Submarine optical cable with optical unit longitudinally-wrapped copper strip structure and preparation method thereof

An optical unit and sea optical cable technology, applied in optical components, fiber mechanical structures, light guides, etc., can solve the problems of increasing the outer diameter and weight of optical cables, crushing optical units, and deteriorating process stability, reducing self-weight and materials. cost, ensuring strength and tightness, reducing the effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A preparation method of a sea optical cable, comprising the following steps:

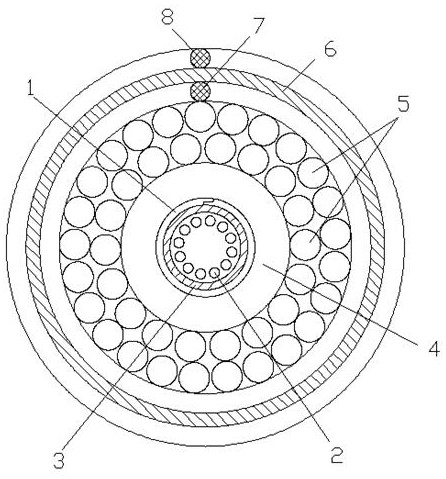

[0041] For the processing of the optical unit, the optical fiber 2 is wrapped in a stainless steel tape and rolled into a stainless steel tube 3, and at the same time, the fiber paste is injected into the stainless steel tube 3, and after welding and fixing, the drawing process is carried out through a drawing mold to improve the strength of the optical unit;

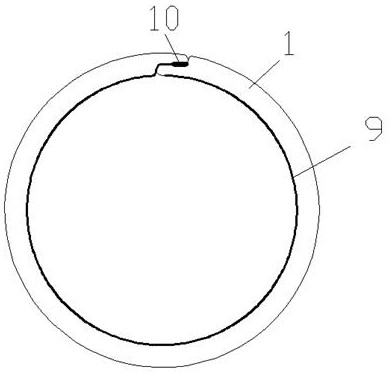

[0042] Longitudinally wrap the copper strip, compound the adhesive film on the inner surface of the copper strip 1 to form a copper-plastic composite strip, then spray glue 9 on the surface of the adhesive film 10 or stainless steel pipe 3 (the glue 9 avoids the edge of the adhesive film 10), and pass through the mold The copper strip 1 is rolled and wrapped on the surface of the stainless steel pipe 3, and an overlapping area is set on the edge of the copper strip 1 to form an overlapping structure. The glue film 10 and glue 9 are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com