Control system of automatic revolving door

An automatic rotation and door control technology, applied in door/window accessories, power control mechanisms, buildings, etc., can solve the problems of inability to control the output torque of the motor, limited selectivity of the revolving door motor, and complex control system, and achieve easy Installation and debugging, low noise, high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

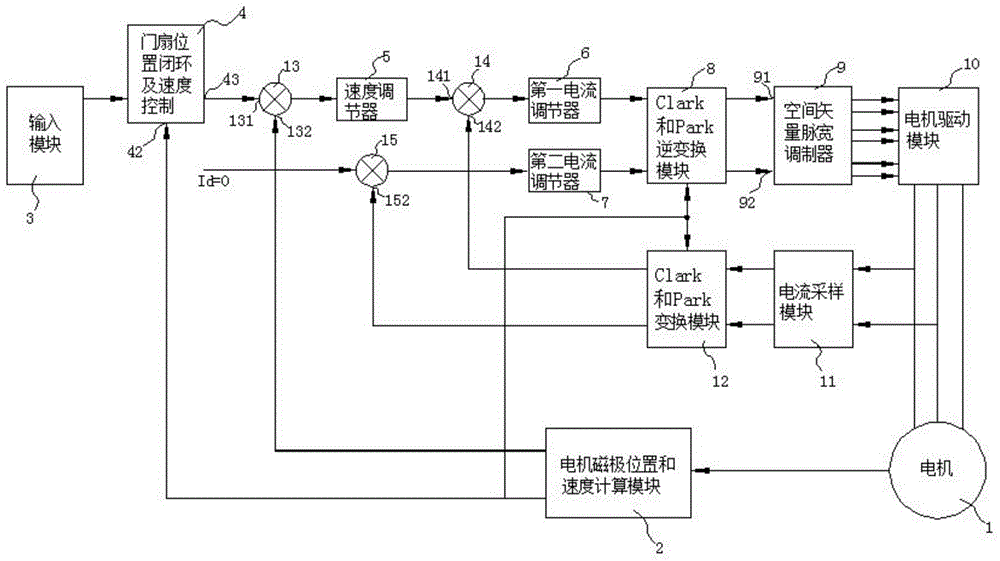

[0022] An automatic revolving door control system, its structural block diagram is as follows figure 1 As shown, the control system of the present invention provides the rotation speed value through the input module 3, and the motor magnetic pole position and speed calculation module 2 respectively provide position feedback signals to the feedback terminal 42 of the door leaf position closed loop and speed control 4, and provide speed feedback signals to the first At the feedback terminal 132 of the node 13 , the sampled signal value of the current sampling module 11 is transformed by the Park and Clark transformation module 12 to the feedback terminals 152 and 142 of the third node 15 and the second node 14 . The door leaf position closed-loop and speed control 4 outputs the given speed value to the output terminal 43 according to the input state of the input module 3, and sends the difference between the given speed value and the feedback value to the speed regulator 5, and t...

Embodiment 2

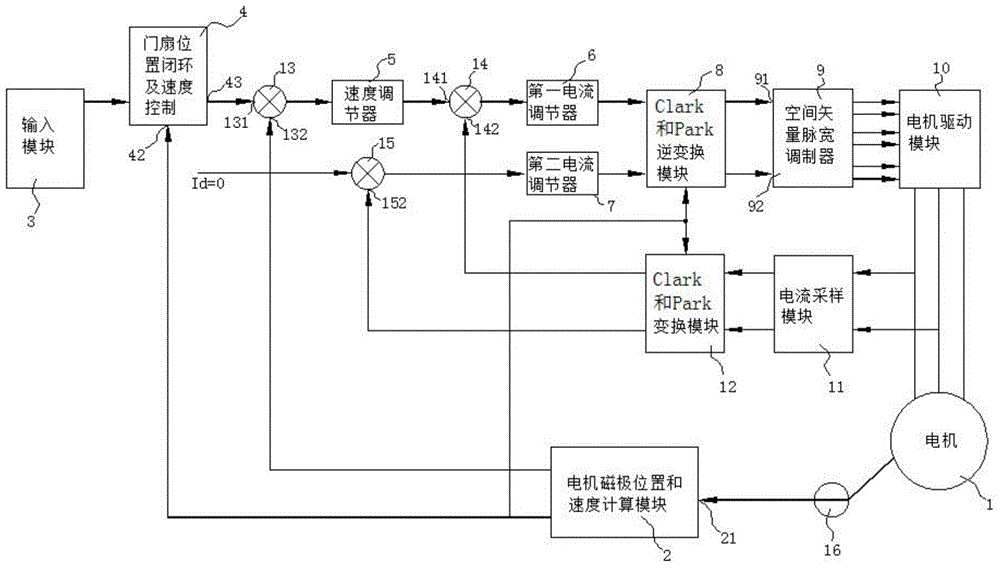

[0029] An automatic revolving door control system, its structural block diagram is as follows figure 2 As shown, the difference from Embodiment 1 is that the output end of the motor 1 of the control system of the present invention includes a magnetic induction encoder 16 installed on the motor 1, and the output end of the magnetic induction encoder 16 is concentric with the rotor of the motor 1 , the output end of the magnetic induction encoder 16 is connected with the input end 21 of the motor magnetic pole position and the speed calculation module 2, and the induction magnet steel connected with the magnetic induction encoder 16 is installed on the rotating shaft of the motor 1, and by the operation of the rotor of the motor 1, the induction The magnetic steel rotates at the same center of circle as the rotor of the motor 1 relative to the magnetic induction encoder 16, wherein the magnetic induction encoder 16 measures the running state of the motor 1 through the induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com