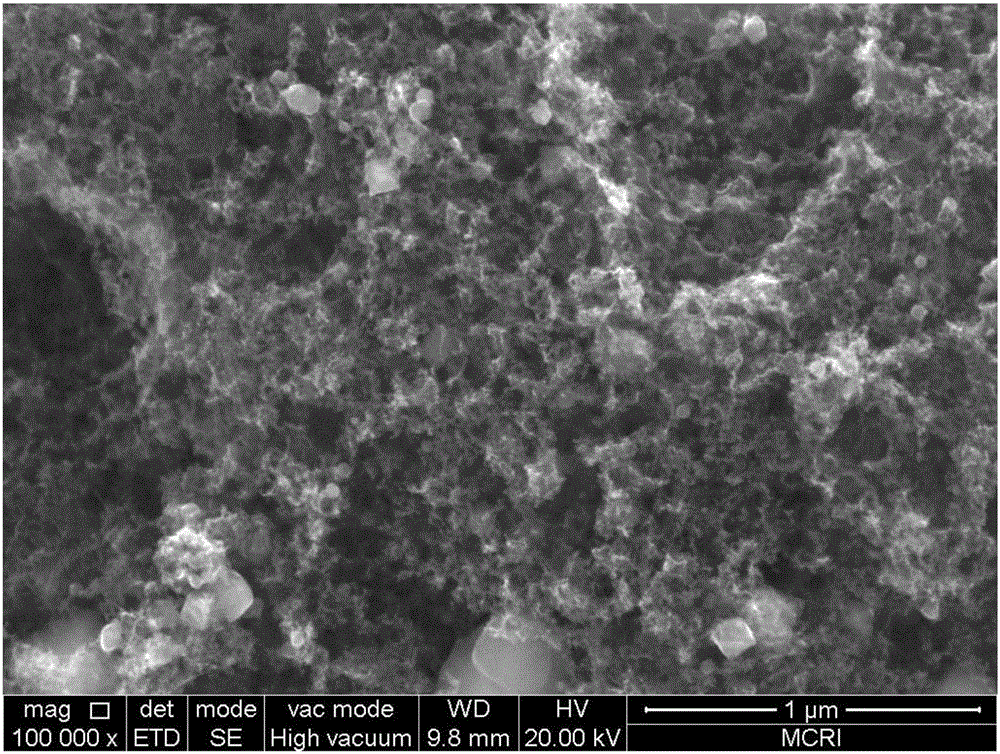

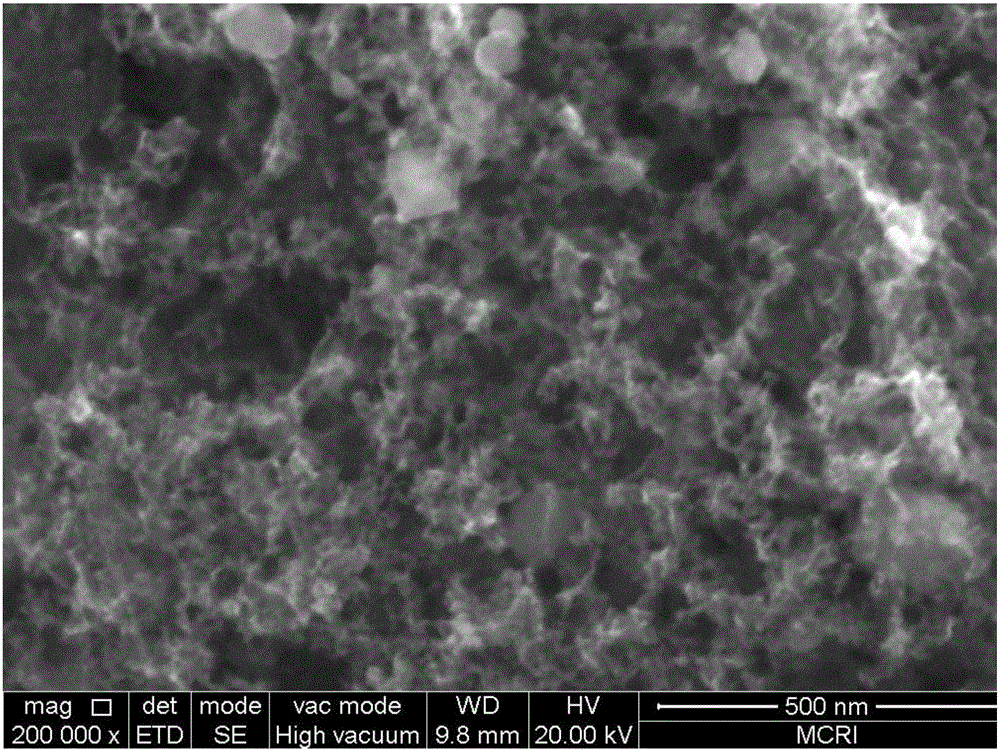

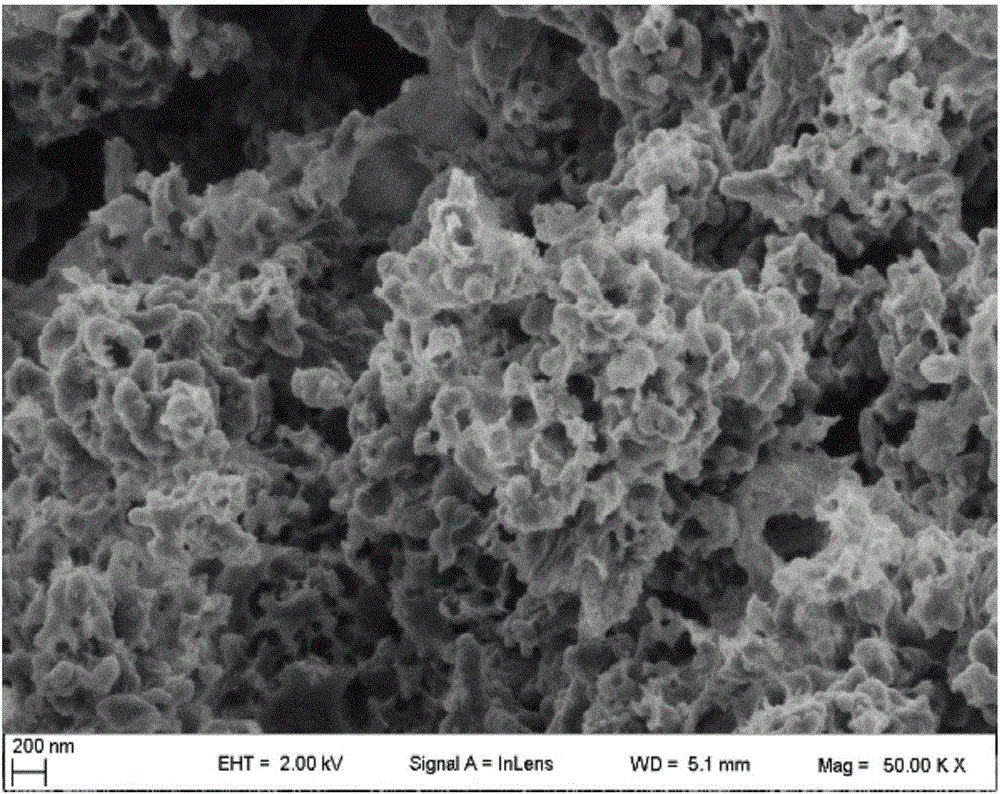

Method for preparing N-doped porous carbon/ferric oxide compound powder

A technology of composite powder and iron oxide, which is applied in the manufacture of hybrid/electric double-layer capacitors and electrodes of hybrid capacitors, can solve problems such as hidden dangers in operation safety, and achieve synergistic effects of optimized structure and capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the N-doped porous carbon / iron oxide composite powder of this embodiment includes:

[0035] Step 1, preparing coal-based polyaniline by in-situ polymerization, specifically comprising the following steps:

[0036] Step 101. Mix 6.7g of aniline, 25mL of concentrated hydrochloric acid (37% in mass concentration) and 60mL of water to obtain a mixed solution A, add 10g of coal powder to the mixed solution A, stir and swell at 30°C for 2h to obtain a swollen coal sample;

[0037] Step 102. Add 60 mL of ammonium persulfate aqueous solution with a concentration of 0.27 g / mL dropwise to the swollen coal sample described in step 101 in a 3° C. ice-water bath with stirring at a rate of 1 mL / min. After the dropwise addition is completed, Continue to stir for 6 hours under the condition of ice-water bath at 3°C, filter with suction, wash the filter cake obtained by suction filtration, then vacuum-dry the filter cake after washing, grind it, and pass it th...

Embodiment 2

[0043] The preparation method of the N-doped porous carbon / iron oxide composite powder of this embodiment includes:

[0044] Step 1, preparing coal-based polyaniline by in-situ polymerization, specifically comprising the following steps:

[0045] Step 101. Mix 5g of aniline, 25mL of concentrated hydrochloric acid (37% in mass concentration) and 60mL of water to obtain a mixed solution A, add 10g of coal powder to the mixed solution A, stir and swell at 25°C for 3h to obtain swollen coal Sample;

[0046] Step 102. In an ice-water bath at 0°C, add 60 mL of ammonium persulfate aqueous solution with a concentration of 0.20 g / mL dropwise to the swollen coal sample described in step 101 under agitation at a rate of 2 mL / min. Continue to stir for 8 hours under the condition of an ice-water bath at 0°C, filter with suction, wash the filter cake obtained by suction filtration, then dry the washed filter cake in vacuum, grind it, and pass it through a 200-mesh screen to obtain coal-bas...

Embodiment 3

[0052] The preparation method of the N-doped porous carbon / iron oxide composite powder of this embodiment includes:

[0053] Step 1, preparing coal-based polyaniline by in-situ polymerization, specifically comprising the following steps:

[0054] Step 101, mix 3.3g of aniline, 25mL of concentrated hydrochloric acid (37% in mass concentration) and 61.7mL of water to obtain a mixed solution A, add 10g of coal powder to the mixed solution A, stir and swell at 35°C for 2.5h, Obtain a swollen coal sample;

[0055] Step 102. Add 60 mL of ammonium persulfate aqueous solution with a concentration of 0.13 g / mL dropwise to the swollen coal sample described in step 101 under stirring in an ice-water bath at 5° C. at a rate of 3 mL / min. After the addition is complete, Continue to stir for 7 hours under the condition of ice-water bath at 5°C, filter with suction, wash the filter cake obtained by suction filtration, then vacuum-dry the filter cake after washing, grind it, and pass it throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com