensite SMA bars. Furthermore, one end of each martensite SMA bar is fixed to the corresponding anchoring block on the web of each steel beam through a thread, and the other end of each martensite SMA bar is fixed through the corresponding high-strength bolt and a nut, wherein pretightening force is exerted on the other end of eachmartensite SMA bar. With the SMA-steel plate set, the restorability of the joint is improved; with the martensite SMA bars, the energy dissipation capacity of the joint is improved; through simple heating, deformation recovery after an earthquake can be realized; the joint is applied to a steel frame for resisting to the earthquake to obviously improve the earthquake-proof performance of a structure, and lowers repairing difficulty and repairing costs.

Owner:HUNAN UNIV

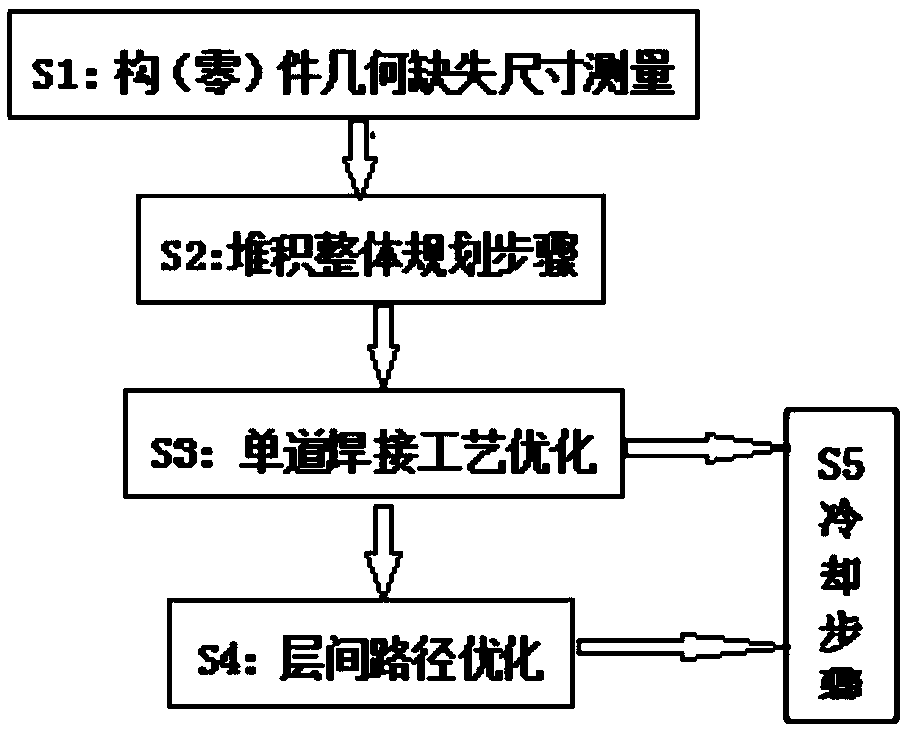

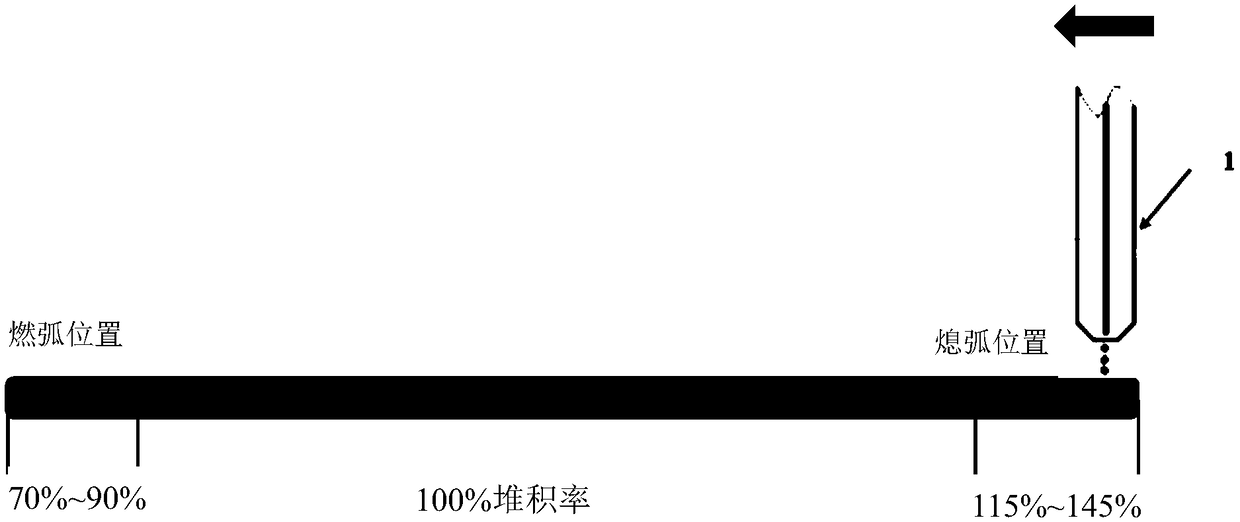

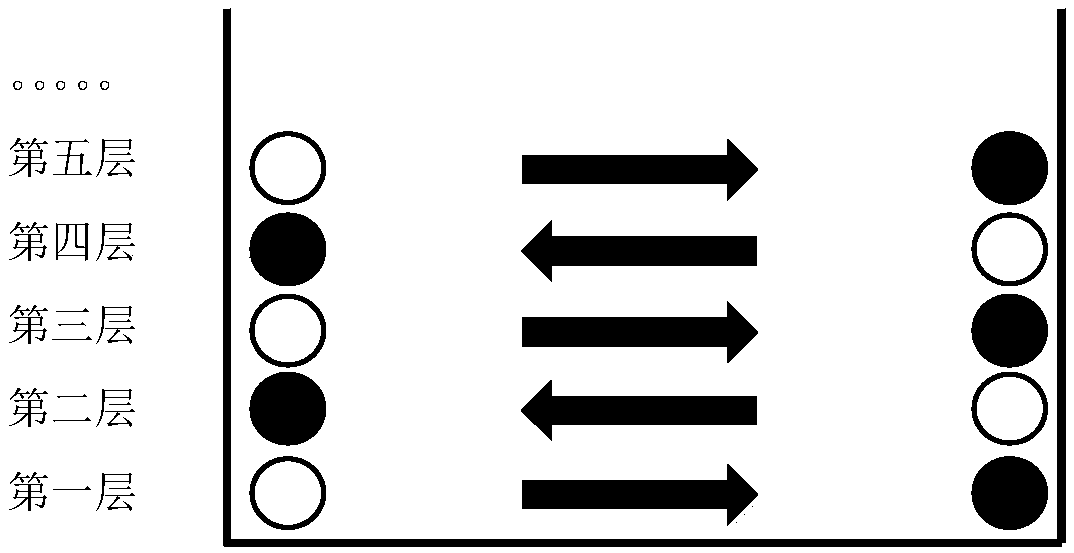

Fracture plate metal inert-gas (MIG) arc welding additive remanufacturing method

InactiveCN108941858AGeometry quick recoveryReduce heat accumulation effectElectrode supporting devicesQuenchingSingle pass

The invention discloses a fracture plate metal inert-gas (MIG) arc welding additive remanufacturing method. The fracture plate MIG arc welding additive remanufacturing method comprises the first stepof measuring the geometrical defect size of a component / part, specifically, the defect size of the fracture part is measured, and the three-dimensional defect size of the fracture part is obtained; the second step of total planning of piling, specifically, by combining the three-dimensional defect size of the fracture part, according to piling heights and widths under different welding piling rates, the number of single-layer weld passes and the number of layers are determined; the third step of optimizing a single pass welding process, specifically, the welding piling rate at the arc startingposition is reduced, and the welding piling rate and welding gun inverse motion at the arc quenching position are improved; the fourth step of optimizing an interlayer path, specifically, the pilingpaths of every two adjacent layers are opposite in moving direction; and the fifth step of cooling, specifically, in the whole welding process, water cooling and / or air cooling are / is carried out on the fracture piece in real time. By means of the method, rapid recovery of the geometric size of size damage of the fracture is achieved, the heat accumulation effect is reduced, the remanufacturing size precision and service performance are improved, the repairing difficulty is lowered, and maneuverability is high.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

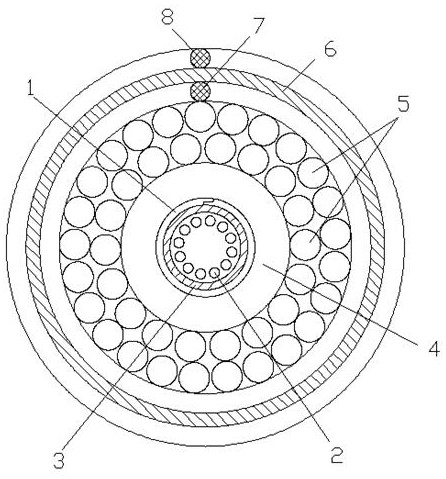

Submarine optical cable with optical unit longitudinally-wrapped copper strip structure and preparation method thereof

InactiveCN111913261AOptimize structureReduce dead weight and material costFibre mechanical structuresAdhesive glueLap joint

The invention discloses a submarine optical cable with an optical unit longitudinally-wrapped copper strip structure and a preparation method thereof, and the submarine optical cable comprises an optical unit, a copper strip, a sheath, an outer armored steel wire, a first PP rope, an asphalt spacing layer and a second PP rope, the surface of the optical unit is longitudinally wrapped by the copperstrip, and the sheath is arranged on the outer surface of the copper strip;the inner surface of the copper strip is partially or completely covered with an adhesive film. glue is arranged between theouter surface of the optical unit and the inner surface of the copper strip or the glue film for bonding, and the edges of the copper strip are partially overlapped for lap joint and fixation. By means of the mode, the sea optical cable of the optical unit longitudinally-wrapped copper strip structure and the preparation method thereof optimize a traditional feed type submarine optical cable structure, reduce self-weight and material cost without argon arc welding, achieve longitudinally-wrapped fixing and sealing of the copper strip on the surface of the optical unit through matching of theadhesive film and glue, ensures the strength and the sealing performance of the lap joint position, and reduces the copper strip repairing difficulty and the construction risk.

Owner:JIANGSU HENGTONG MARINE CABLE SYST CO LTD

Heavy rare earth metal target material repairing method

ActiveCN110373642ALower diffusion temperatureHigh densityVacuum evaporation coatingSputtering coatingRare earthHigh pressure

The invention provides a heavy rare earth metal target material repairing method and belongs to the technical field of magnetron sputtering surface treatment. The heavy rare earth metal target material repairing method comprises the following steps: filling the loss area of a to-be-repaired target material with alloy powder, and performing the repairing operation by adopting a vacuum sintering method or a high-pressure cold spraying method, wherein the alloy powder comprises a dysprosium-terbium alloy or one or two of dysprosium and terbium and one or two of metalloids. The heavy rare earth metal target material repairing method provided by the invention has the beneficial effects that the alloy powder is adopted as a repairing material; the repairing operation is performed by adopting thevacuum sintering method or the high-pressure cold spraying method; the alloy powder plays a role in brazing, and thus the sintering temperature during the follow-up target material repairing operation is reduced; furthermore, the diffusion temperature after the film coating operation on a magnetic sheet is reduced, and the repairing difficulty and cost are reduced; according to the structure of the target material repaired through the heavy rare earth metal target material repairing method, the problem that the existing target surface cannot be reused after being defective is effectively solved; and the process is simple, the cycle is short, the use effect is close to a new target material, and the application value is good.

Owner:BAOTOU JINSHAN MAGNETIC MATERIAL

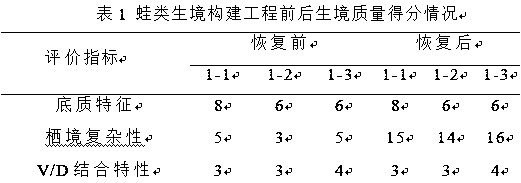

Cold region abandoned sand yard amphibian degraded habitat restoring method

InactiveCN107581148AImprove Habitat QualityIncrease biodiversityClimate change adaptationCultivating equipmentsVegetationAmphibian

The invention discloses a cold region abandoned sand yard amphibian degraded habitat restoring method. The method comprises the following steps of 1 restoring scheme design, 2 geomorphic type modification, 3 rapid vegetation restoring and 4 ecological habitat building. The habitat quality of amphibians can be rapidly and effectively improved, then, the biological diversity of the water ecosystem is improved, the ecosystem functions are restored, and the method is low in cost, good in ecological benefits, and suitable for being used and popularized in regions seriously and physically disturbedby cold region rivers.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Orthogonal plywood shear wall-concrete core tube mixed lateral-load-resistance system

ActiveCN108708479AImprove side resistanceEliminate residual deformationWallsProtective buildings/sheltersLoad resistancePre stress

The invention relates to an orthogonal plywood shear wall-concrete core tube mixed lateral-load-resistance system. The system includes an orthogonal plywood shear wall, a concrete core tube, replaceable energy-dissipation connectors, a concrete foundation, prestressing swing supports, a first post-tensioned unbonded prestressing bar, a second post-tensioned unbonded prestressing bar, a first steelshim and a second steel shim. The orthogonal plywood shear wall is connected with the concrete core tube through the several replaceable energy-dissipation connectors, the concrete core tube is connected with the concrete foundation through the first steel shim, the second steel shim and the several prestressing swing support, the first post-tensioned unbonded prestressing bar runs through the concrete core tube longitudinally and is fixed by an anchorage device, and the first post-tensioned unbonded prestressing bar runs through the orthogonal plywood shear wall longitudinally and is fixed by an anchorage device and the second post-tensioned unbonded prestressing bar runs through the concrete core tube longitudinally and is fixed by an anchorage device. Compared with the prior art, the system can effectively reduce the damage of orthogonal plywood wallboards and concrete shear walls in an earthquake, energy-dissipation components are easily replaced, and the difficulty and cost of post-earthquake repair can be reduced.

Owner:TONGJI UNIV

Assembling multi-section beam steel frame capable of self-centering after earthquake

The invention discloses an assembling multi-section beam steel frame capable of self-centering after earthquake. An I-beam is connected with special-shaped columns of different forms through a web angle steel and a flange angle steel to form a connecting form of full bolts without weld seams; a middle I-beam is connected with an end I-beam through a web connecting plate and a high-strength silicone rubber plate to form a connecting form of full bolts without weld seams with good ductility and high energy consumption; a prestressed steel cable is applied at the connecting part of the full boltswithout the weld seams of the middle I-beam and the end I-beam to form self-centering nodes after the prestressed earthquake, and after the nodes are connected in sequence, a precast concrete-profiled steel plate composite slab or a poured concrete slab is assembled to form an assembling multi-section beam steel frame structure system capable of self-centering after the earthquake.

Owner:BEIJING UNIV OF TECH

GOA circuit repairing method

ActiveCN104766581AReduce the difficulty of repairImprove yieldStatic indicating devicesControl signalEngineering

The invention provides a GOA circuit repairing method. Through a repairing signal line (L1), Repair signals are connected into an <N>th-level and <N + 1>th-level GOA unit circuits and are used as output signals of the <N>th-level GOA unit circuit and scanning control signals of the <N + 1>th-level GOA unit circuit respectively to achieve repairing of the <N>th-level GOA unit circuit, or through a starting signal line (L5), starting signals (STV) are connected into the <N + 1>th-level GOA unit circuit and an <N + 2>th-level GOA unit circuit and are used as output signals of the <N + 1>th-level GOA unit circuit and scanning control signals of the <N + 2>th-level GOA unit circuit respectively to achieve repairing of the <N + 1>th-level GOA unit circuit respectively, meanwhile, through the repairing signal line (L1), Repair signals are connected into the <N + 2>th-level and <N + 3>th-level GOA unit circuits and are used as output signals of the <N + 2>th-level GOA unit circuit and scanning control signals of the <N + 3>th-level GOA unit circuit respectively to achieve repairing of the <N + 2>th-level GOA unit circuit, the repairing difficulty of the GOA circuits can be lowered, the yield of GOA products can be improved, and production cost is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Post-earthquake self-resetting assembled multi-section beam shear wall steel frame

InactiveCN109208774AImprove securityImprove seismic performanceProtective buildings/sheltersShock proofingShaped beamFloor slab

The invention discloses a post-earthquake self-resetting assembled multi-section beam shear wall steel frame, which is characterized in that a I-shaped steel beam is connected with different forms ofspecial-shaped columns through web angle steel and flange angle steel to form a weldless full-bolt connection mode; a middle I-shaped beam is connected with end I-shaped beams through web connecting plates and high-strength silicone rubber plates to form a weldless full-bolt connection mode with good ductility and strong energy dissipation ability; prestressed steel cables are applied to the junction of the weldless full-bolt middle I-shaped beam and the end I-shaped beams to form prestressed post-earthquake self-resetting nodes, and prefabricated concrete-profiled steel plate composite floorslabs or poured concrete floor slabs are assembled after the nodes are sequentially connected to form a post-earthquake self-resetting assembled multi-section beam shear wall steel frame structure system.

Owner:BEIJING UNIV OF TECH

Repair method for steel storage tank corrosion pit

InactiveCN105345388AReduce the difficulty of repairReduce the possibility of using open flamesMolten spray coatingFiberCarbon fibers

The invention relates to a repair method for a steel storage tank corrosion pit and belongs to the technical field of welding. A pit after repair comprises three parts, including aluminum for filling up the pit, an aluminum-sprayed erosion resistant coating on the inner surface and a carbon fiber sheet back-up coat on the outer surface. In the repair method, the aluminum for filling up the pit plays the roles of smoothing tank wall and facilitating construction of the erosion resistant coating in later period and delaying of tank wall corrosion because the erosion resistant coating is used as a positive pole after corrosion perforation; the aluminum-sprayed erosion resistant coating on the inner surface can isolate direct contact between stored matter and steel of the tank wall and play the roles of delaying or even stopping further erosion and protecting the tank wall; the carbon fiber sheet back-up coat on the outer surface plays the roles of solidifying the tank body and shearing internal pressure so as to prevent discarding of the storage tank caused by the fact that the tank wall is thinned and cannot bear internal pressure. The combined use of the three parts can lastingly and effectively protect and solidify the storage tank.

Owner:WUHAN UNIV

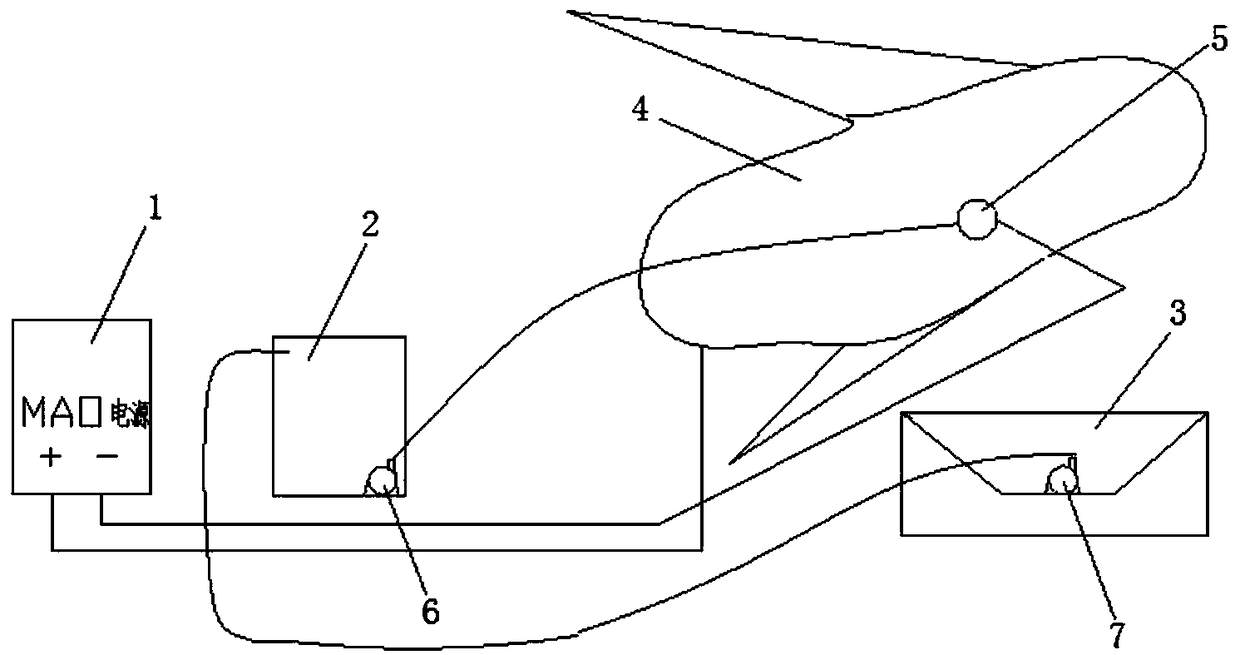

Local corrosion-resistant scanning type micro-arc oxidation treatment process and device for shipboard aircraft

InactiveCN109161948ANo pollution in the processPerfect surface modification technologyAnodisationMicro arc oxidationEnvironmental engineering

The invention discloses a local corrosion-resistant scanning type micro-arc oxidation treatment process for a shipboard aircraft. The process comprises the following steps: polishing and completely washing a to-be-repaired area of a part; setting an insulating layer on the edge of the to-be-repaired area and setting a flow guide glue strip in the to-be-repaired area; starting a scanning type micro-arc oxidation treatment device, uniformly spraying electrolyte in the to-be-repaired area to perform micro-arc oxidation reaction on the to-be-repaired area, generating a micro-arc oxidation ceramiclayer in the to-be-repaired area and turning off the scanning type micro-arc oxidation treatment device; cleaning the micro-arc oxidation ceramic layer and blow-drying with hot air. The process and the device are suitable for repairing the to-be-repaired part on site, the parts do not need to be disassembled, the repairing efficiency is improved, and the repairing difficulty is reduced.

Owner:XIAN TECHNOLOGICAL UNIV +1

Assembling multi-section beam center prestress support steel frame capable of self-centering after earthquake

The invention discloses an assembling multi-section beam center prestress support steel frame capable of self-centering after earthquake. An I-beam is connected with special-shaped columns of different forms through a web angle steel and a flange angle steel to form a connecting form of full bolts without weld seams; a middle I-beam is connected with an end I-beam through a web connecting plate and a high-strength silicone rubber plate to form a connecting form of full bolts without weld seams with good ductility and high energy consumption; a prestressed steel cable is applied at the connecting part of the full bolts without the weld seams of the middle I-beam and the end I-beam to form self-centering nodes after the prestressed earthquake, and after the nodes are connected in sequence, aprecast concrete-profiled steel plate composite slab or a poured concrete slab assembling prestress center support member is assembled to form an assembling multi-section beam center prestress support steel frame structure system capable of self-centering after the earthquake.

Owner:BEIJING UNIV OF TECH

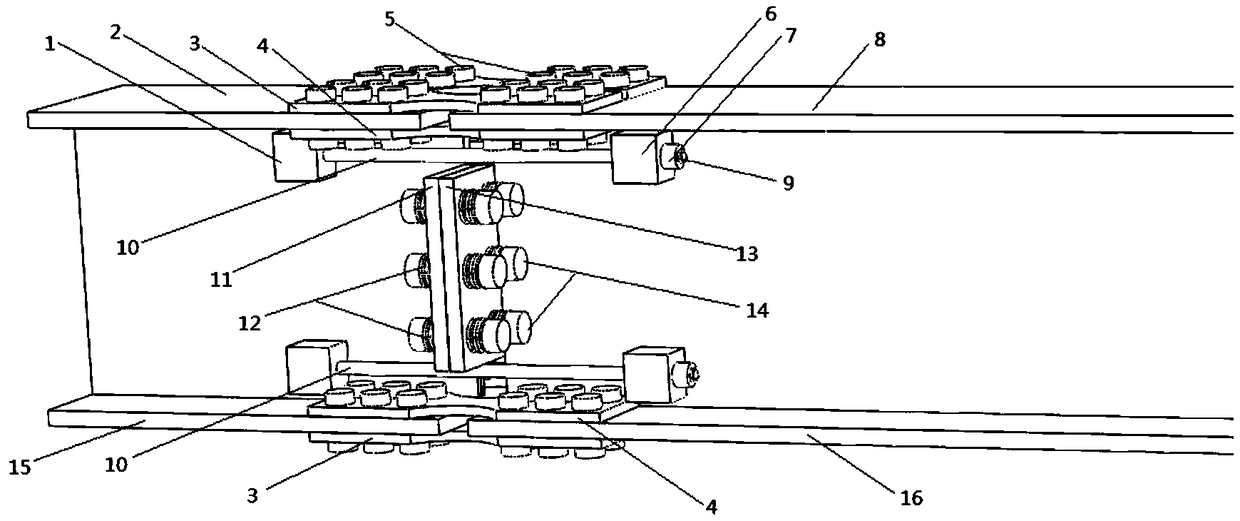

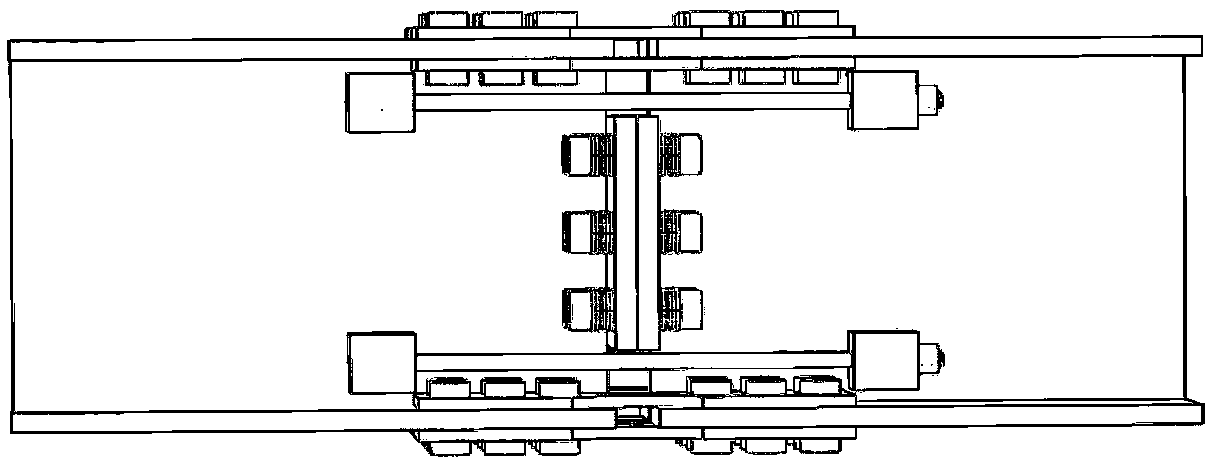

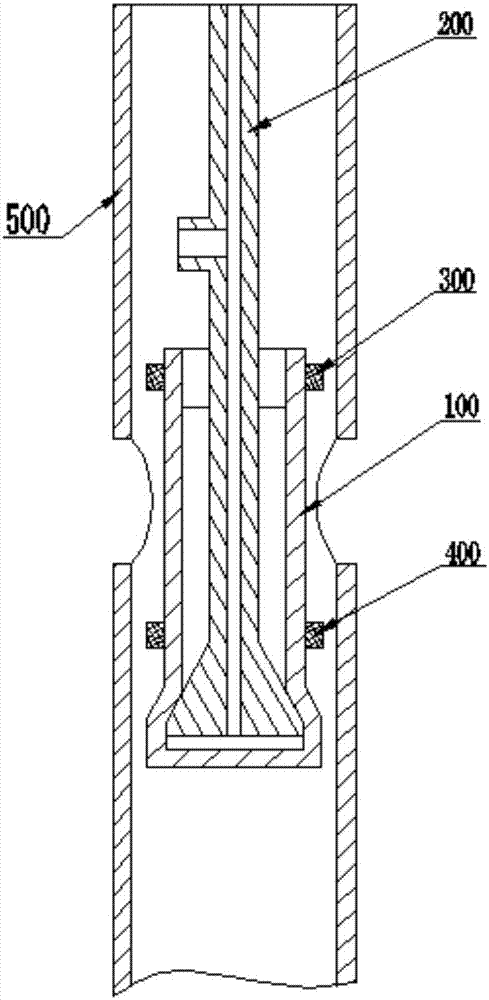

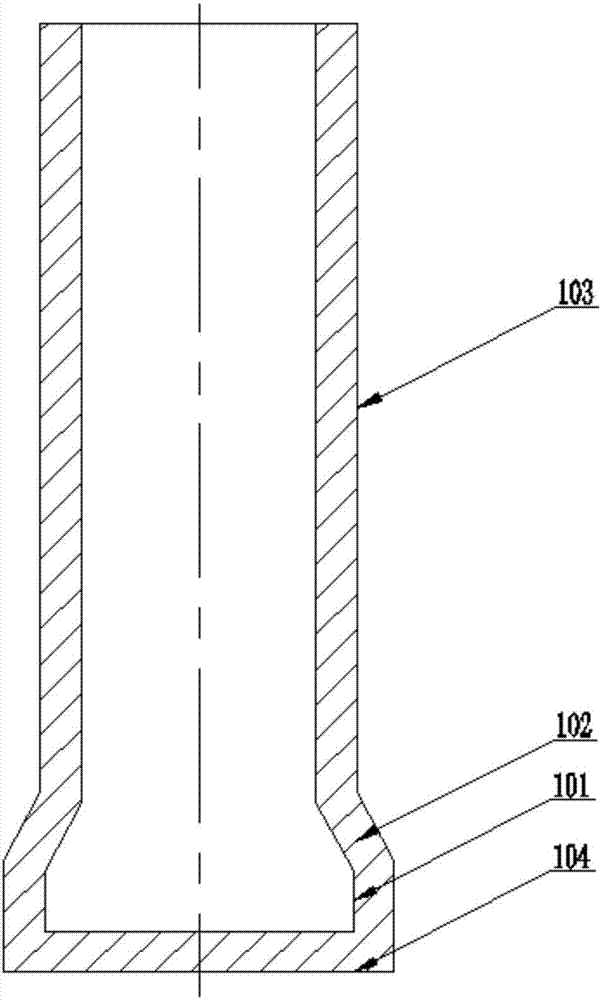

Casing damage well thin walled pipe patching device

InactiveCN107503701AReduce repair costsReduce the difficulty of repairBorehole/well accessoriesWell drillingEngineering

The invention discloses a casing damage well thin walled pipe patching device, and belongs to the technical field of casing pipe repair. The casing damage well thin walled pipe patching device comprises a patching pipe, an expansion cone of which the lower end is arranged inside the patching pipe, an upper sealing ring arranged at the upper end of the outer wall of the patching pipe and a lower sealing ring arranged at the lower end of the outer wall of the patching pipe, wherein a middle conical section of the expansion cone and a first conical section are matched with each other, high-pressure power liquid is injected into an inner cavity between the expansion cone and the patching pipe through a through hole formed in the center of the expansion cone, under driving of pressure difference force, the expansion cone moves to the upper portion of the patching pipe from the lower portion, the patching pipe continuously expands in the process that the expansion cone moves inside the patching pipe till the patching pipe is attached to the casing pipe, the patching pipe is permanently deformed under the effect of the expansion cone, and reinforcement of the thin walled pipe of a casing damage well and repair of loopholes are achieved. By the adoption of the upper sealing ring and the lower sealing ring, the sealing effect after the casing damage well is repaired is guaranteed, the repair cost and the repair difficulty of the casing damage well are lowered, and the well drilling cost is very obviously lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

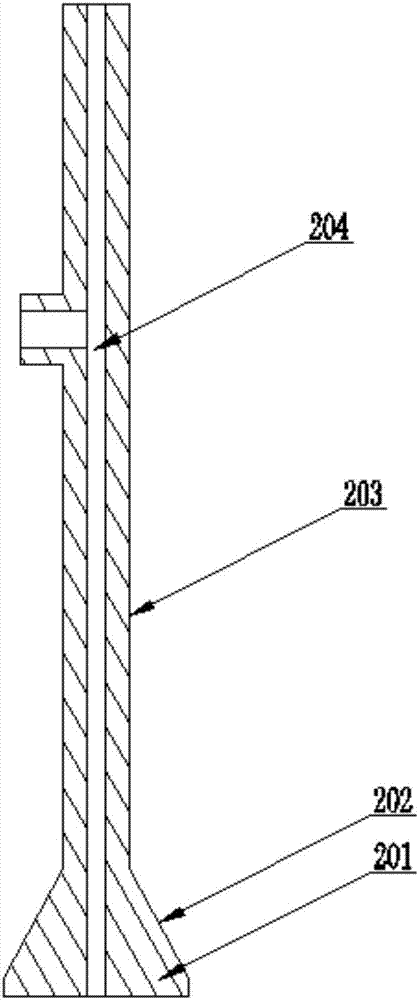

Repairing method of inner heat insulating layer

ActiveCN108115953APromote repairReduce the difficulty of repairCosmonautic thermal protectionFuselage insulationInsulation layerEngineering

The invention provides a repairing method of an inner heat insulating layer. By trimming the damaged portion of the inner heat insulating layer, machining the to-be-repaired contact face of the innerheat insulating layer, machining the inner heat insulating layer for repairing and filling, performing surface treatment, using a gap heat insulation material to perform gap filling, adhering a sealing heat insulation pad to the joint position of the to-be-repaired surface, and adhering two-side polytetrafluoroethylene to treat varnished glass cloth and the like to achieve repairing of the inner heat insulation layer. According to the repairing method of the inner heat insulating layer, repairing is convenient, repairing can be performed just trimming the inner heat insulation layer at the damaged position, it is not needed to disassemble and replace a whole heat insulating module, and therefore influences by devices in equipment are avoided, and the repairing difficulty and the repairingworkload are reduced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

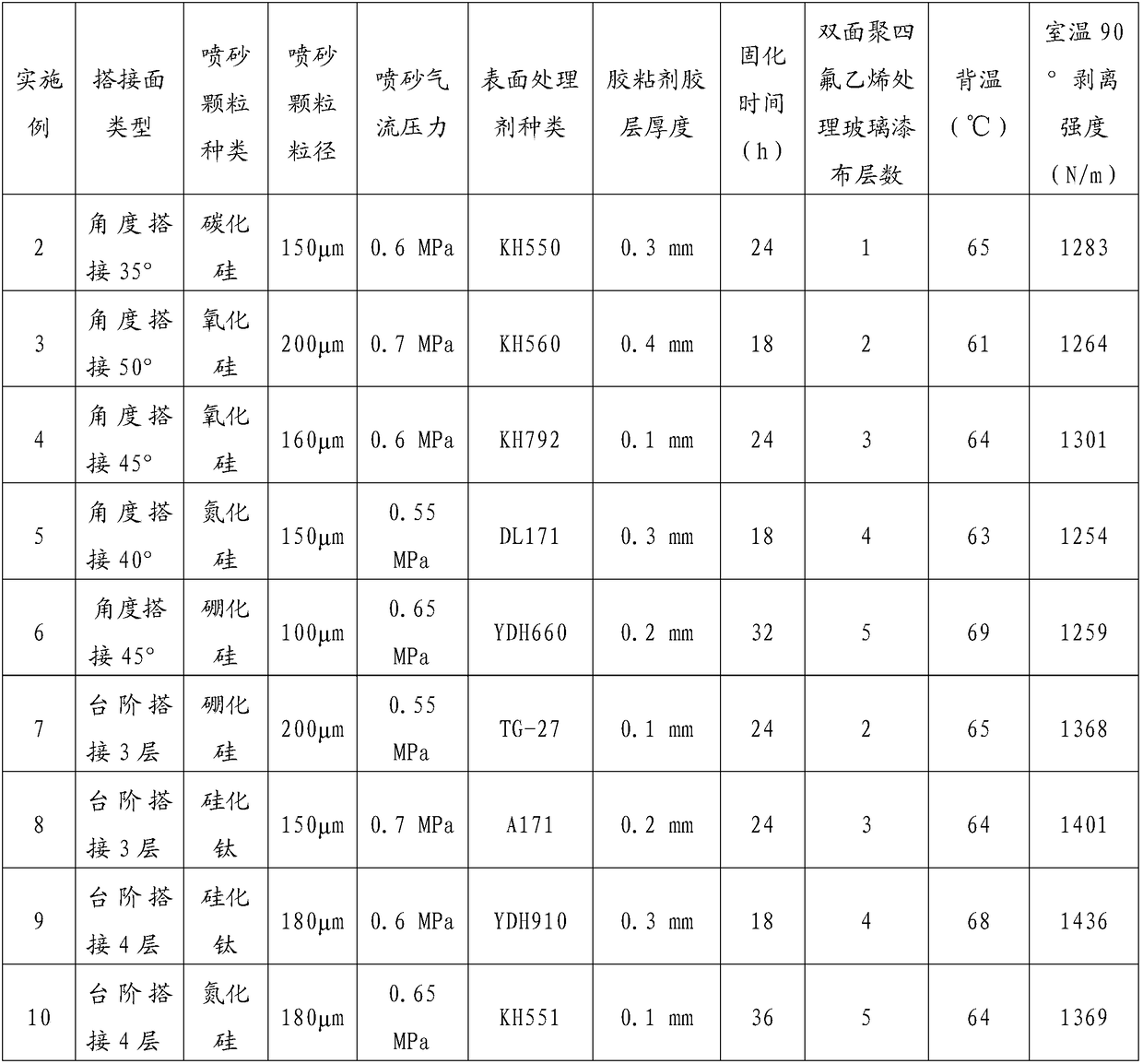

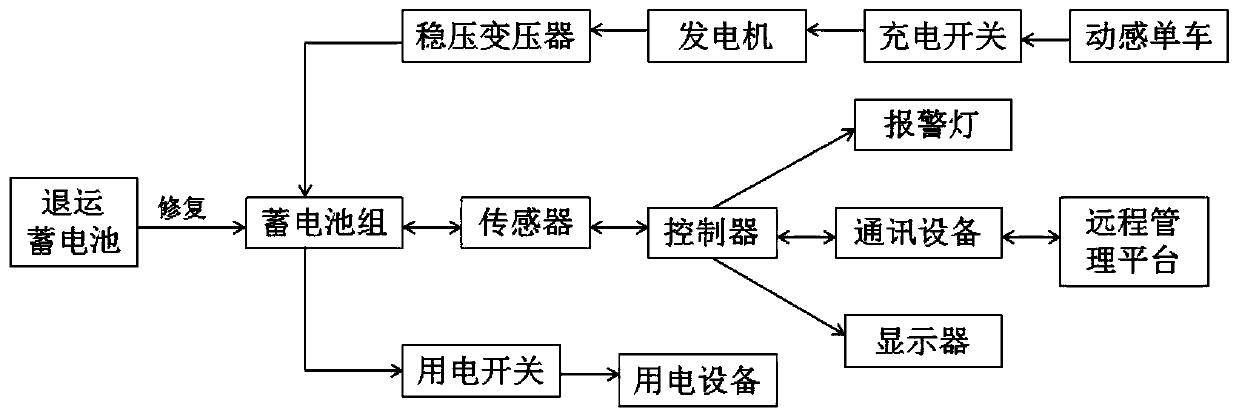

Substation retired storage battery detection and gradient utilization method

PendingCN111129622AAchieve recyclingReduce management costsWaste accumulators reclaimingSecondary cells servicing/maintenanceBattery chargeIntelligent management

The invention relates to a substation retired storage battery detection and gradient utilization method. The method comprises the steps: repairing a returned storage battery of a transformer substation as much as possible through various feasible methods; and then enabling the repaired battery to be connected to a monitoring platform and a remote operation platform, the charging platform is controlled to charge the storage battery and supply power to the power utilization terminal through scheduling of the remote operation platform; during the period, the monitoring platform monitors the stateof the storage battery in real time and can give an alarm for abnormal conditions, so maintenance and management of management personnel are facilitated. According to the method, repair and reutilization of the returned storage battery of the transformer substation are achieved to the maximum extent, the recycling application range and utilization rate of the returned storage battery are expanded, informationized and intelligent management of the storage battery is achieved, and good economic and social benefits are achieved.

Owner:孝感市光源电力集团有限责任公司

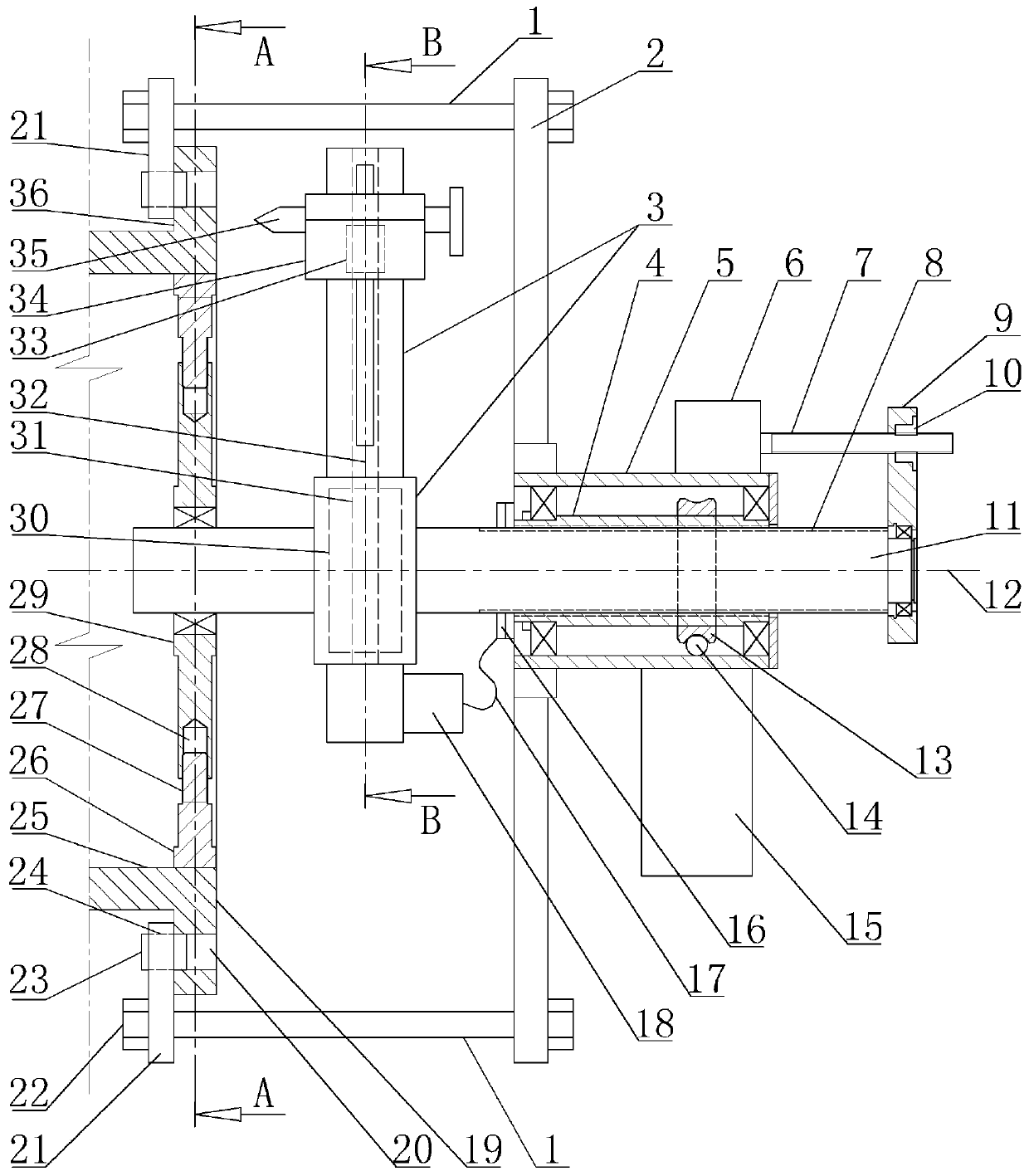

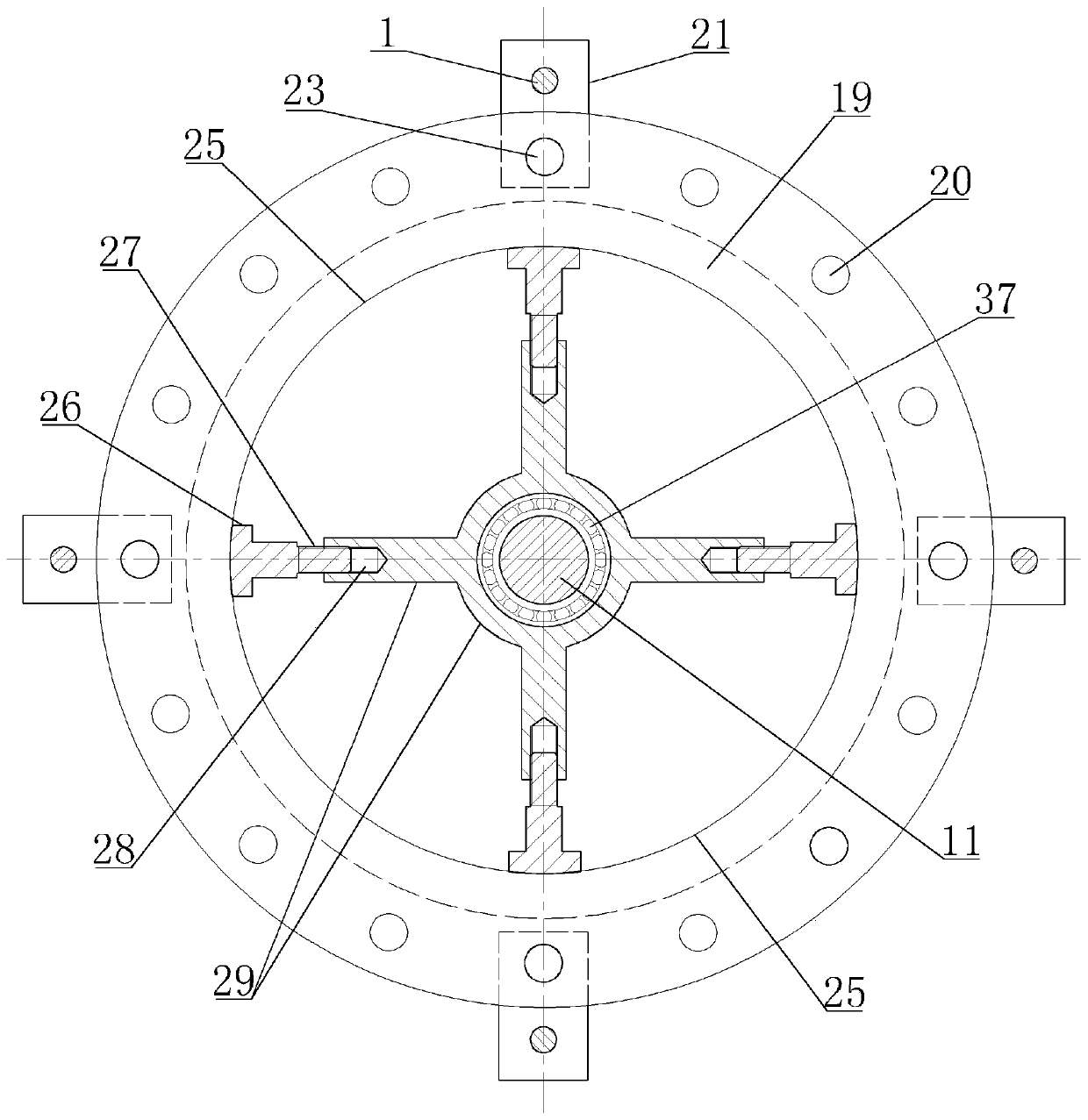

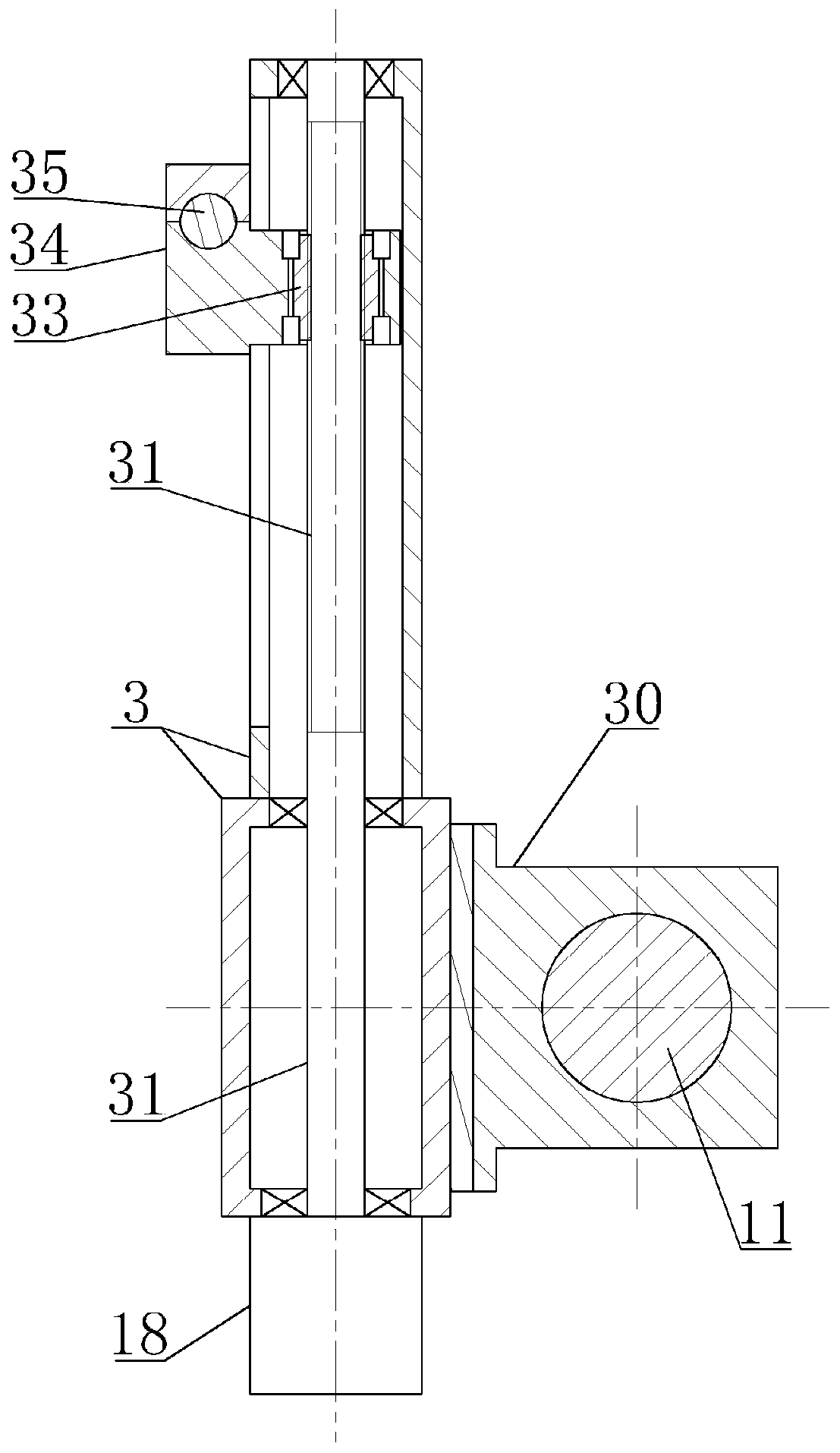

Double-support flange machining machine

PendingCN109986137AImprove support strengthReduce repair difficulty and repair costEdge surfaceDouble support

The invention discloses a double-support flange machining machine. The machine is used for machining a flange on equipment on site, and the main shaft of the double-support flange machining machine issequentially provided with an inner supporting plate, a knife rest and a shaft sleeve, plurality of screw holes are formed in the outer edge surface of the inner supporting plate, screw rods are arranged in the screw holes, supporting legs are arranged at the outer ends of the screw rods, a rotating arm is arranged on the knife rest, a feeding screw and a feeding motor are arranged on the rotating arm, a feeding screw is arranged on the feeding screw, a sliding knife holder is arranged on the feeding nut, an organic frame is arranged on the shaft sleeve, an outer supporting plate is fixedly arranged on the machine frame, the rotating motor, a plurality of pull rods are uniformly distributed on the periphery of the outer support plate, a pull rod nut is arranged at the outer end of each pull rod, the rotary motor drives the shaft sleeve to rotate, the longitudinal pushing motor is provided with a longitudinal pushing screw, a longitudinal pushing nut on the longitudinal pushing screw is provided with a connecting plate, the connecting plate is fixedly connected with the main shaft, the inner supporting plate is arranged in the flange hole, the pull rod is connected with the flangebolt hole, and therefore the rack is fixed on the flange plate, high-precision machining and repairing can be carried out on the butt joint surface of the flange on site, the repairing difficulty andthe repairing cost are reduced, the repairing efficiency is improved, and the working time is saved.

Owner:吉林市维特新工贸有限公司

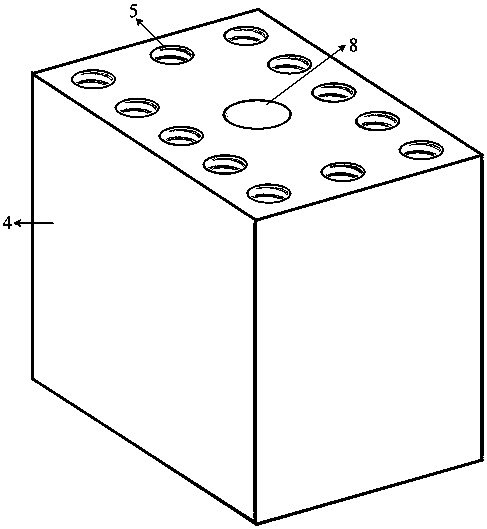

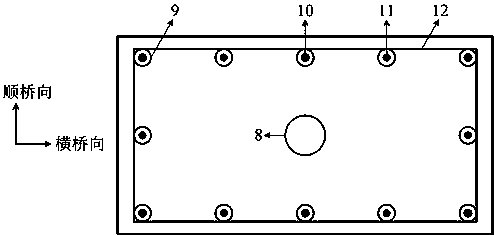

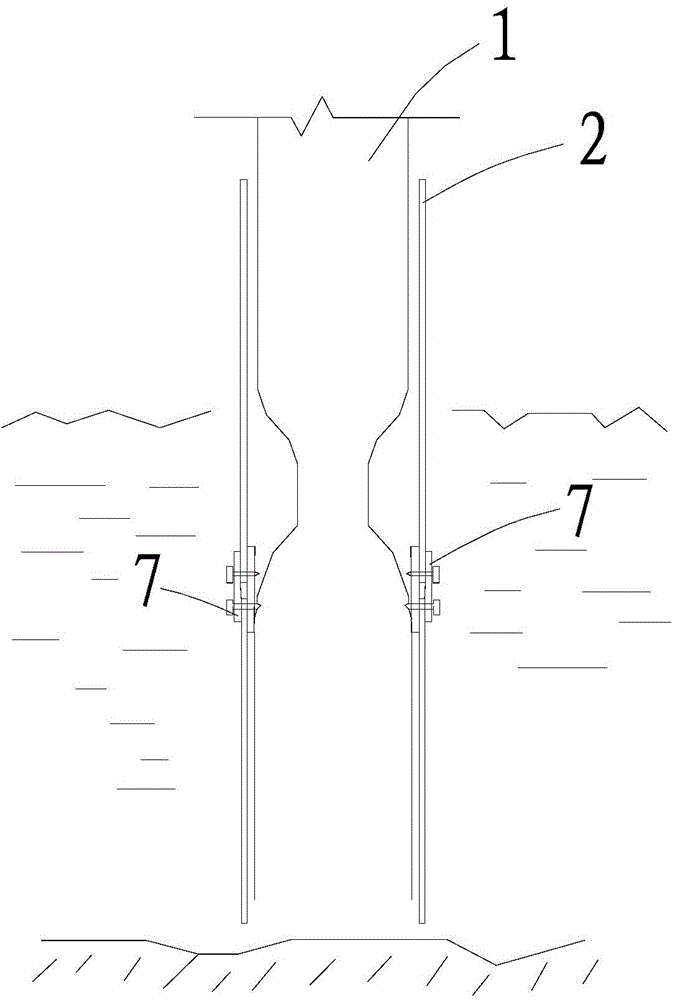

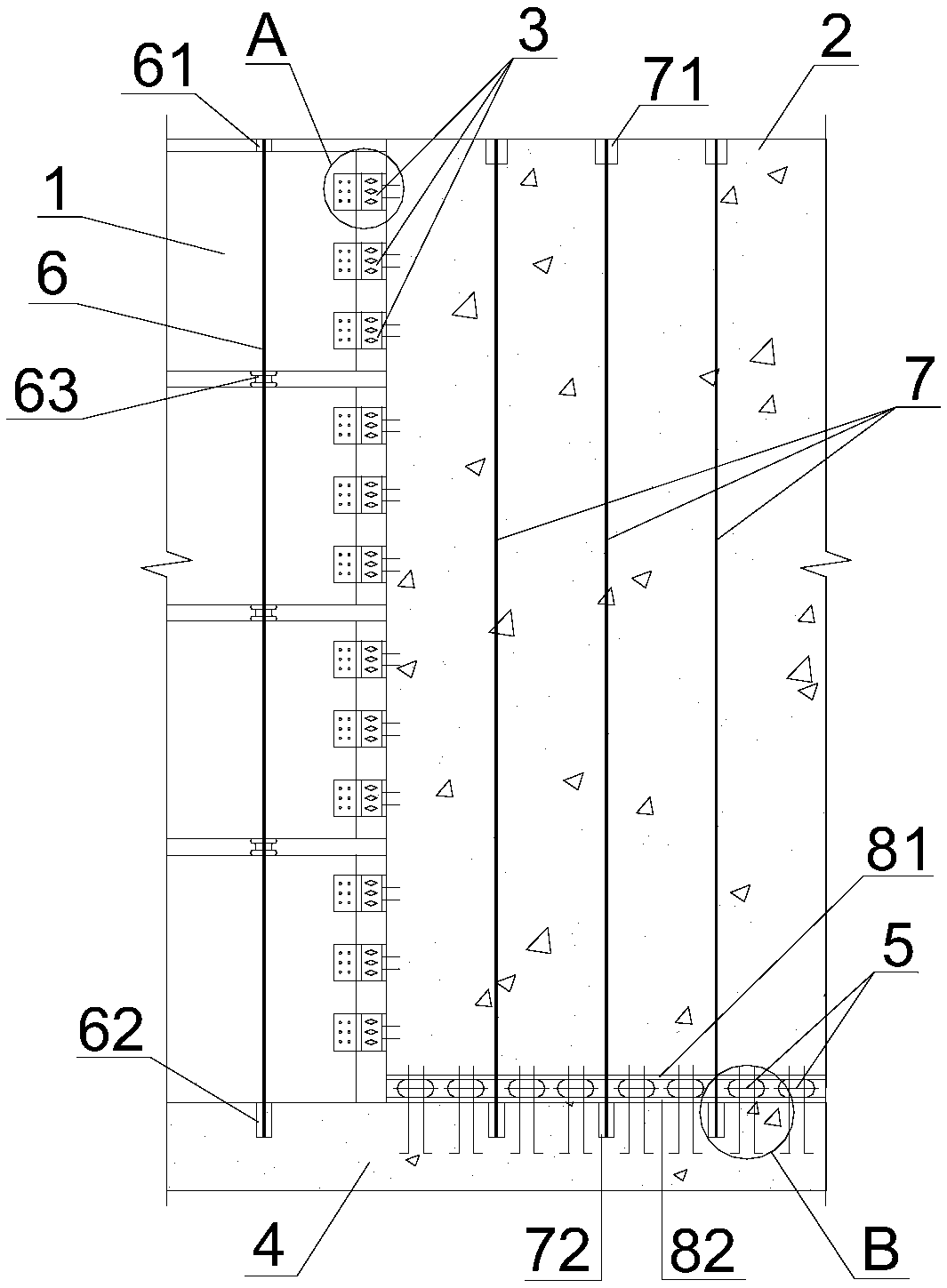

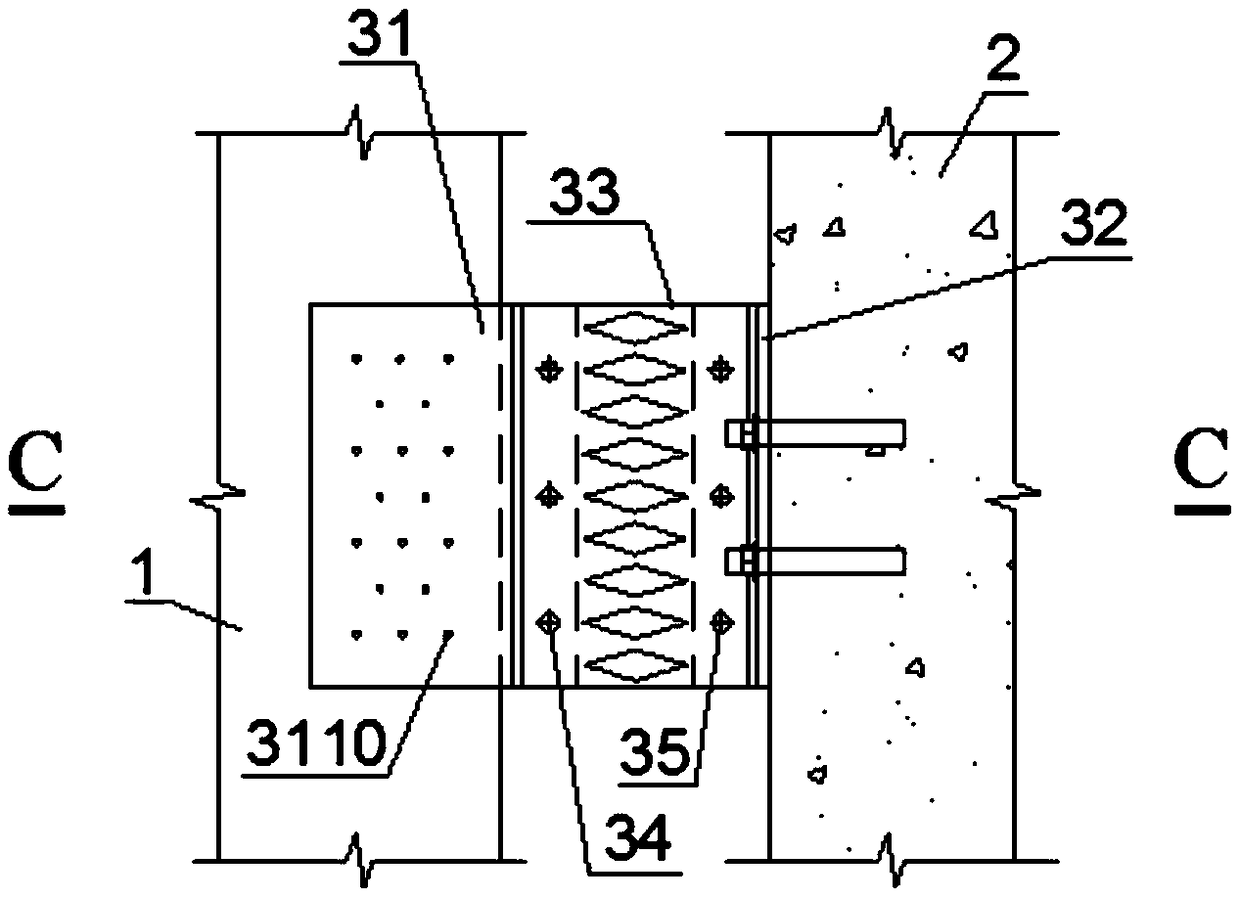

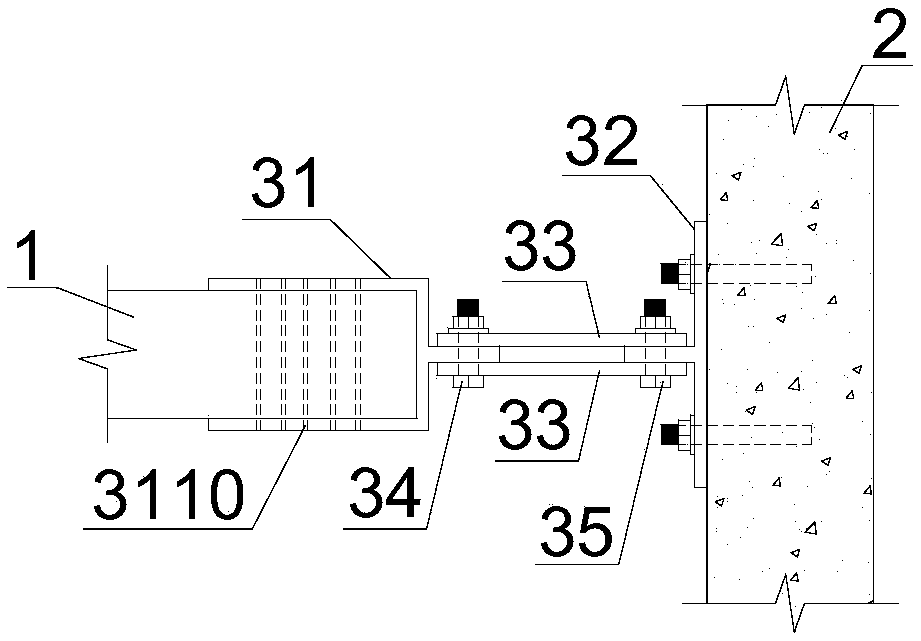

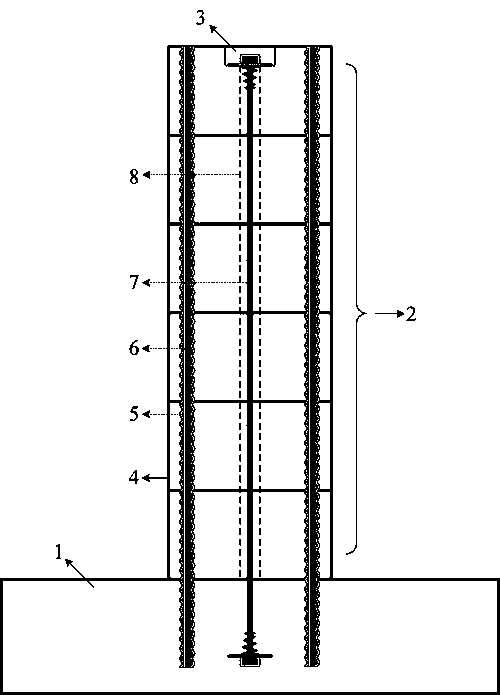

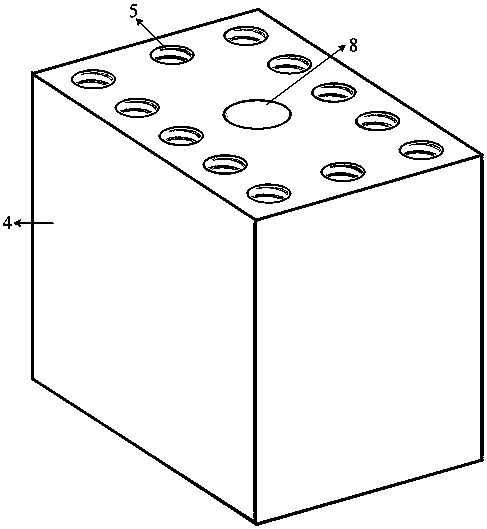

Assembled pier using mixed reinforcements of ordinary steel bars and screw-thread steel bars

InactiveCN108316130AGood self-resetting performanceImprove post-earthquake functionalityBridge structural detailsBridge erection/assemblyPile capPre stress

The invention provides an assembled pier using mixed reinforcements of ordinary steel bars and screw-thread steel bars. The assembled pier using the mixed reinforcement of the ordinary steel bar and the screw-thread steel bar comprises a concrete pile cap (1), assembled pier bodies (2), a through longitudinal bars (6) and an unbonded prestressing tendon (7) and is characterized in that the throughlongitudinal bars (6) are obtained by mixing the ordinary steel bars and the screw-thread steel bars; and the through longitudinal bars (6) and the unbonded prestressing tendon (7) connect the concrete pile cap (1) with each assembled pier body (2) to form a complete pier system.

Owner:HENGQIN GONGE TECH CO LTD

Fixture for solder paste printing and method for repairing integrated circuit board by utilizing same

InactiveCN102076178AReduce the difficulty of repairLower repair costsPrinted circuit assemblingSemiconductor/solid-state device manufacturingSolder pasteIntegrated circuit

The invention provides a fixture for solder paste printing, and the fixture is used for fixing a chip during solder paste printing. The fixture comprises a support plate, wherein, the front face of the support plate is equipped with a plurality of chip accommodating grooves, and the bottoms of the chip accommodating grooves are equipped with pin holes which are corresponding to the pins of the accommodated chips and penetrate through the rear face of the support plate. The fixture for solder paste printing has the advantages of lowering the repair difficulty and the repair cost, solving the difficulty in solder paste printing on a repair circuit board, and reducing the local damage degree of products caused by repair.

Owner:SHIN TECH ENG

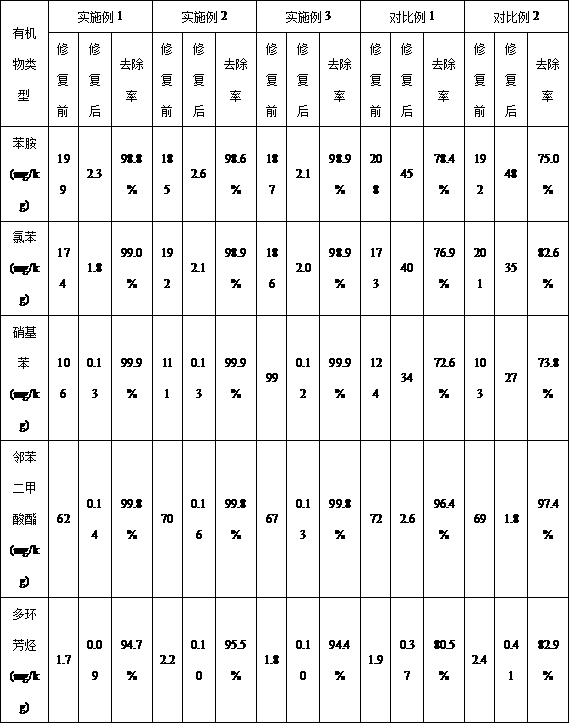

In-situ remediation method for organic matter polluted soil

InactiveCN111360059APromote degradationIncrease the rate of photocatalytic reactionsContaminated soil reclamationPhotocatalytic reactionEngineering

The invention discloses an in-situ remediation method for organic matter polluted soil. Firstly, organic matter polluted soil is simply pretreated; then, solubilizer / TiO2 / CdS bentonite magnetic hydrogel microspheres are sprayed on the surface layer of the soil; organic pollutants are photo-catalytically decomposed under the irradiation of sunlight; the used solubilizer / TiO2 / CdS bentonite magnetichydrogel microspheres are simple to prepare, can be separated and recycled under the action of an external magnetic field, and can be repeatedly used according to the organic matter pollution degree of soil; the soil remediation difficulty is greatly reduced, and the manpower and equipment are saved. In-situ remediation is carried out on the soil surface, the photocatalytic reaction speed is high,there is no pollutant selectivity, the remediation time is short, the soil remediation can be repeatedly carried out, the remediation method is suitable for soil with different pollution degrees, nopost-treatment is needed, no chemical reagent is used, no secondary pollution is generated, sowing can be directly carried out after remediation, and economic benefits are good.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

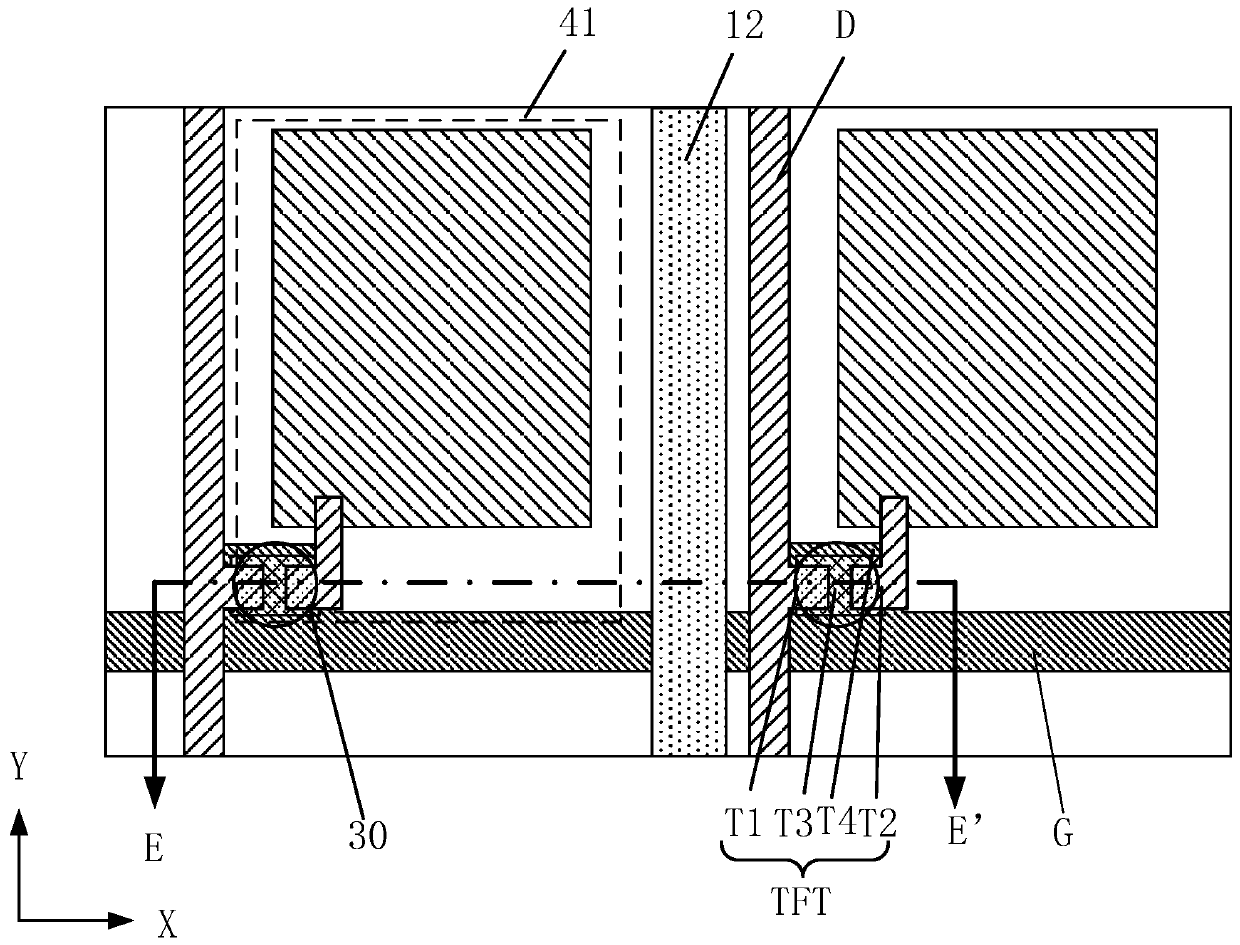

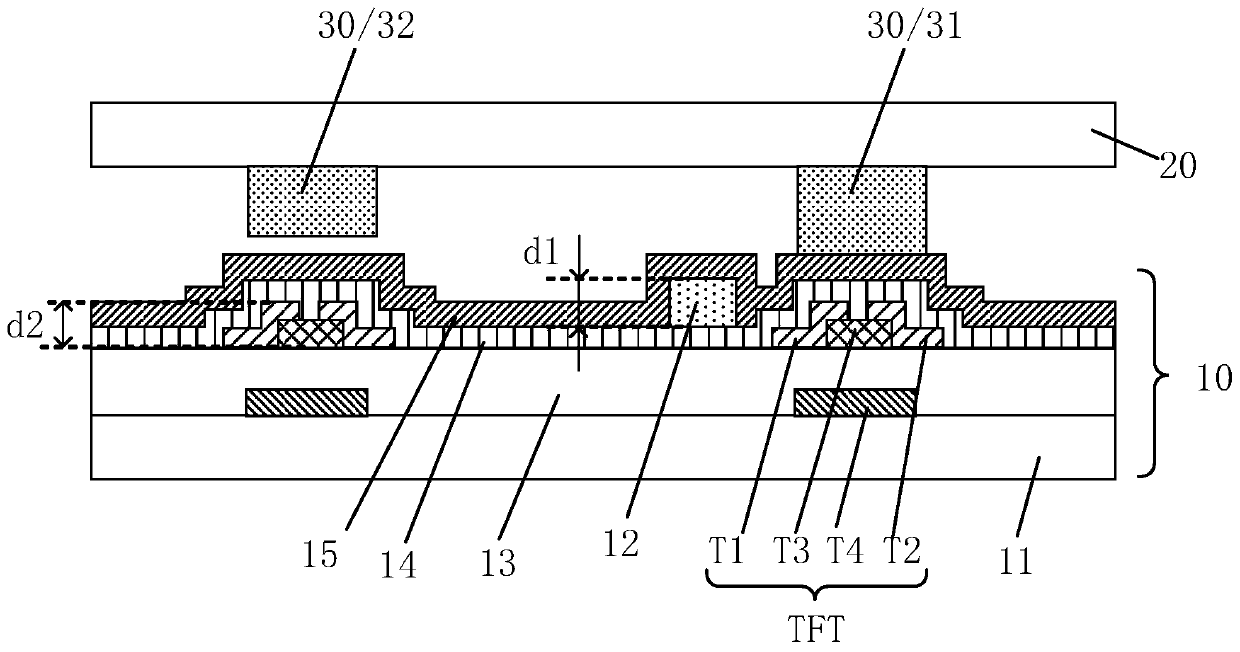

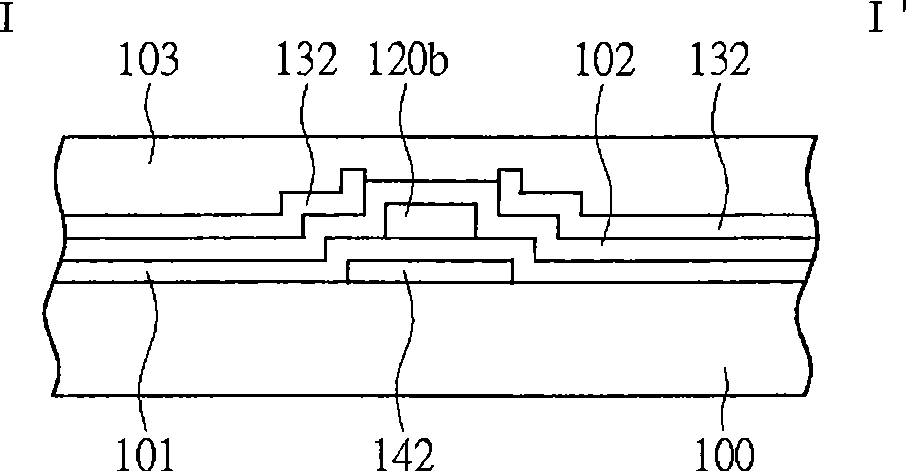

Display panel and display device

ActiveCN110888269AReduce the difficulty of repairImprove repair efficiencyNon-linear opticsDisplay deviceColor film

The invention, which relates to the technical field of display, discloses a display panel and a display device. The display panel comprises an array substrate and a color film substrate which are oppositely arranged. A plurality of support columns are arranged between the array substrate and the color film substrate. The array substrate includes a substrate body, a plurality of data lines, a plurality of repairing lines and a plurality of pixel units arranged in an array, wherein the plurality of data lines, the plurality of repairing lines and the plurality of pixel units are arranged on thesubstrate body. Each pixel unit includes at least two sub-pixels arranged in a first direction; and each sub-pixel includes a thin film transistor. The support columns and the thin film transistors are at least stacked partially in a direction perpendicular to the array substrate; and the film thickness of the repairing line is d1 and the total film thickness of the source electrode of the thin film transistor and the semiconductor part of the thin film transistor is d2, wherein the d1 is smaller than or equal to the d2, the d1 is larger than 0, and the d2 is larger than 0. Therefore, the difficulty of repairing the data lines in the display panel is effectively reduced; meanwhile, the supporting performance of the supporting column in the display panel is not affected.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Active array substrate, LCD panel and its mending method

InactiveCN101431083AThe repair method is convenient and fastImprove production pass rateSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayNeck parts

The invention provides an active array basal plate, a liquid crystal display panel and a mending method thereof. The active array basal plate comprises a substrate, a plurality of scanning beams, a plurality of digital beams, a plurality of pixel units and a common electrode, wherein the common electrode is provided with a main body part, a branch part and a neck part, the branch part is overlapped with at least one of the digital beams and a pixel electrode of the two adjacent pixel units corresponding to the digital beam. The mending method of the invention is more convenient and rapid, and furthermore, the production yield is increased, and the mending difficulty is reduced.

Owner:AU OPTRONICS CORP

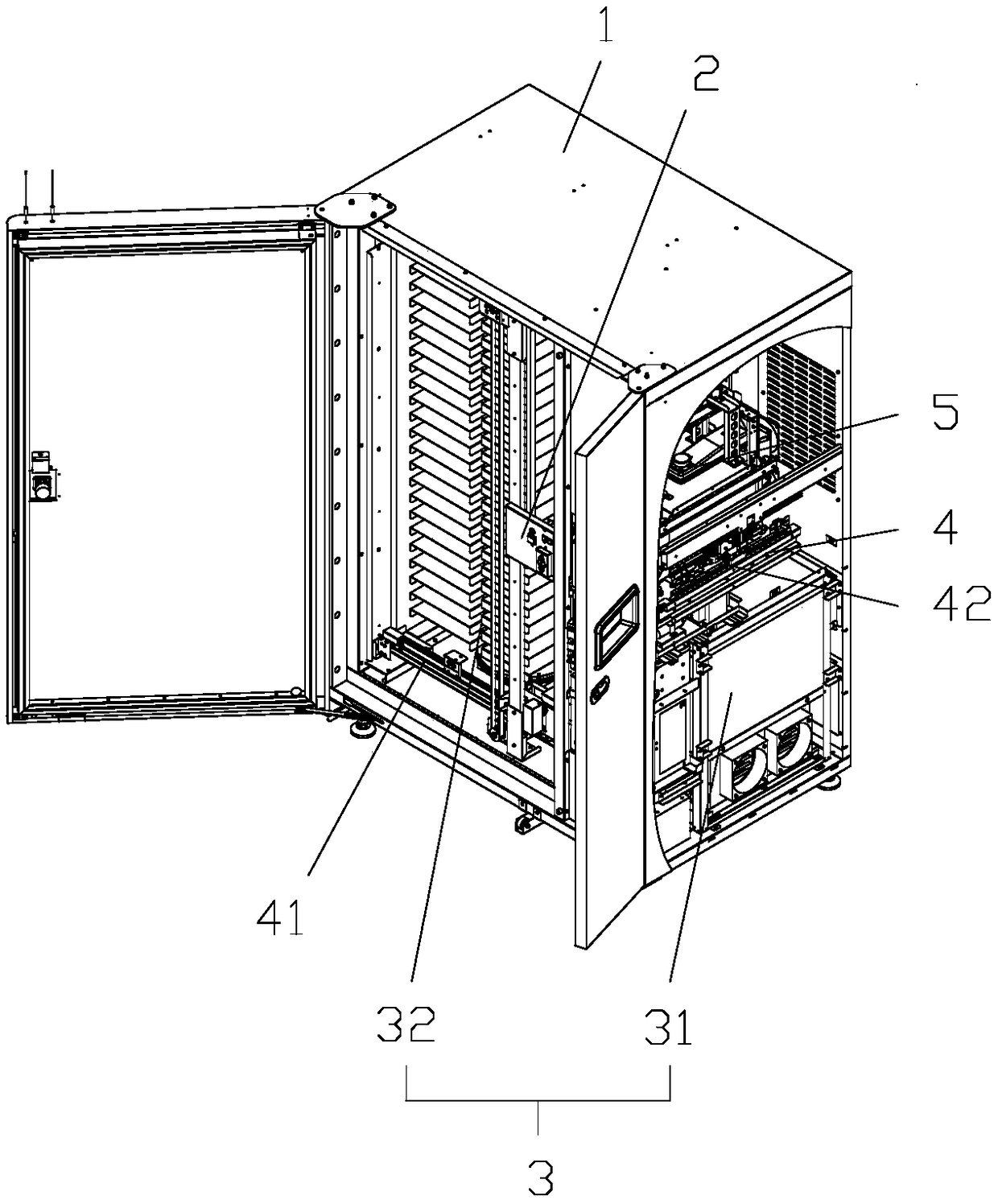

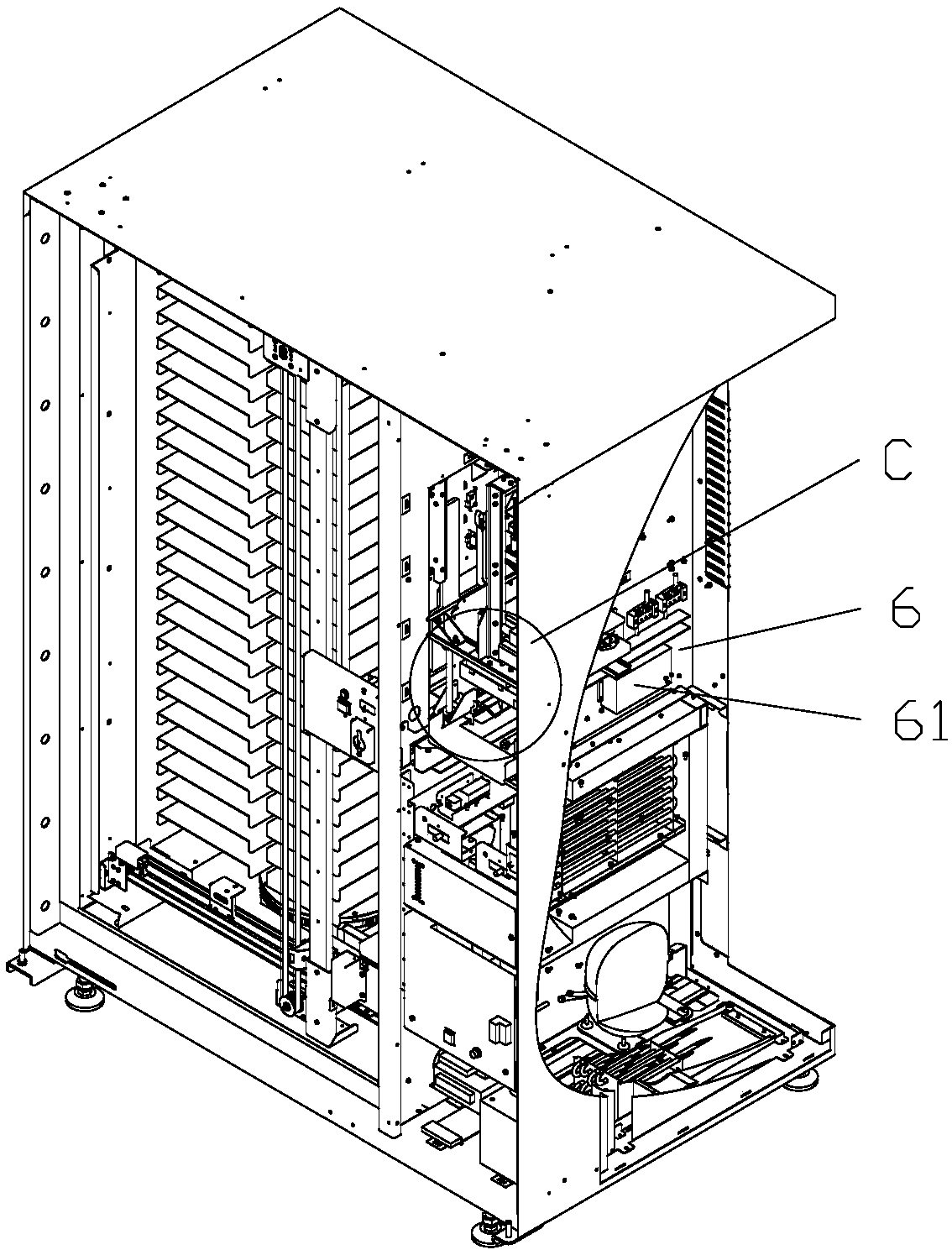

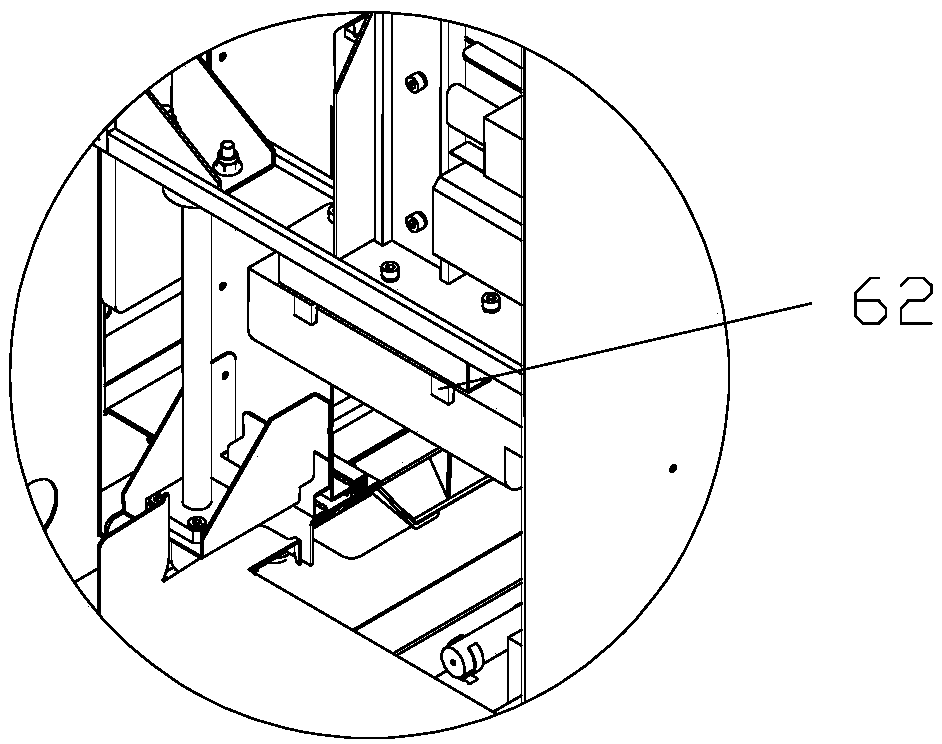

Box lunch vending machine

InactiveCN108898747AReduce maintenance difficultyReduce the difficulty of repairApparatus for meter-controlled dispensingControl systemProcess engineering

The invention discloses a box lunch vending machine, and belongs to the technical field of vending machines. The box lunch vending machine comprises a frame, a control system, a refrigeration system,a delivery system, and a heating system, wherein the refrigeration system is used for storing a box lunch to be sold, the delivery system comprises an internal delivery module which is used for movingthe box lunch to the heating system and an external delivery module which is used for pushing the box lunch out of the heating system, and the heating system is used for heating the box lunch. The box lunch vending machine in the invention separates the refrigeration system from the heating system and modularizes the refrigerating and heating functions, as a result of which if one function fails,all that is needed is to repair or replace the broken parts instead of inspecting and repairing the whole machine, thereby reducing the difficulty and cost in maintenance and repair.

Owner:浙江嘉丰机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com