Shape memory alloy reinforced wood structure beam column bolt joint and manufacturing method thereof

A memory alloy and bolt joint technology, which is used in building construction, building maintenance, construction, etc., can solve the problem that the bending bearing capacity and deformation capacity are not fully utilized, the irreversible deformation cannot be reduced, and the self-resetting effect cannot be achieved. and other problems, to achieve good self-reset function, improve self-reset performance, and inhibit transverse cracking damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

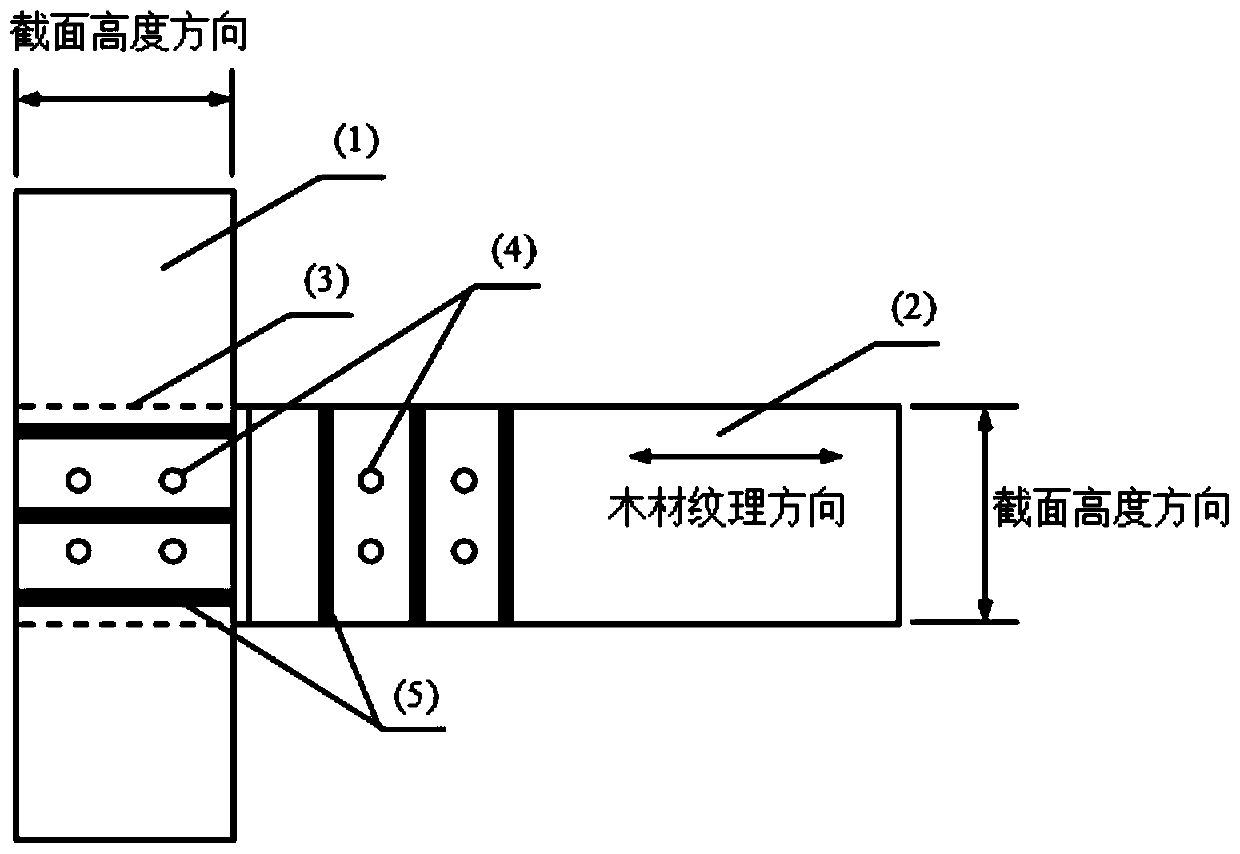

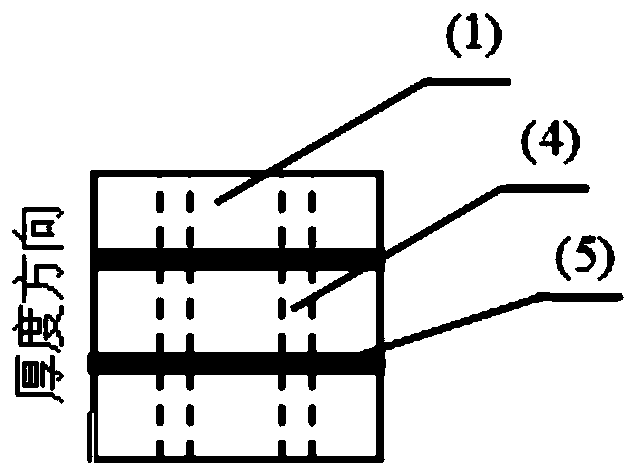

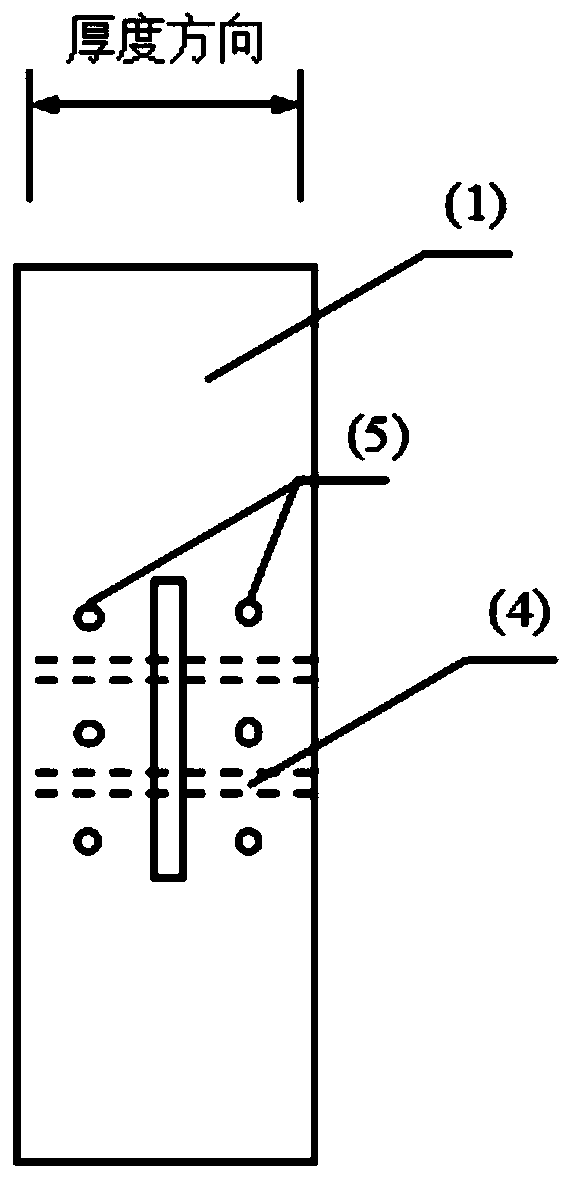

[0023] see Figure 1-Figure 3 , a beam-column bolt joint of a wood structure reinforced by a shape memory alloy, comprising two wood members, a wood member 1 and a wood member 2 2, the wood members are in the shape of a rectangle, and their length direction is the direction of wood grain; The reinforced part of wooden member 1 is located at the end, and the reinforced part of wooden member 2 is located at the abdomen; the reinforced part is: at least one steel filler plate groove parallel to the length direction is opened in the middle of the wooden member in the thickness direction, and the wooden member and the The corresponding position of the steel filler plate 3 is pre-drilled some bolt holes in the thickness direction, the steel filler plate 3 is inserted into the groove of the steel filler plate, and each bolt 4 is inserted into the resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com