Assembled pier using mixed reinforcements of ordinary steel bars and screw-thread steel bars

A technology of fine-rolled threads and ordinary steel bars, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems that it is difficult to simultaneously reduce the maximum displacement response and post-earthquake residual displacement, so as to achieve rapid bridge construction and improve piers Self-resetting ability, reducing the effect of maximum displacement response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

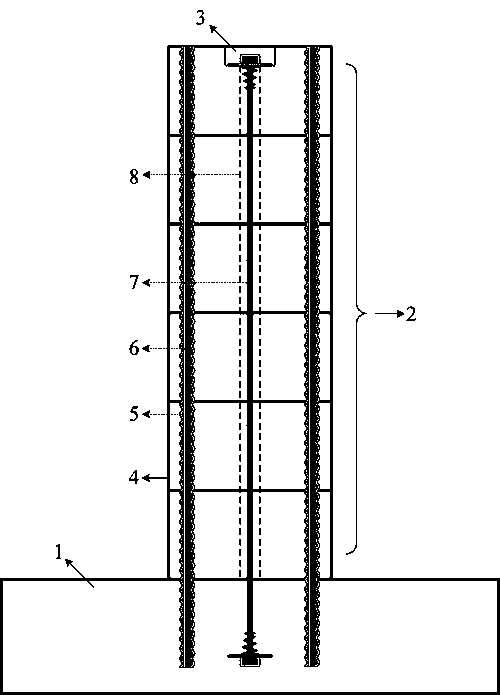

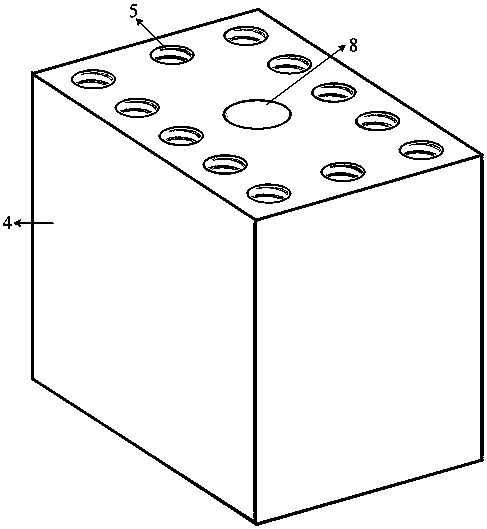

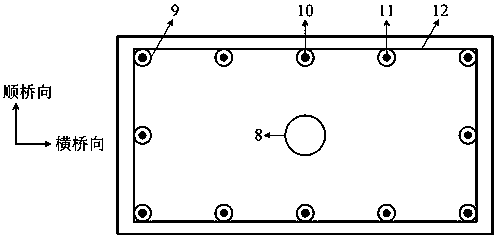

[0025] Example 1, such as figure 1 As shown, the present invention provides an assembled pier with mixed reinforcement of ordinary steel bars and fine-rolled threaded steel bars, including concrete caps (1), assembled pier body (2), through longitudinal bars (6) and unbonded prestressed bars (7). The assembled pier body is formed by stacking a certain number of individual prefabricated segments (4) vertically, and is stretched by unbonded prestressed tendons (7) to form the pier as a whole. Each prefabricated segment (4) has a rectangular section with the same size, and each segment has the same height. The segment height is twice the long side of the section, so that the plastic hinge of the pier can be fully developed to ensure the seismic energy dissipation capacity, and the volume and weight of a single segment can be small and easy to assemble. Such as figure 2 As shown, each prefabricated segment (4) is arranged with the same number of reserved corrugated channels (...

Embodiment 2

[0026] Example 2, such as Figure 5As shown, the difference between this embodiment and the foregoing embodiment 1 is that the pier body of the assembled pier with mixed reinforcement of common steel bars and finished rolled threaded steel bars has only one prefabricated segment (4). When the slenderness ratio of the pier is not greater than 6, the entire pier body can be prefabricated as a whole segment, which can improve the efficiency of pier assembly. Moreover, since the slenderness ratio of the pier is not greater than 6, the size and weight of the entire segment will not be too large to be difficult to transport and assemble. When adopting the same or similar design and construction scheme as in Example 2, it should be noted that the size and weight of the prefabricated pier body segments meet the relevant traffic regulations and do not exceed the tonnage limit of the hoisting and lifting equipment.

Embodiment 3

[0027] Example 3, such as Figure 6 As shown, the difference between this embodiment and the foregoing embodiment 1 is that ordinary steel bars and finished rolled threaded steel bars only pass through several sections of the lower part of the assembled pier body 2, and are not arranged along the entire pier body. For cantilever piers, the bending moment at the bottom of the pier is the largest under earthquake action, and the bending moment gradually decreases from the bottom of the pier upwards. During seismic design, according to the distribution of pier bending moment, the longitudinal reinforcement ratio can be gradually reduced, and finally cut off at a reasonable height. The determination of the truncation position of the longitudinal reinforcement shall comply with the provisions of the corresponding seismic design codes. When the height of the assembled pier with mixed reinforcement of ordinary steel bars and fine-rolled threaded steel bars is large, the adoption of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com