Orthogonal plywood shear wall-concrete core tube mixed lateral-load-resistance system

A shear wall and glulam technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve problems such as insufficient lateral resistance, achieve superior seismic performance, reduce repair costs and difficulties, and improve lateral resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

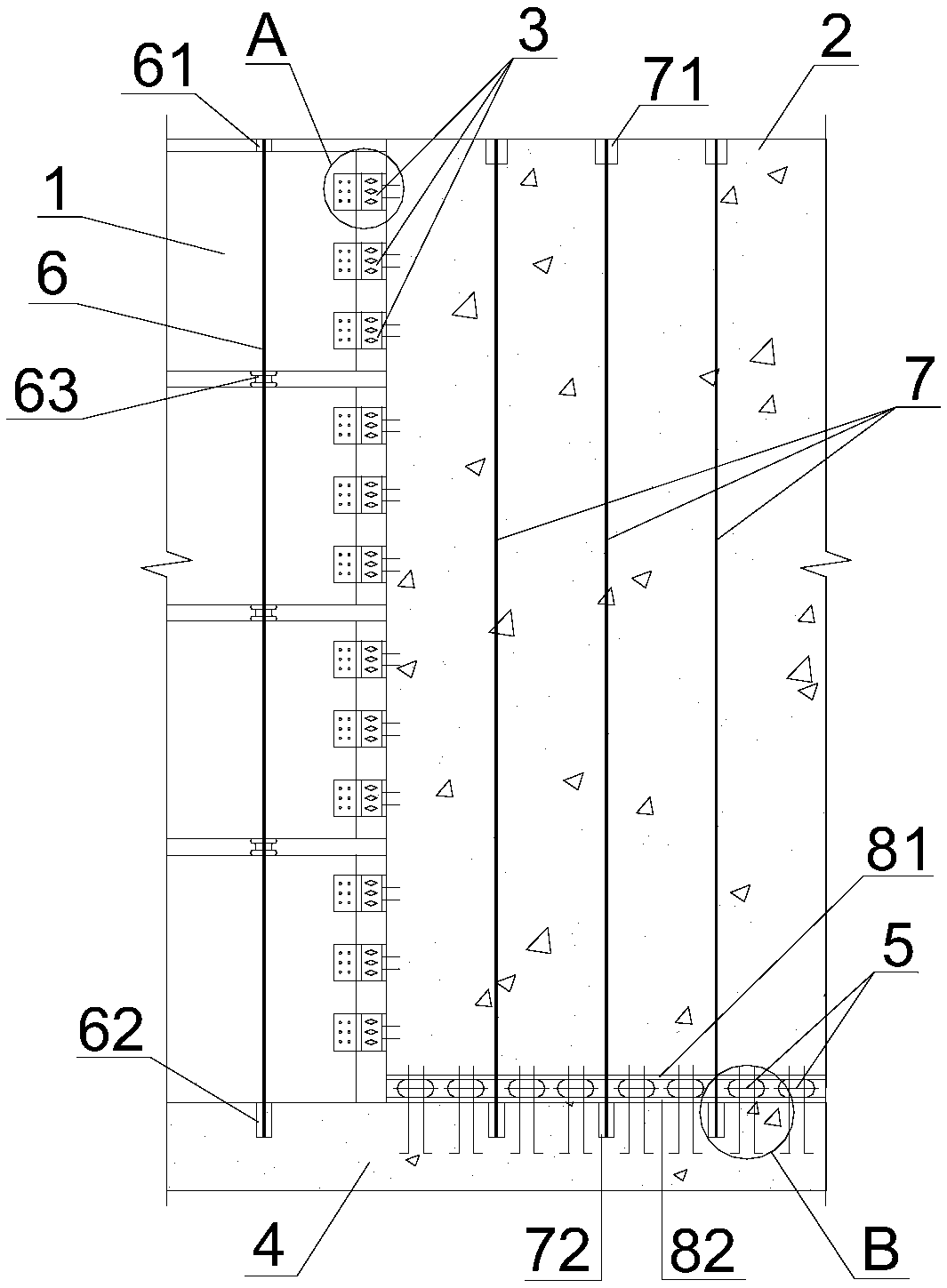

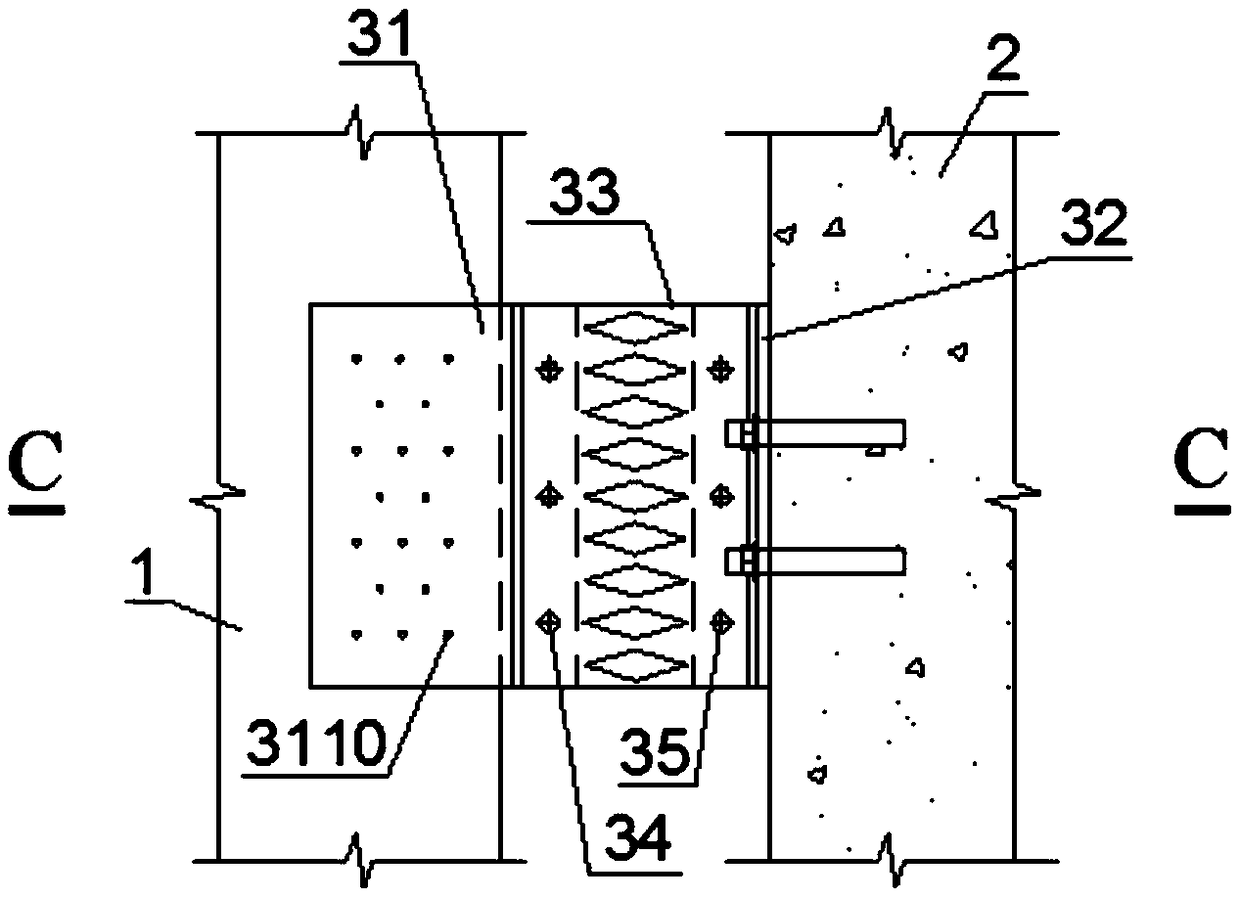

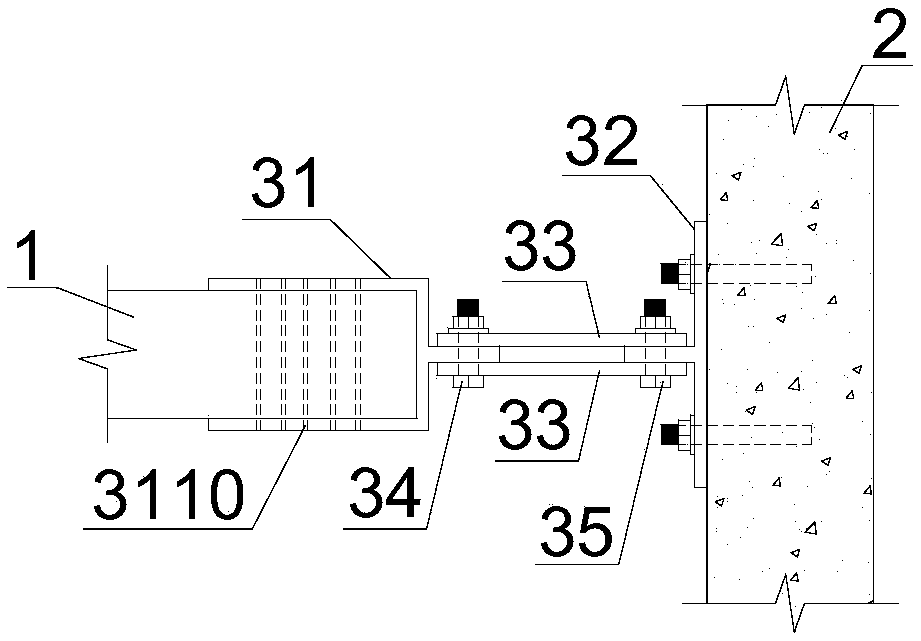

[0039] like figure 1 As shown, the cross-glued wood shear wall-concrete core tube hybrid lateral force system includes cross-glued wood shear wall 1, concrete core tube 2, replaceable energy-dissipating connectors 3, concrete foundation 4, and prestressed swing Support 5, first post-tensioned unbonded prestressed tendon 6, second post-tensioned unbonded prestressed tendon 7, first steel backing plate 81, second steel backing plate 82, cross-glued wood shear wall 1 It is connected with the concrete core tube 2 through several replaceable energy-dissipating connectors 3. The concrete foundation 4 is located under the cross-laminated timber shear wall 1 and the concrete core tube 2. The space between the concrete core tube 2 and the concrete foundation 4 passes through the first The steel backing plate 81, the second steel backing plate 82 and several prestressed swing supports 5 are connected, the first post-tensioned unbonded prestressed tendon 6 runs through the cross-glued wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com