Assembling multi-section beam steel frame capable of self-centering after earthquake

A steel frame and self-resetting technology, which is applied in the fields of earthquake resistance, building components, construction, etc., can solve the problems of little research on prestressing technology and insufficient depth, so as to reduce the construction period cost and labor cost, obtain materials easily, and increase the net height of the room Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

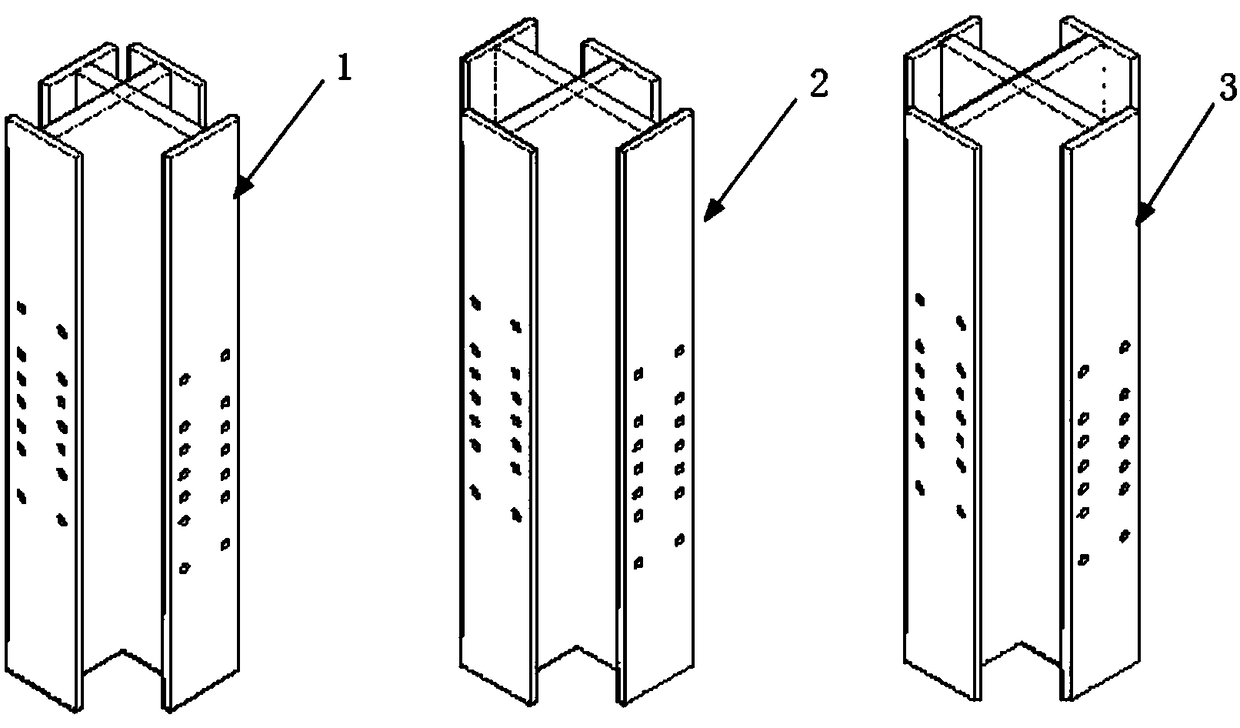

[0030] as attached figure 1 As shown, in the post-earthquake self-resetting multi-section beam steel frame of the present invention, the involved special-shaped columns are respectively: the frame corner frame column 1 is the L-shaped column, the frame side frame column 2 is the T-shaped column, and the frame middle Frame column 3 is a cross-shaped column;

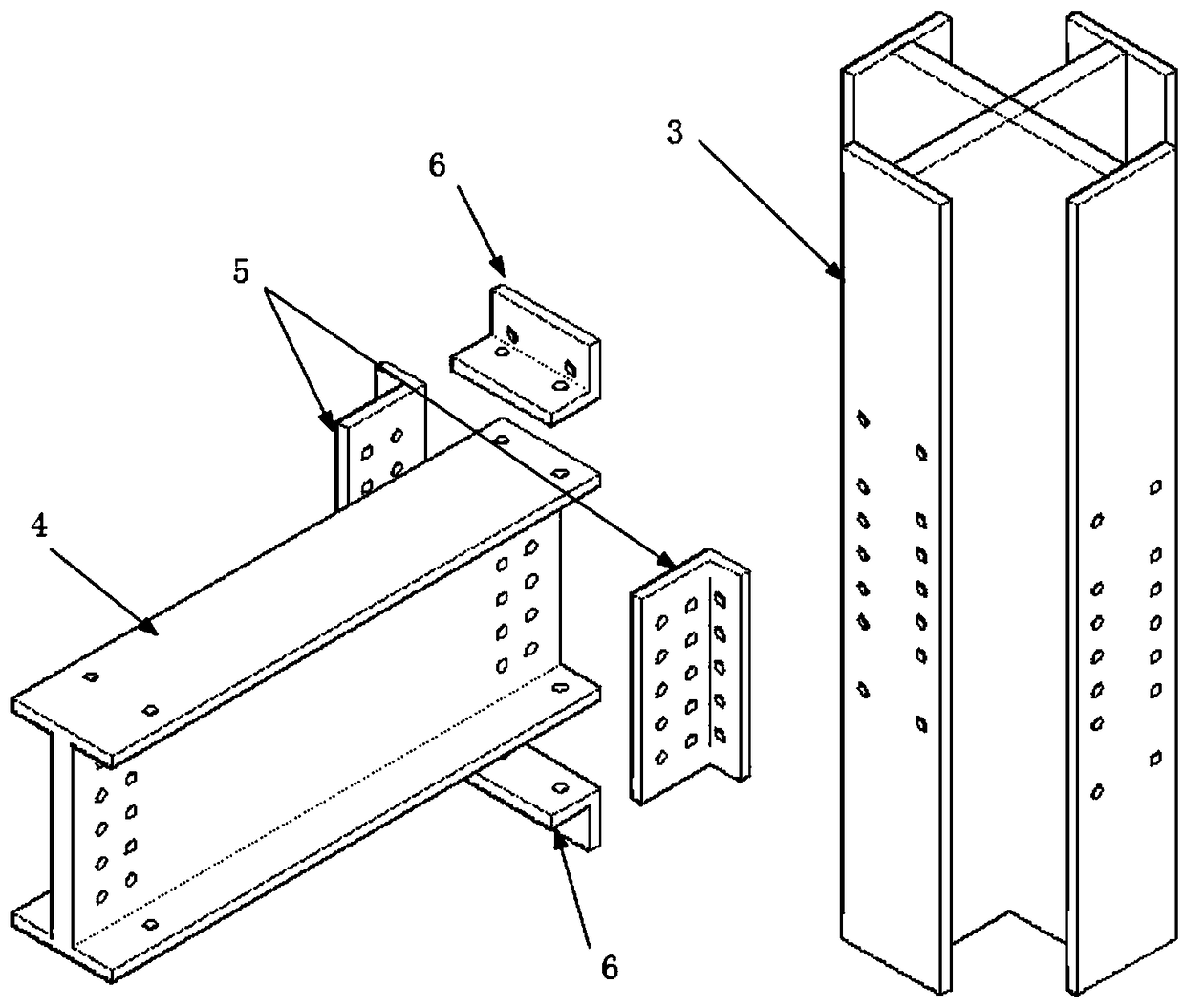

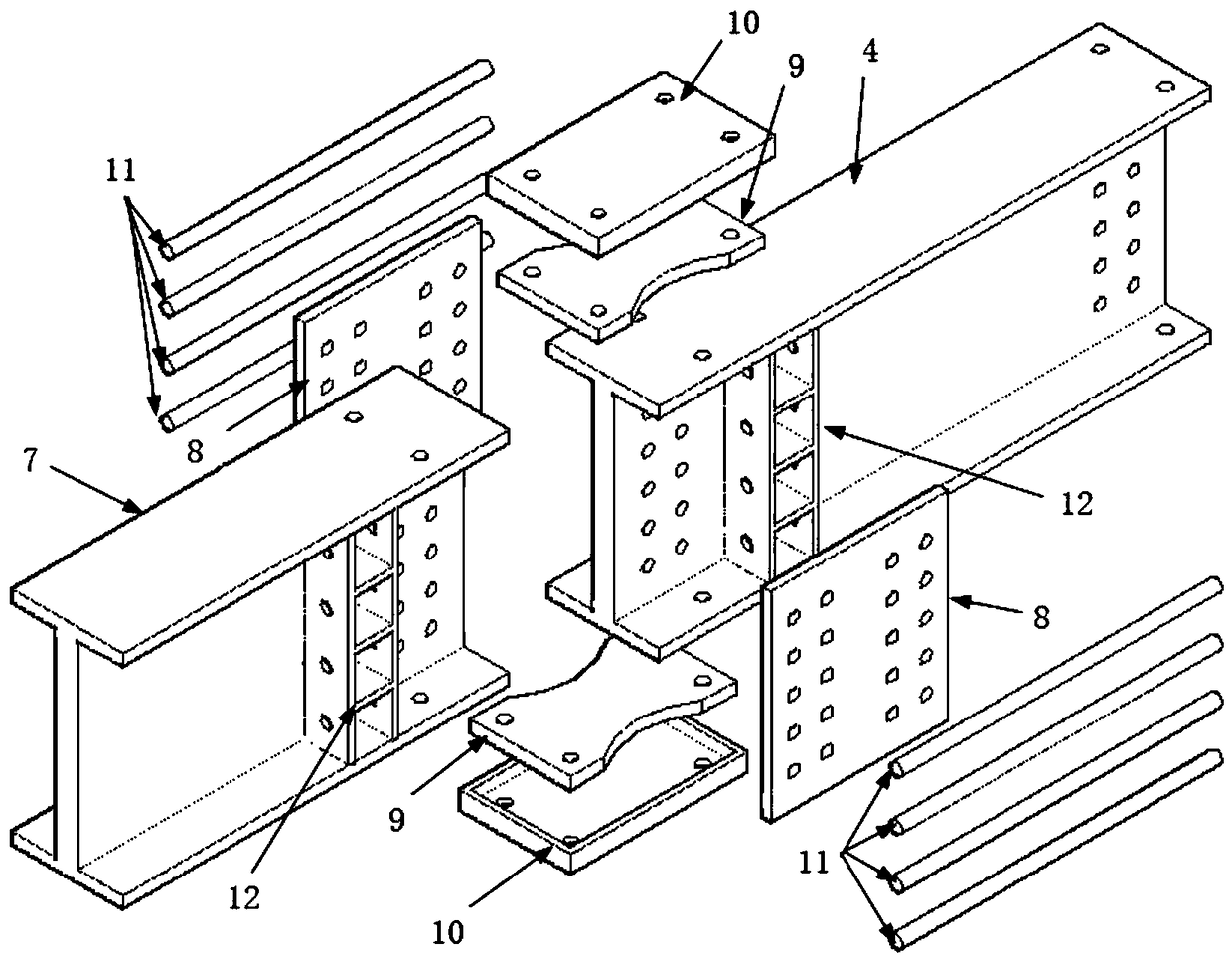

[0031] as attached figure 2 As shown, the post-earthquake self-resettable multi-section beam steel frame of the present invention mainly includes L-shaped, T-shaped, and cross-shaped joints. Taking the cross-shaped joint as an example in the figure, the cross-shaped joint is split. The connection is that the frame column 3 in the middle of the frame is connected with the I-beam 4 at the end. Specific connection steps: the hoisting equipment connects the end I-beam 4 with the frame column 3 in the middle of the frame ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com